Patents

Literature

54 results about "Low-level waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-level waste (LLW) is nuclear waste that does not fit into the categorical definitions for intermediate-level waste (ILW), high-level waste (HLW), spent nuclear fuel (SNF), transuranic waste (TRU), or certain byproduct materials known as 11e(2) wastes, such as uranium mill tailings. In essence, it is a definition by exclusion, and LLW is that category of radioactive wastes that do not fit into the other categories. If LLW is mixed with hazardous wastes, then it has a special status as mixed low-level waste (MLLW) and must satisfy treatment, storage, and disposal regulations both as LLW and as hazardous waste. While the bulk of LLW is not highly radioactive, the definition of LLW does not include references to its activity, and some LLW may be quite radioactive, as in the case of radioactive sources used in industry and medicine.

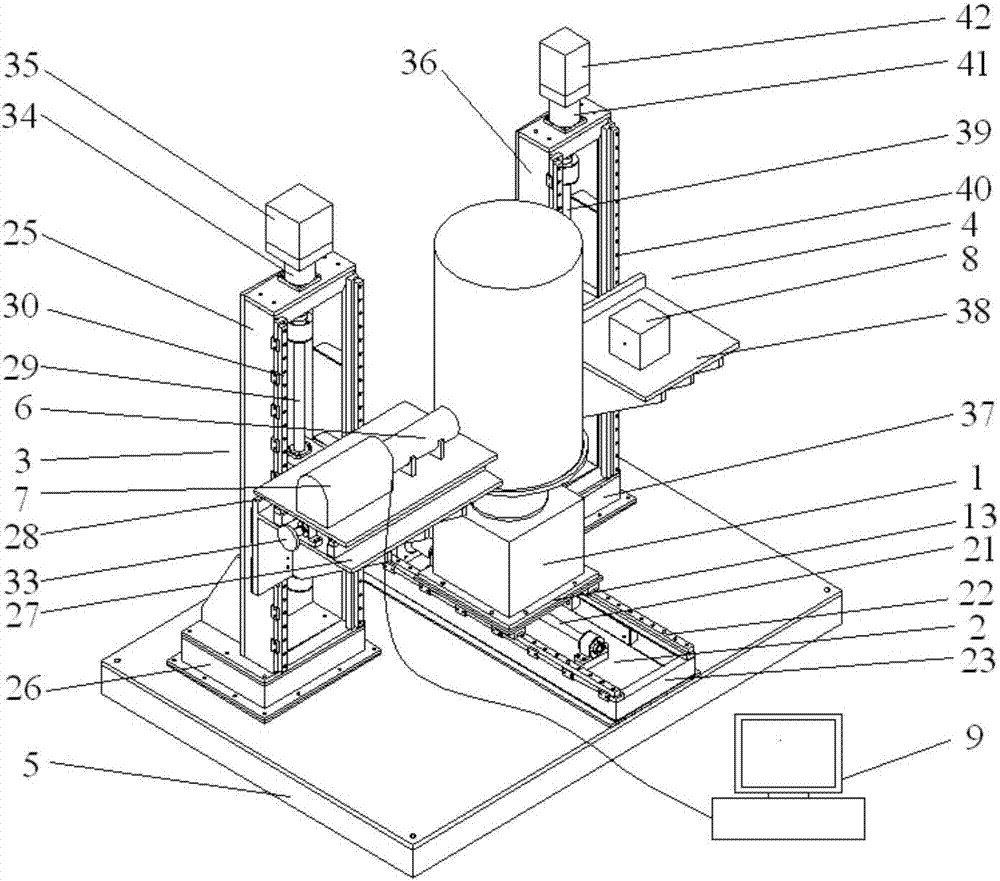

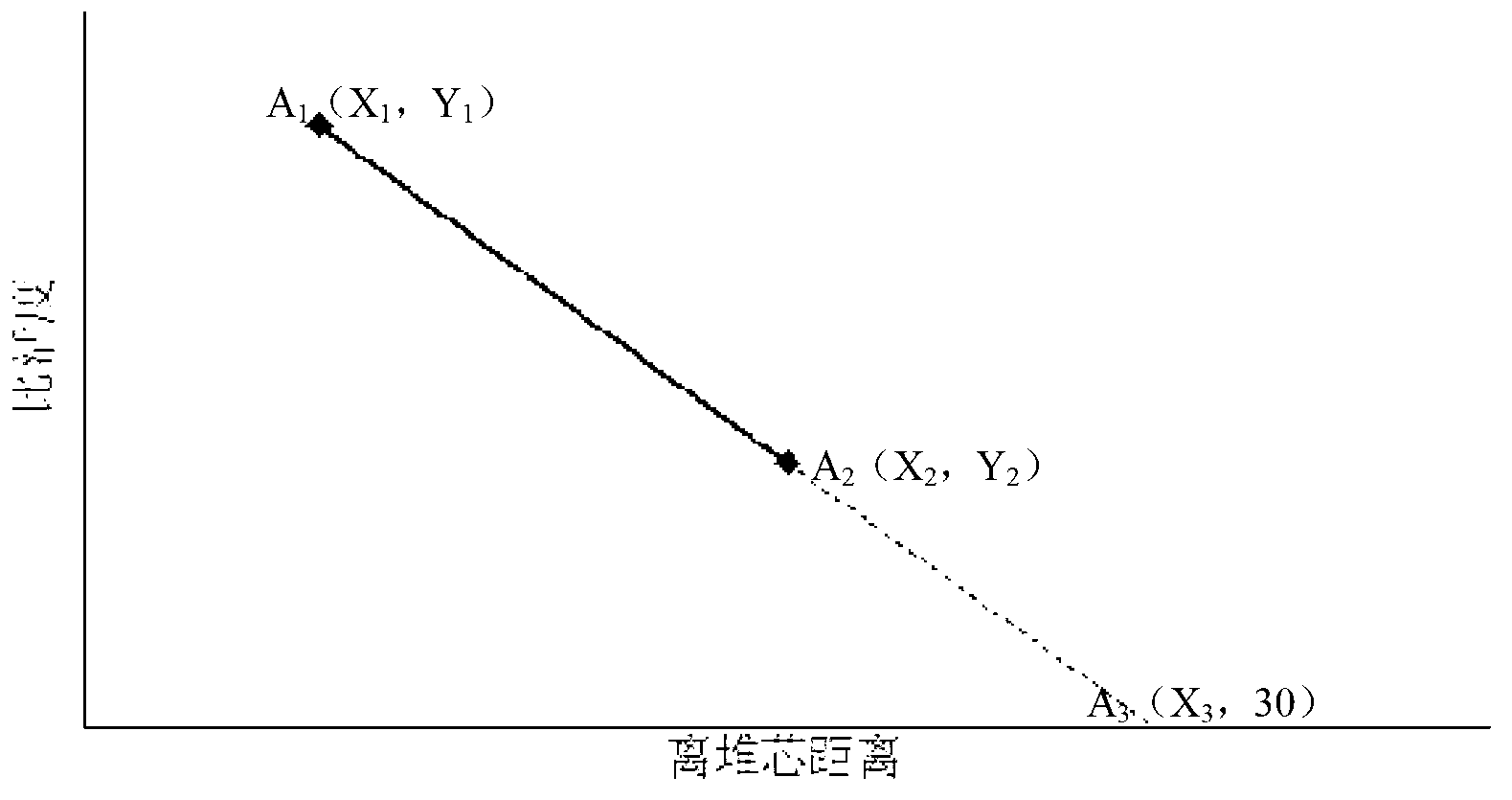

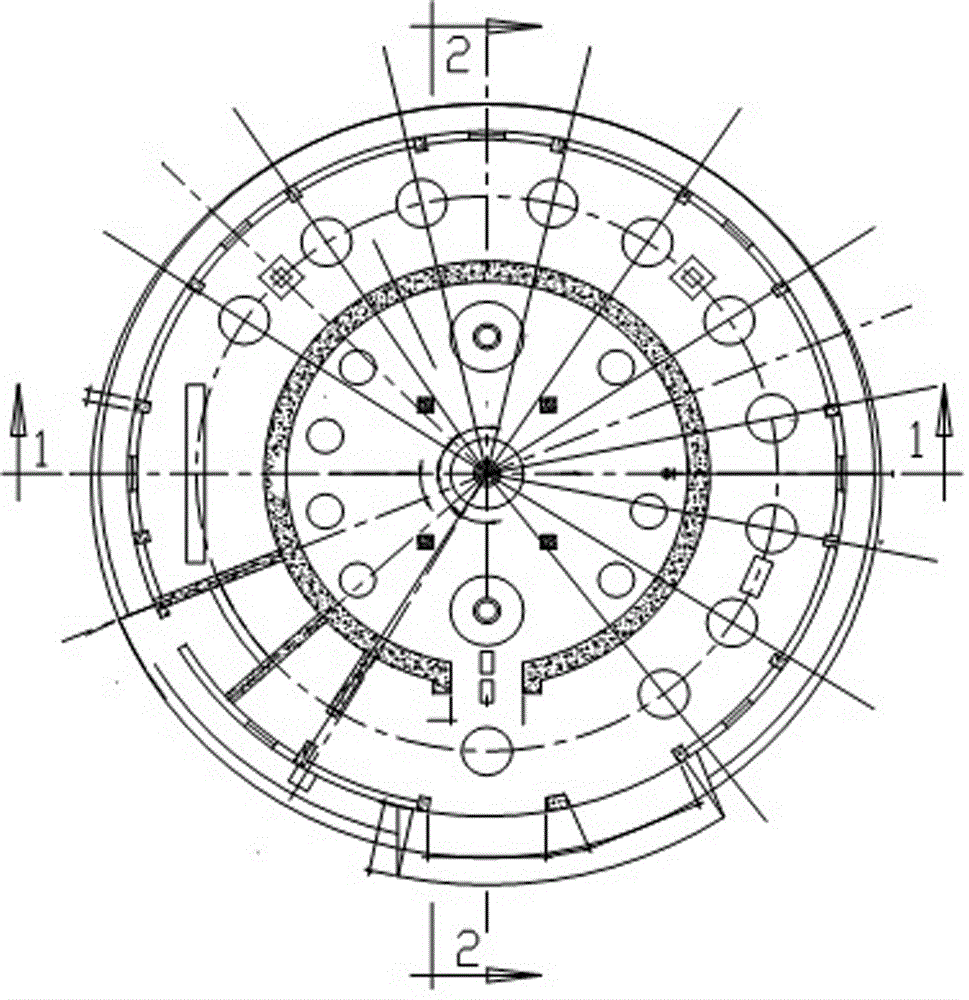

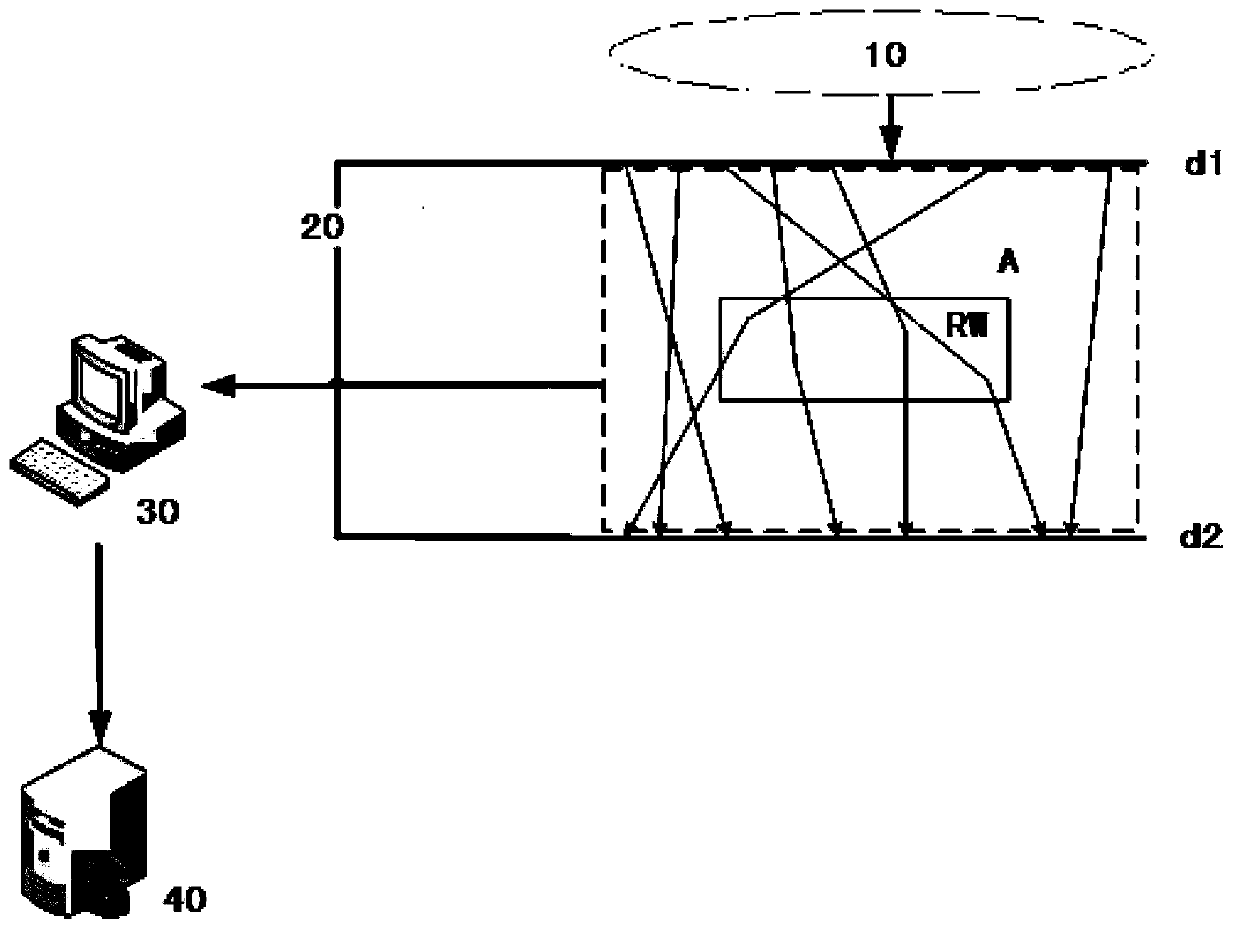

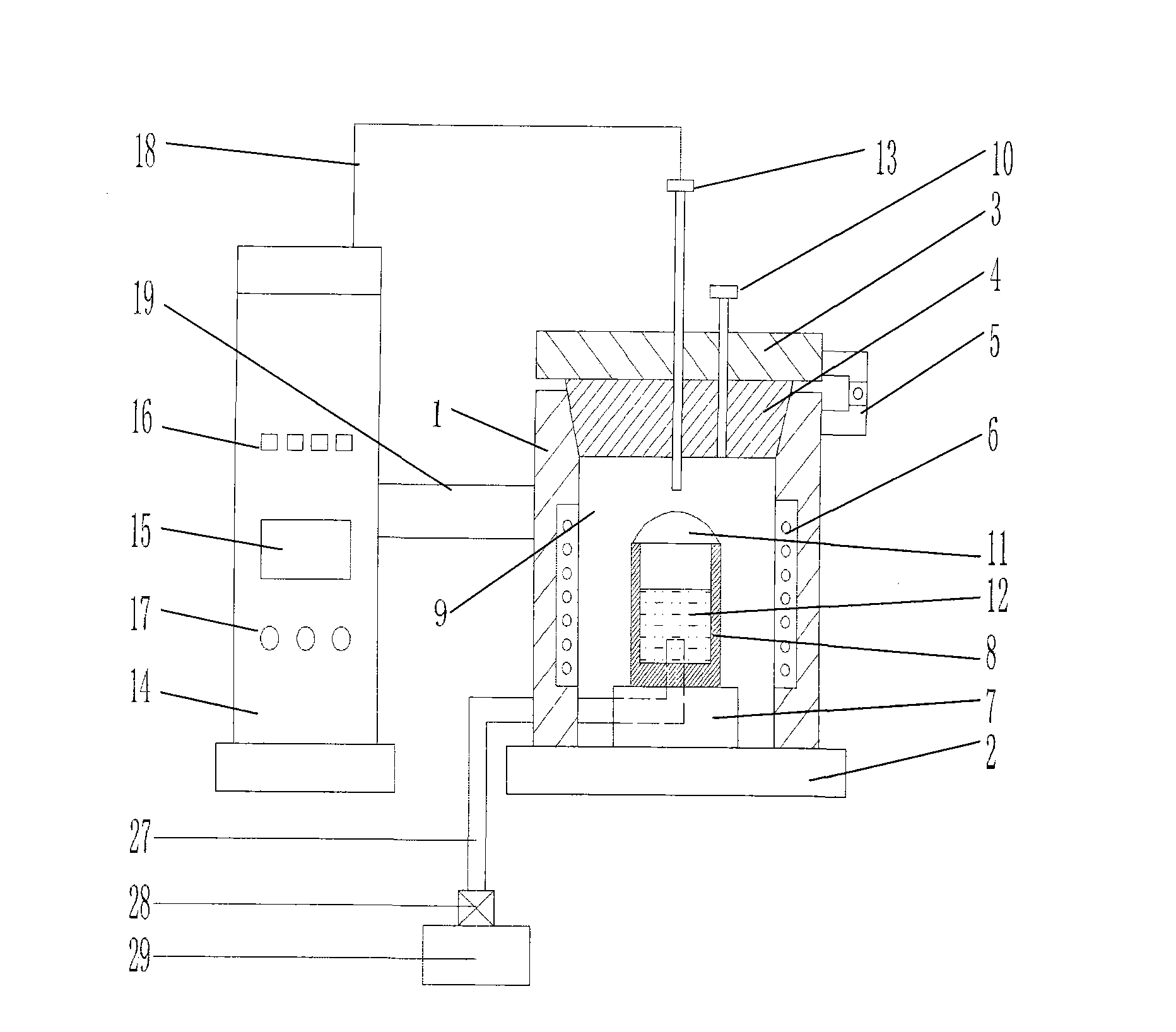

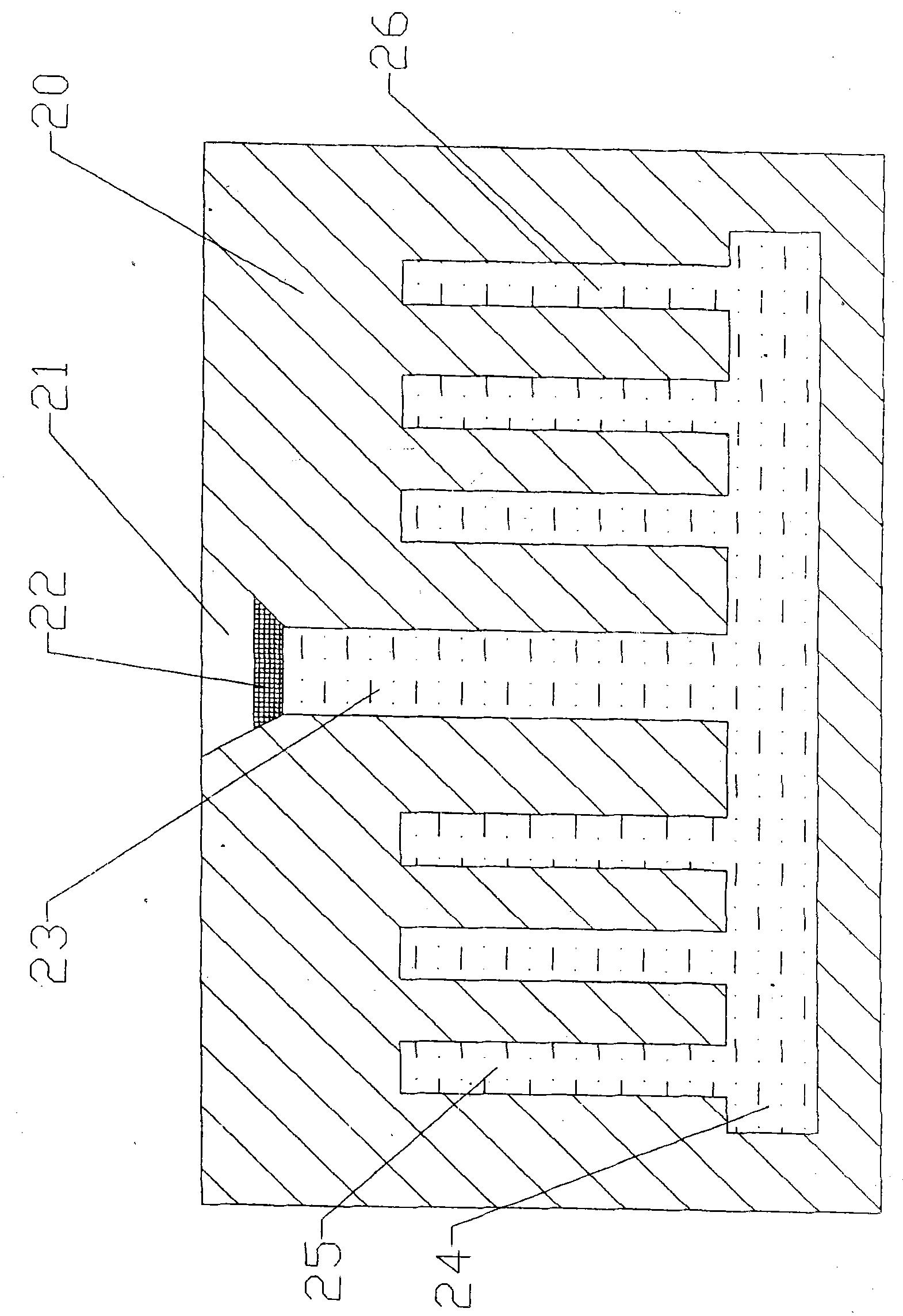

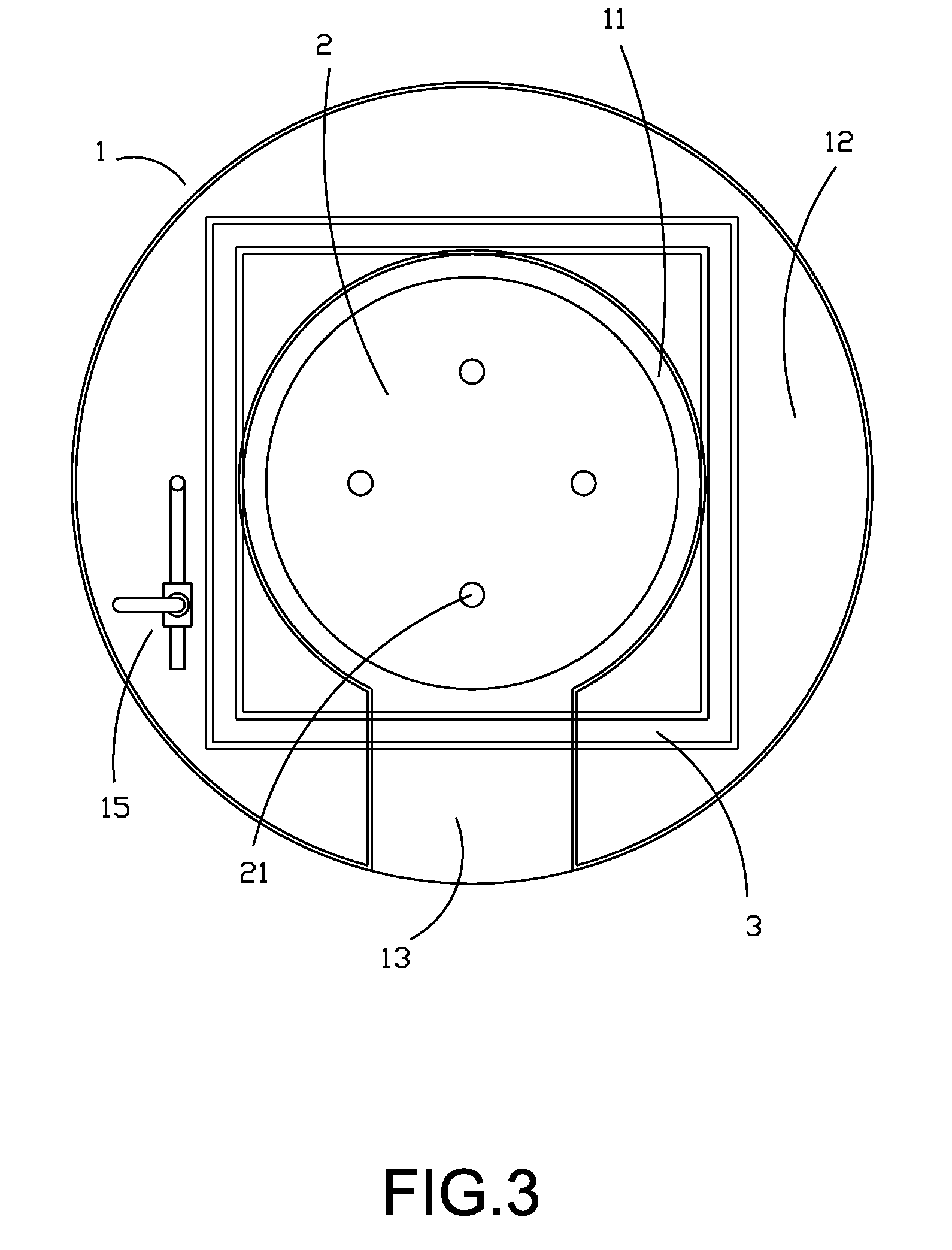

Semi-chromatography gamma scanning method for low-medium radioactive waste barrel measurement

ActiveCN104714245AHigh measurement accuracyTomoscanX/gamma/cosmic radiation measurmentCounting rateLow-level waste

The invention provides a semi-chromatography gamma scanning method for low-medium radioactive waste barrel measurement. A rotary platform, a detector platform, a detector with a collimator, a transmission source platform, a transmission source, a shielding part of the transmission source and an analysis module are adopted in the method. A waste barrel is divided into multiple section layers in the height direction, the waste barrel is rotated, surface distribution of radioactive point sources on the section layers is changed into linear distribution of ring sources in the radius direction, the detector conducts measurement at different section layer heights and different eccentric positions in the section layers, an equation set reflecting the mutual relation between the detector counting rate and the activity of nuclide in annular grids is established, the equation set is solved, distribution of the activity of the radioactive nuclide in the waste barrel in the diameter direction and the height direction of the barrel is acquired, and the total activity of the radioactive nuclide in the waste barrel is acquired through summation. The method is high in measurement accuracy, short in measurement time and high in practical value and application prospect.

Owner:SHANGHAI JIAO TONG UNIV

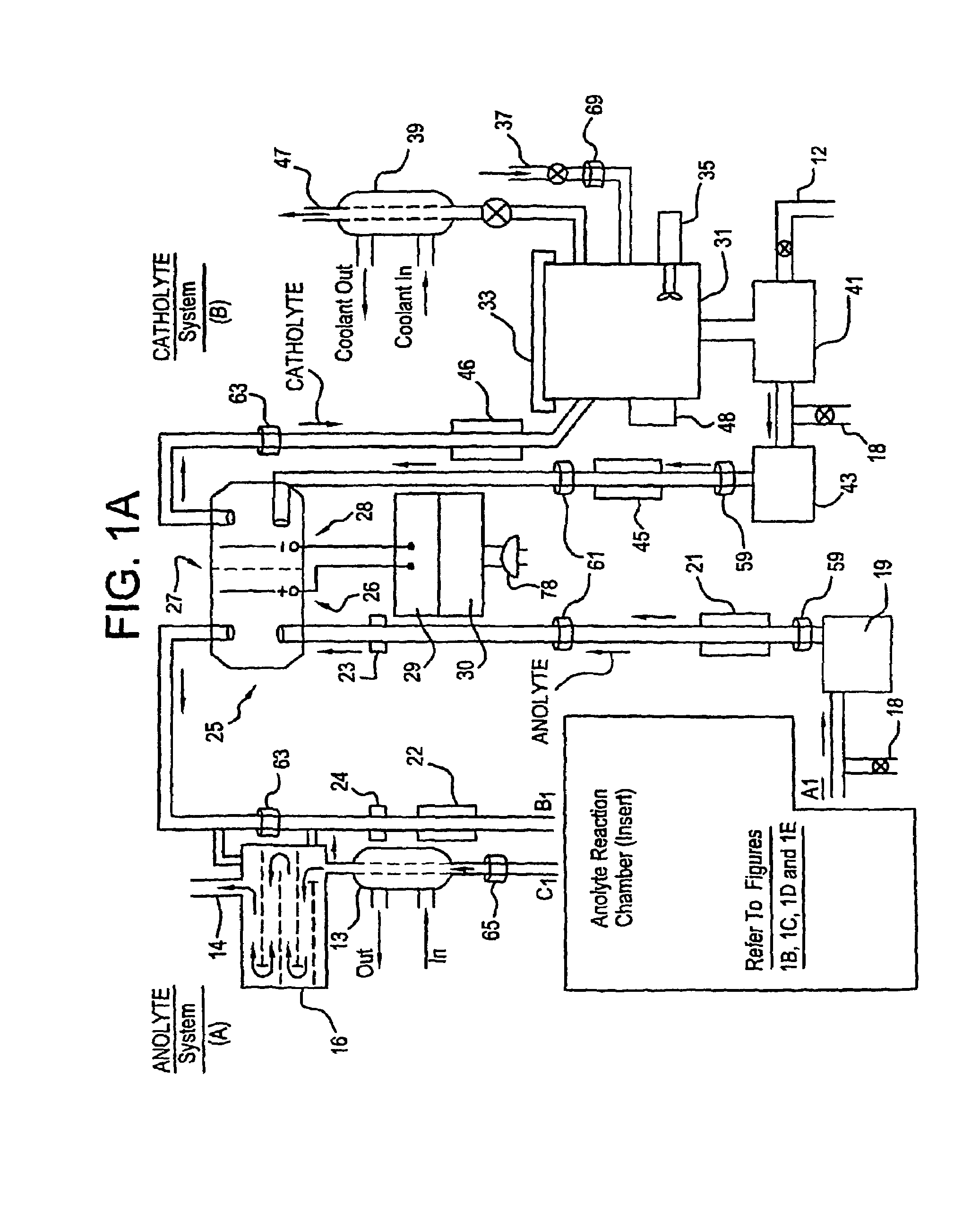

Mediated electrochemical oxidation for decontamination

InactiveUS7531708B2Improve efficiencyElectrolysis componentsPhotography auxillary processesLow-level wasteContaminated equipment

