Integrated thermochemical treatment device for low-and-intermediate level radioactive wastes

A processing device and thermochemical technology, which is applied in the field of medium and low radioactive waste processing equipment, can solve the problems of high thermal ignition reduction rate, insufficient combustion, easy blockage of pyrolysis products, etc., and achieve high volume reduction rate, fly ash and smoke amount Less, reduce the effect of nuclear radioactive pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

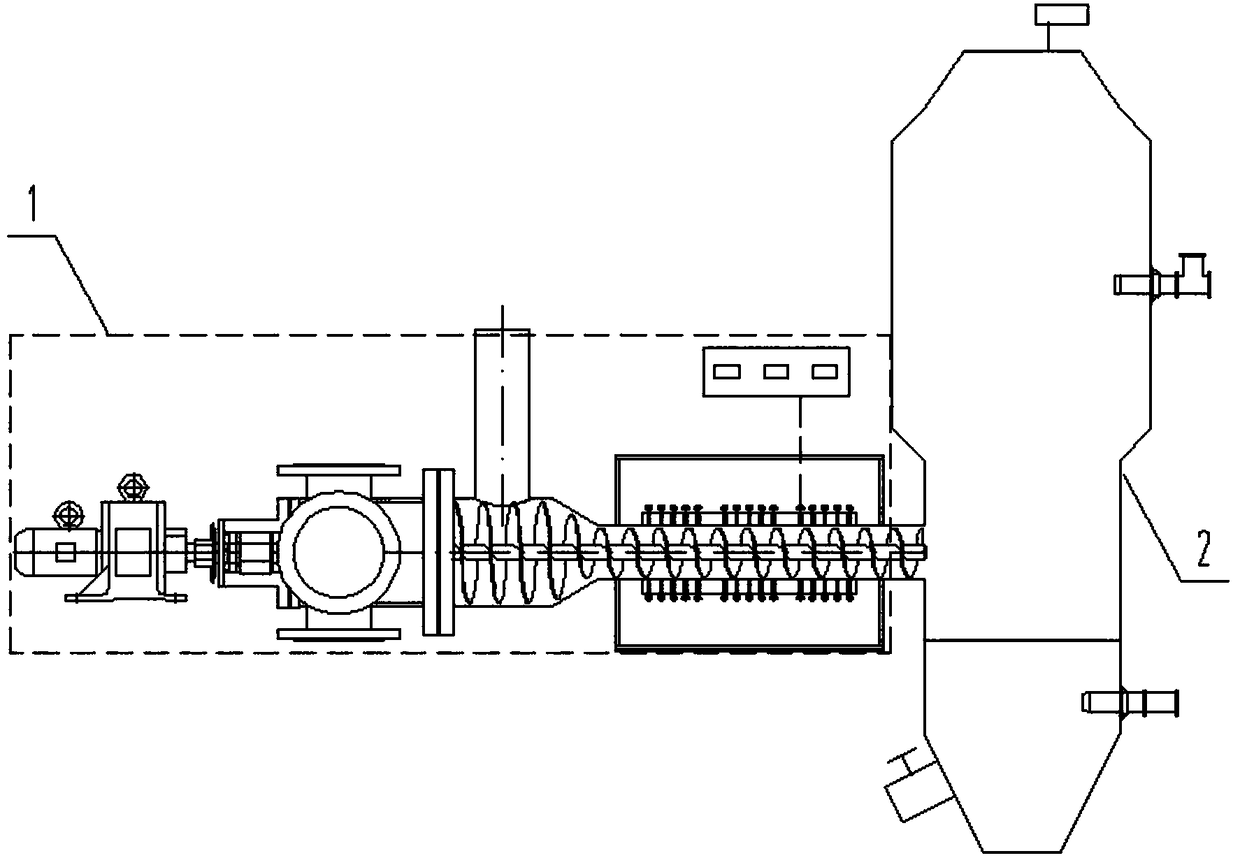

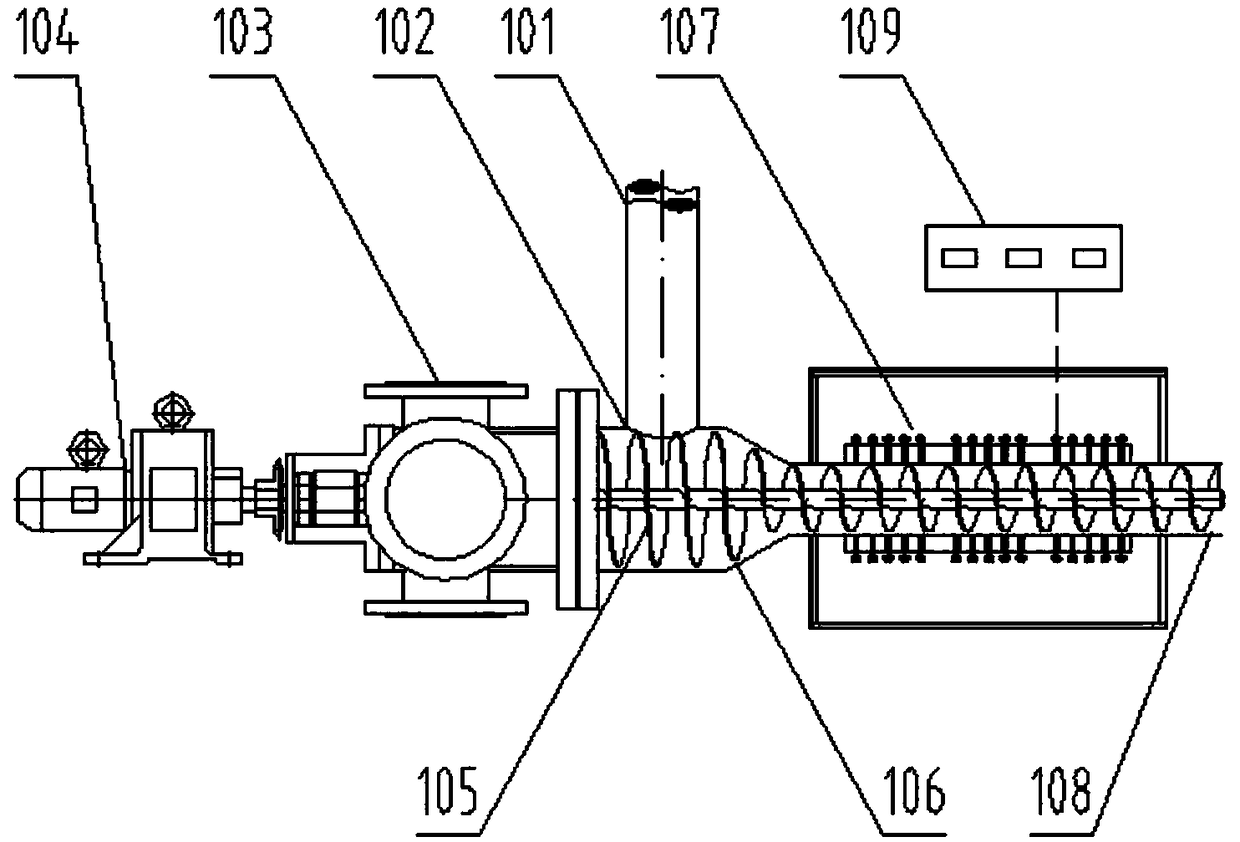

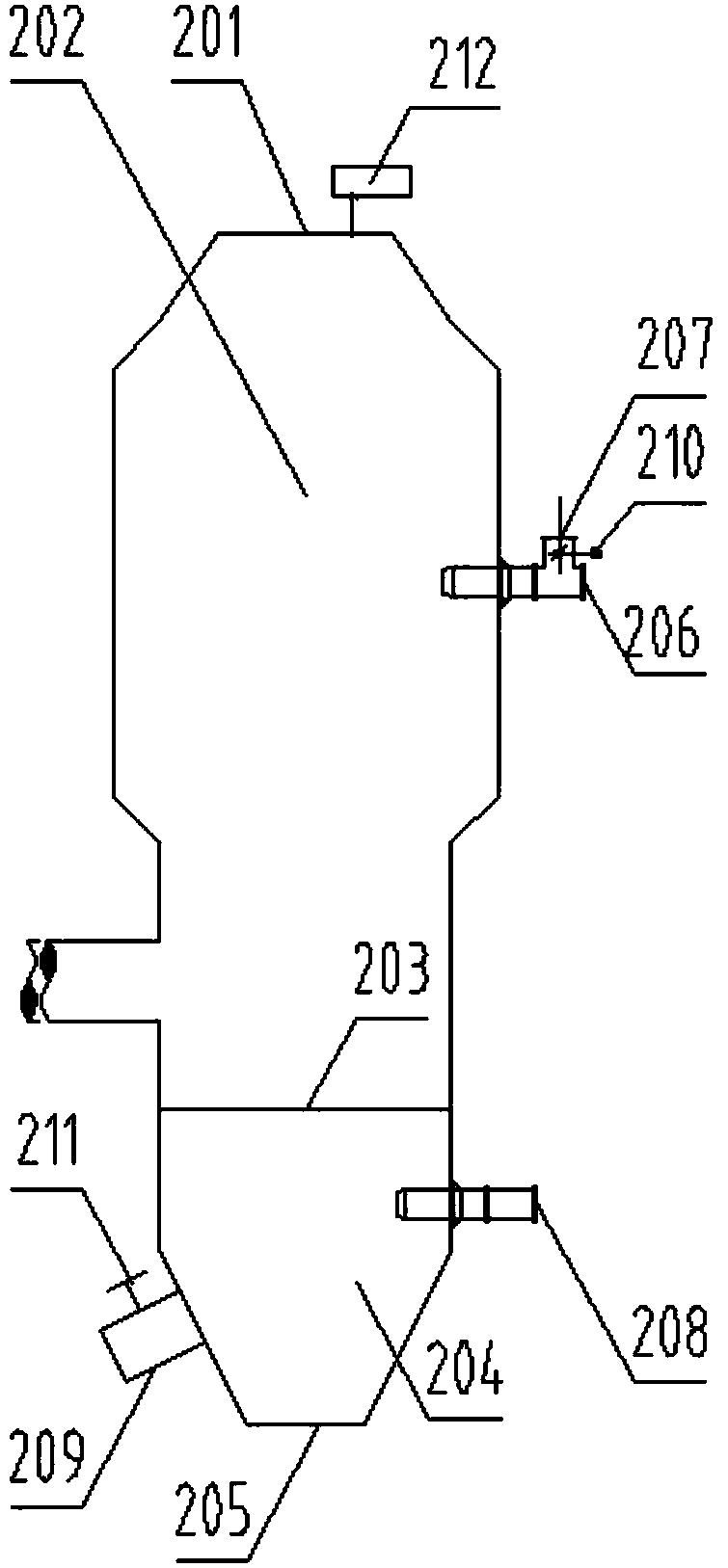

[0024] The main structure of the thermochemical integrated processing device for low- and medium-level radioactive wastes involved in this embodiment includes a pyrolysis device 1 and a combustion device 2, and the pyrolysis device 1 and the combustion device 2 adopt an integrated structure that is directly connected without pipes; The main structure of the device 1 includes a sealed feed section 101, a large mouth storage section 102, a dynamic seal 103, a drive motor 104, a screw propeller 105, a variable diameter feed section 106, a heating device 107, a pyrolysis