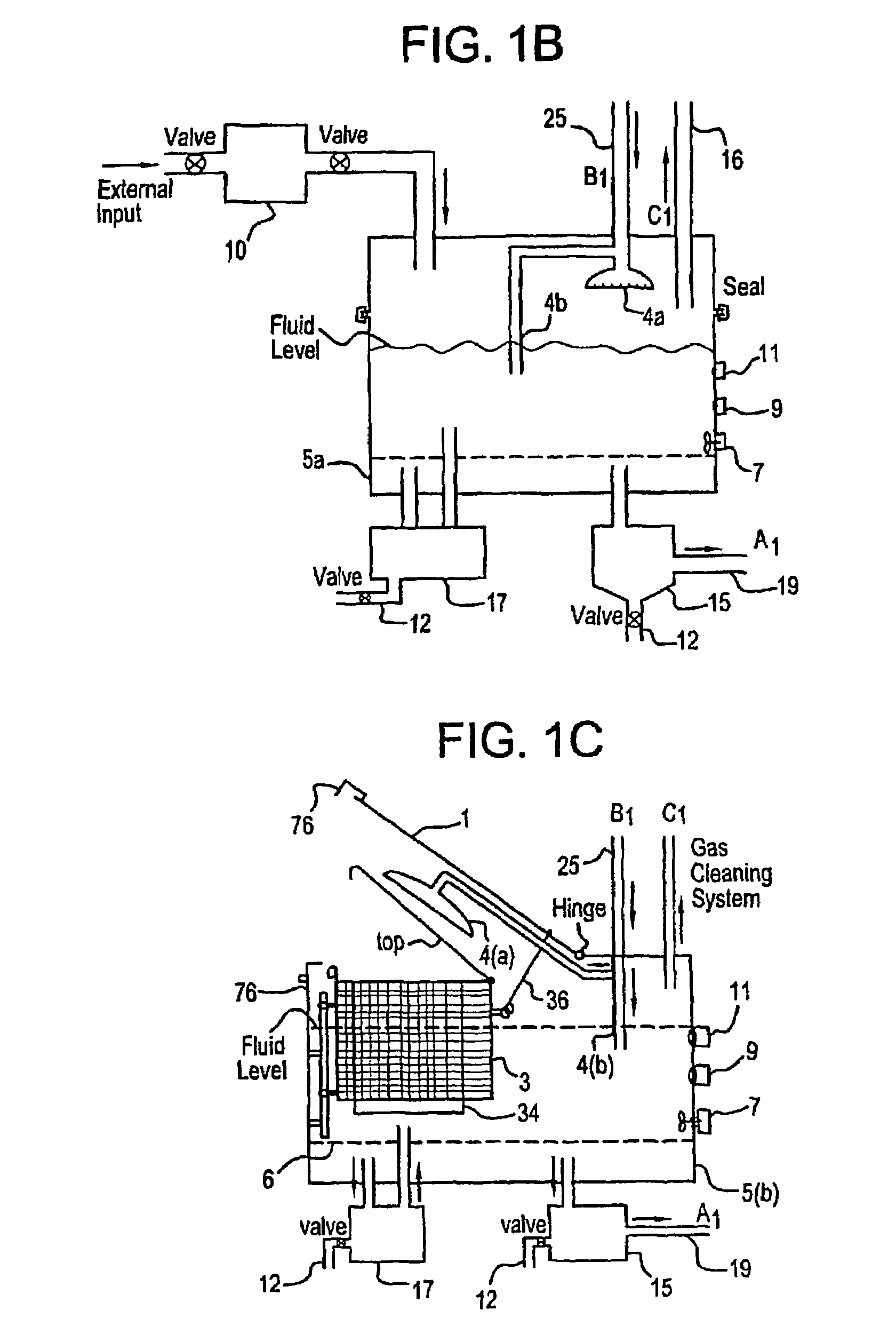

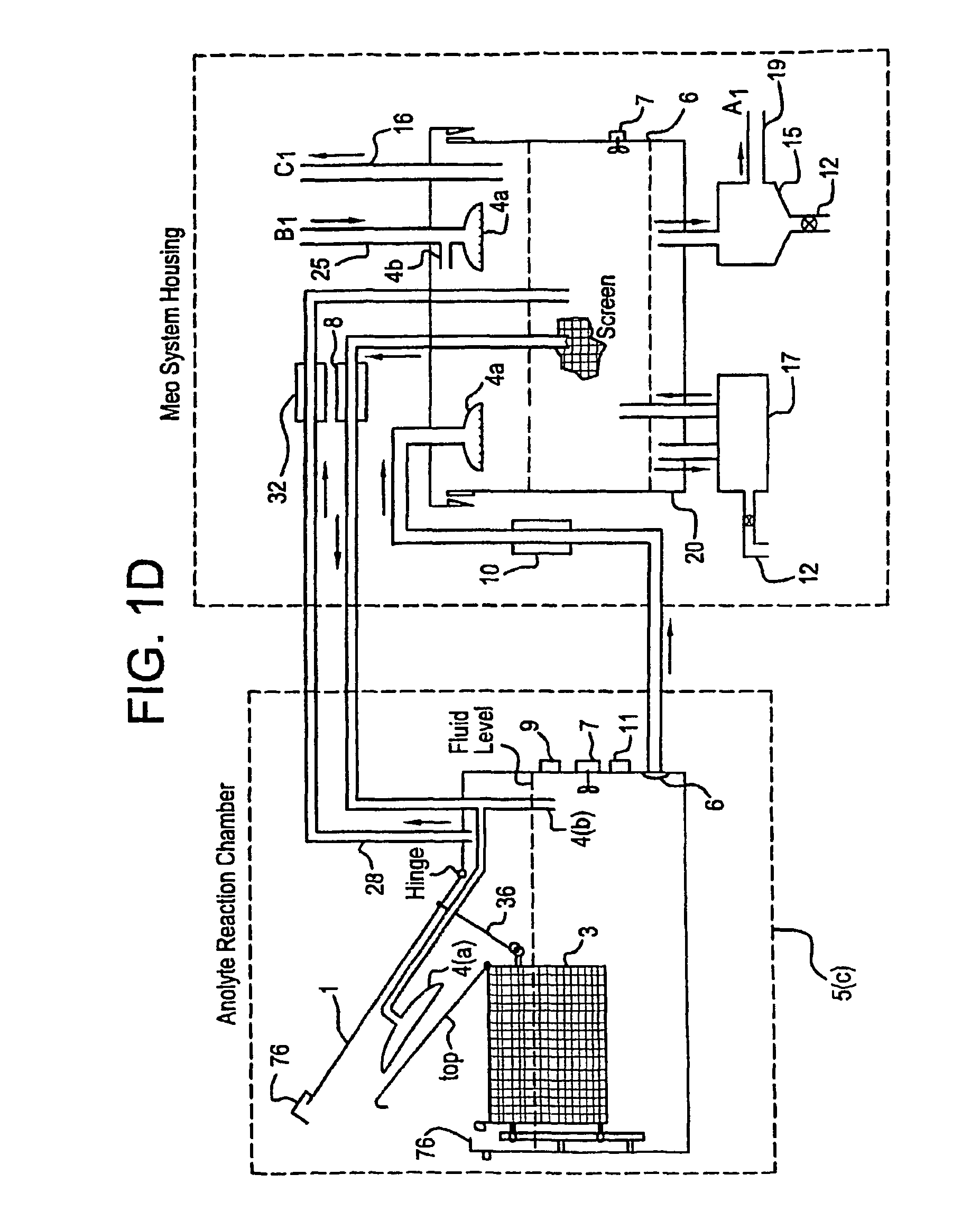

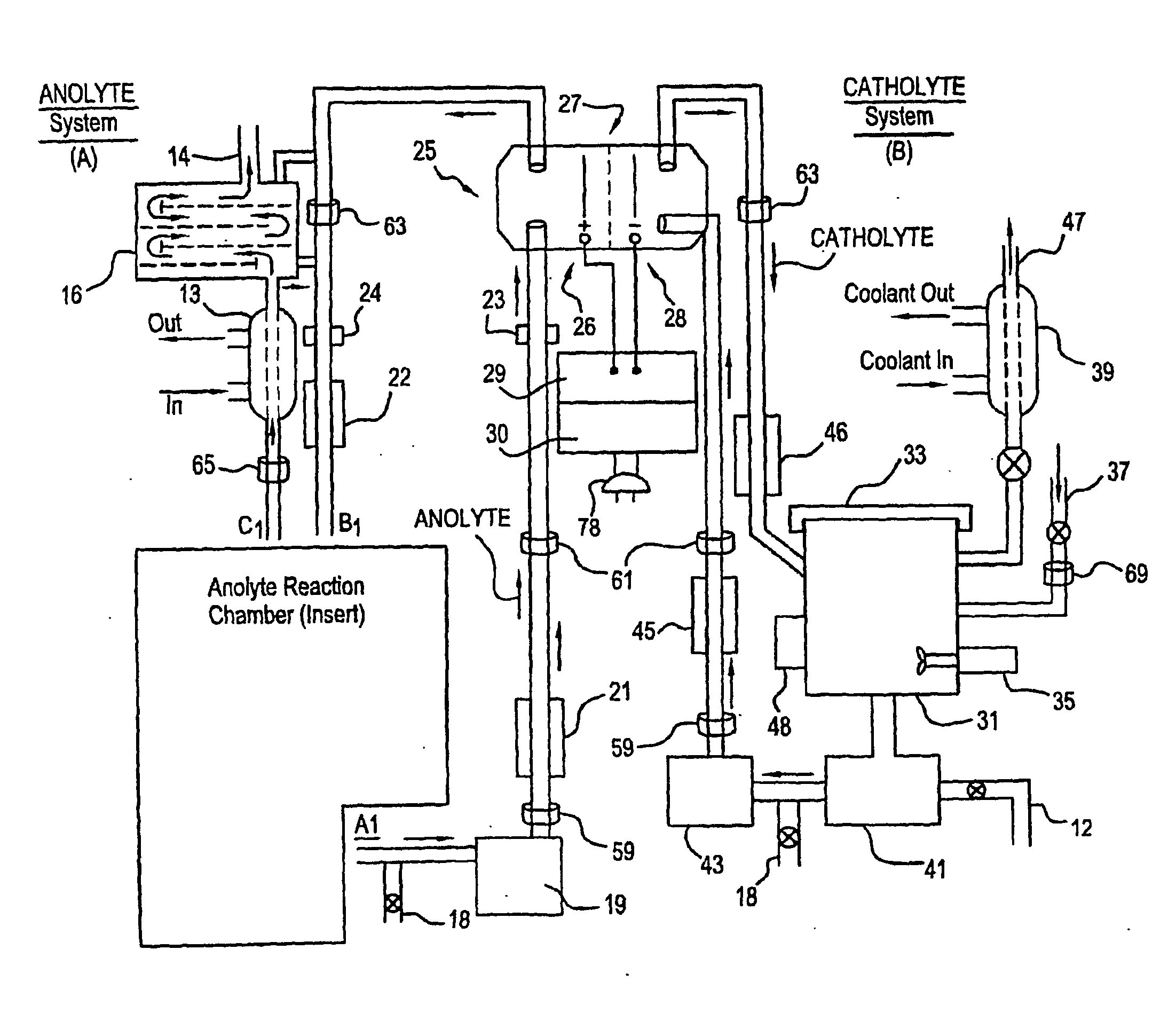

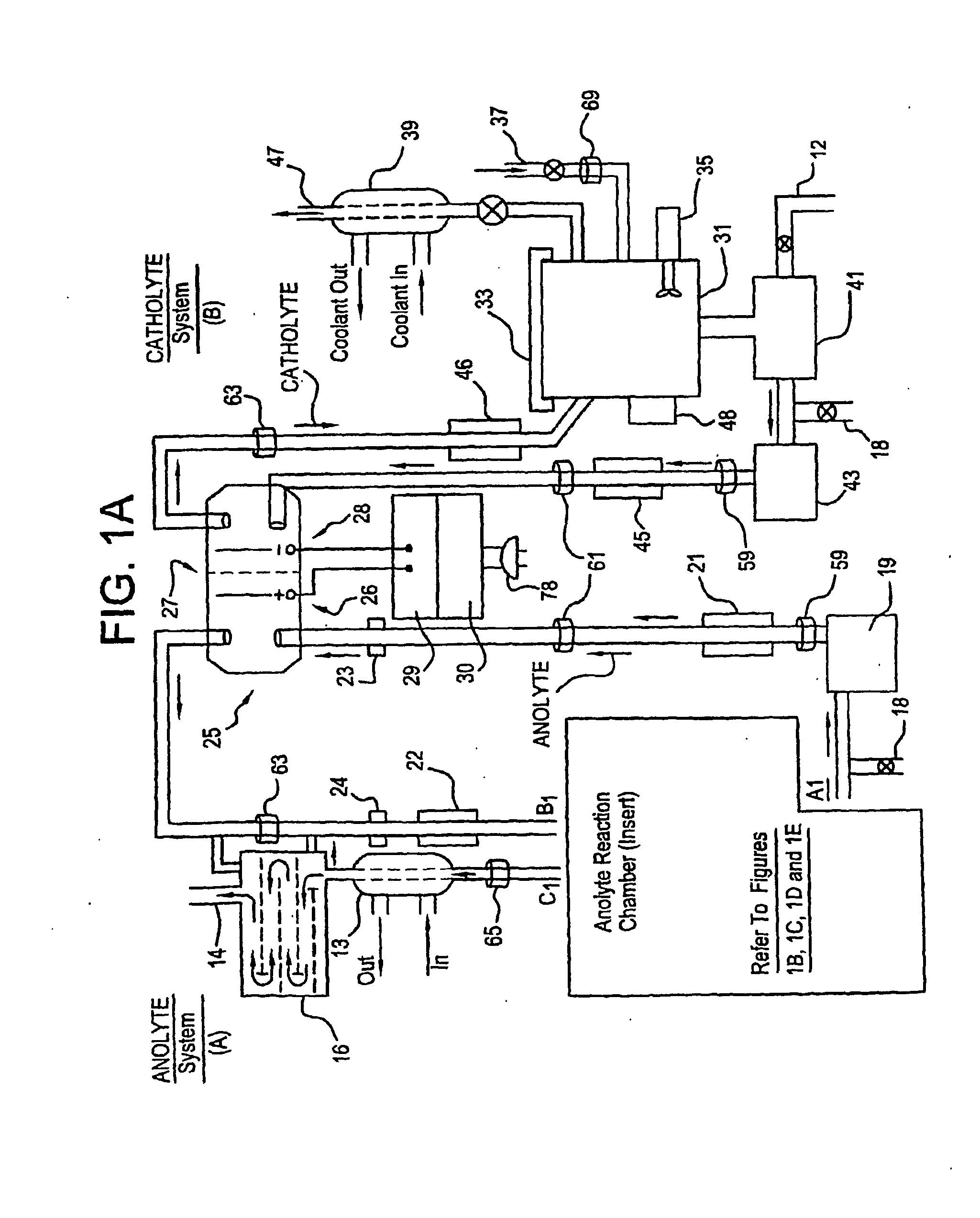

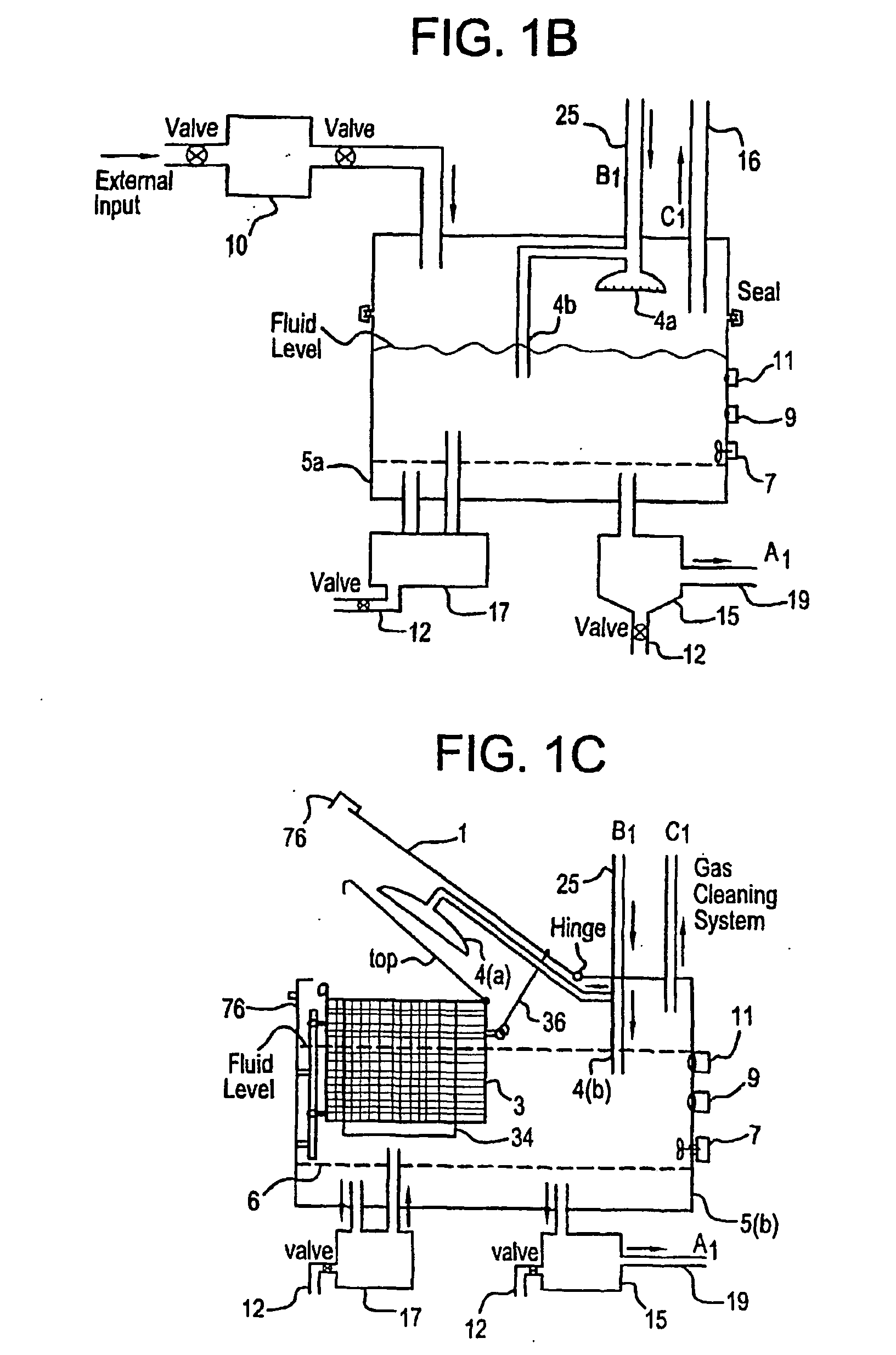

A mixed waste mediated electrochemical oxidation process (MEO) process and apparatus for the dissolution of transuranic elements, and / or compounds thereof in transuranic waste, low level waste (LLW), low level mixed waste, special case waste, and greater than class C LLWS, and also the destruction of the non-fluorocarbon organic component in the waste. The MEO process and apparatus operates in three different modes: dissolution, destruction, and decontamination. In the first mode, dissolution, the process runs until the transuranics such as a mixed oxide or carbide, and / or mixture of oxides or carbides of uranium and plutonium are totally dissolved into solution. The second mode, destruction, the process is operated such that the mixed waste materials are reduced to CO2, water and small amounts of inorganic salts. The third mode, decontamination, involves contaminated equipment. In the decontamination mode the MEO process destroys the mixed wastes that have contaminated the equipment.

Owner:SCIMIST LNC

Mediated electrochemical oxidation used for the destruction of organics contaminated with radioactive materials, dissoulution of atransuranics, and the decontamination of equipment contaminated with mixed waste

InactiveUS20060016689A1Improve efficiencyPhotography auxillary processesElectrolysis componentsRadioactive agentLow-level waste

A mixed waste mediated electrochemical oxidation process (MEO) process and apparatus for the dissolution of transuranic elements, and / or compounds thereof in transuranic waste, low level waste (LLW), low level mixed waste, special case waste, and greater than class C LLWS, and also the destruction of the non-fluorocarbon organic component in the waste. The MEO process and apparatus operates in three different modes: dissolution, destruction, and decontamination. In the first mode, dissolution, the process runs until the transuranics such as a mixed oxide or carbide, and / or mixture of oxides or carbides of uranium and plutonium are totally dissolved into solution. The second mode, destruction, the process is operated such that the mixed waste materials are reduced to CO2, water and small amounts of inorganic salts. The third mode, decontamination, involves contaminated equipment. In the decontamination mode the MEO process destroys the mixed wastes that have contaminated the equipment.

Owner:SCIMIST LNC

Method for recovering magnesium alloy low-level waste

InactiveCN101736160AReduce pollutionComposition is stableProcess efficiency improvementChemical compositionAcid washing

The invention relates to a method for recovering magnesium alloy low-level waste, aiming at the actual situation that the magnesium alloy low-level wastes are multiple in varieties, large in quantity, serious in pollution and difficult to recover. A magnesium alloy low-level waste ingot is prepared by mechanical cutting, repeated acid-washing, water washing, smelting in a resistance furnace, refining and casting into ingot; and the magnesium alloy low-level waste ingot has the chemical composition close to the composition quantity value index of a magnesium alloy ingot, and the mechanical property close to the quantity value of the magnesium alloy ingot, so as to be made into industrial part again. The recovery smelting and refining method is advanced, reasonable, short in process flow, low in environmental pollution, easy to recover, high in yield reaching up to 94.5%, good in material purity, and stable in metallographic structure and chemical composition, thus being an ideal method for recovering, smelting and refining the magnesium alloy low-level waste.

Owner:TAIYUAN UNIV OF TECH

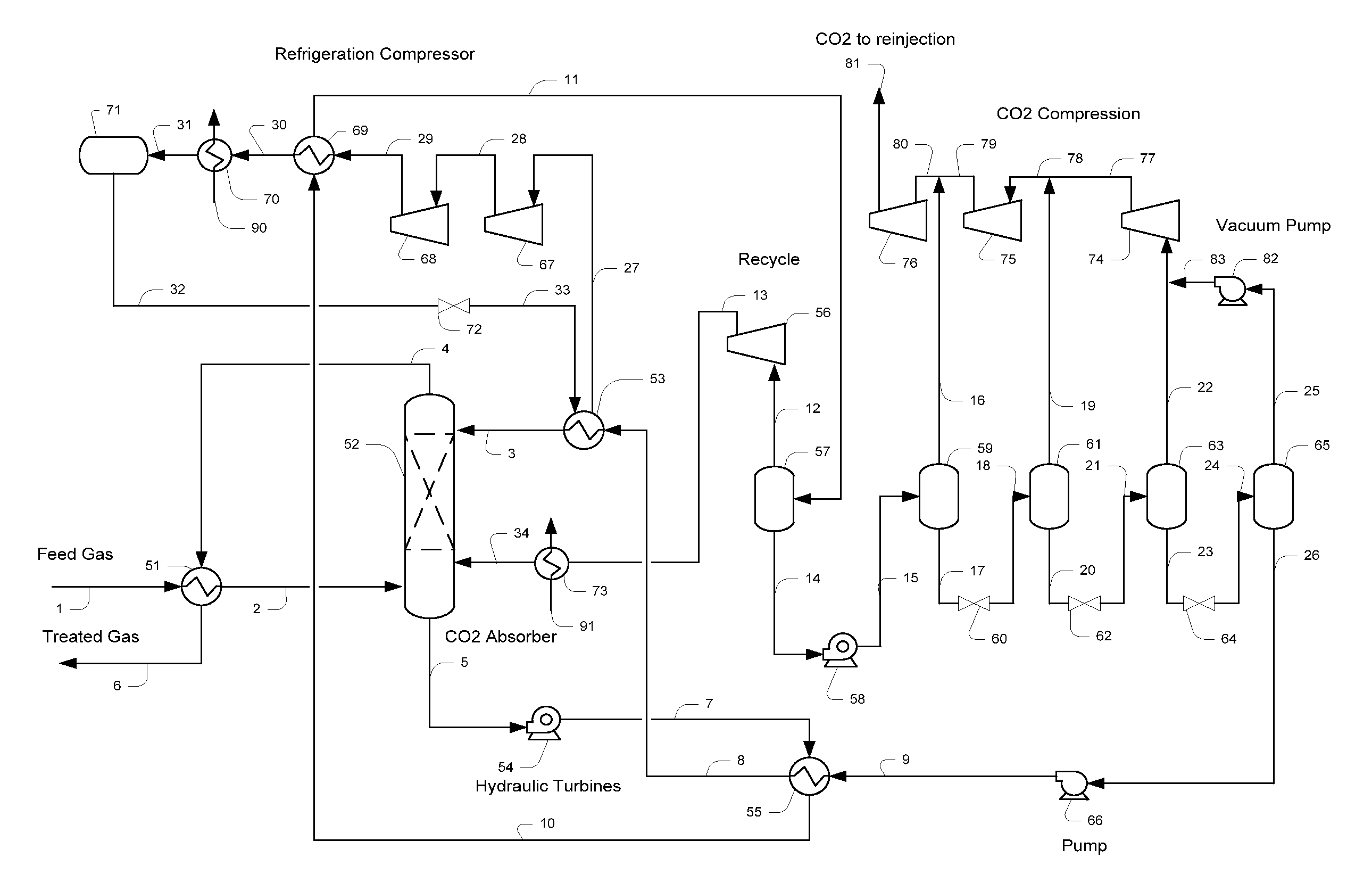

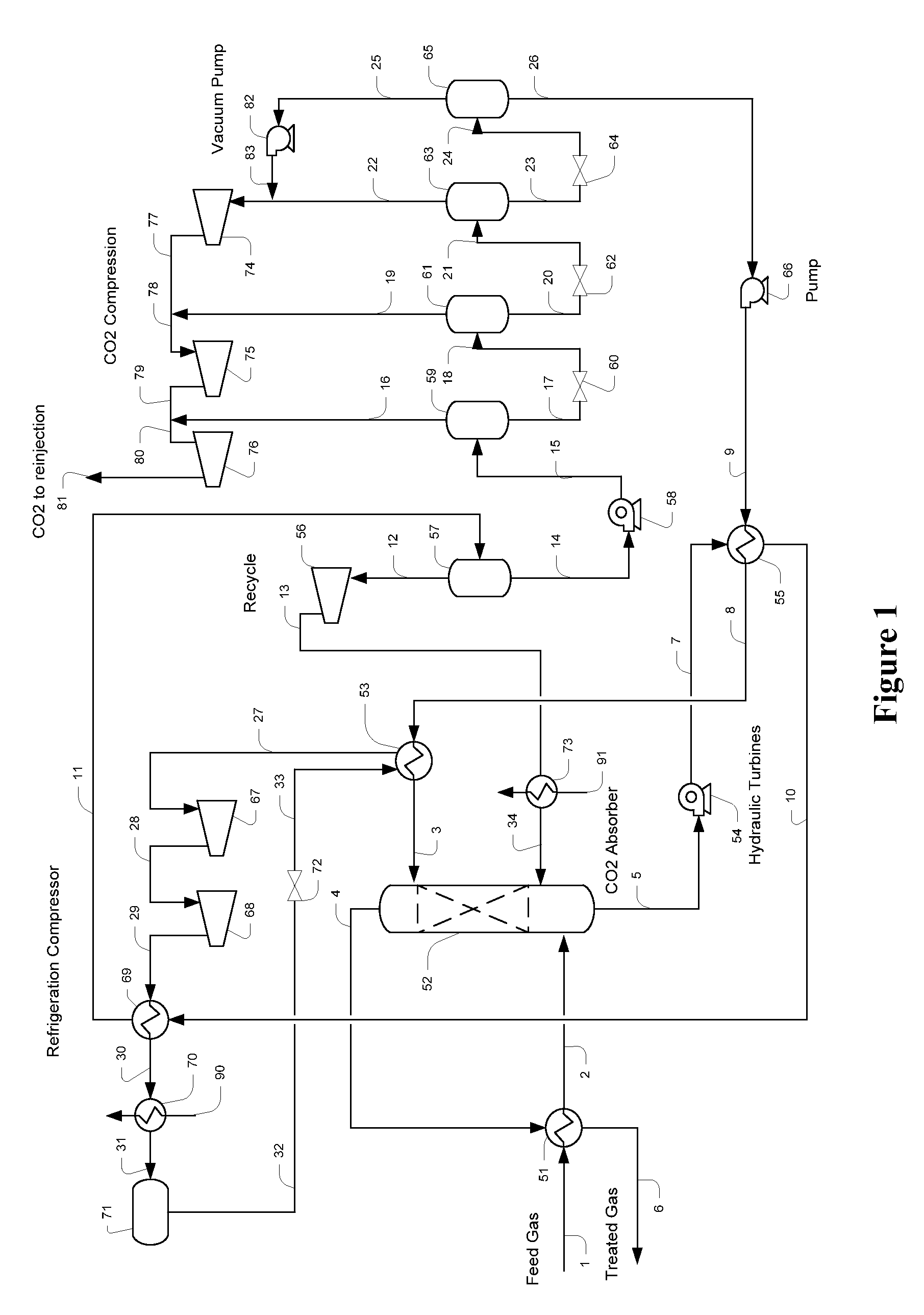

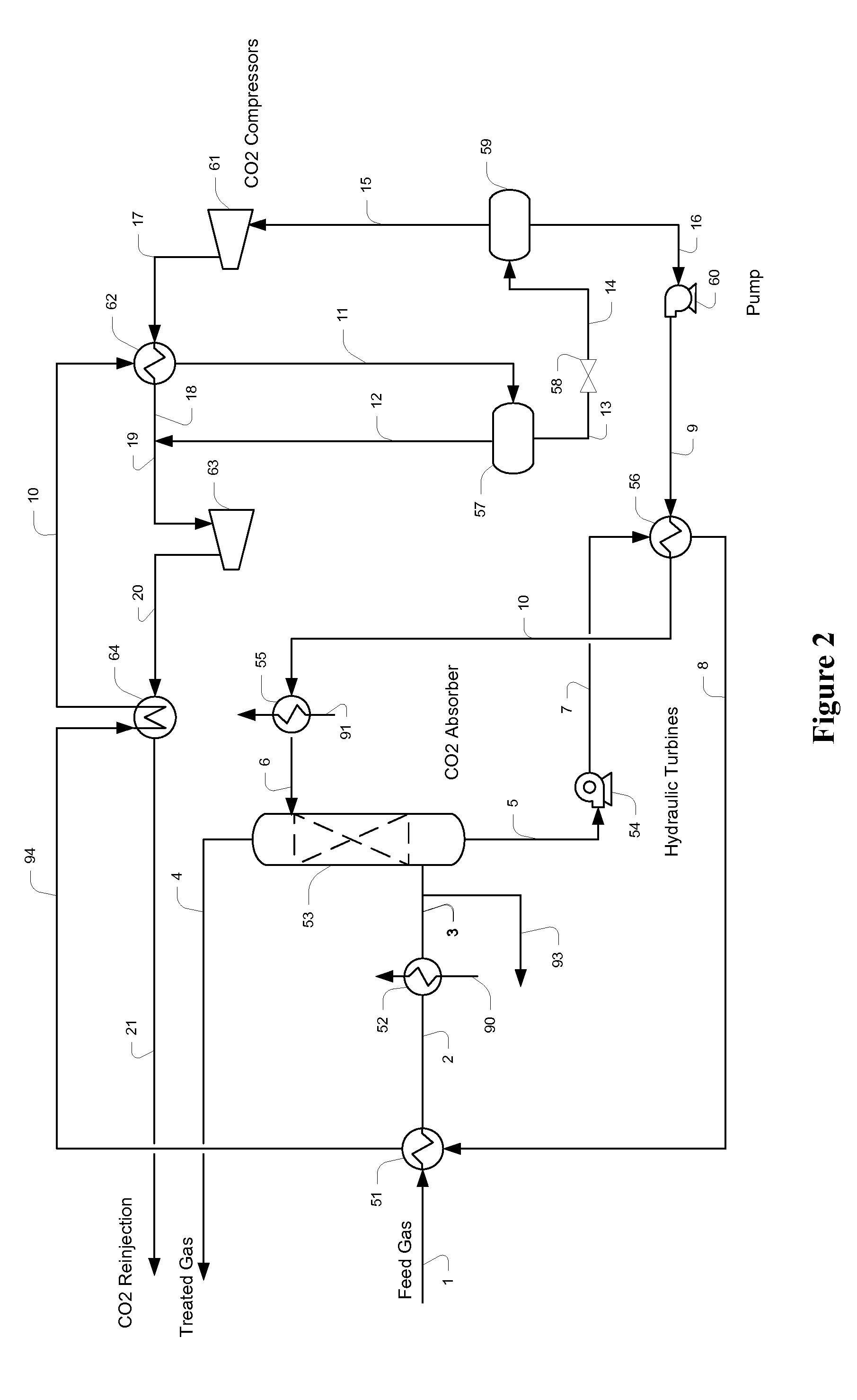

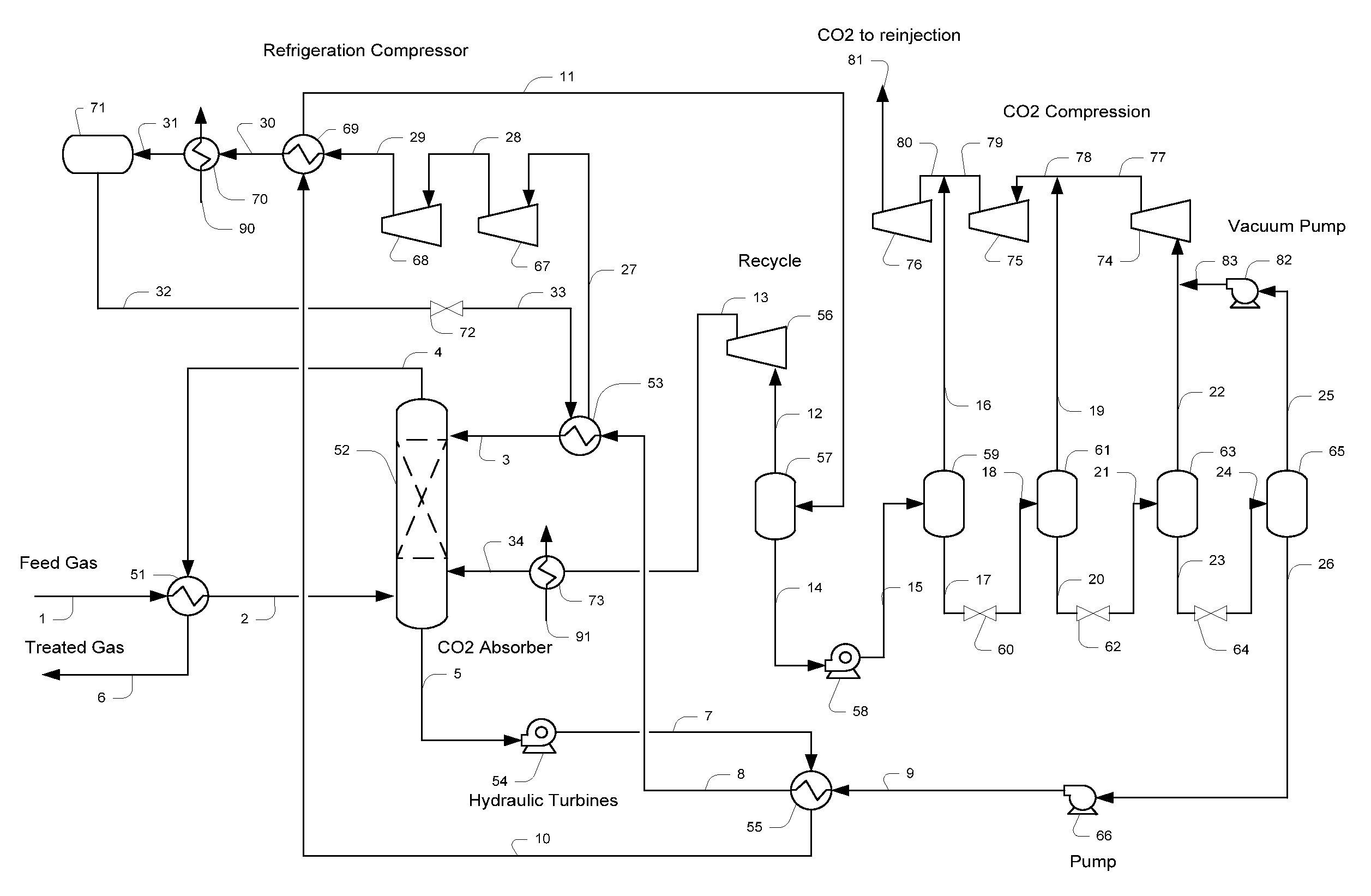

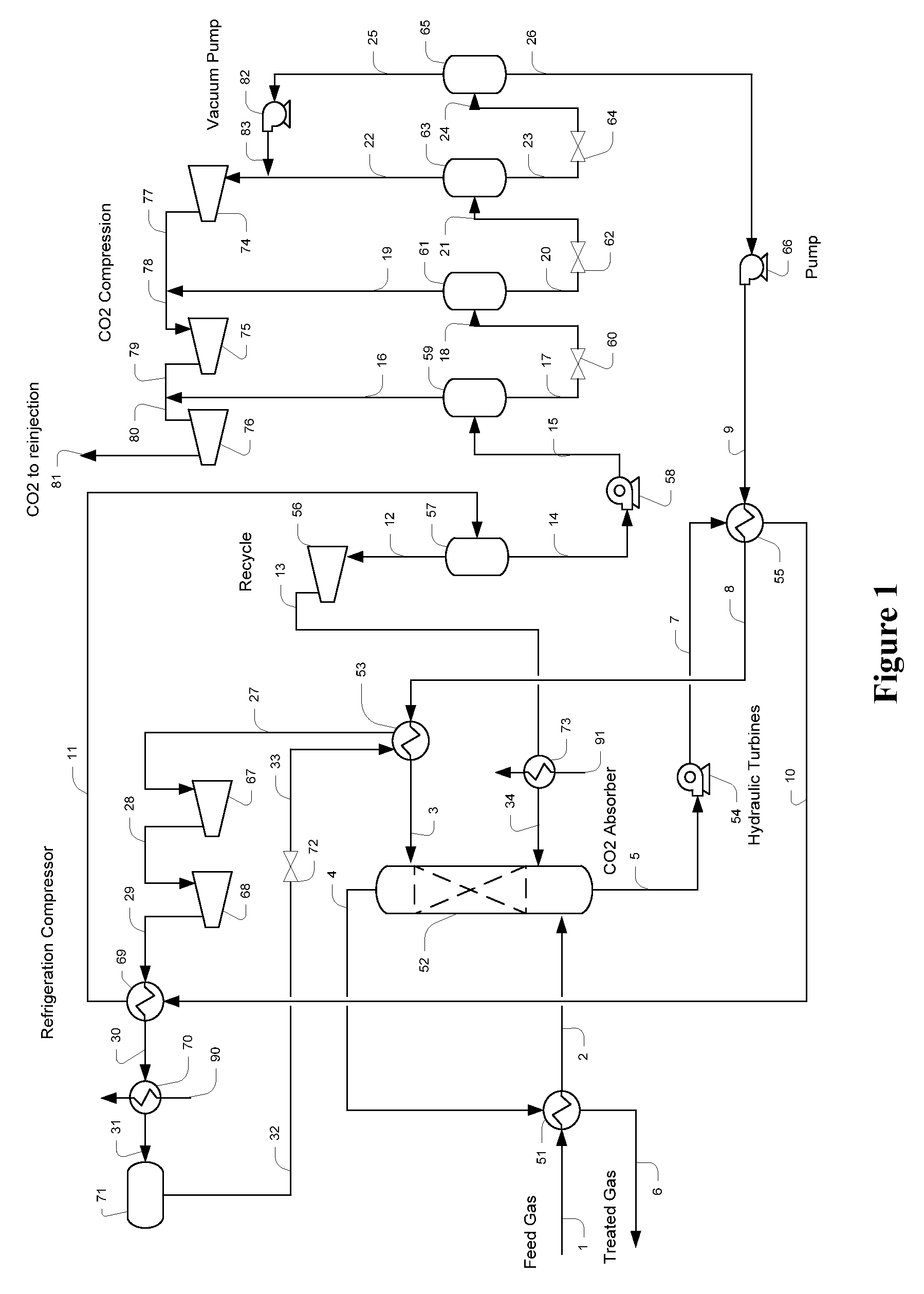

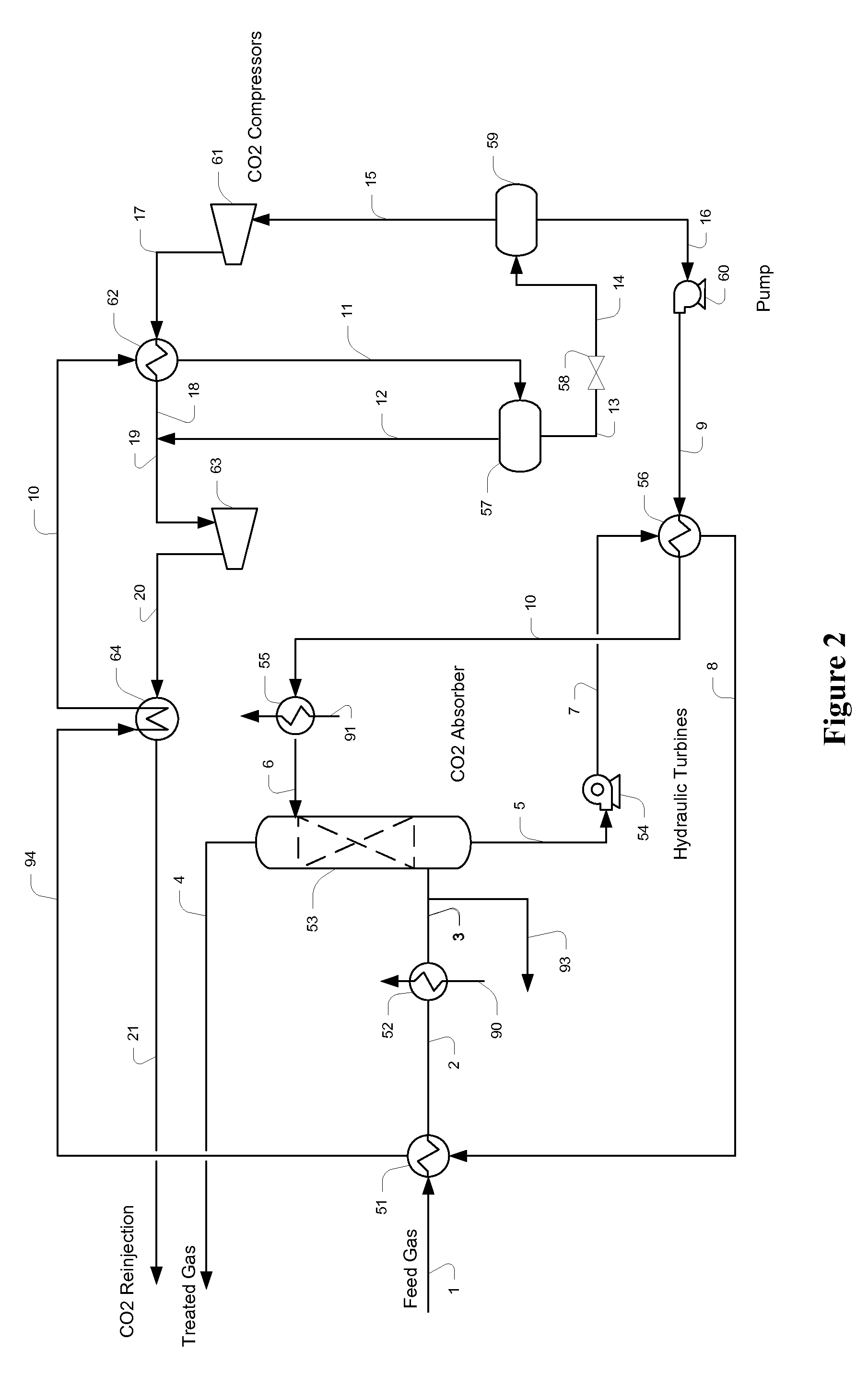

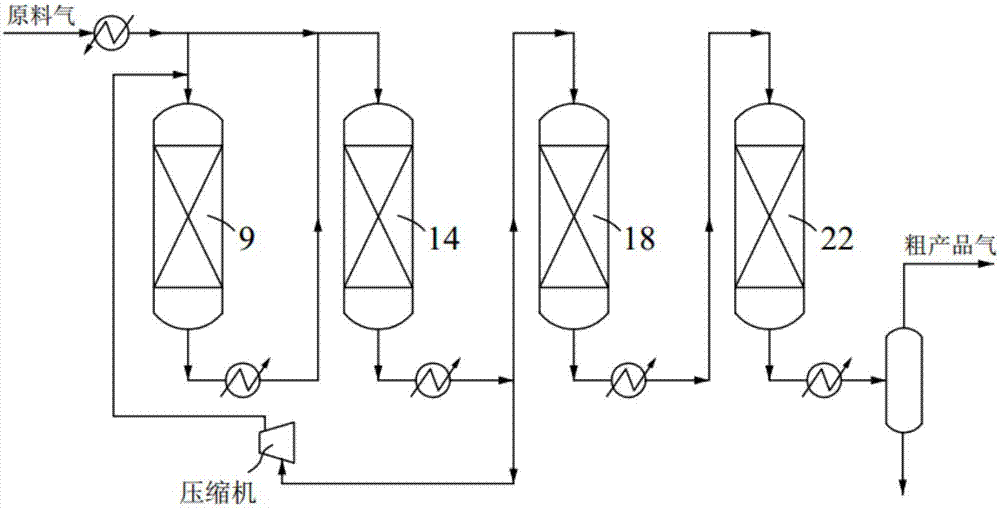

Configurations And Methods Of High Pressure Acid Gas Removal

Acid gas is removed from a feed gas using a physical solvent that is regenerated using successive flashing stages after heating of the rich solvent using low-level waste heat that is preferably produced or available within the acid gas removal plant. Especially preferred waste heat sources include compressor discharges of the refrigeration system and / or recompression system for CO2, and / or (low level) heat content from the feed gas.

Owner:FLUOR TECH CORP

Configurations and methods of high pressure acid gas removal

Acid gas is removed from a feed gas using a physical solvent that is regenerated using successive flashing stages after heating of the rich solvent using low-level waste heat that is preferably produced or available within the acid gas removal plant. Especially preferred waste heat sources include compressor discharges of the refrigeration system and / or recompression system for CO2, and / or (low level) heat content from the feed gas.

Owner:FLUOR TECH CORP

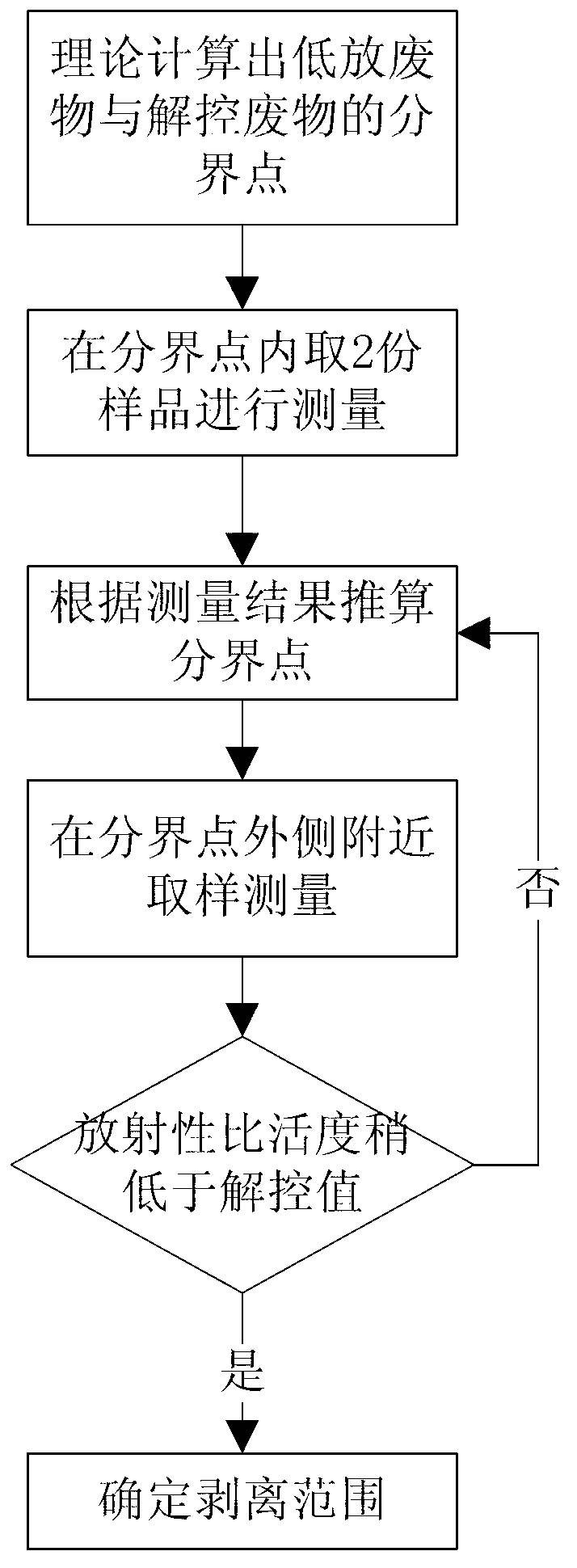

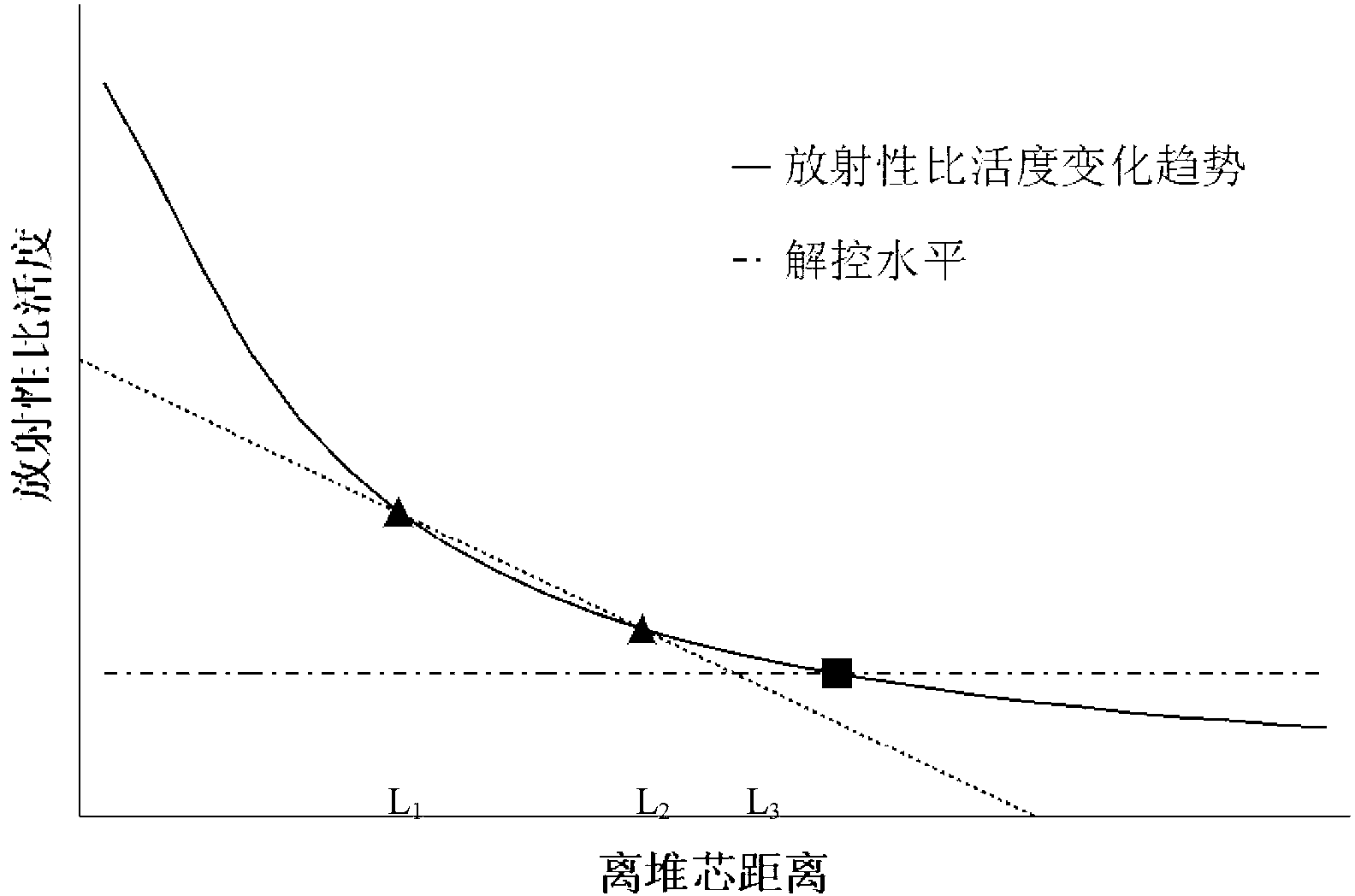

Reactor pool cleaning method used for miniature neutron source reactor decommissioning

InactiveCN103308936AAccurately determineReduce cleanupX/gamma/cosmic radiation measurmentRadioactive decontaminationDemarcation pointLow-level waste

The invention discloses a reactor pool cleaning method used for miniature neutron source reactor decommissioning. The method includes the following steps: (1), theoretically calculating demarcation points of low level waste and deregulated waste; (2) sampling two points within the demarcation points for gamma spectrum analysis to acquire radioactive nuclide specific activity; (3), reasoning positions of the demarcation points according to nuclide specific activity and the position thereof; (4), sampling at positions closed to the outer sides of the demarcation points for gamma spectrum analysis to acquire radioactive nuclide specific activity; (5), comparing the acquired activity with a deregulating value, if the activity is smaller than the deregulating value, determining the positions to be the interface of the deregulating waste and the low level waste, peeling the portion within the positions and cleaning, and if the activity is larger than the deregulating value, repeating step (3) and (4) until the acquired activity is smaller than the deregulating value, and cleaning. By the method, sampling and measuring while peeling can be realized, secondary radioactive waste quantity can be reduced, and measuring workload and classifying time of radioactive waste can be reduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

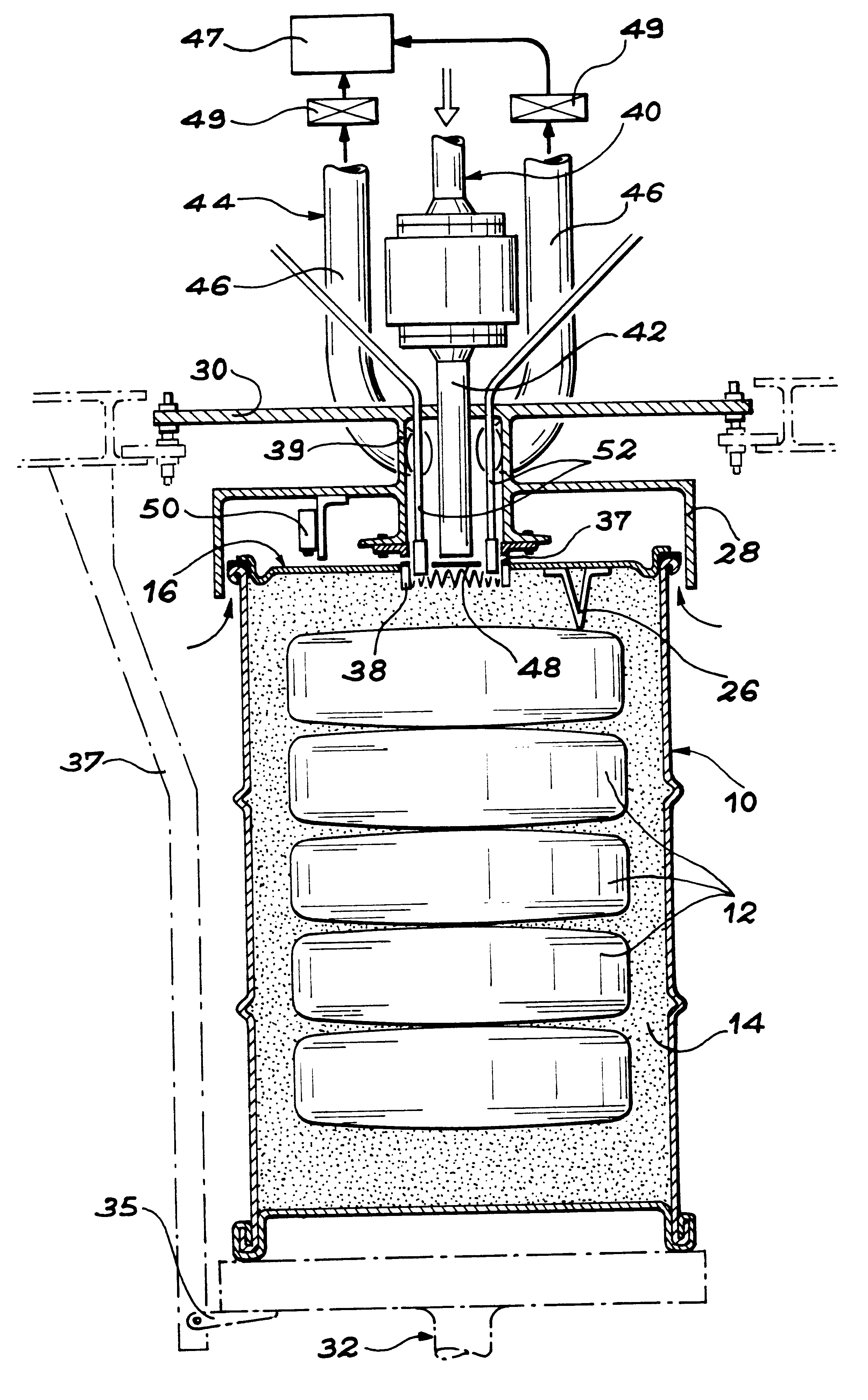

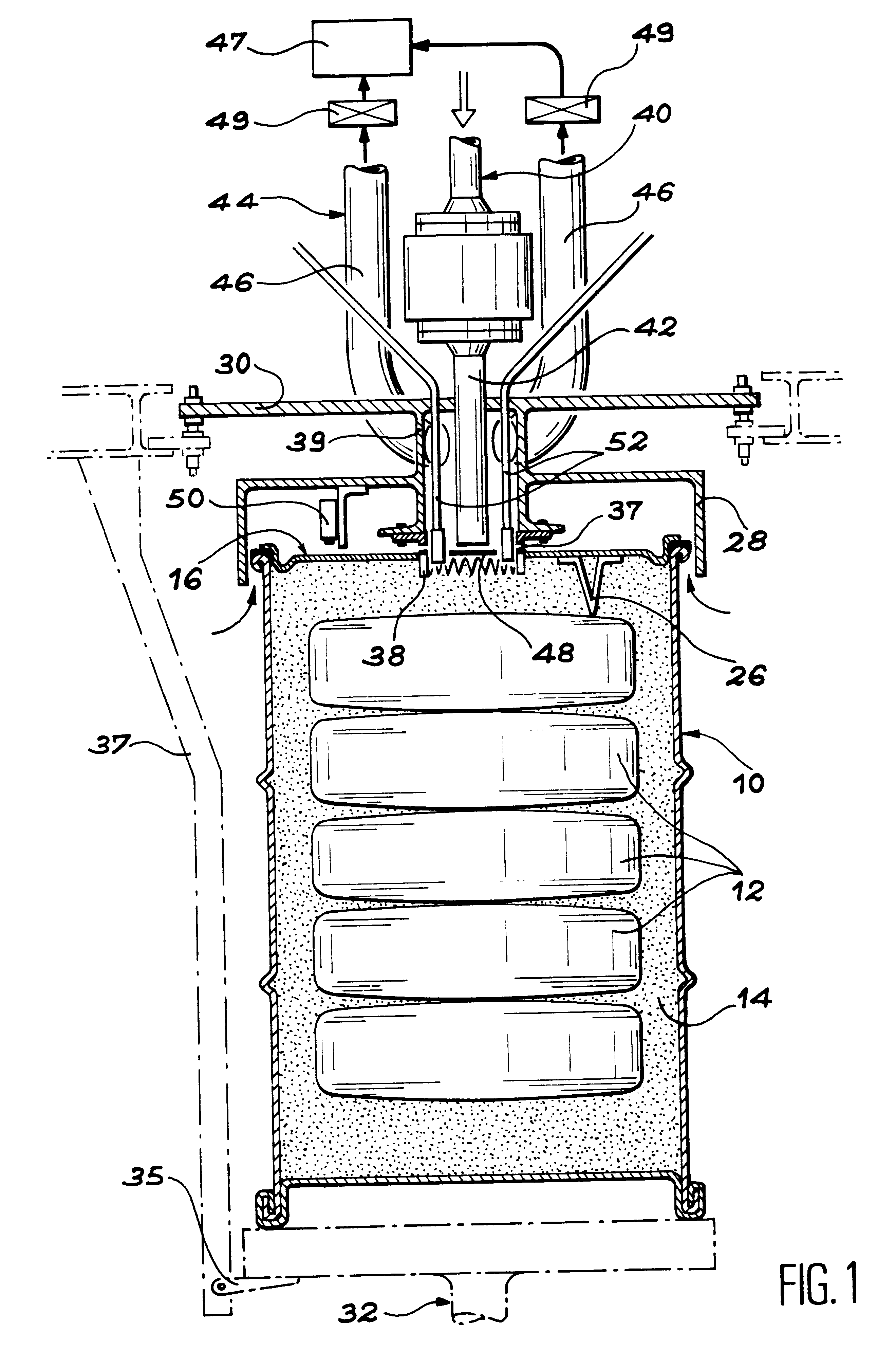

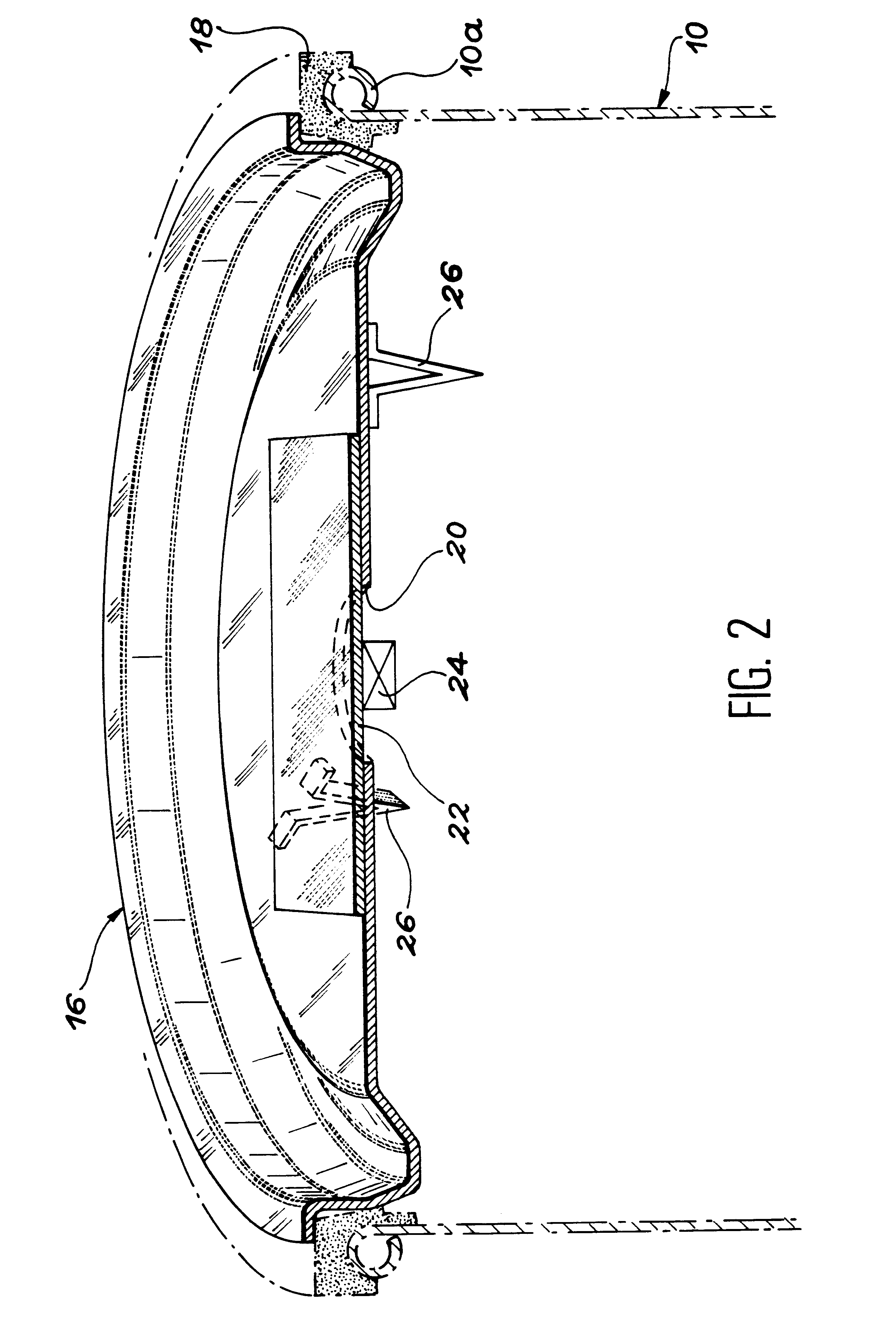

Method and device for filling drums containing dangerous waste

InactiveUS6666003B1Ensure sealing performanceAvoid pollutionOpening closed containersBottle/container closureLow-level wasteEngineering

Dangerous wastes, such as very low level radioactive waste are processed and compacted under the form of flat cakes (12) stacked in metallic drums (10) closed by an intermediary lid (16) provided with a cap. A blocking material is then injected into the drum by an injection nozzle (42), after a toothed crown (38) surrounding this nozzle has perforated the cap. The toothed crown (38) is carried by a dynamic containment hood (28) in which there is also a circuit (44) for negative pressure application to the drum (10) and the hood. This circuit sucks out the contaminated air contained in the tank when it is perforated and during injection. The operation is thus carried out without risk of contaminating the workshop and the external surface of the drum.

Owner:CO GENERALE DES MATIERES NUCLEAIRES

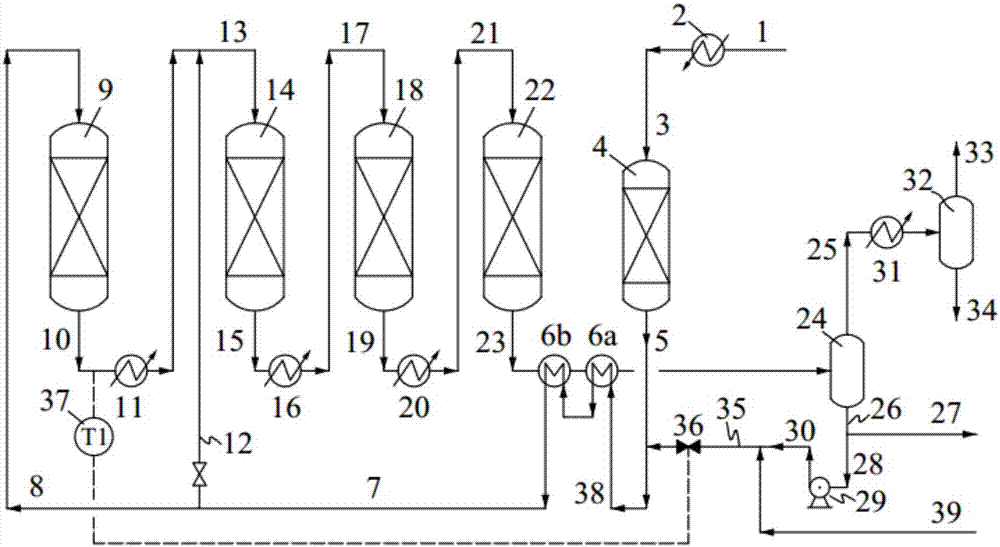

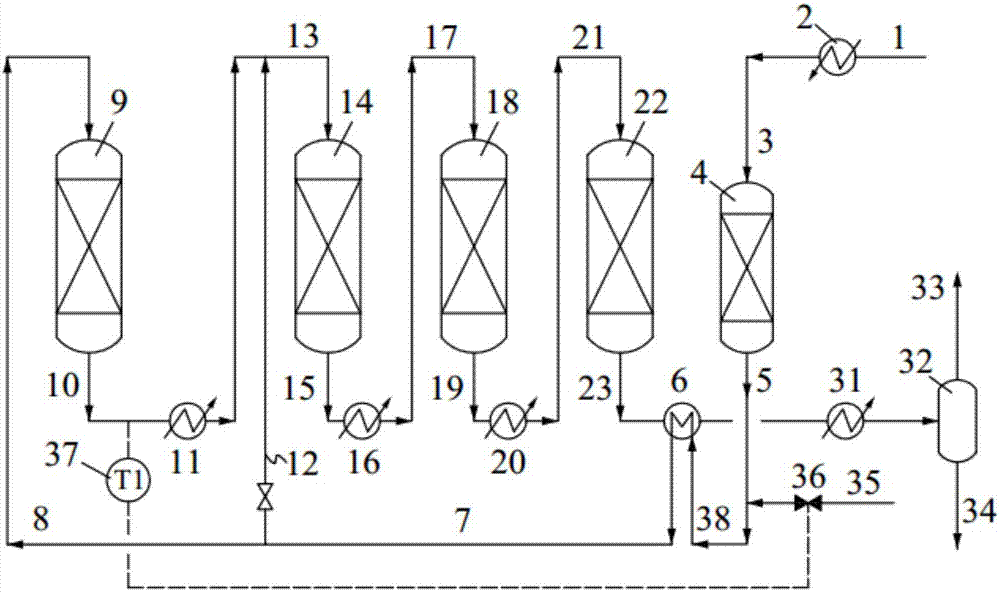

Methanation process for effectively recovering low-grade waste heat

The invention relates to a methanation process for effectively recovering low-grade waste heat. The methanation process is characterized in that by a mode of filling water into raw synthesis gas, the gasifying-balance partial pressure and the gasifying temperature of water are reduced; and an evaporator and a superheater are arranged on an outlet pipeline of a final-stage methanation reactor, and the filled water is gasified till to be superheated by utilizing low-grade waste heat at an outlet of the final-stage methanation reactor. The methanation process has the advantages that on one hand, the recovery utilization rate of the final-stage low-level waste heat of the methanation reaction is increased, the yield of side-product steam is increased and the comprehensive energy efficiency of the methanation process is improved; on the other hand, according to the water filling amount, the heat release of the methanation reaction can be effectively controlled, the use of a high-temperature circulating gas compressor is avoided, the methanation reaction is easy to control and the safety of operation is improved.