delivery section 108 and a temperature control unit. Instrument 109; the input end of the horizontally arranged tubular screw propeller 105 is vertically provided with a tubular sealed feed section 101, and the front end of the screw propeller 105 is provided with a large-mouth storage section 102 for temporarily storing low-medium-level combustible organic waste, The large-mouth material storage section 102 and th...

Embodiment 2

[0037] The difference between this implementation and Example 1 is that the ratio of the diameter of the gas-liquid combustion chamber to the diameter of the solid combustion chamber is 2.2. The specific process steps of using the low-level and medium-level waste thermochemical integrated treatment device involved in this embodiment to process low-level and low-level combustible organic waste are different from Example 1 in that the speed of the drive motor in step (1) is 4r / min In the step (2), the temperature of the pyrolysis conveying section 108 is set to be 600°C; in the step (8), 0.4% of the radioactive substances are discharged to the flue gas post-treatment system through the flue gas outlet 201 along with the flue gas produced by combustion , 99.6% of the radioactive substances are discharged together with the residue through the slag outlet 205 at the lower end of the solid combustion chamber 204, sealed up and processed in a unified manner.

Embodiment 3

[0039] The difference between this implementation and Example 1 is that the ratio of the diameter of the gas-liquid combustion chamber to the diameter of the solid combustion chamber is 1.2, the equipment is more compact, the floor space is small, and it is suitable for projects with tight land use; The specific process steps of low-level combustible organic waste in the treatment of low-level waste thermochemical integrated treatment device are different from Example 1 in that: the rotating speed of the driving motor in step (1) is 5r / min; The temperature of the pyrolysis conveying section 108 is 700°C; in step (8), 1% of the radioactive substances are discharged to the flue gas post-treatment system through the flue gas outlet 201 along with the flue gas produced by combustion, and 99% of the radioactive substances are processed with the residue Discharge through the slag outlet 205 at the lower end of the solid combustion chamber 204 for unified storage and treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com