Owner:WISON ENG +1

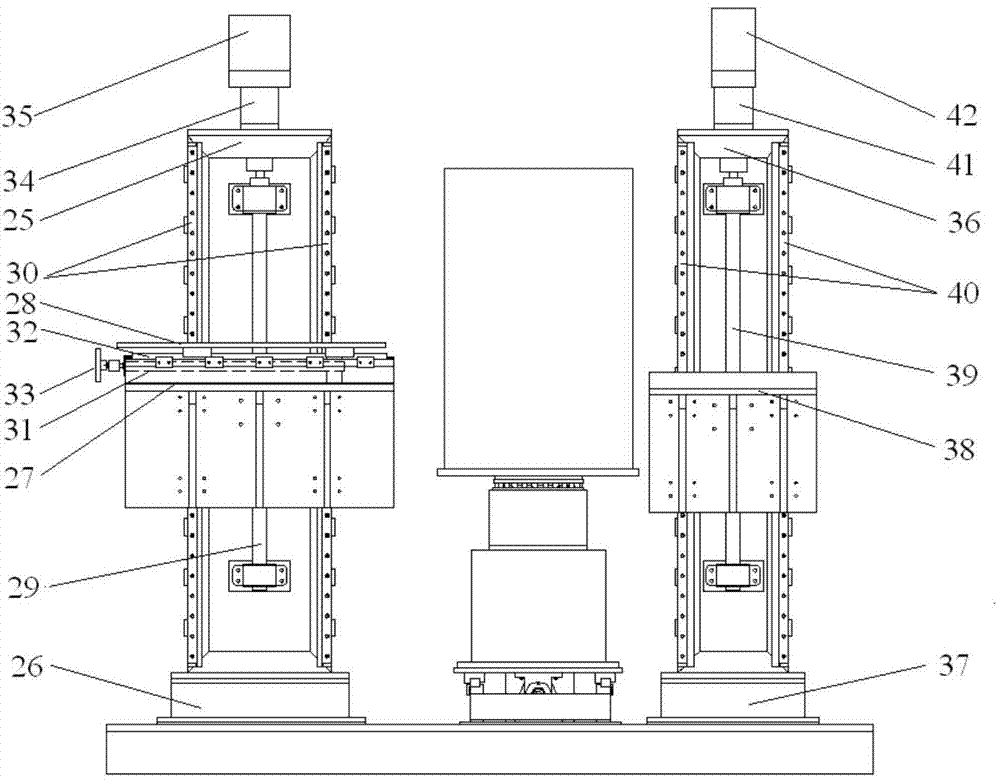

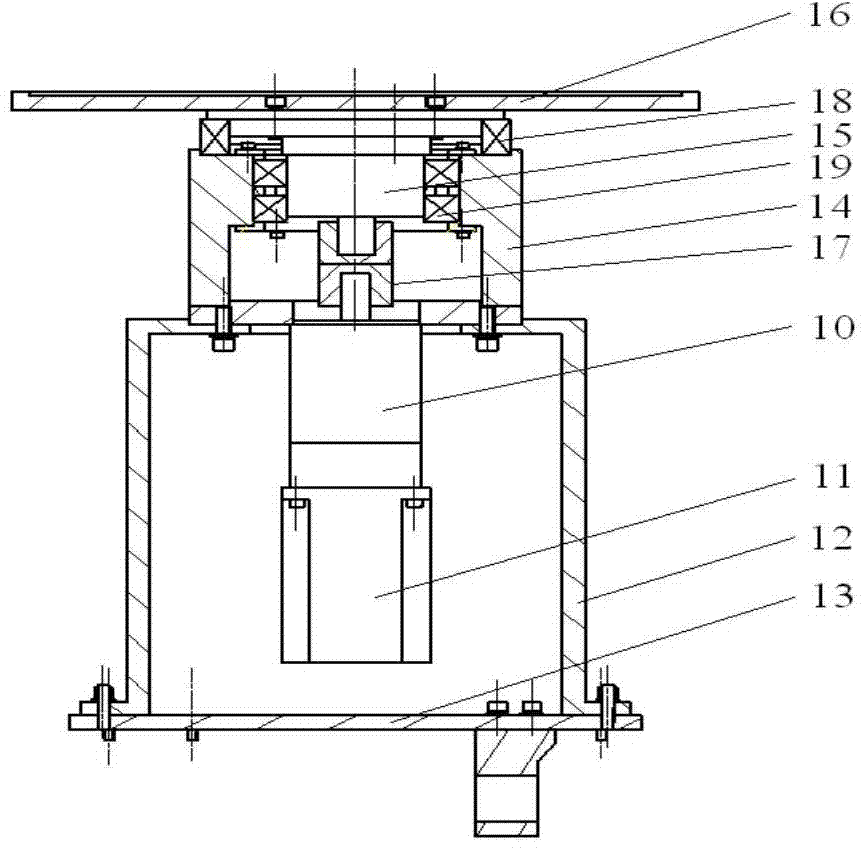

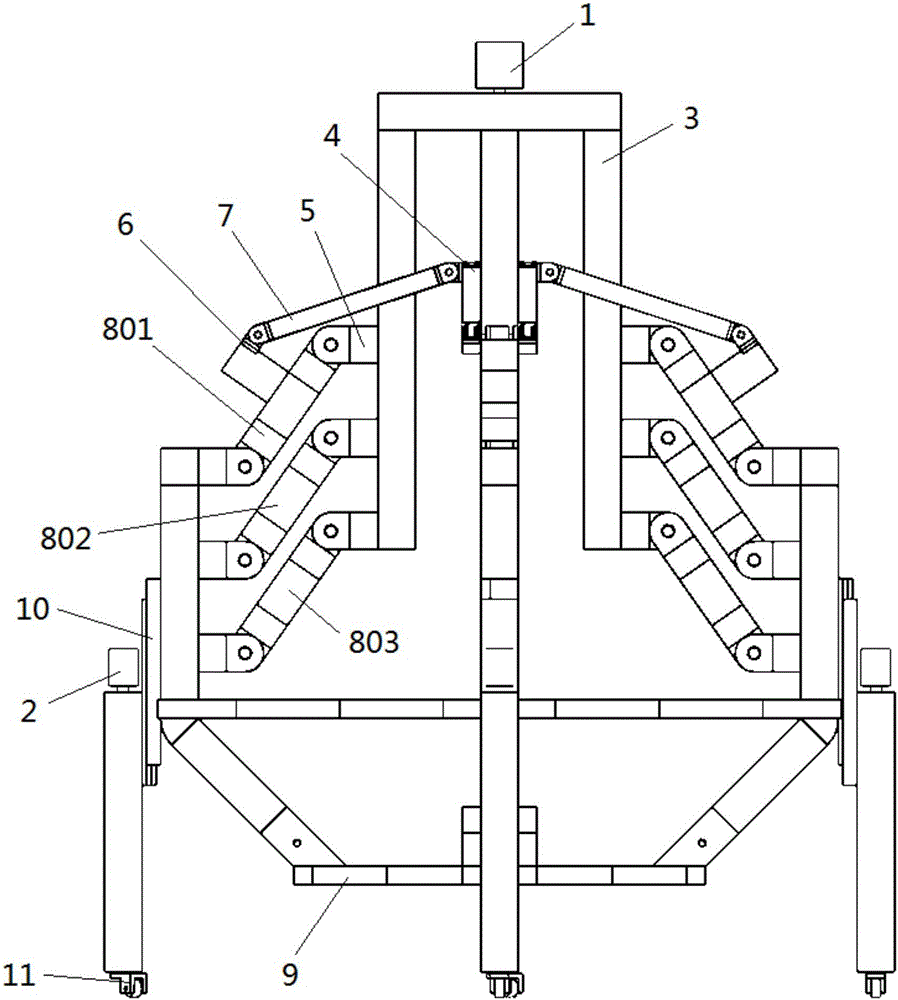

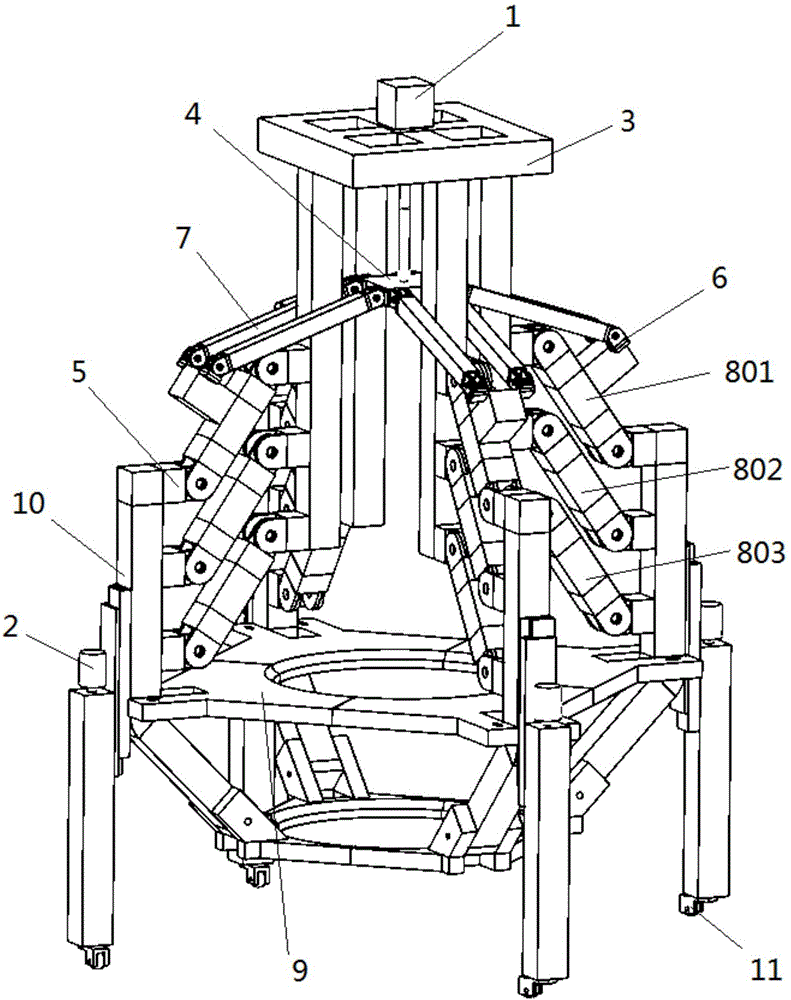

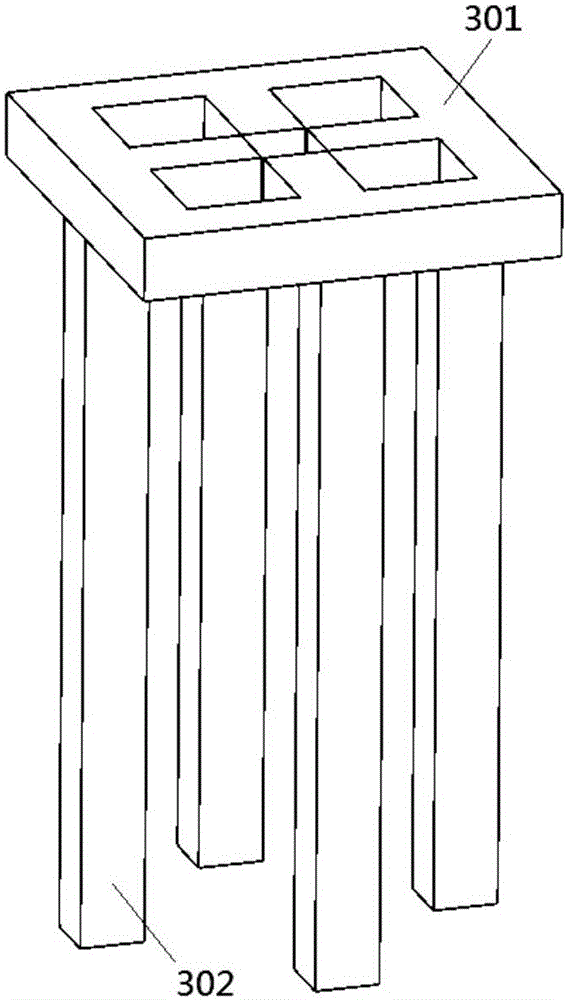

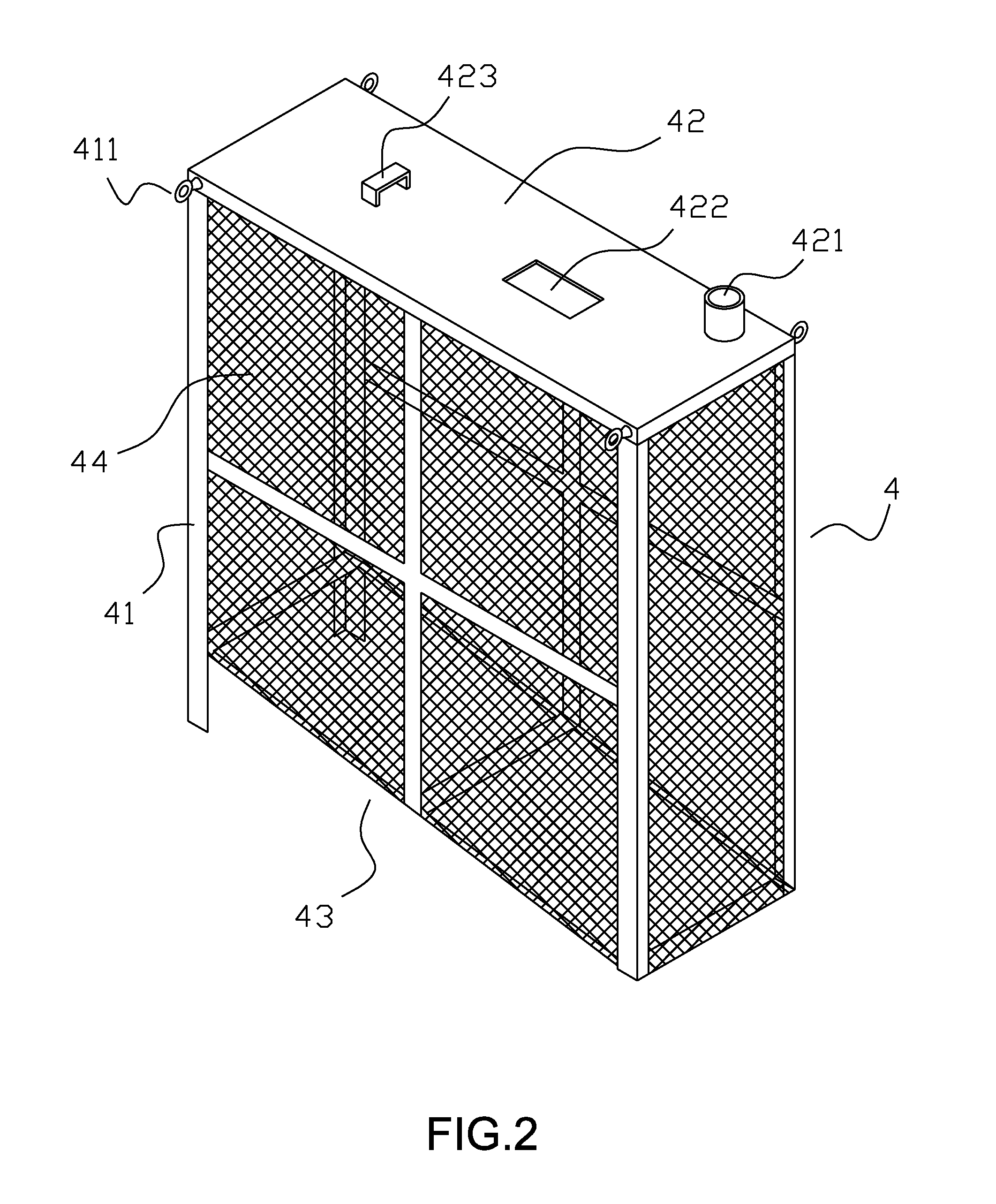

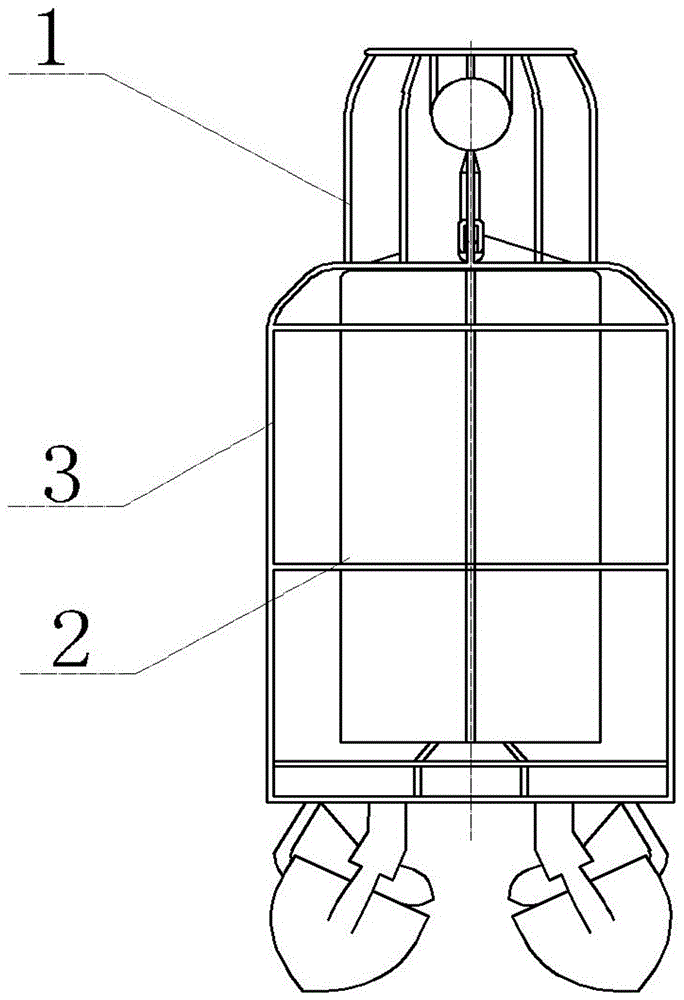

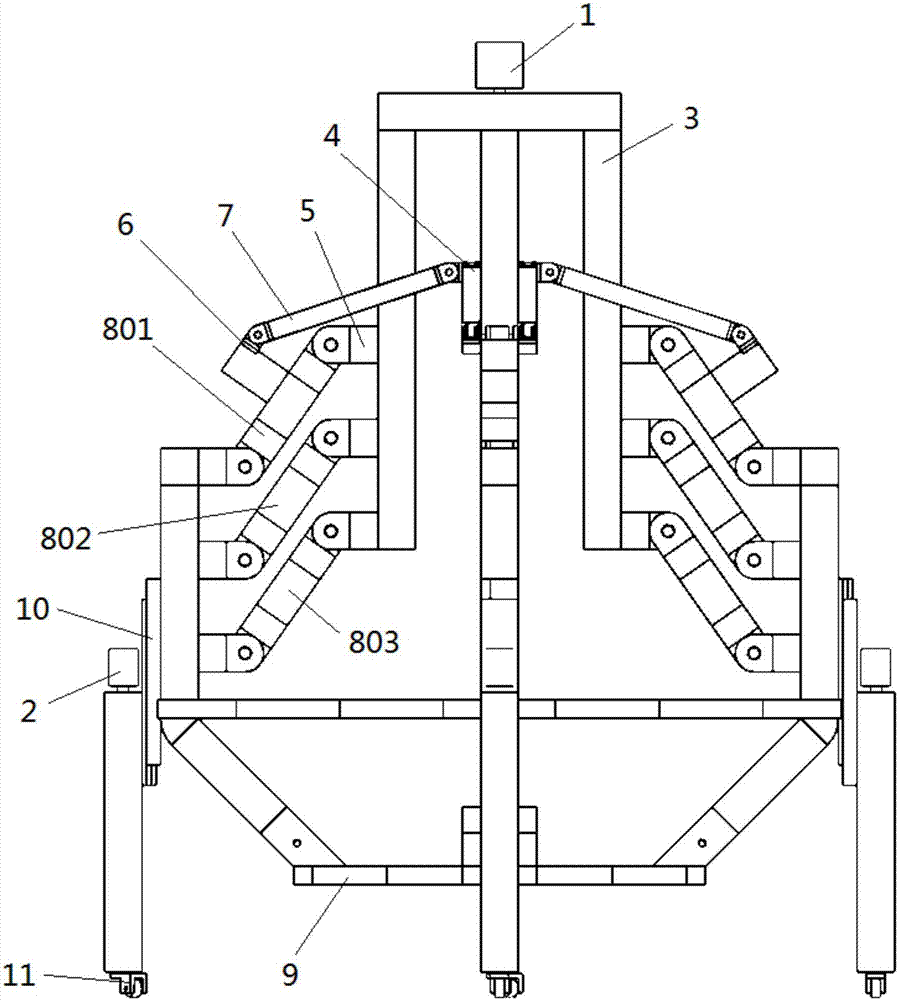

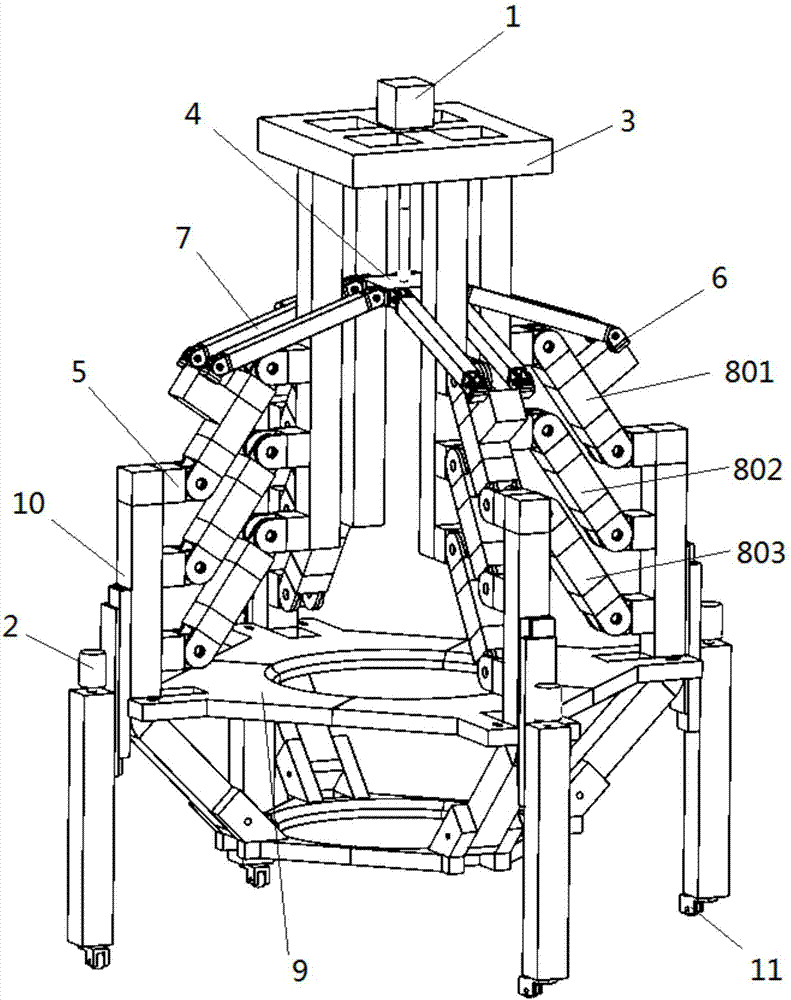

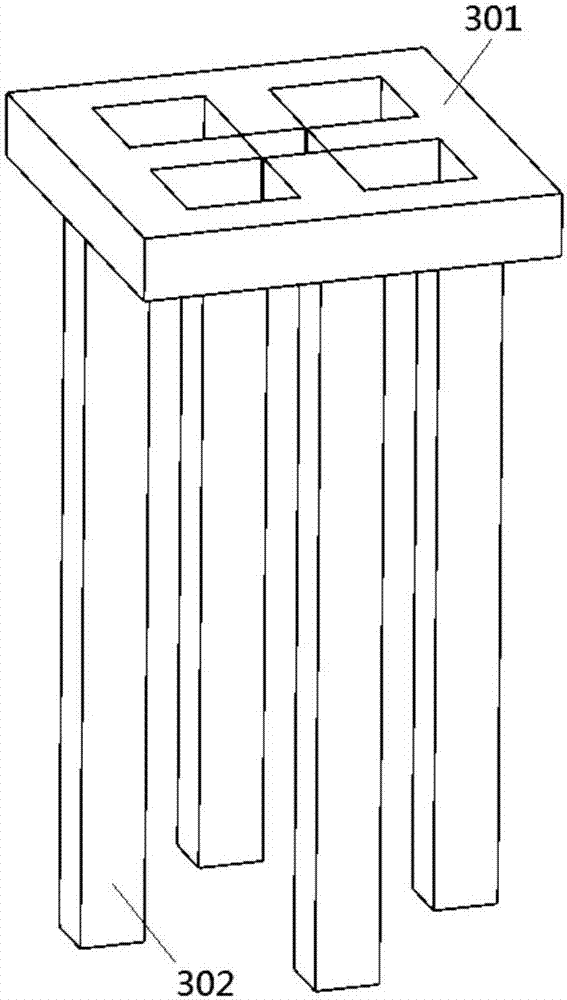

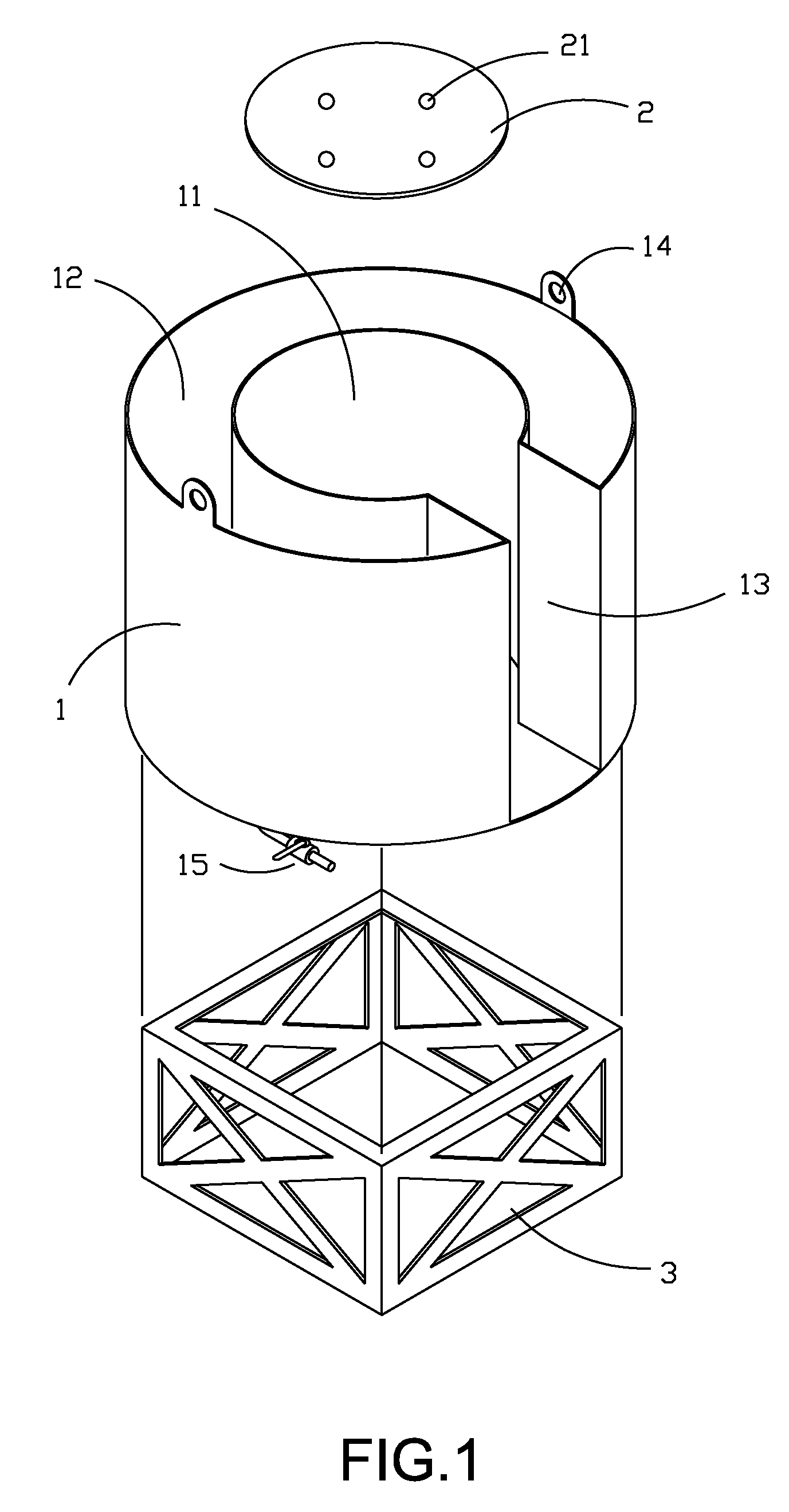

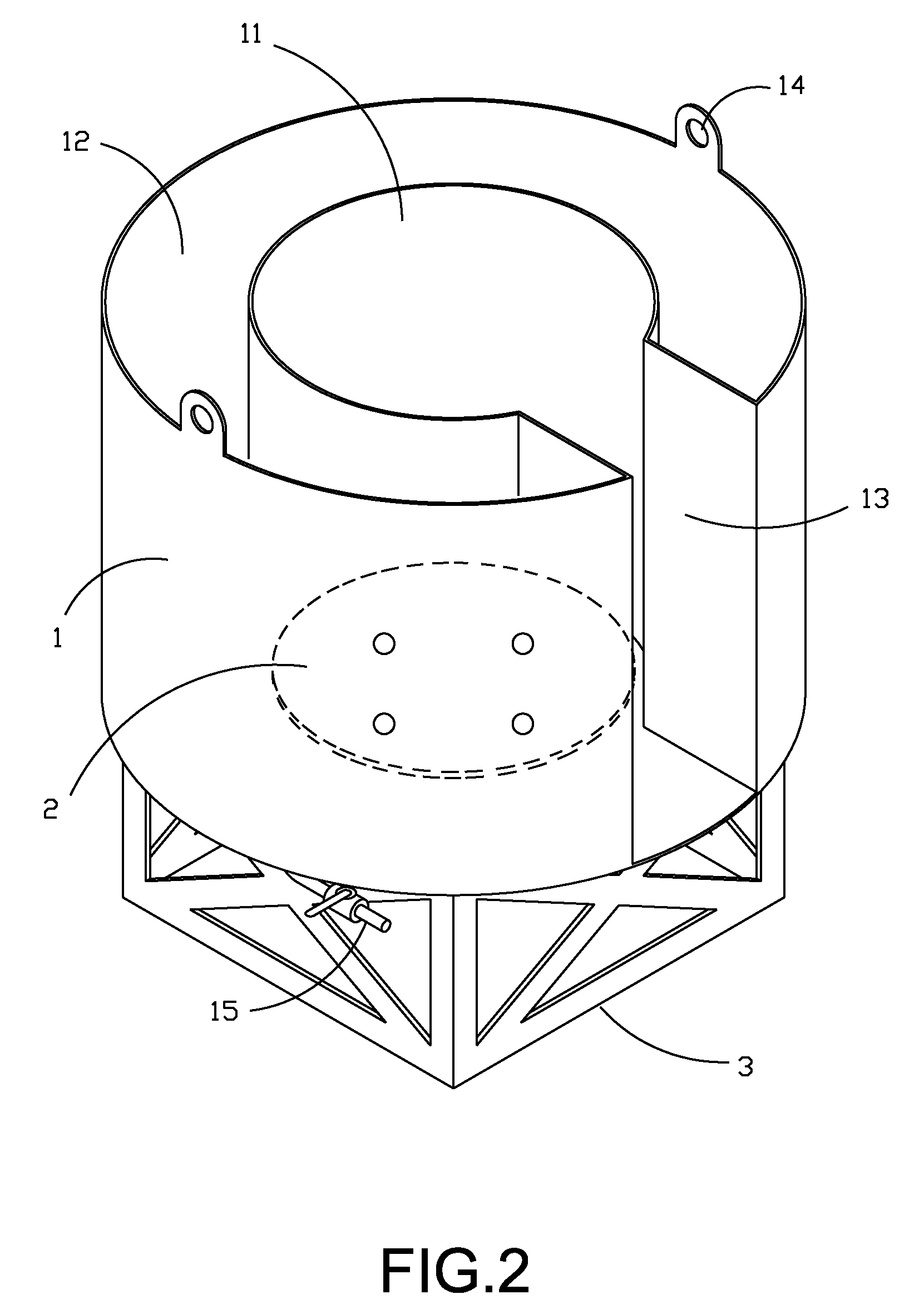

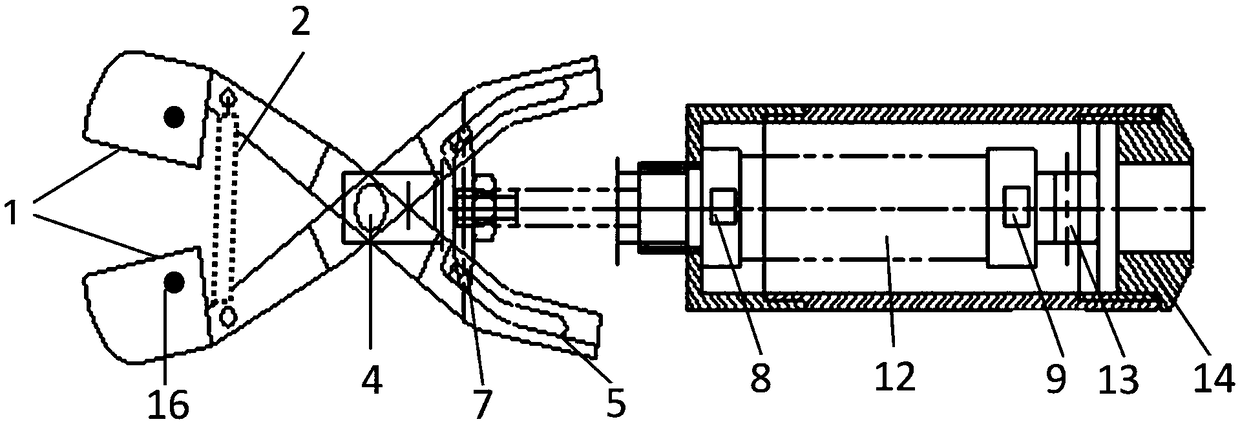

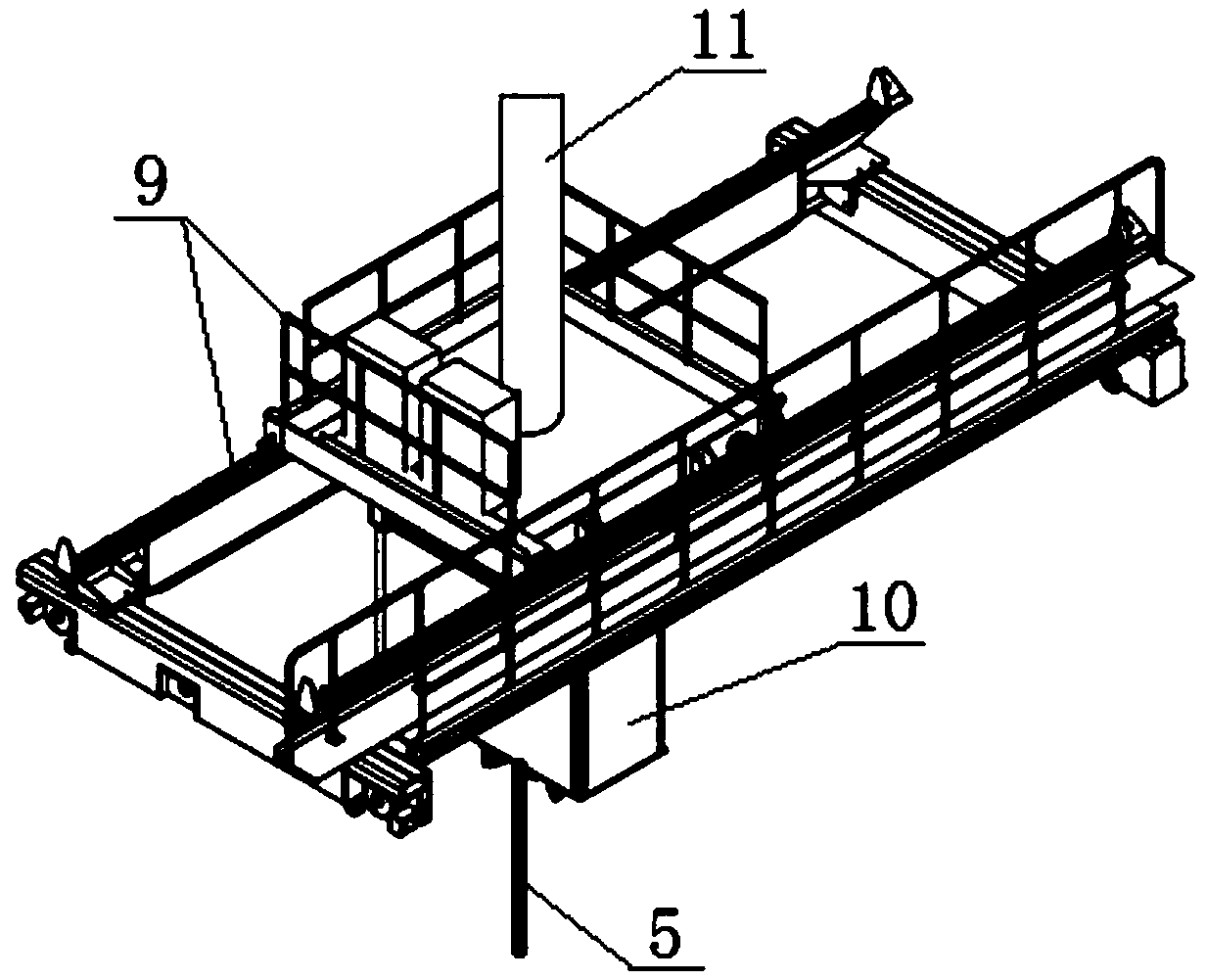

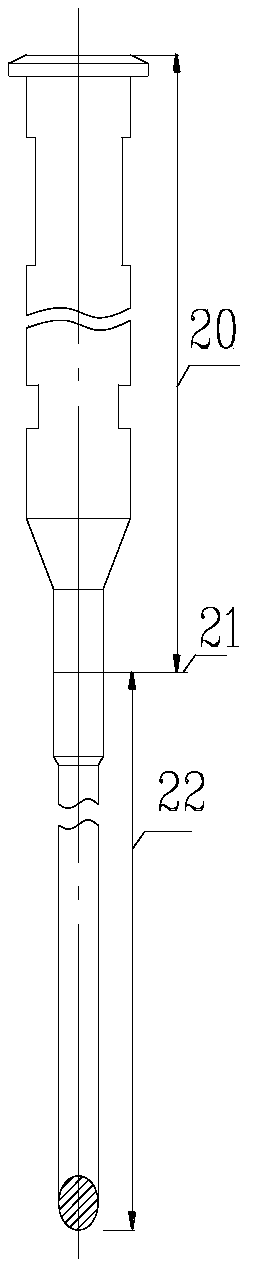

Grabbing device used for medium-low-radioactivity waste barrels

InactiveCN105895181ARealize automatic centeringAvoid a destructive situationProgramme-controlled manipulatorConveyorsNon destructiveStress conditions

Owner:SHANGHAI JIAO TONG UNIV

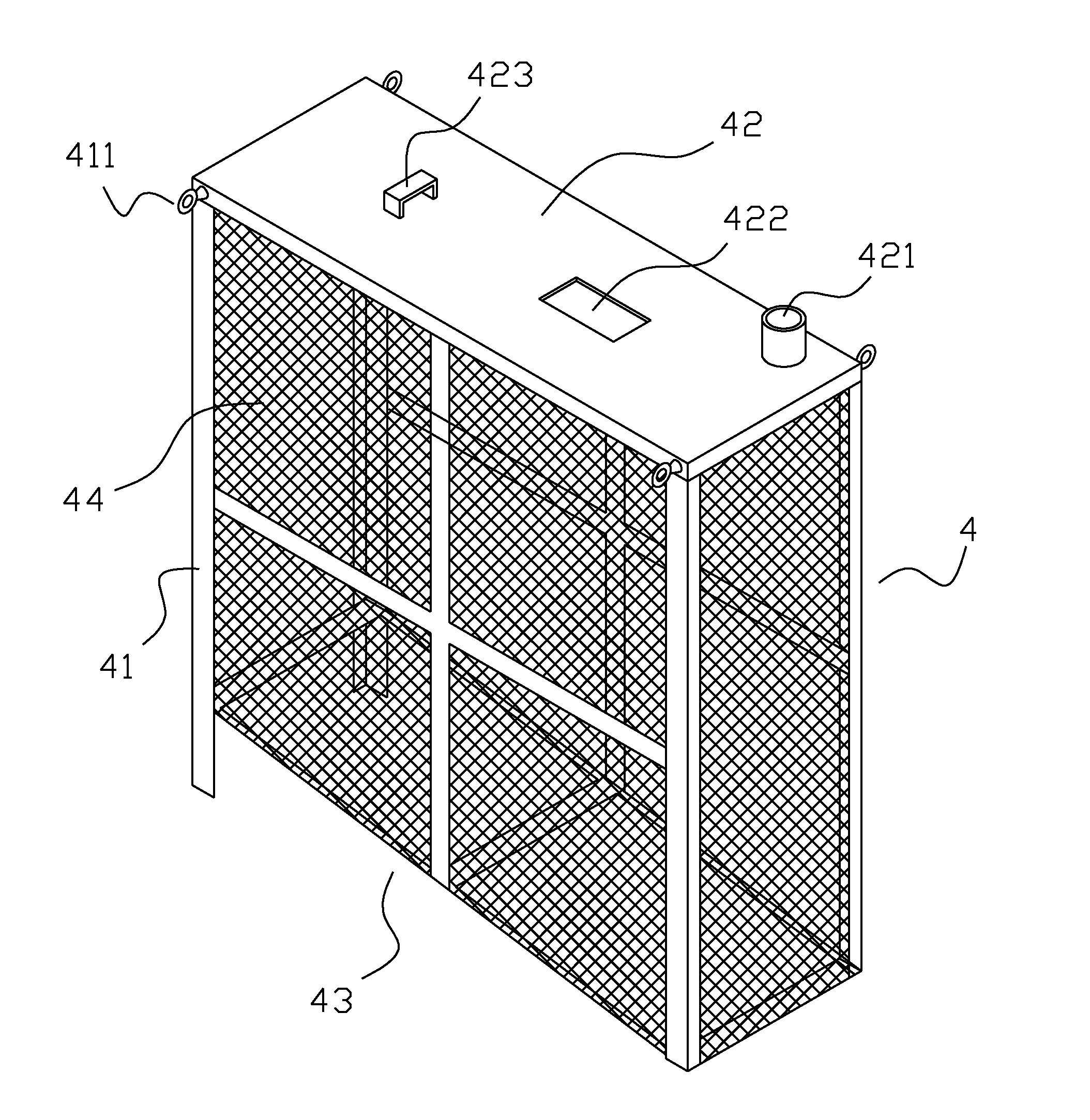

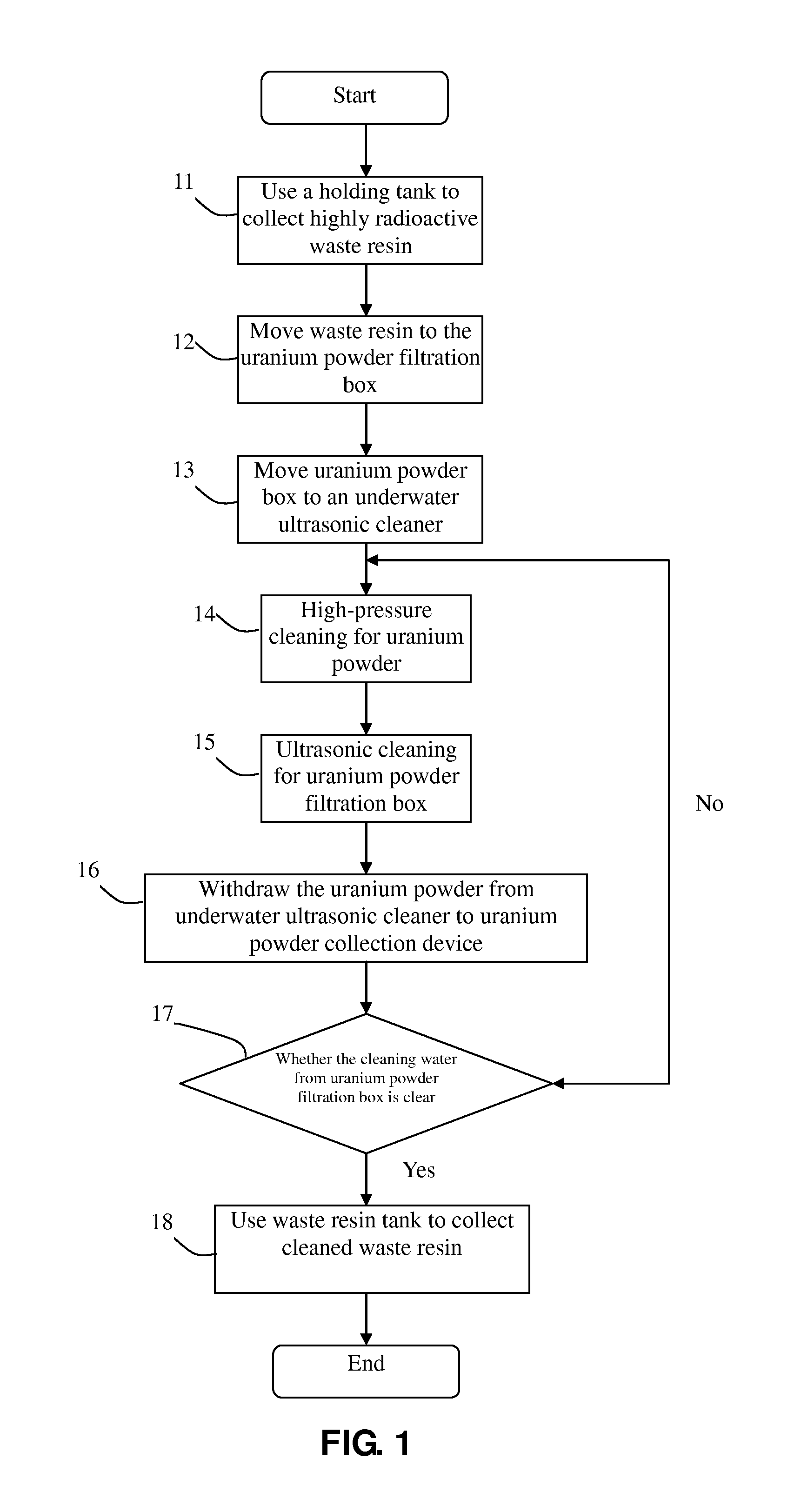

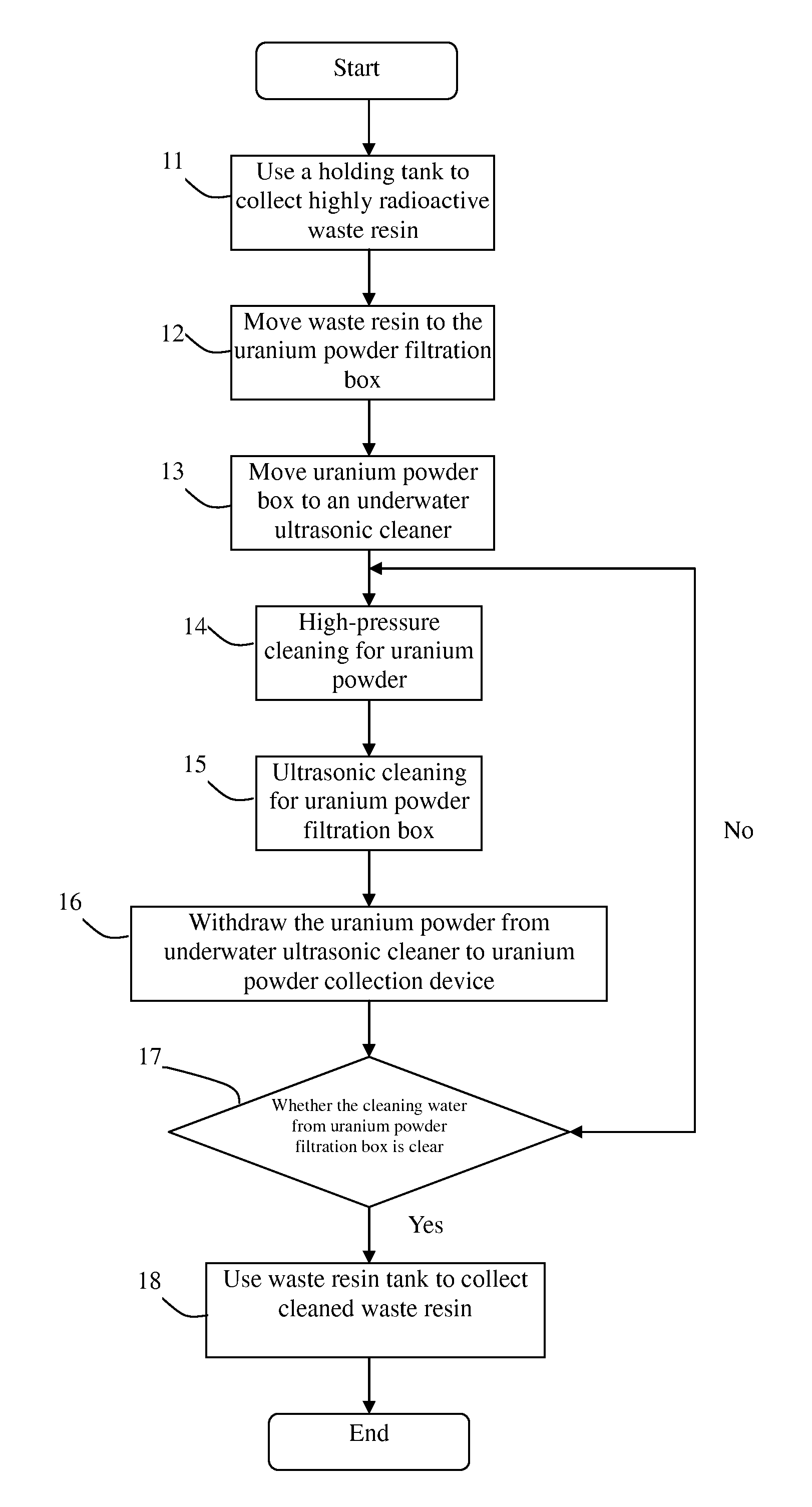

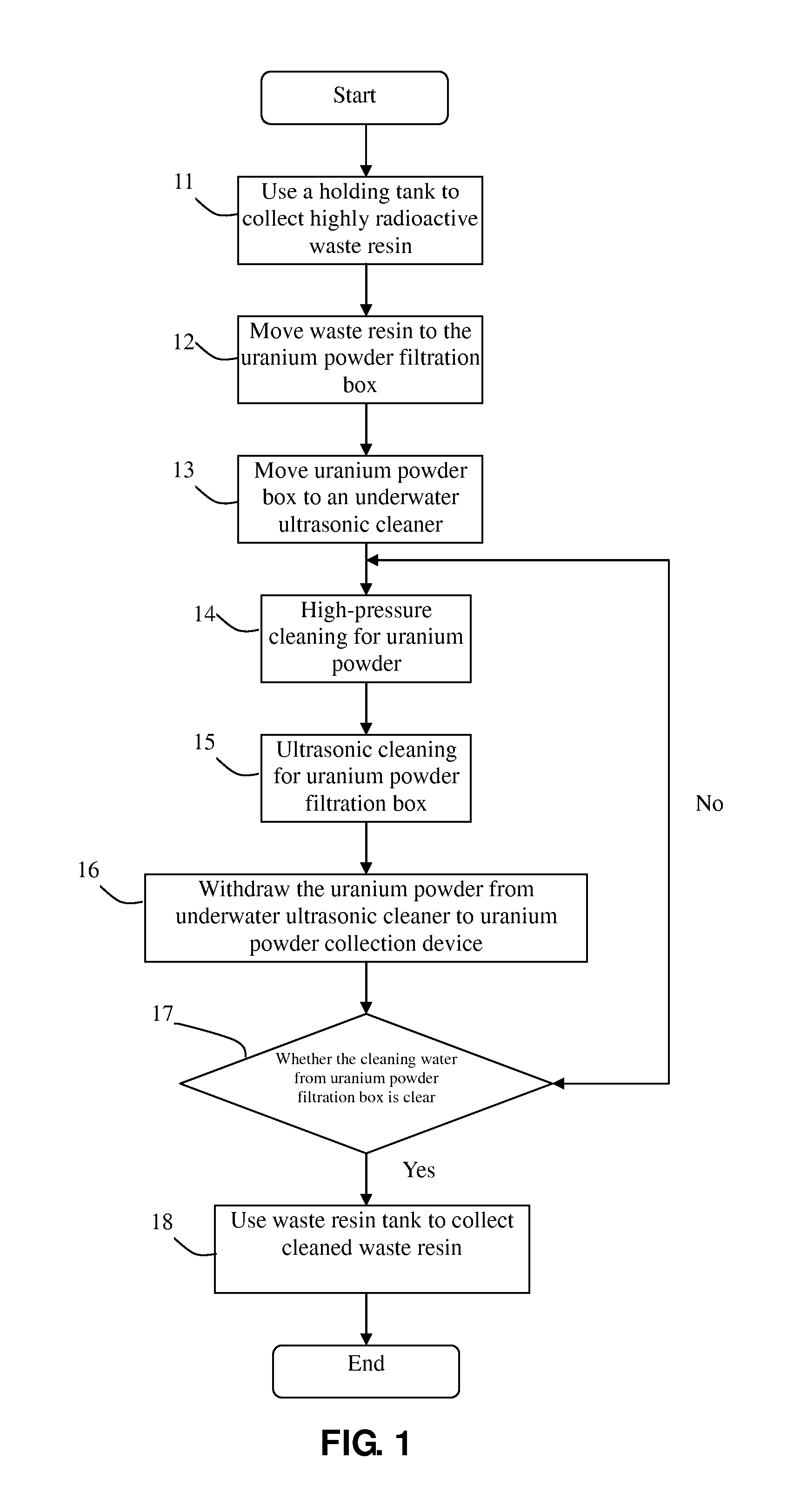

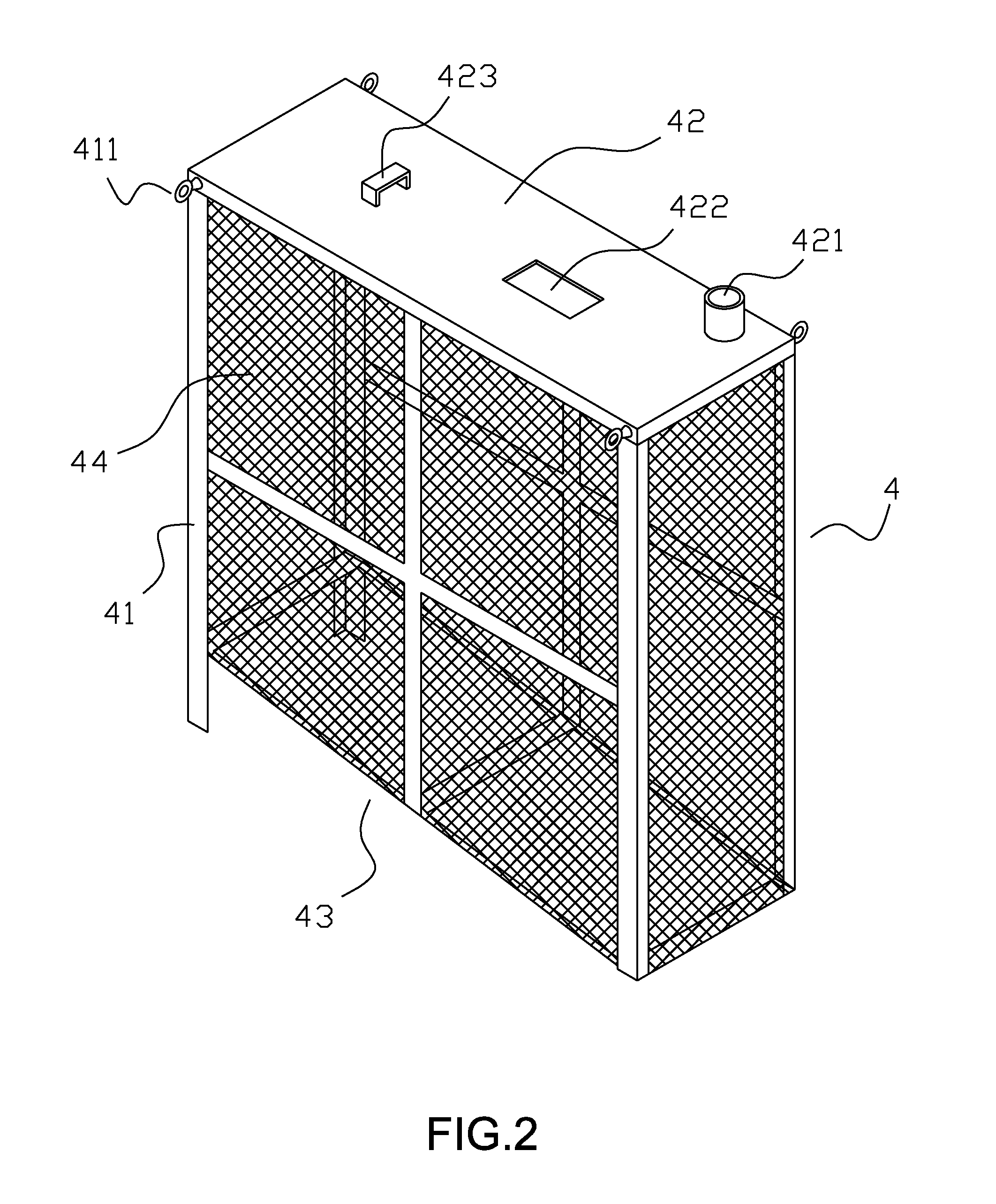

Filtration separation method for waste resin containing highly radioactive uranium powder and device thereof

InactiveUS20110024364A1Minimising exposure to radiationSimple processShaking/oscillating/vibrating mixersIon-exchanger regenerationFiltrationLow-level waste

A filtration separation method for waste resin containing highly radioactive uranium powder and device thereof is mainly used for the waste resin after water treatment process in a nuclear facility. The uranium powder contained in the waste resin is highly radioactive. Thus, prior to the treatment of the waste resin, it is necessary to filter and separate the highly radioactive uranium powder to reduce the radioactivity. It is to put the uranium powder containing waste resin into an underwater holding tank and withdraw the waste resin by an underwater pump into a uranium powder filtration box. Then the uranium powder filtration box is lifted by a hoist to move to an underwater ultrasonic cleaner. High-pressure water flushing is applied and followed by underwater ultrasonic cleaning. Then the cleaning water (containing precipitated uranium powder) from the ultrasonic cleaner is drained to uranium powder collection device. If the radioactivity of the waste resin is still high, high-pressure cleaning by water nozzle flushing and ultrasonic cleaning are applied several times until the radioactivity of the waste resin is lowered to the treatment standard and converted to low-radioactivity waste for further treatment.

Owner:INST NUCLEAR ENERGY RES ROCAEC

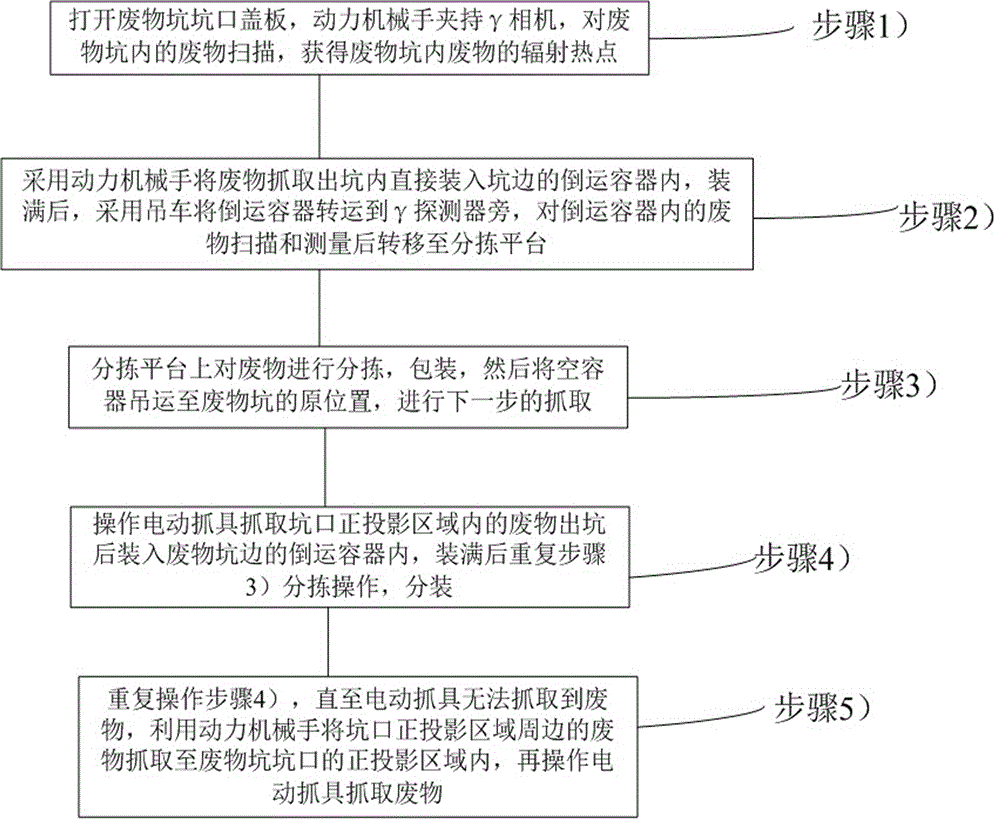

Retrieving method for low-level waste in waste pit

ActiveCN106297935ASolve the technical problems of retrievalImprove retrieval efficiencyRadioactive decontaminationLow-level wasteManipulator

The invention discloses a retrieving method for low-level waste in a waste pit. The method comprises the steps that waste in a pit opening of the waste pit is gripped to an orthographic projection area under the pit opening of the waste pit through a power manipulator, and then the waste in the orthographic projection area under the pit opening of the waste pit is gripped outside the waste pit and loaded in a waste package box or a transfer container through an electric gripper. According to the retrieving method for the low-level waste in the waste pit, the power manipulator and the electric gripper are combined together according to a certain operation sequence in the operating process, therefore, the technical problem of retrieving the low-level waste in the pit is solved, and imitation and reference value is provided for retirement of other pit type waste libraries in China. Compared with the prior art, the method has the advantages that by adopting a robot gripping mode, the retrieving efficiency of the low-level waste is improved; the exposure dose of operating personnel is decreased, and safety of the operating personnel is guaranteed.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

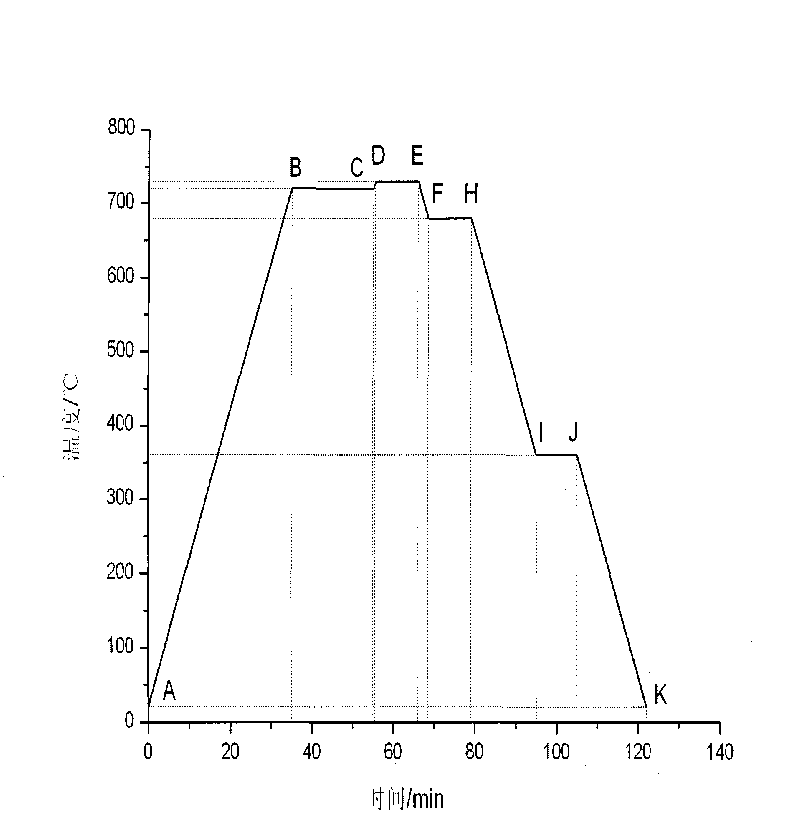

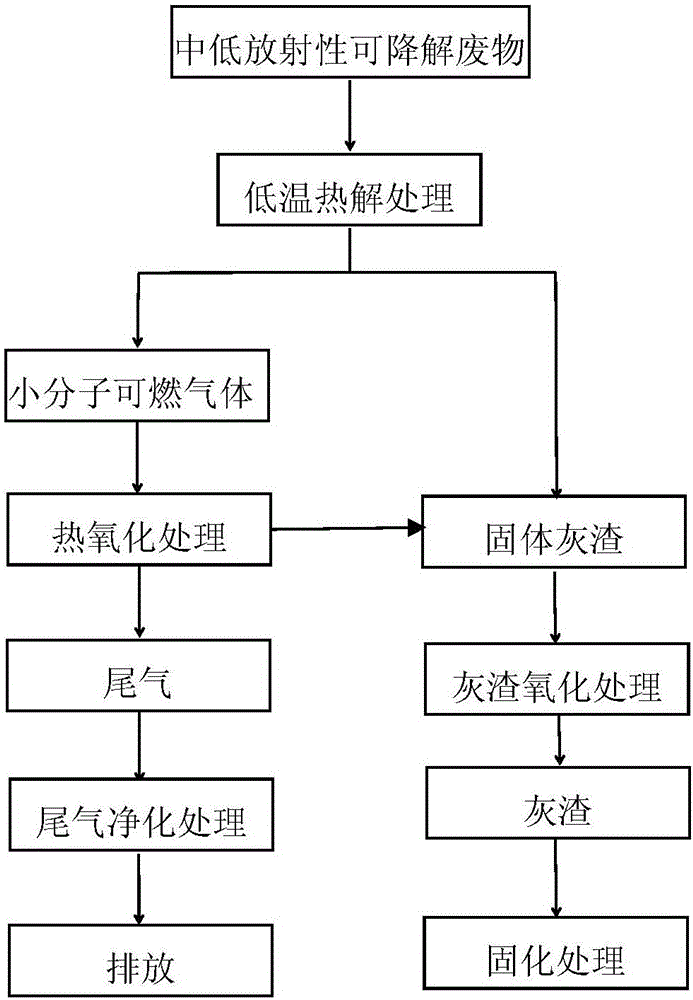

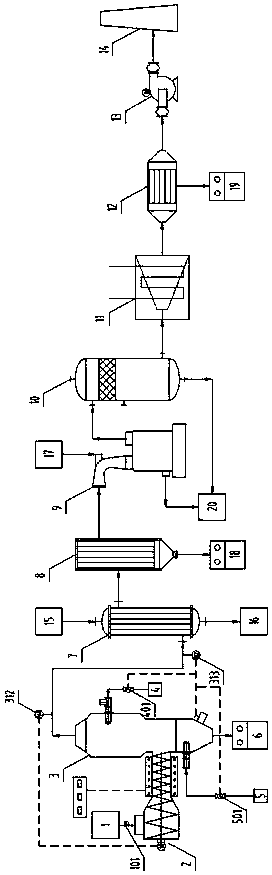

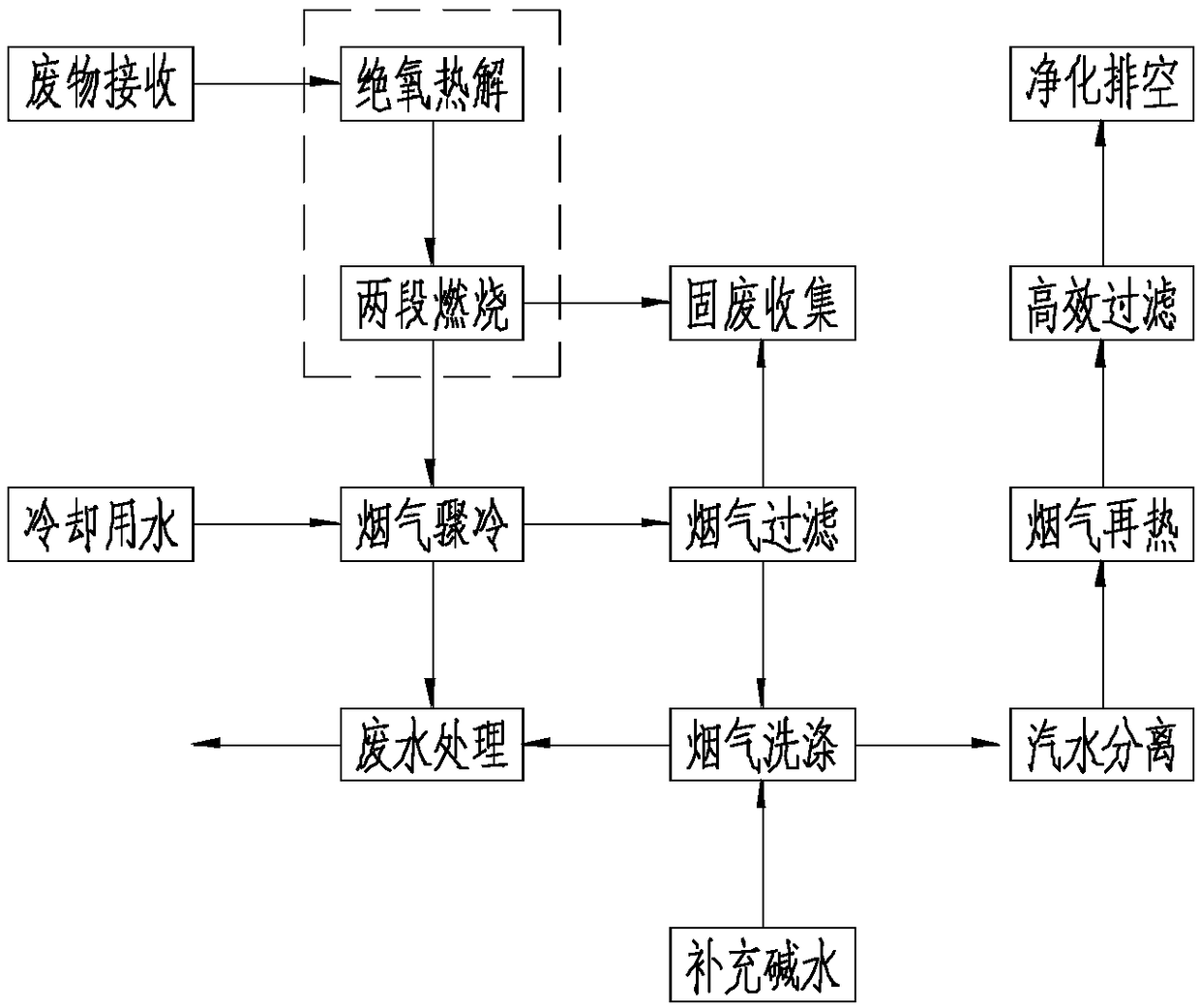

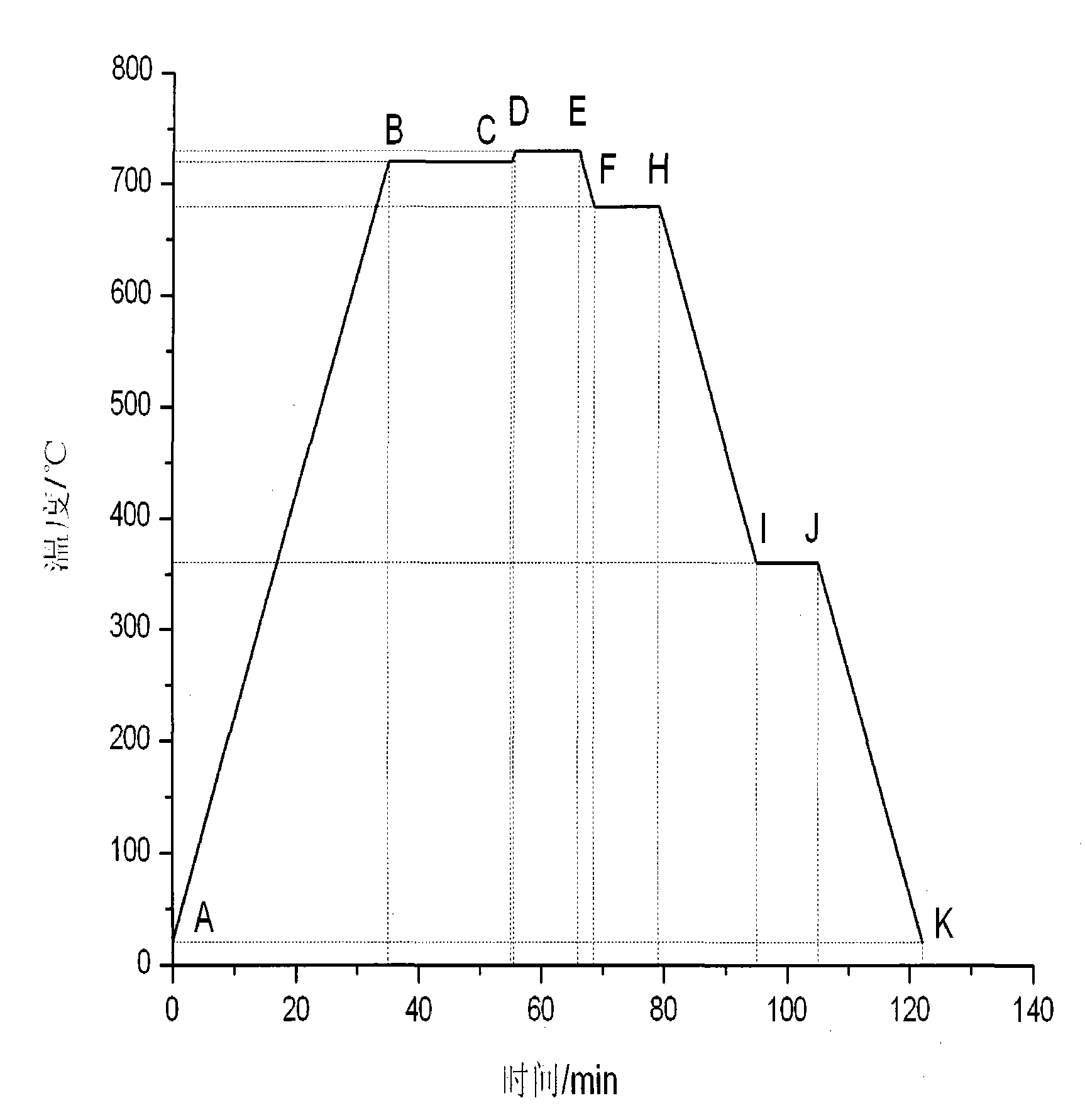

Technology for low-temperature pyrolysis treatment of intermediate-and-low-radioactivity degradable waste

InactiveCN106782737AReduce storageReduce accumulationRadioactive decontaminationReduction treatmentSlag

The invention discloses a technology for low-temperature pyrolysis treatment of intermediate-and-low-radioactivity degradable waste. The technical process includes the steps that the intermediate-and-low-radioactivity degradable waste is subjected to low-temperature pyrolysis and converted into small-molecular combustible gas or solid coal slag, and the coal slag is subjected to a further oxidation reaction so that residual coal in the coal slag or waste which is not completely reacted thoroughly reacts; the gas is completely converted into oxidized gas through a thermal oxidation reaction, the gas is treated through a purification system so as to meet the standard and be exhausted, and the coal slag generated after oxidation is subjected to ceramic-like solidification. The technology solves the problems about storage and accumulation of degradable articles in the nuclear power industry, overcomes the defects of existing related treatment technologies, and achieves harmless volume reduction and weight reduction treatment of intermediate-and-low-radioactivity degradable products in the nuclear power industry or the military industry through pyrolysis heating and oxidation.

Owner:杨红波

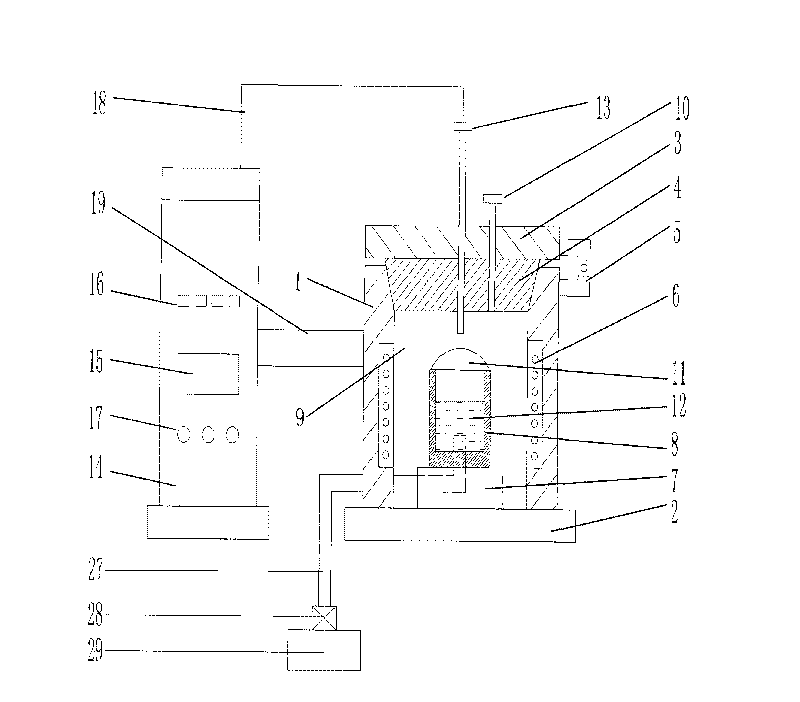

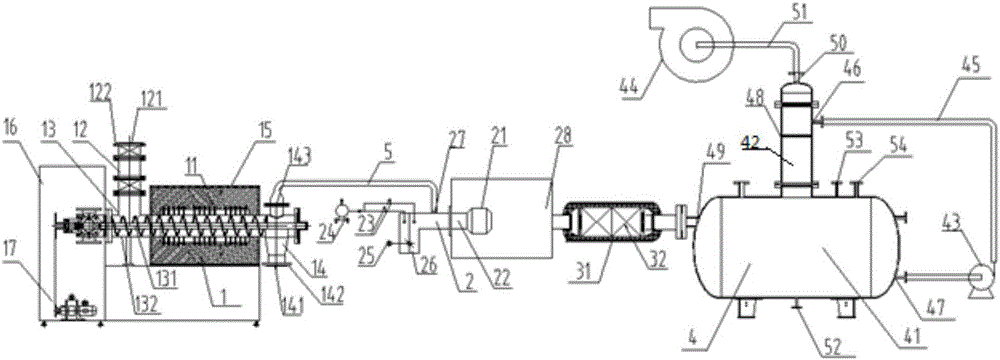

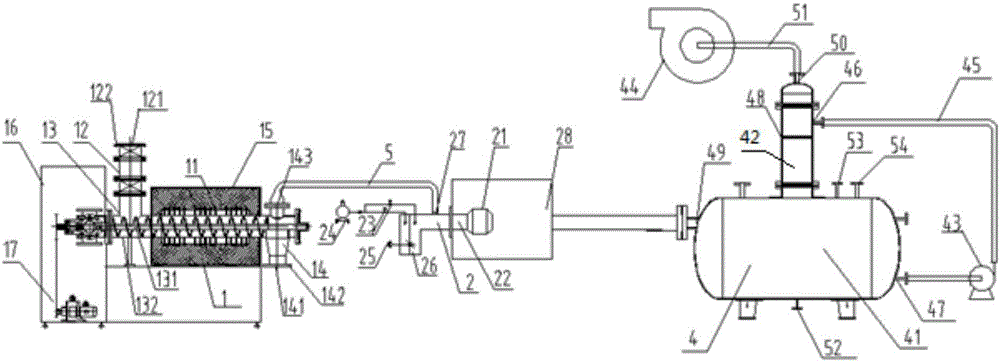

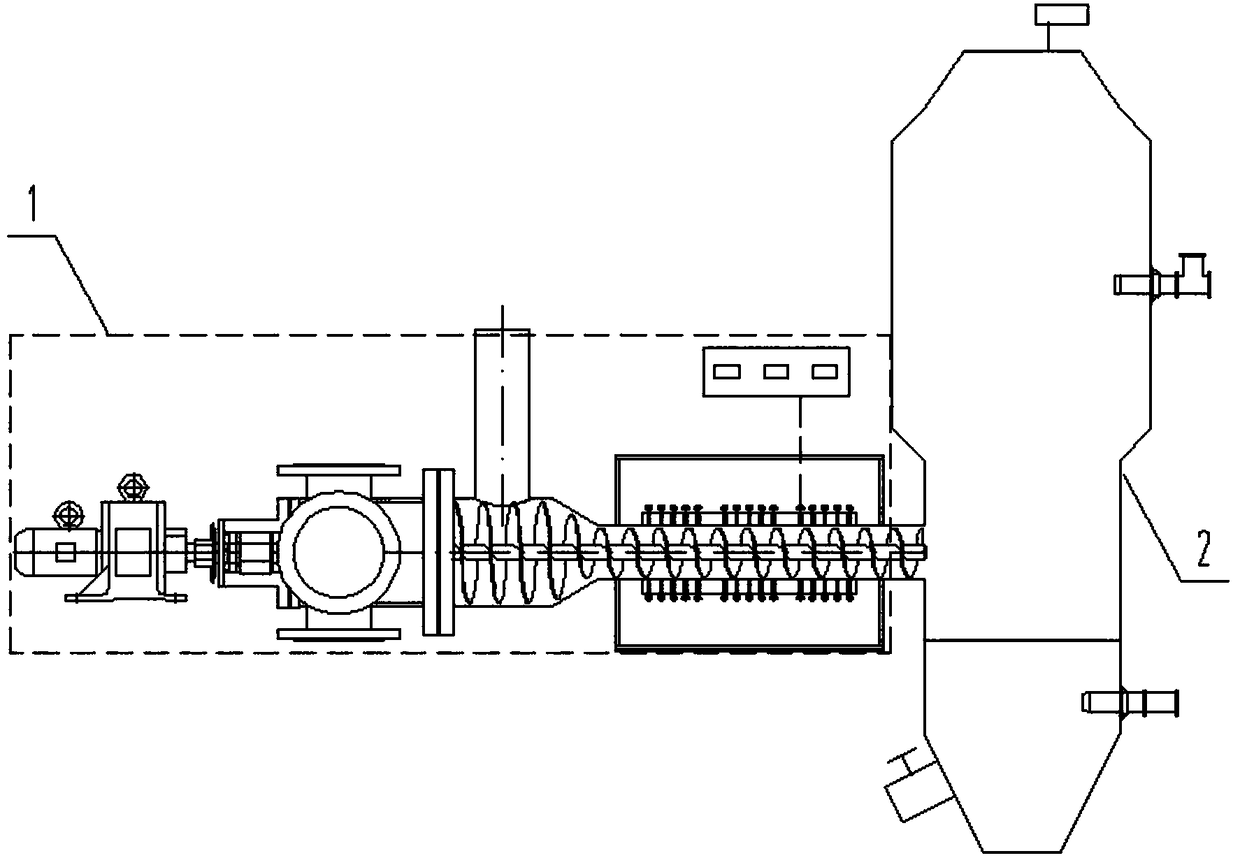

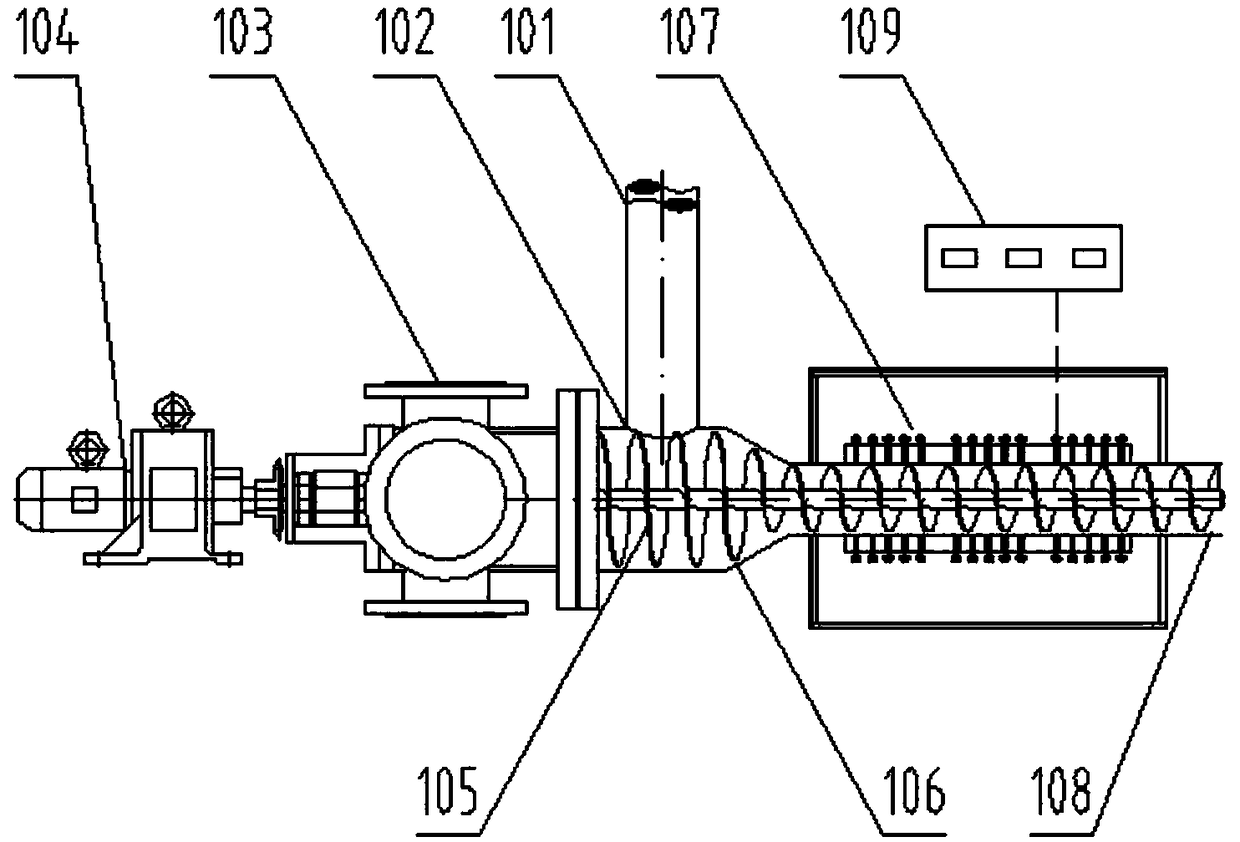

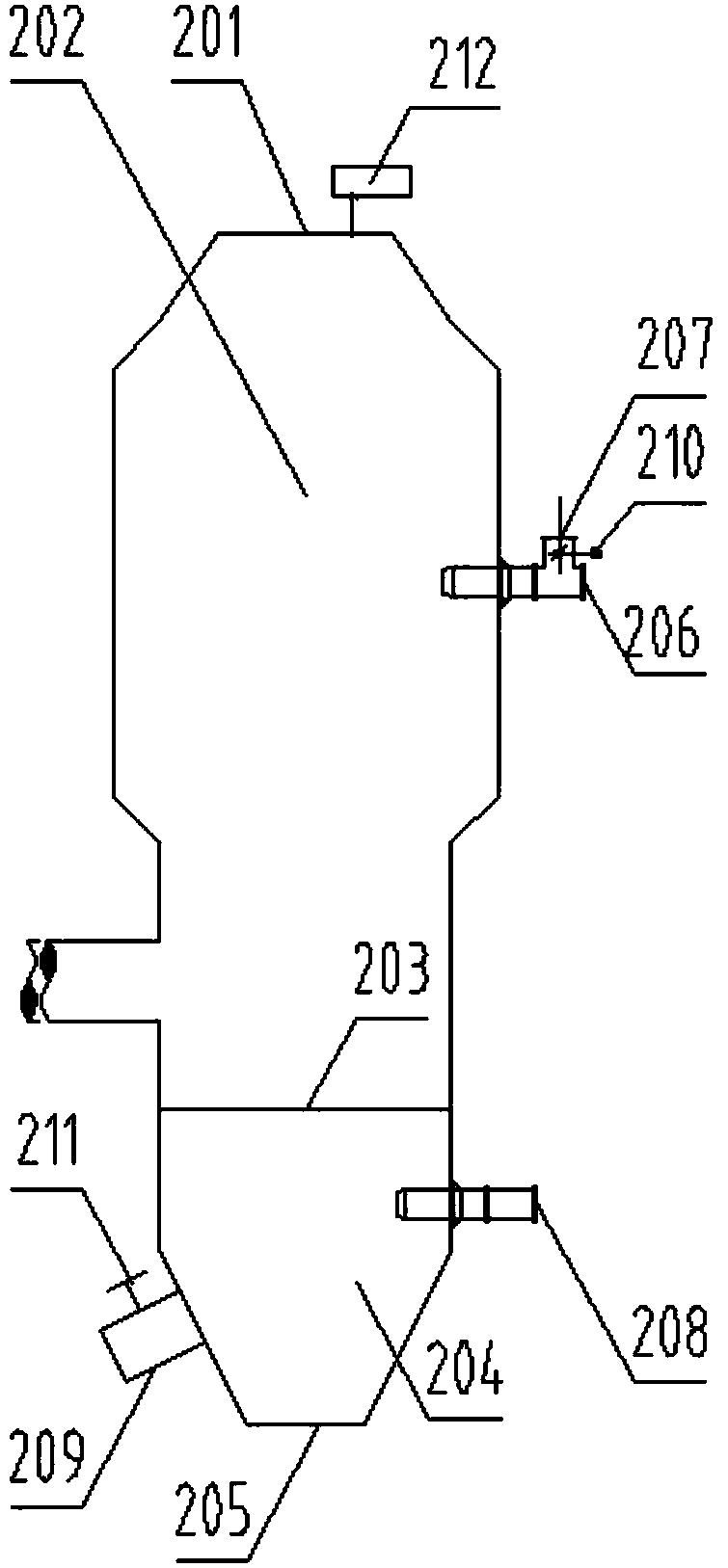

Middle-low radioactive waste treatment device

ActiveCN106653130AEasy to storeEasy landfill disposalRadioactive decontaminationOperational costsRadioactive agent

The invention belongs to the technical field of middle-low radioactive waste treatment equipment, relates to a waste treatment device, in particular to a middle-low radioactive waste treatment device. The middle-low radioactive waste treatment device is used for treating organic combustible type waste which is generated in a nuclear power plant and contains a middle-low radioactive substance, and is also used for treating middle-low radioactive waste generated in a hospital, a plant, a research institution and the like, so that volume reduction treatment and innocent treatment of the middle-low radioactive waste are achieved, and the middle-low radioactive waste treatment device comprises a pyrolysis reactor, a combustor, a catalytic converter, a spraying water scrubber and a high-temperature resistant pipeline, and all the devices are communicated through the high-temperature resistant pipeline; the middle-low radioactive waste treatment device makes it convenient for sealing up and landfill treatment of the waste, the volume reduction rate exceeds 95%, and the nuclear radiation pollution and atmospheric environmental pollution can be eliminated; a mild thermolcatalytic degradation process is adopted; the middle-low radioactive waste treatment device is simple in structure, reliable in principle, high in volume reduction rate, good in solidification effect, application environmentally friendly, low in investment and operation cost, and good in environmental protection effect, and has a good economic benefit and a wide market prospect.

Owner:青岛天和清原科技有限公司

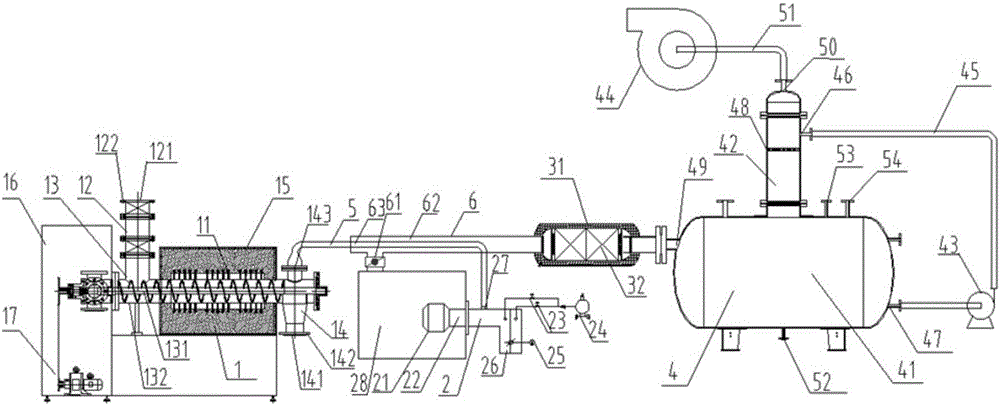

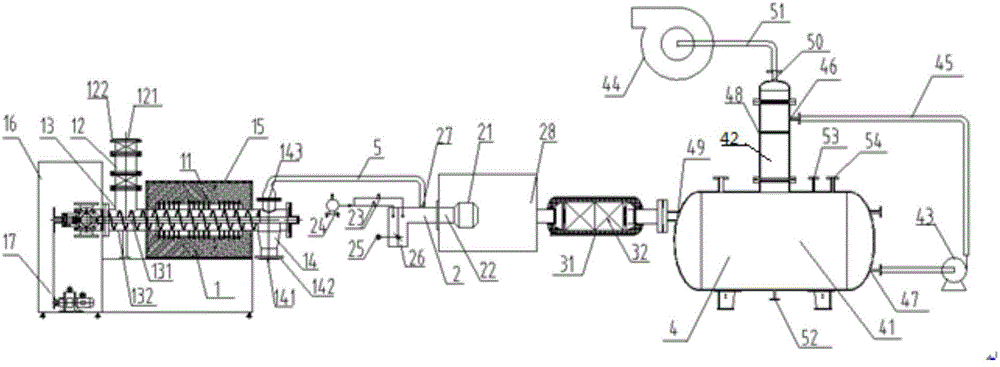

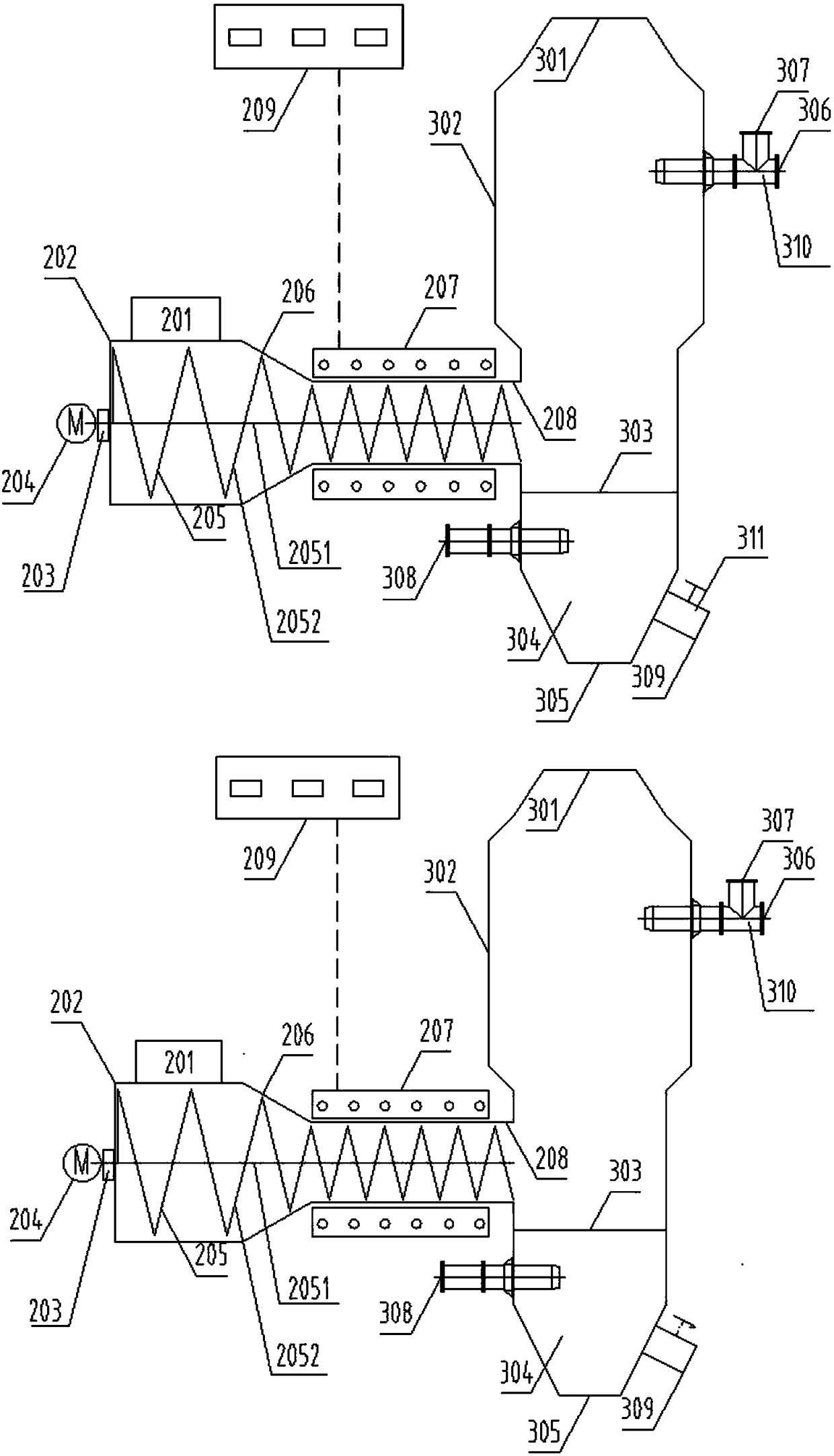

Integrated thermochemical treatment device for low-and-intermediate level radioactive wastes

PendingCN108224435AReduce volumeReduce pollutionIncinerator apparatusCombustion chamberOperational costs

The invention belongs to the technical field of low-and-intermediate level radioactive waste treatment devices, and relates to an integrated thermochemical treatment device for low-and-intermediate level radioactive wastes. The integrated thermochemical treatment device for the low-and-intermediate level radioactive wastes is used for treating organic combustible wastes containing radioactive substances produced by hospitals, scientific research institutions and nuclear power departments, solves the problems of insufficient combustion, easiness in blocking a pipeline through pyrolysis products, and higher clinker ignition loss, and realizes volume-reduction innocent treatment. A main body structure of the integrated thermochemical treatment device for the low-and-intermediate level radioactive wastes comprises a pyrolysis device and a combustion device, and is of an integrated structure; the pyrolysis products fall into a solid combustion chamber through a fire grate so as to be firedagain, so that the clinker ignition loss is reduced; a tapered feeding section realizes a sealing function; the diameter of a gas-liquid combustion chamber is larger than the diameter of the solid combustion chamber, so that the flue gas wind speed is retarded, and the fly ash quantity is reduced; and the integrated thermochemical treatment device for the low-and-intermediate level radioactive wastes is simple in overall structure, reliable in principle, compact in device, less in occupied area, high in volume reduction rate, good in curing effect, low in secondary pollution, friendly to an application environment, low in investment and operation cost, energy-saving, environmental-friendly, favorable in economic benefit and wide in market prospect.

Owner:青岛天和清原科技有限公司

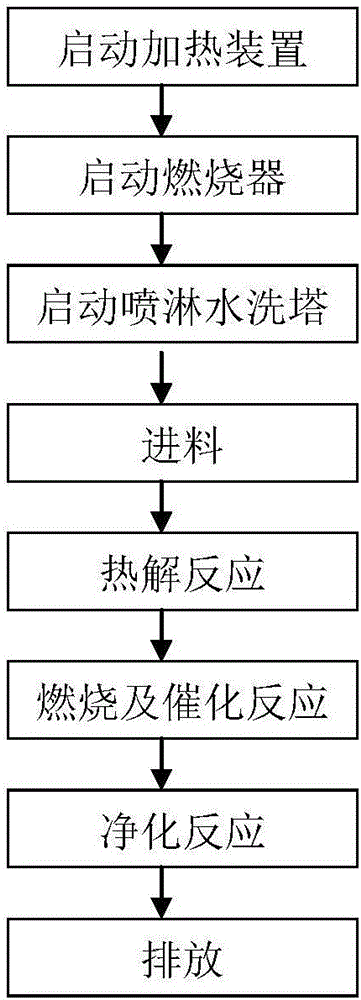

Intermediate- and low-level radioactive waste treatment method

ActiveCN106782734AEliminate pollutionEasy to storeRadioactive decontaminationOperational costsCombustor

The invention belongs to the technical field of intermediate- and low-level radioactive waste treatment and relates to an intermediate- and low-level radioactive waste treatment method. The intermediate- and low-level radioactive waste treatment method is achieved in an intermediate- and low-level radioactive waste treatment device and is used for treating organic combustible waste which contains radioactive substances and is generated by hospitals, factories, research institutions and nuclear power plants. The sludge volume reduction and the harmless treatment of the intermediate- and low-level radioactive waste are achieved. The sludge volume reduction rate is more than 95%. The difficulties of big deposit volume and difficult storage of the intermediate- and low-level radioactive waste are solved. Firstly, heating equipment is started, then a burner is started, then a spray water scrubber is started to carry out pre-treatment, then feedstock is carried out, the waste is pyrolyzed, burned, and experiences catalytic reaction, and finally, is purified and discharged. The process is simple in method, reliable in principle, high in sludge volume reduction rate, good in curing effect, environmentally friendly in application, low in investment and operation costs, energy-saving and environmentally friendly, and has a good economic benefit and a wide market prospect.

Owner:青岛天和清原科技有限公司

Remote infection control device

InactiveUS20080146140A1Provide informationAvoid pollutionDust-free enclosuresElectric switchesTransceiverHand held

A device is provided for encapsulating a hand held electromagnetic radiation transceiver, the device comprising a hollow body having a top panel, a bottom panel, two side walls, and a front wall, said panels and walls continuously attached at their respective joints; a rear wall having an opening to allow insertion of the transceiver; whereby the device is finally hermetically sealed so as to prevent contamination of the transceiver by biological fluids, such as saliva, blood, and non-biological fluids, such as low-level radioactive waste, or organic materials. The device also contains indicators for pathogen and / or toxic agent contamination.

Owner:HARTY ROBERT D

Filtration separation method for waste resin containing highly radioactive uranium powder and device thereof

InactiveUS8333893B2Minimising exposure to radiationSimple processShaking/oscillating/vibrating mixersIon-exchanger regenerationFiltrationLow-level waste

A filtration separation method for waste resin containing highly radioactive uranium powder and device thereof is mainly used for the waste resin after water treatment process in a nuclear facility. The uranium powder contained in the waste resin is highly radioactive. Thus, prior to the treatment of the waste resin, it is necessary to filter and separate the highly radioactive uranium powder to reduce the radioactivity. It is to put the uranium powder containing waste resin into an underwater holding tank and withdraw the waste resin by an underwater pump into a uranium powder filtration box. Then the uranium powder filtration box is lifted by a hoist to move to an underwater ultrasonic cleaner. High-pressure water flushing is applied and followed by underwater ultrasonic cleaning. Then the cleaning water (containing precipitated uranium powder) from the ultrasonic cleaner is drained to uranium powder collection device. If the radioactivity of the waste resin is still high, high-pressure cleaning by water nozzle flushing and ultrasonic cleaning are applied several times until the radioactivity of the waste resin is lowered to the treatment standard and converted to low-radioactivity waste for further treatment.

Owner:INST NUCLEAR ENERGY RES ROCAEC

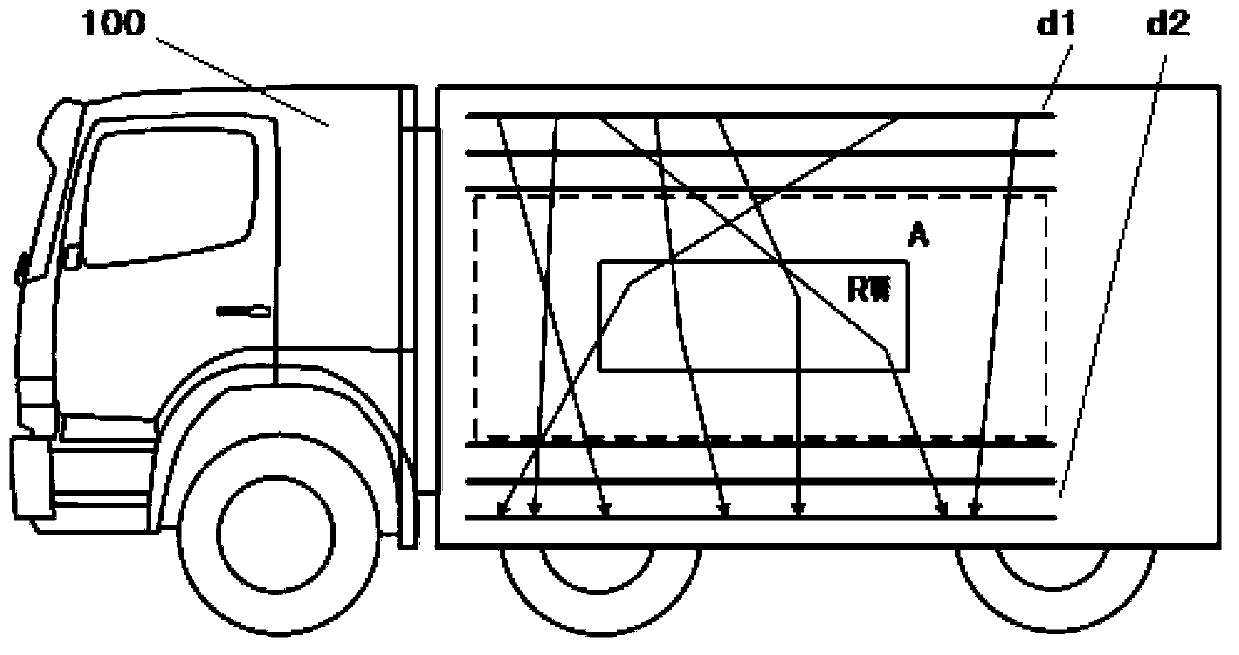

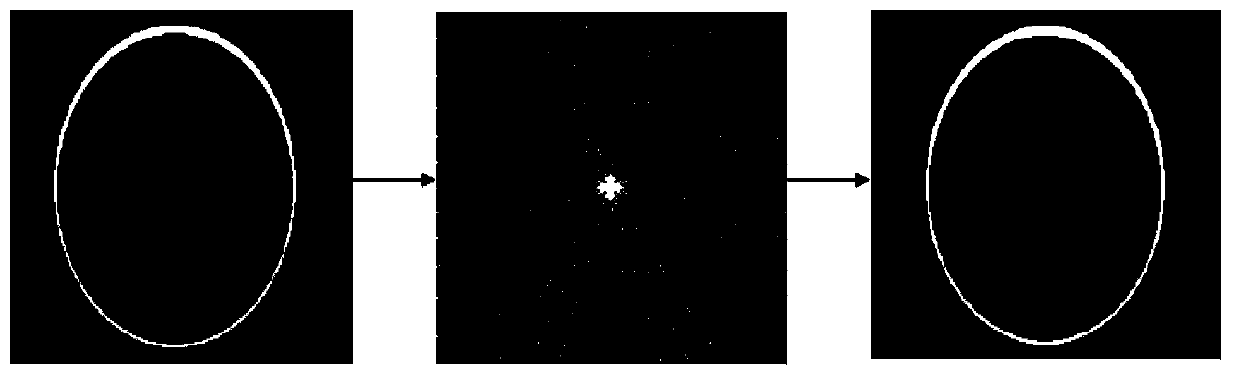

Muon imaging method and vehicle-mounted radioactive material monitoring system

InactiveCN104181575AMonitor state changesRadioactivity monitoring real-timeImage enhancementMaterial analysis using wave/particle radiationState variationRadioactive agent

The invention provides a muon imaging method and a vehicle-mounted radioactive material monitoring system. The muon imaging method is characterized by comprising the following steps: S1, track reconstruction algorithm is used for carrying out reconstruction on muon angle measurement data, and an initial reconstruction image f0 is obtained; S2, the initial reconstruction image f0 serves as an initial value, algebraic reconstruction algorithm is used for iteration, and a reconstruction image fART is obtained; S3, several times of minimal total variation are carried out on the fART to obtain an image fART-TV; S4, the second step and the third step are repeated until a reconstruction image ft which can meet the preset quality can be obtained; and S5, the algebraic reconstruction algorithm is used for carrying out iteration on the ft and a final reconstruction image ffinal is obtained. Thus, radioactive monitoring can be carried out in real time, state changes of radioactive waste material in the transportation process can be particularly monitored, and thus hidden risks during the transportation process of the radioactive waste material can be reduced.

Owner:NUCLEAR & RADIATION SAFETY CENT

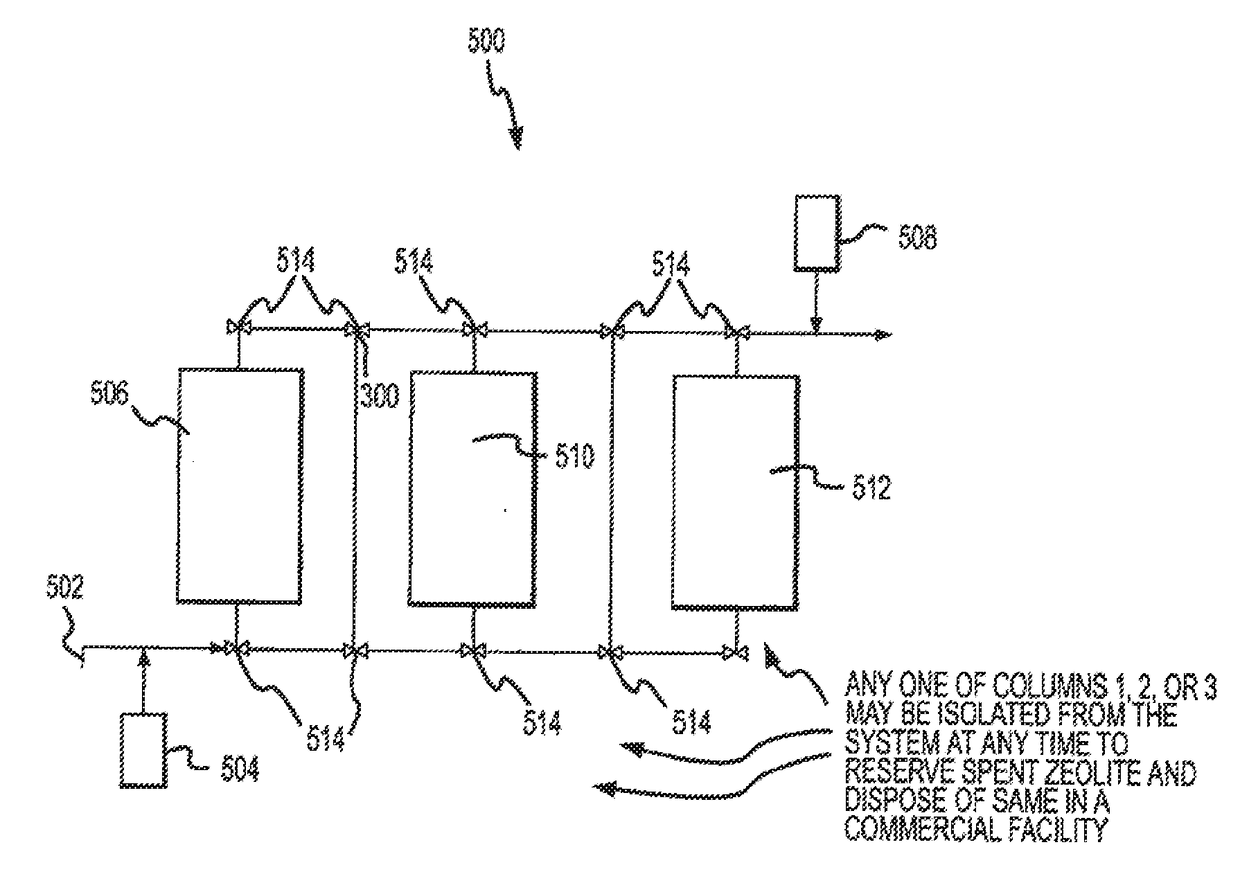

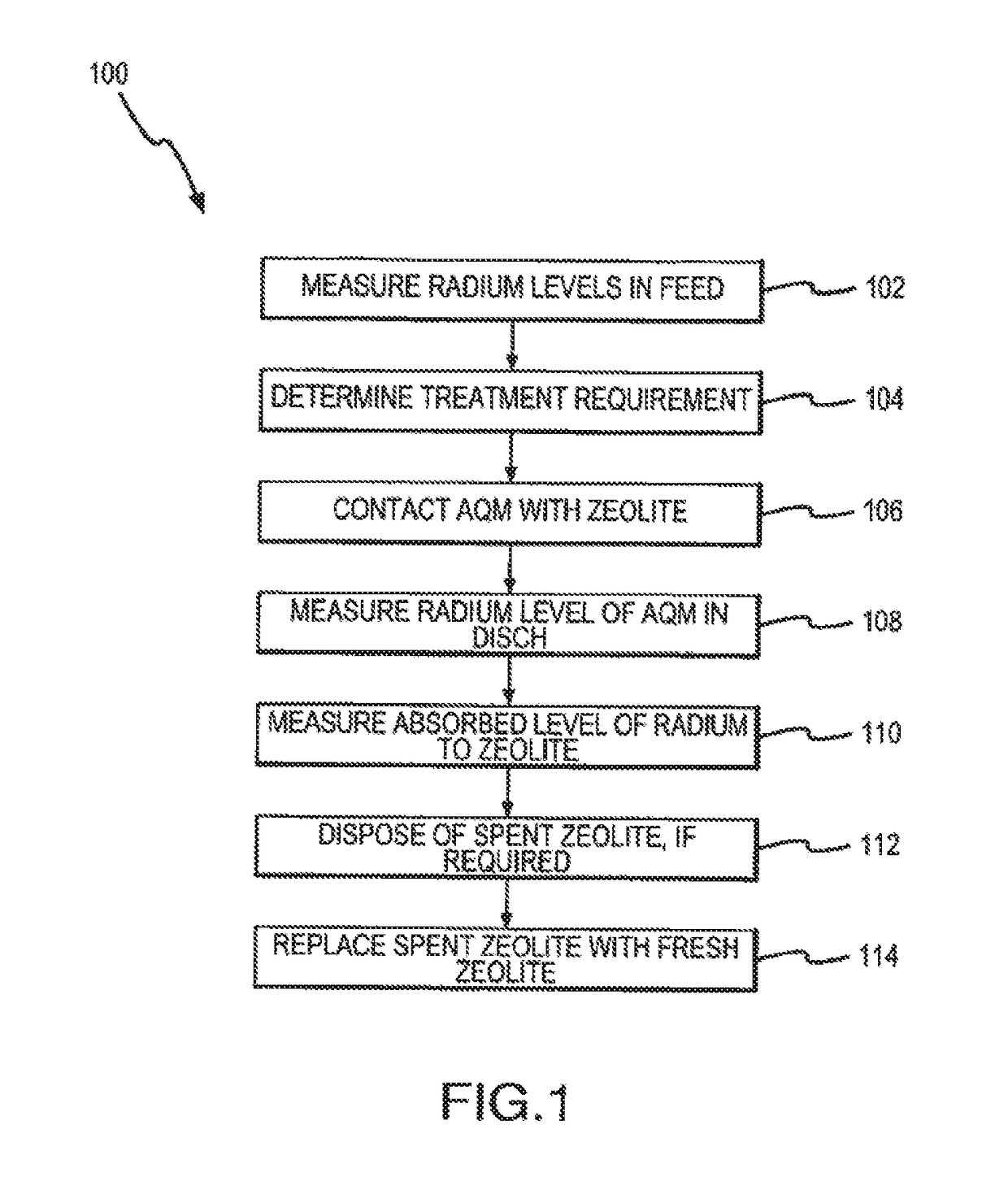

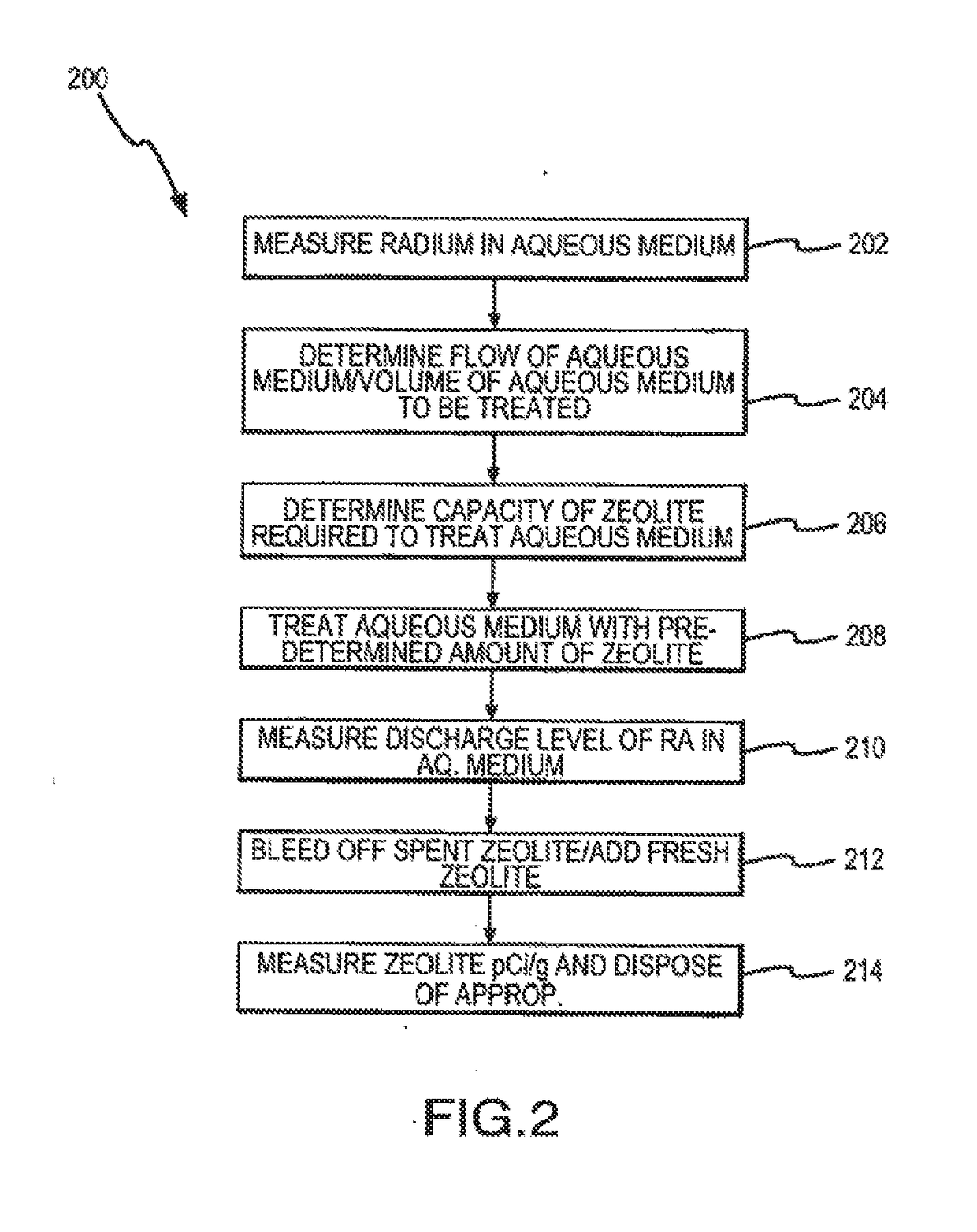

Radium Removal from Aqueous Media Using Zeolite Materials

InactiveUS20180194643A1Specific water treatment objectivesWater/sewage treatment by ion-exchangeLow-level wasteAqueous medium

Systems and methods are provided for the removal and disposal of radium form an aqueous medium. The systems and methods include the removal of radium from a source by contact with either natural or synthetic zeolite. The spent zeolite is monitored for radiation levels and replaced with fresh zeolite when the level of radioactivity reaches approximately 9,000 pCi / g. Spent zeolite is disposed of at a low-level radioactive waste site. A system for monitoring and maintaining radium removal and disposal by an off-site provided is also disclosed.

Owner:WRT INT

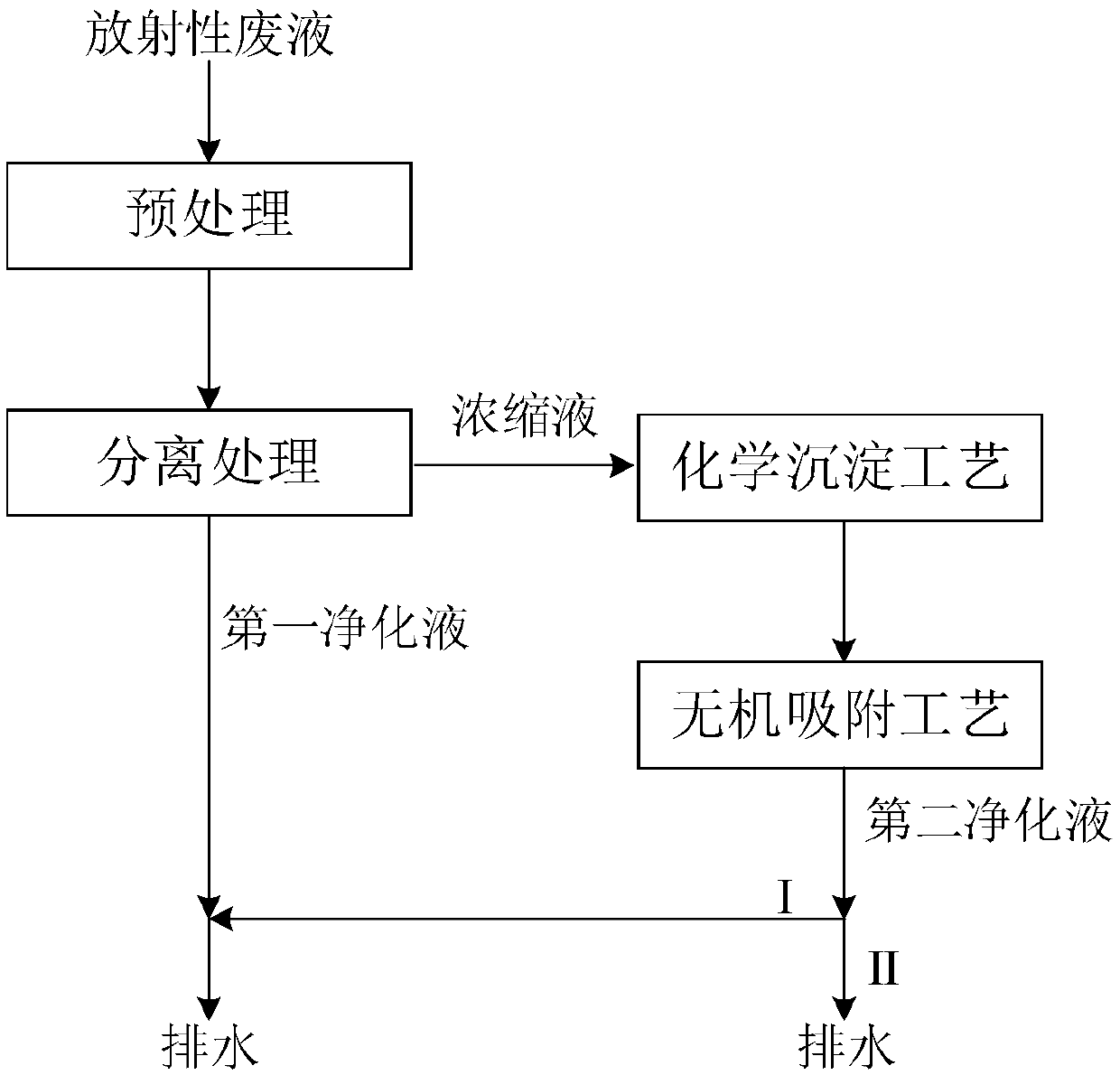

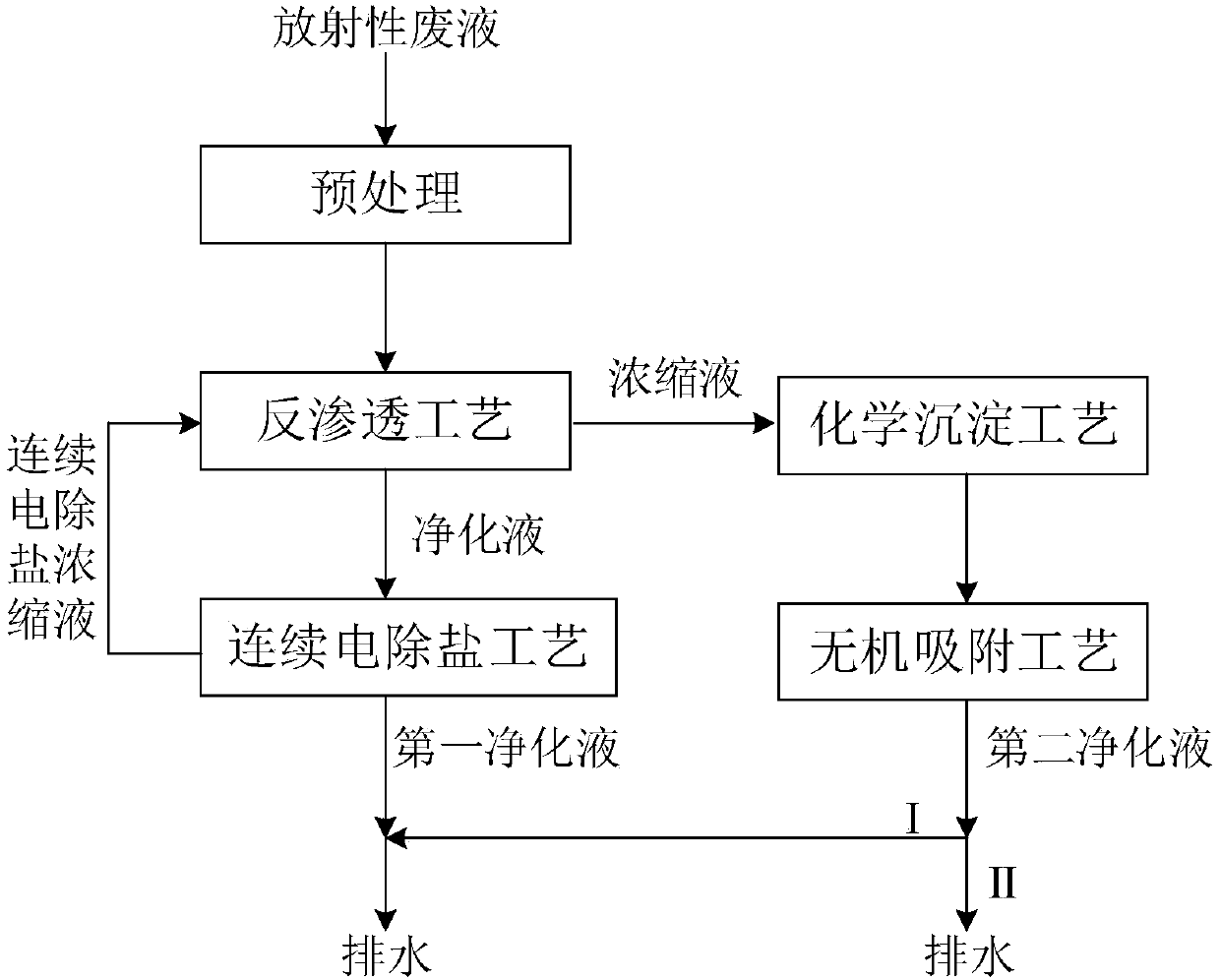

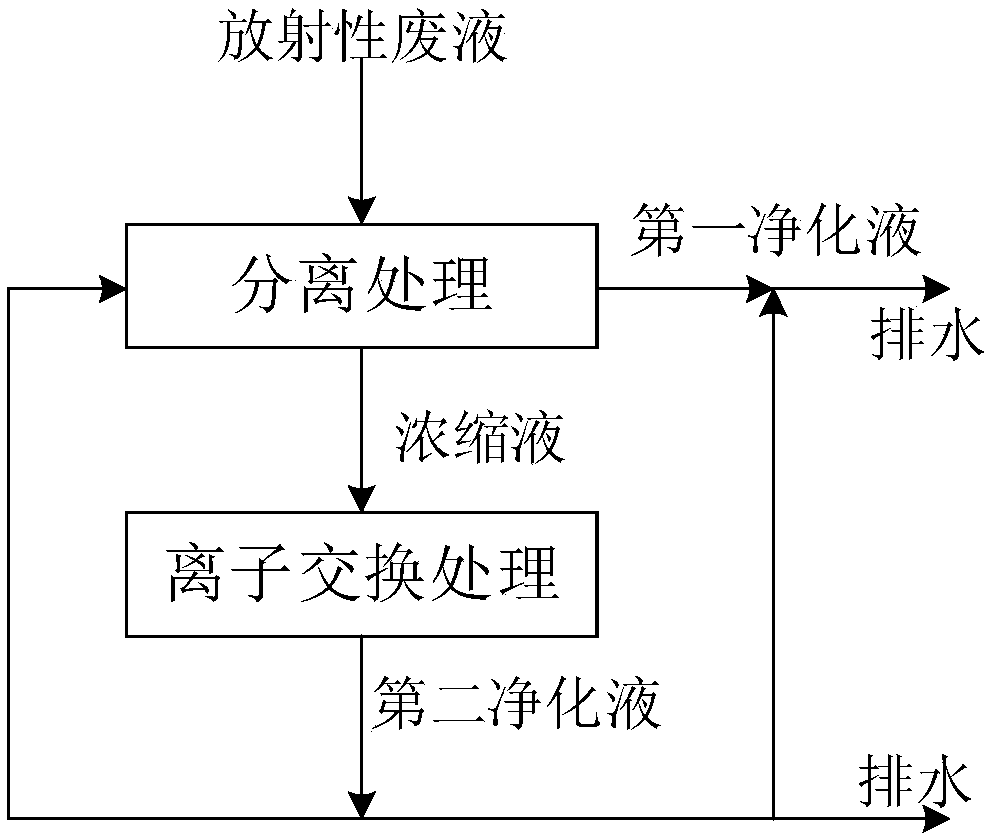

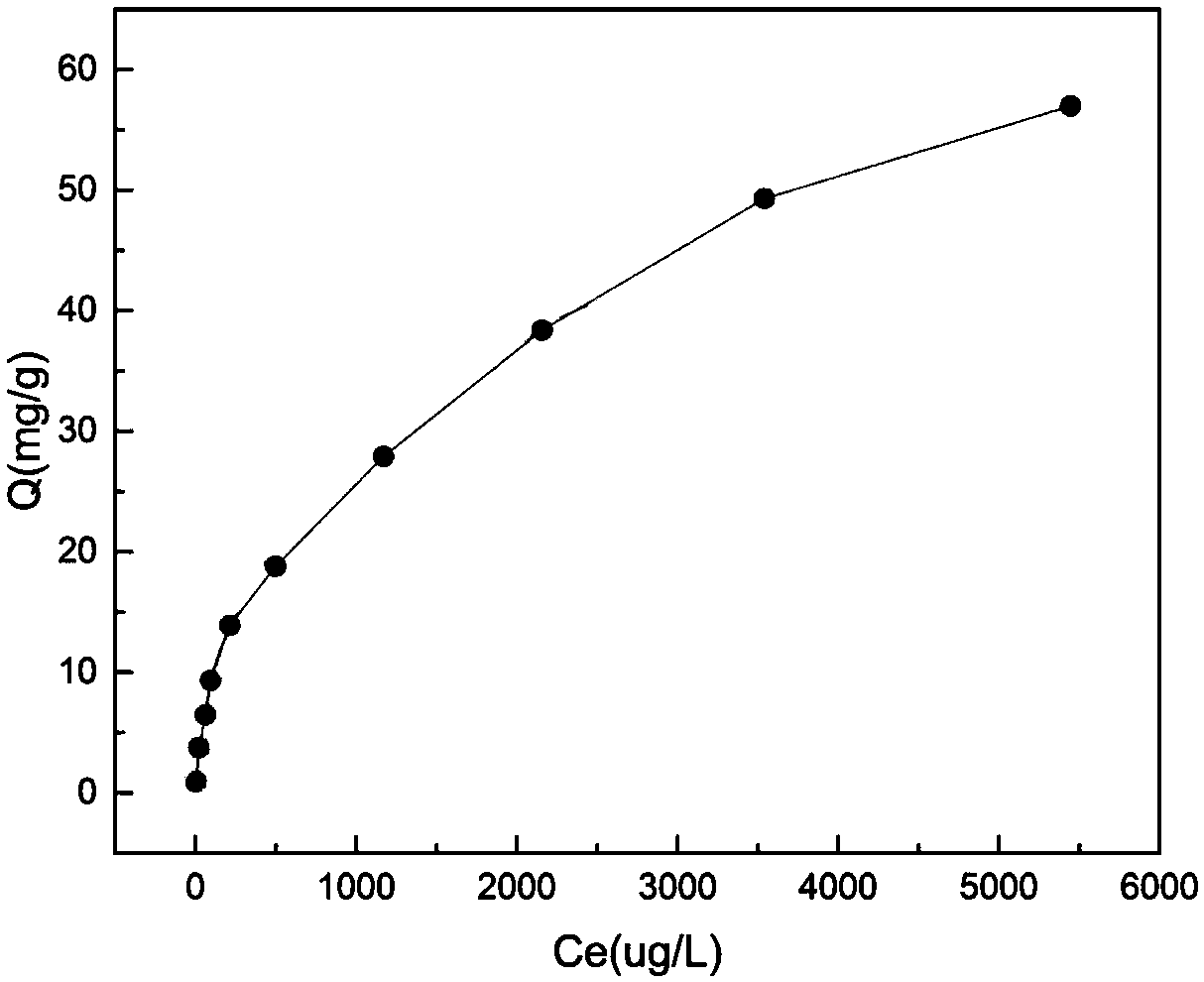

Radioactive waste liquid treatment method and device

PendingCN110379532AReduce volumeImprove decontamination factorGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisLow-level wastePrecipitation

The invention discloses a radioactive waste liquid treatment method and device. The radioactive waste liquid treatment method comprises the steps that radioactive waste liquid is subjected to separation treatment to obtain first purified liquid and concentrated liquid; radioactive nuclide removal treatment is performed on the concentrated liquid to obtain second purified liquid, wherein the step of performing the radioactive nuclide removal treatment on the concentrated liquid includes chemical precipitation technology processing of the concentrated liquid; and the first purified liquid and the second purified liquid are discharged. The radioactive waste liquid treatment method and device have a higher radioactive waste liquid purification level, and can significantly reduce the amount ofradioactive waste generated, thereby achieving small quantification of the radioactive waste.

Owner:TSINGHUA UNIV

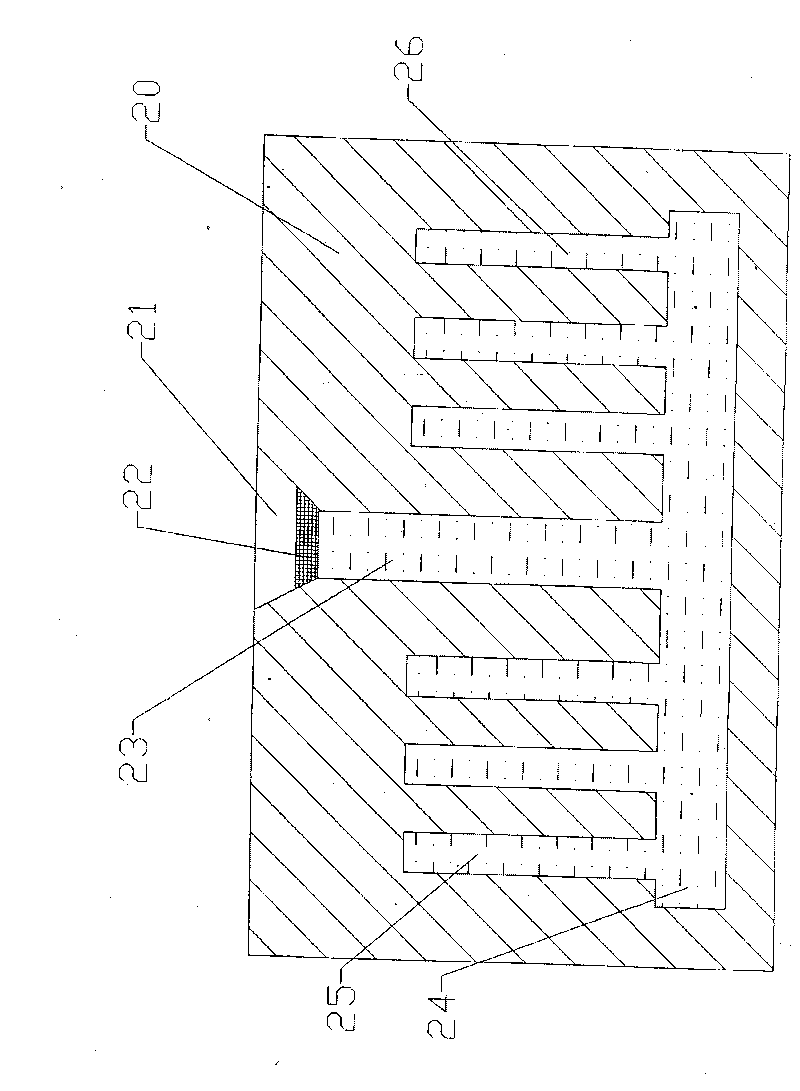

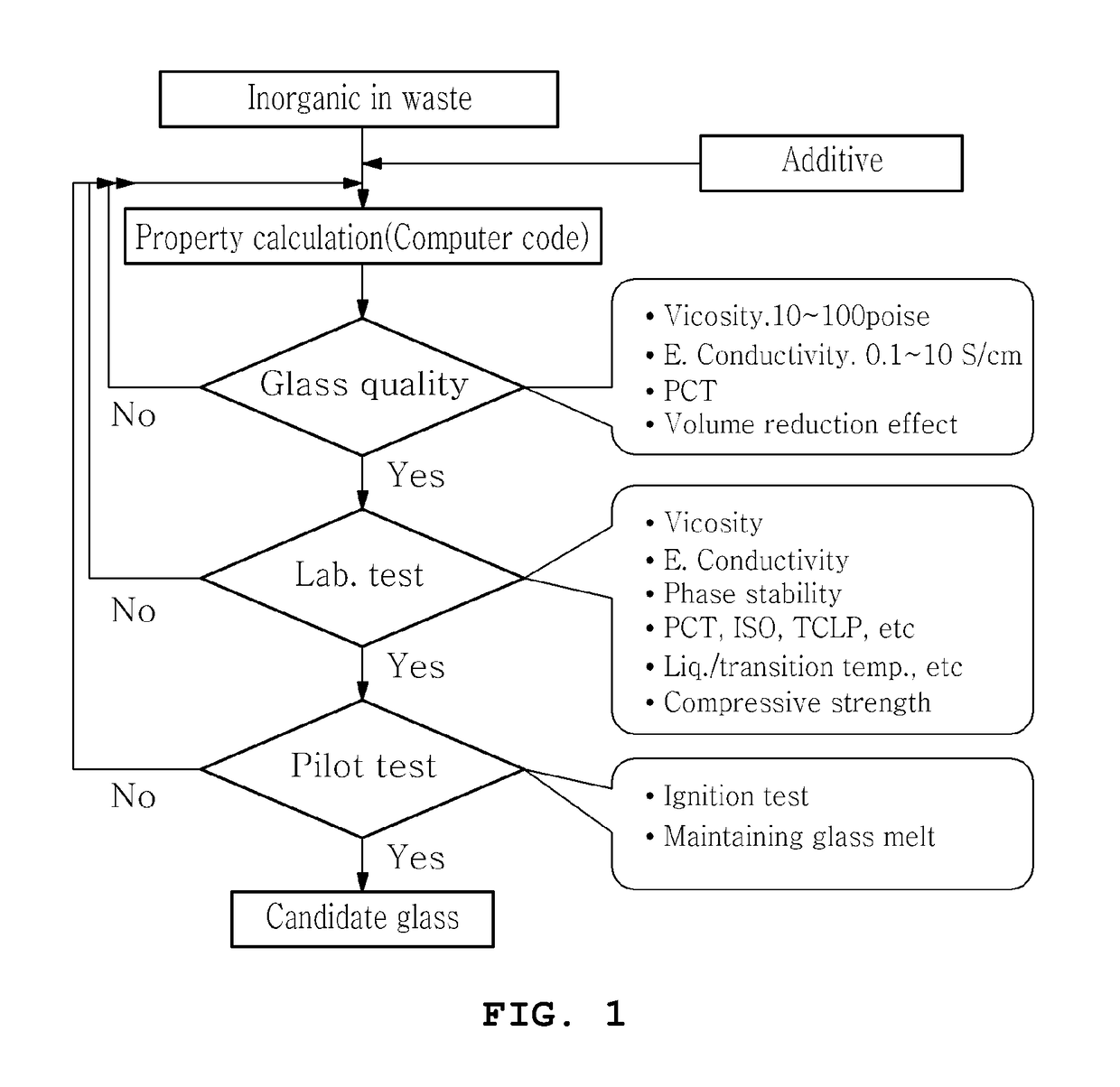

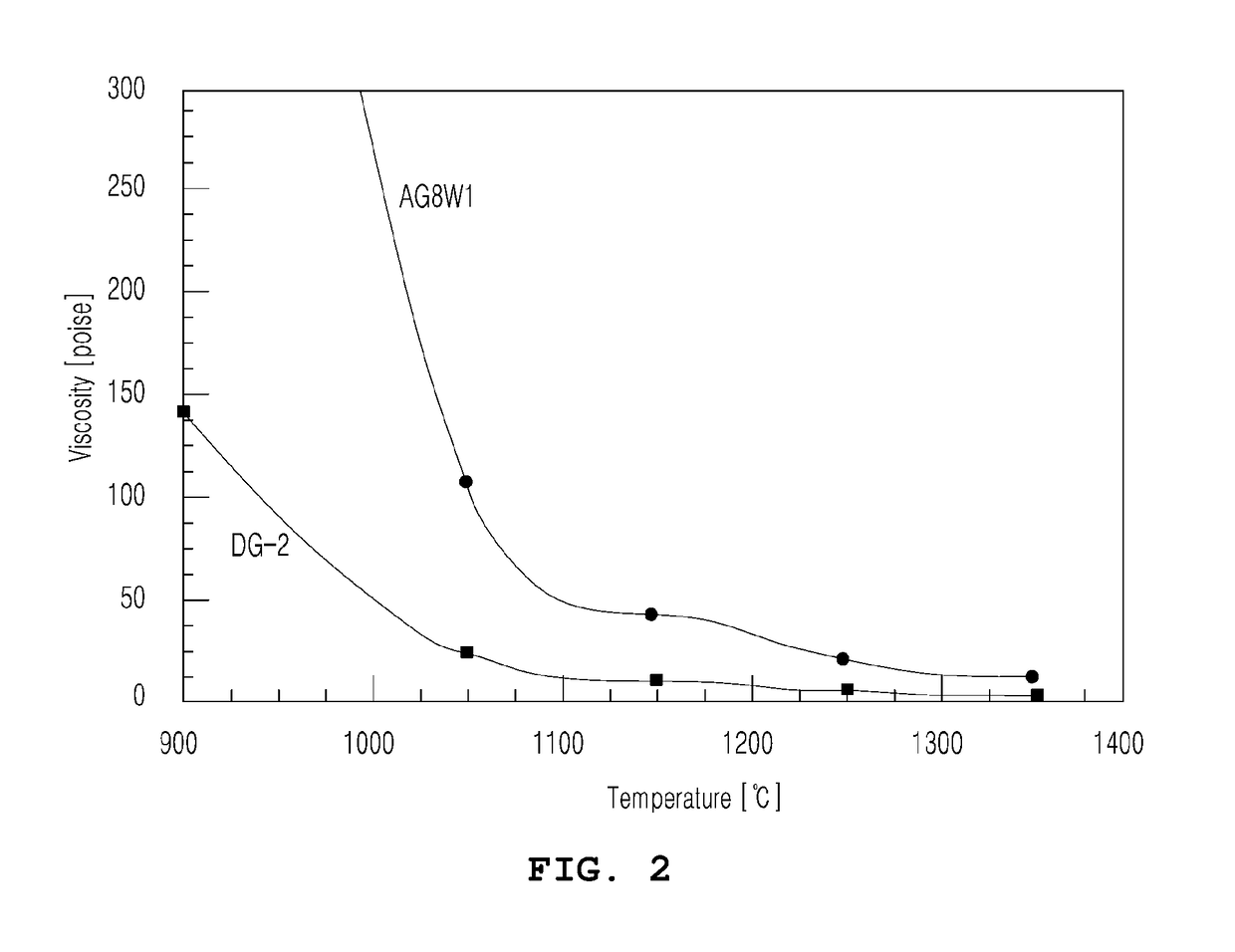

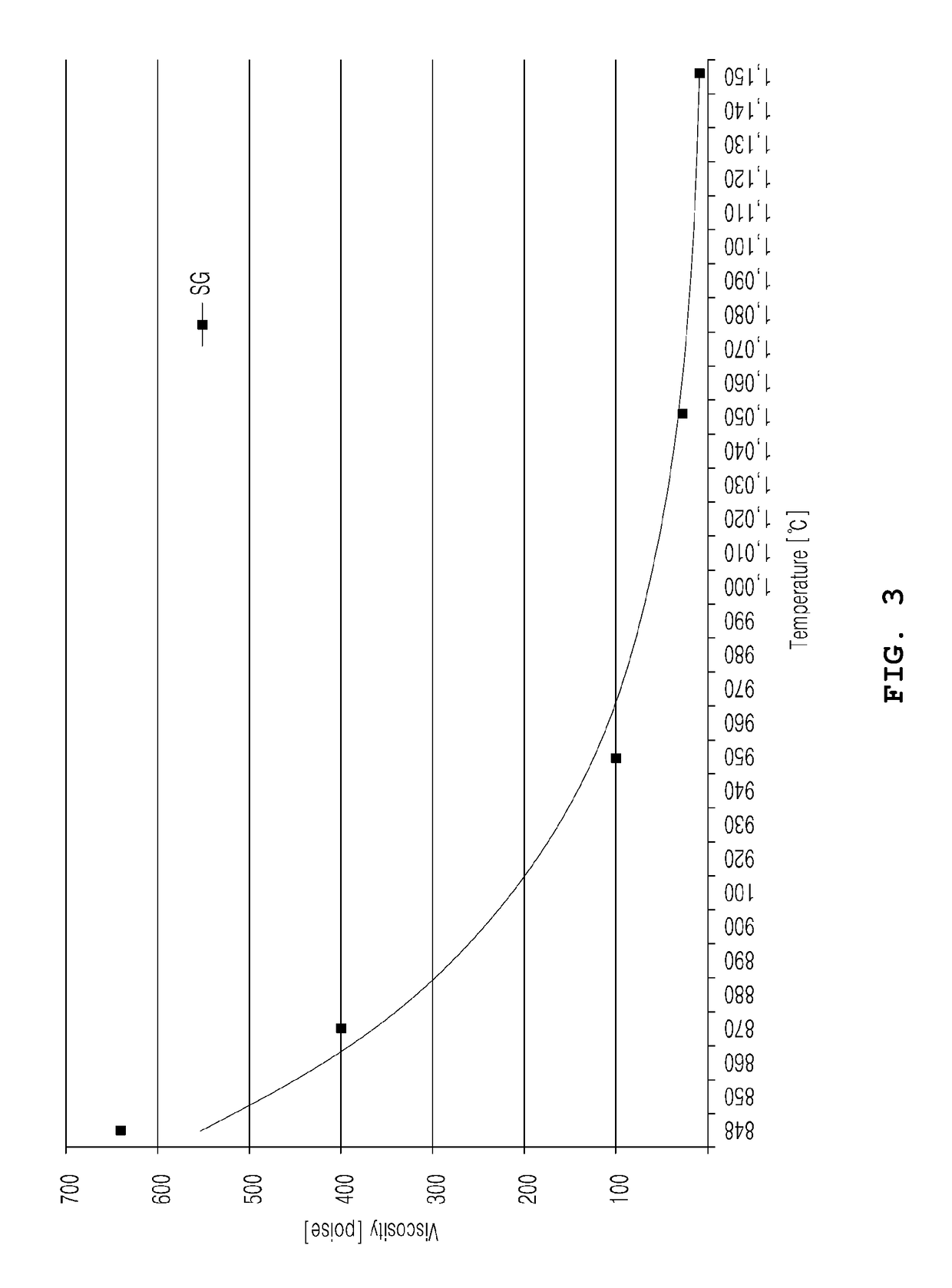

Glass composition for vitrifying flammable waste products

ActiveUS9988297B2Lower the volumeMaximally delaying and completely preventingSolid waste disposalRadioactive decontaminationVitrificationRadioactive agent

This invention relates to the vitrification of radioactive waste products. According to this invention, a glass composition, which is suitable for flammable waste products, such as gloves, working clothes, plastic waste, and rubber, and a method of vitrifying the flammable waste products using the same are provided to significantly reduce the volume of radioactive waste products and to vitrify the flammable waste products using the glass composition, which is suitable for vitrifying the flammable waste products, thereby maximally delaying or completely preventing the leakage of radioactive materials from a molten solidified body.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

A grabbing device for barrels of medium and low radioactive waste

InactiveCN105895181BRealize automatic centeringAvoid a destructive situationProgramme-controlled manipulatorConveyorsStress conditionsLow-level waste

Owner:SHANGHAI JIAOTONG UNIV

Thermal chemical treatment method for low-and-intermediate level radioactive waste

ActiveCN108361713AReduce volumeEasy to storeIncinerator apparatusChemical treatmentOperational costs

The invention belongs to the technical field of low-and-intermediate level radioactive waste and relates to a thermal chemical treatment method for low-and-intermediate level radioactive waste for treating low-and-intermediate level radioactive organic combustible waste comprising radioactive substances generated by hospitals, scientific research institutions and nuclear power units, solving the problem of great deposit volume and difficulty of storage of the low-and-intermediate level radioactive waste, and achieving volume reduction and harmless treatment of the low-and-intermediate level radioactive waste. 0.1-1% of the purified radioactive substance smoke sucked by a power device is exhausted from a smoke air outlet, and 99-99.9% of radioactive elements are left in incombustible ash residues to be sealed uniformly and cured with cement, so that the processing course of the low-and-intermediate level radioactive combustible waste is finished. The volume reduction ratio of the low-and-intermediate level radioactive organic combustible waste reaches 97-99%. The method is reliable in principle, high in volume reduction ratio, good in curing effect, low in secondary pollution, friendly in application environment, low in investment and operation costs and energy-saving and environment-friendly, and has a good economical benefit and a wide market prospect.

Owner:青岛天和清原科技有限公司

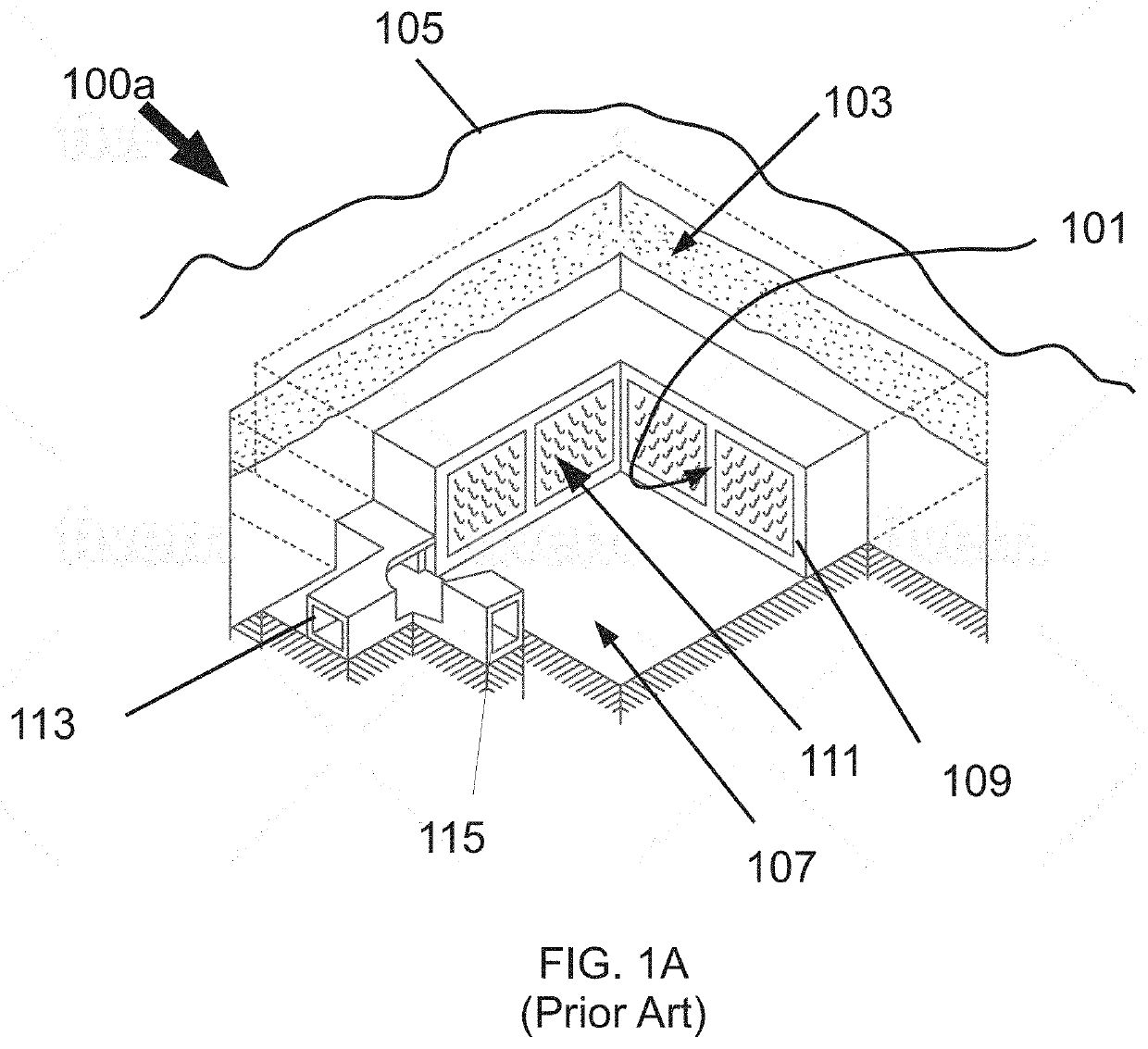

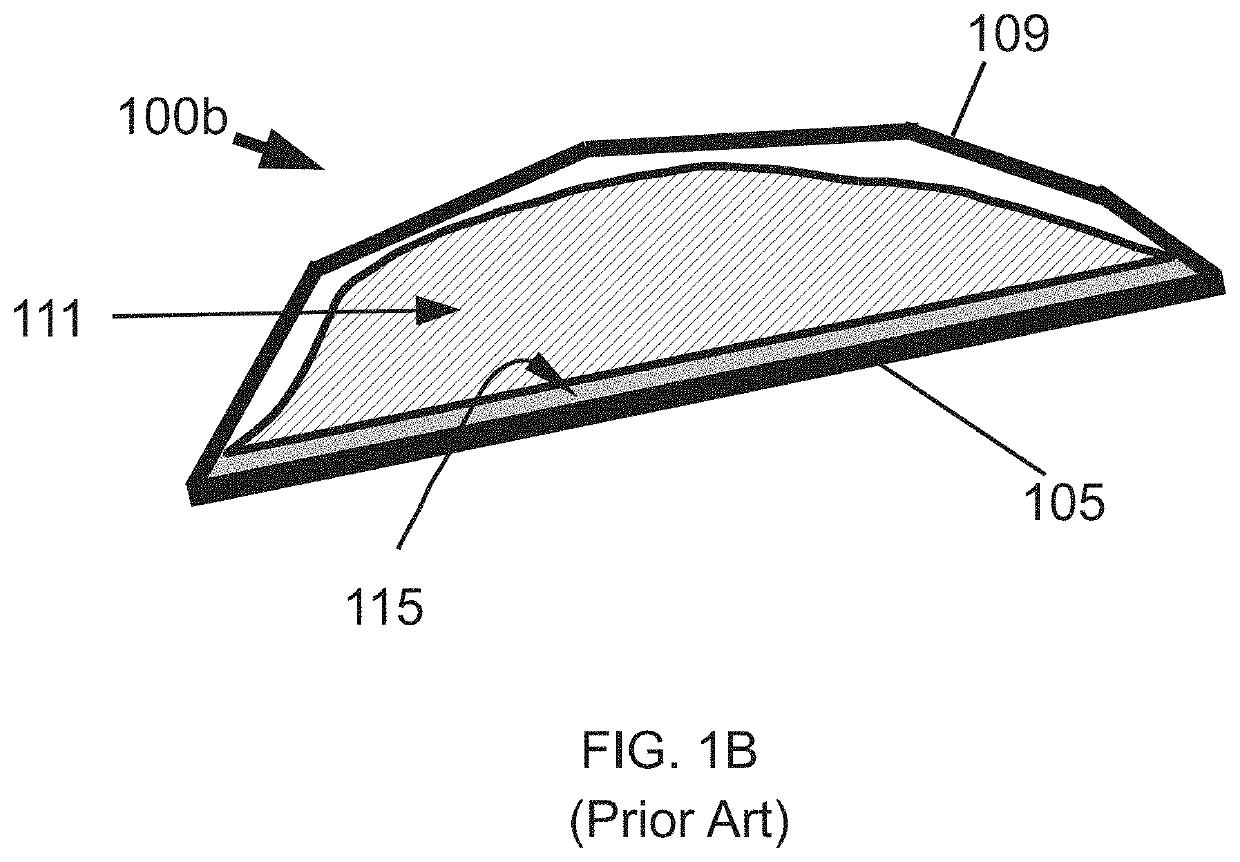

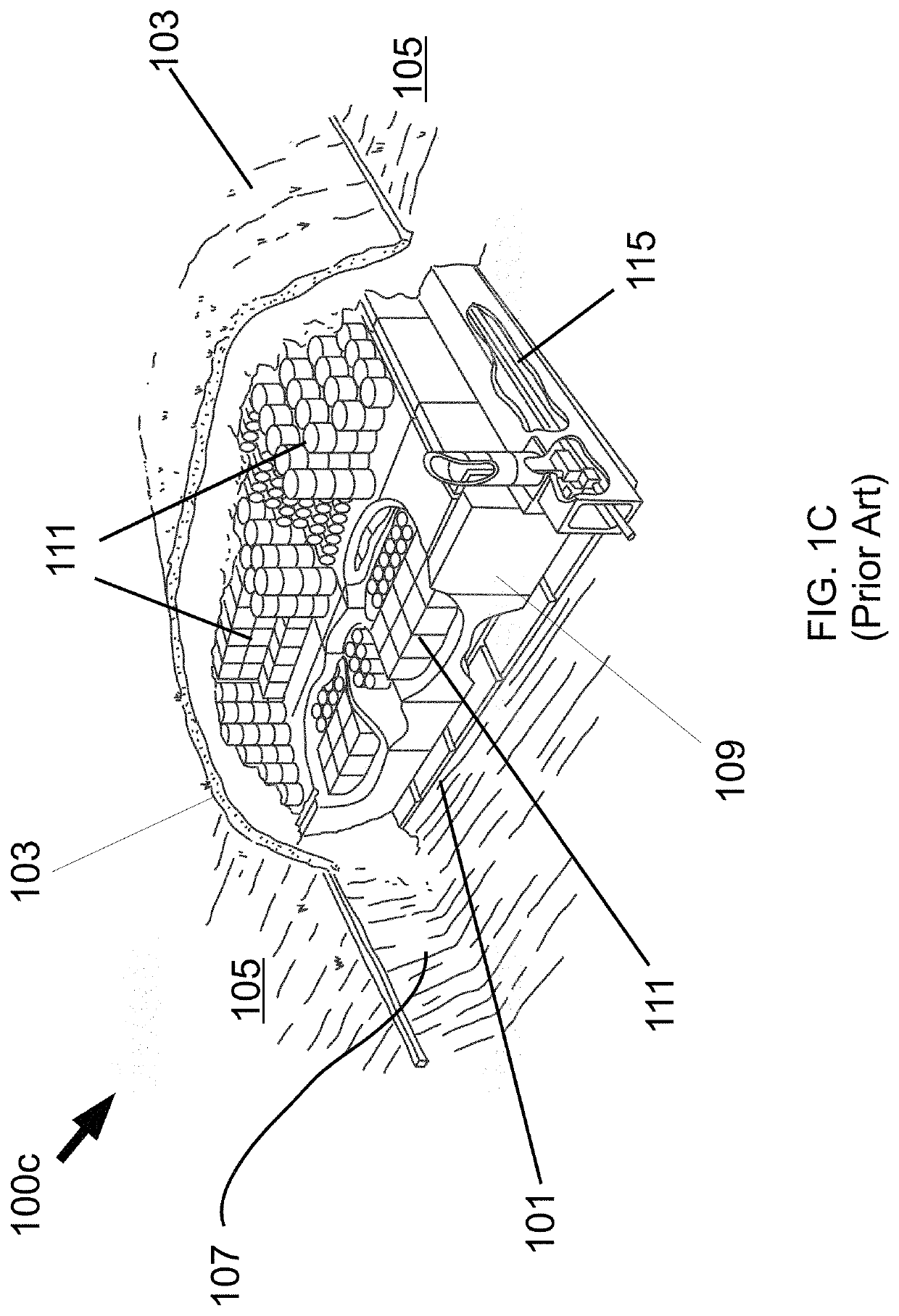

Systems and methods for low level waste disposal

Open pit mine (OPM) structures are modified or built new for use in disposing of low-level radioactive / nuclear waste (LLW). A drainage system is added to the OPM to drain water, such as, but not limited to, rain water, out of a volume of the OPM and to a particular geologic zone located far below the OPM that is isolated away from the local water table. Cells are formed within the volume of the OPM that are configured to receive the LLW. Cells are added to the OPM from a bottom towards a top of the OPM. Void spaces around the LLW materials within the cells are filled in with a protective-medium to mitigate against radionuclide migration away from the LLW materials within the cells. The protective-medium may be a blend of carbon nanotubes and a foam cement slurry. The carbon nanotubes may be made from reacting ethylene with vermiculite.

Owner:CRICHLOW HENRY

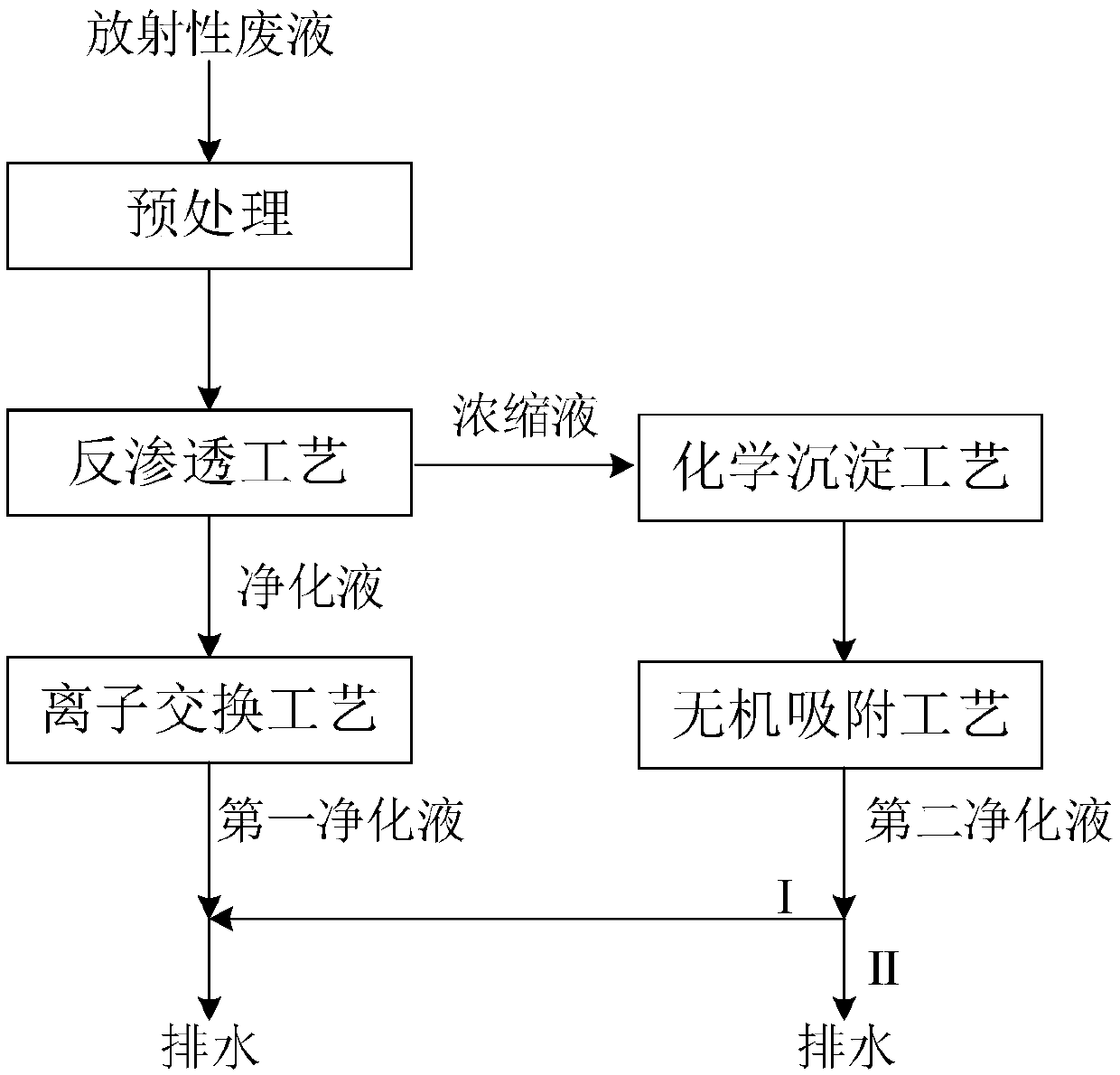

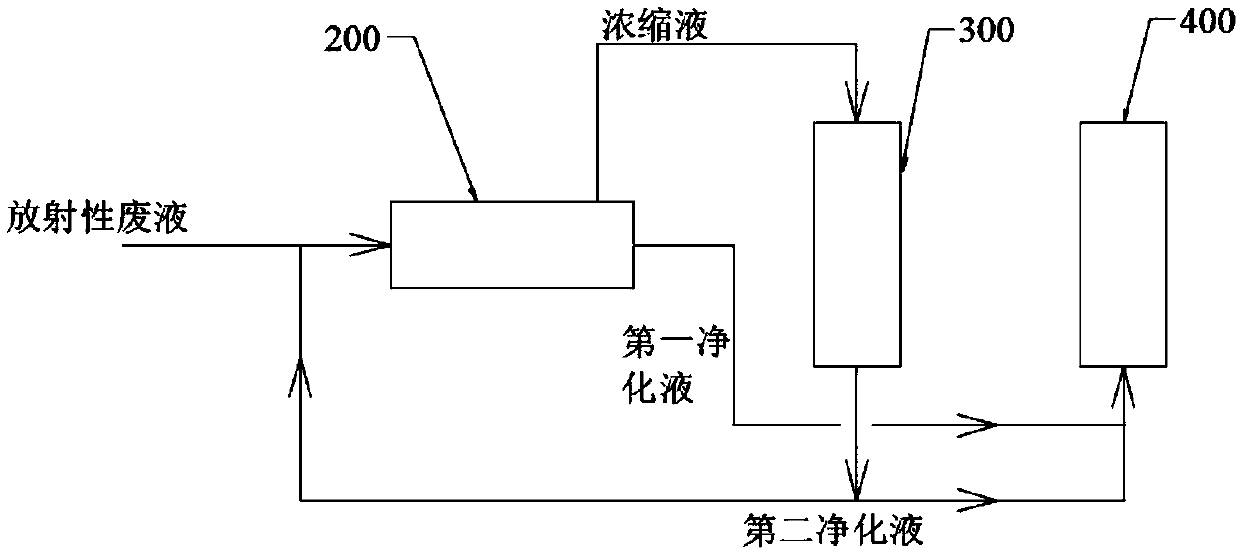

Radioactive waste liquid treatment method and device

ActiveCN110349690AReduce productionHigh radionuclide concentrationRadioactive decontaminationLiquid wasteIon exchange

The embodiments of the invention provide a radioactive waste liquid treatment method and device. The radioactive waste liquid treatment method includes the steps that radioactive waste liquid is separated to obtain first purified liquid and concentrated liquid; and the concentrated liquid is subjected to ion exchanging treatment to obtain second purified liquid, wherein the first purified liquid and the second purified liquid are discharged, or the second purified liquid returns to a separation treatment process, and the first purified liquid is discharged, or part of the second purified liquid returns to the separation treatment process, and the first purified liquid and the rest part of the second purified liquid are discharged. According to the radioactive waste liquid treatment methodand device, the higher radioactive waste liquid purification level is achieved, meanwhile, the production amount of radioactive waste can be significantly decreased, and the radioactive waste is minified.

Owner:TSINGHUA UNIV

Method for recovering magnesium alloy low-level waste

InactiveCN101736160BReduce pollutionComposition is stableProcess efficiency improvementChemical compositionLow-level waste

The invention relates to a method for recovering magnesium alloy low-level waste, aiming at the actual situation that the magnesium alloy low-level wastes are multiple in varieties, large in quantity, serious in pollution and difficult to recover. A magnesium alloy low-level waste ingot is prepared by mechanical cutting, repeated acid-washing, water washing, smelting in a resistance furnace, refining and casting into ingot; and the magnesium alloy low-level waste ingot has the chemical composition close to the composition quantity value index of a magnesium alloy ingot, and the mechanical property close to the quantity value of the magnesium alloy ingot, so as to be made into industrial part again. The recovery smelting and refining method is advanced, reasonable, short in process flow, low in environmental pollution, easy to recover, high in yield reaching up to 94.5%, good in material purity, and stable in metallographic structure and chemical composition, thus being an ideal methodfor recovering, smelting and refining the magnesium alloy low-level waste.

Owner:TAIYUAN UNIV OF TECH

Apparatus for disposal of low-level surface radioactive pollutants

InactiveUS7798951B2Easy to operateImprove work efficiencySolid waste disposalRadioactive decontaminationLow-level wasteEngineering

Owner:INST NUCLEAR ENERGY RES ROCAEC

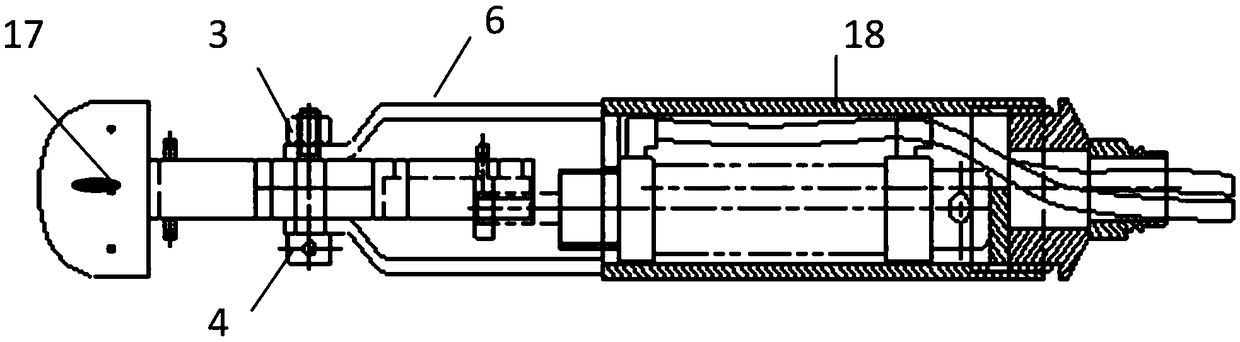

Radioactive storage tank sediment sampler and using method thereof

PendingCN109470526AAddress representationResolution statusWithdrawing sample devicesNuclear energy generationChemical industryLiquid storage tank

The invention belongs to the technical field of sampling operation of radioactive sites, and in particular relates to a radioactive storage tank sediment sampler and a using method of the radioactivestorage tank sediment sampler. The sampler comprises a sampling bowl, a scissor frame, a cylinder and a connecting piece; the sampling bowl is formed by closing two half-bowl structures, the front endof the scissor frame is fixedly connected with the sampling bowl, and the rear end of the scissor frame is connected with the cylinder through the connecting piece. The sampler adopts a long-distancemanually controlled cylinder to automatically clamp sediments in a radioactive waste liquid storage tank, and has the advantages of wide application range, flexible and convenient use and the like, and can realize sampling in a deformed container by penetrating through an arc-shaped channel or irregular channel through connecting a rigid sampling rod or a flexible sampling rod. The sampler can beused not only for sampling the sediments in low-level waste liquid storage tanks, but also can be suitable for sampling the sediments in medium and high-level waste liquid storage tanks and waste liquid, and realizing sampling operations in the field of chemical industry or other toxic and hazardous industries.

Owner:SICHUAN ENVIRONMENTAL PROTECTION ENG CO LTD CNNC

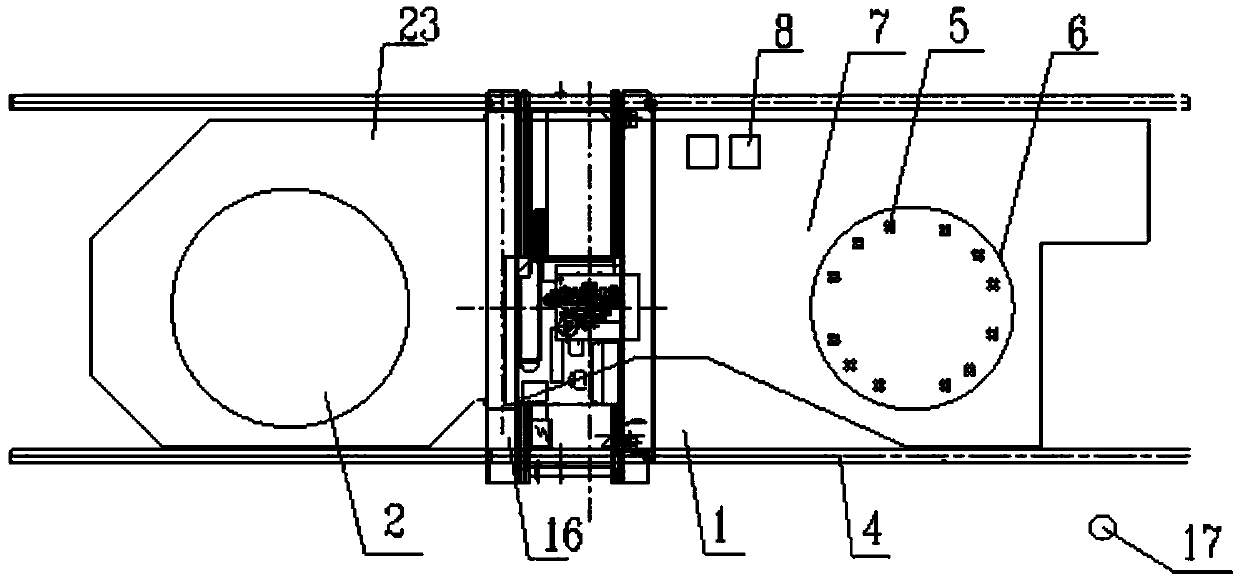

A detector assembly dismantling process and its special dismantling equipment

ActiveCN107767976BReduce exposure timeEasy transferNuclear energy generationReactor fuel elementsLow-level wasteEngineering

The invention discloses a detector component dismantling process and its special dismantling equipment. The large and small car components are moved and the gripper is lowered, and the gripper is lifted after the detector component is removed. The component is cut off; the end of the detector component is put into the low-level waste container; the winding module inside the shearing and shrinking component drives the detector component to rotate, and the detector component is pulled out from the guide structure under the action of the shearing and shrinking component, and wound The final detector assembly forms a cylindrical reel and falls into the temporary storage container; repeat the above action to remove other detector assemblies in the same group; move the large and small car assemblies after dismantling, roll the detector assembly and drop it into the high release container; repeat The above actions continue to remove other groups of detector components; after all the detector components are removed, restore the components to their original storage positions. The technology design of the whole extraction process of the invention is reasonable, the operation time is shortened, and the shielding of the water in the refueling pool is used to achieve good radiation protection.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com