Technology for low-temperature pyrolysis treatment of intermediate-and-low-radioactivity degradable waste

A low-temperature pyrolysis and low-radioactive technology, applied in radioactive purification, nuclear engineering, etc., can solve the problems of secondary pollution and low volume reduction rate, and achieve the effects of reduced treatment, reduced storage, and eliminated hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

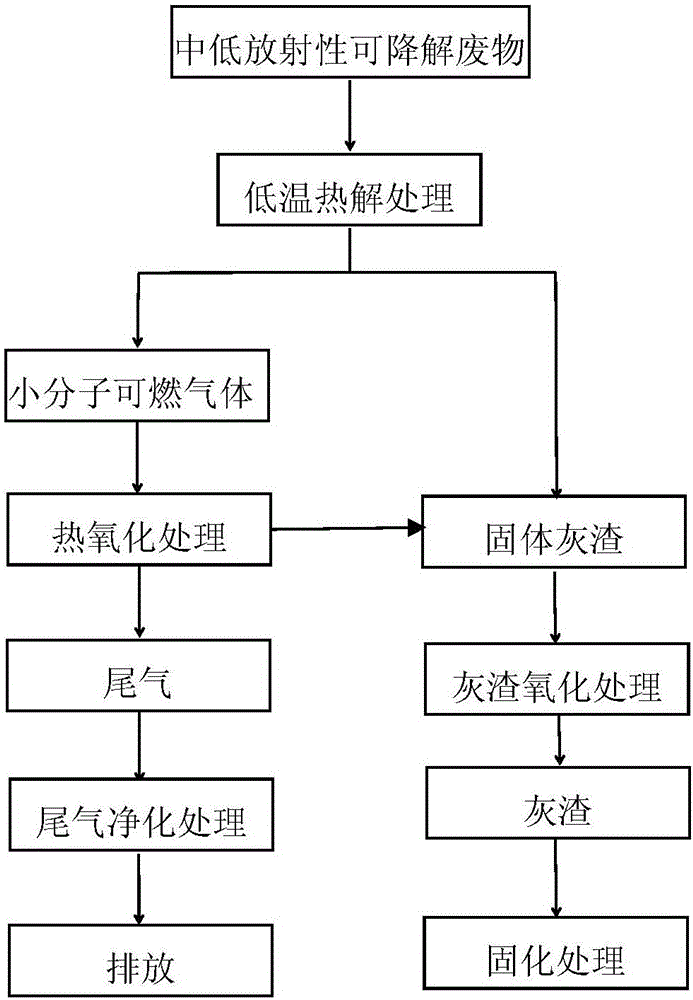

[0023] Such as figure 1 As shown, a low-temperature pyrolysis process for treating low- and medium-level radioactive degradable wastes, the process is as follows:

[0024] A process for low-temperature pyrolysis treatment of low- and medium-level radioactive degradable waste, the process is as follows:

[0025] (1) Low-temperature pyrolysis treatment: carry out negative-pressure pyrolysis reaction on low- and medium-level radioactive degradable waste to convert it into small molecule combustible gas and solid ash. The low-temperature pyrolysis treatment pressure is -100Pa and the temperature is 550°C ;

[0026] (2) Thermal oxidation treatment: the small molecular combustible gas obtained by low-temperature pyrolysis treatment is subjected to thermal oxidation treatment, and through a sufficient reaction with oxygen, it is converted into tail gas including carbon dioxide, nitrogen oxides, and sulfides and a small portion of residues. Thermal oxidation treatment reaction tempe...

Embodiment 2

[0032] Such as figure 1 As shown, a low-temperature pyrolysis process for treating low- and medium-level radioactive degradable wastes, the process is as follows:

[0033] A process for low-temperature pyrolysis treatment of low- and medium-level radioactive degradable waste, the process is as follows:

[0034] (1) Low-temperature pyrolysis treatment: carry out negative pressure pyrolysis reaction on low- and medium-level radioactive degradable waste to convert it into small molecular combustible gas and solid ash. The low-temperature pyrolysis treatment pressure is -500Pa and temperature is 350°C ;

[0035] (2) Thermal oxidation treatment: The small molecule combustible gas obtained by low-temperature pyrolysis treatment is subjected to thermal oxidation treatment, and through a sufficient reaction with oxygen, it is converted into tail gas and a small part of residues including carbon dioxide, nitrogen oxides, and sulfides. is 1200°C;

[0036] (3) Tail gas purification tr...

Embodiment 3

[0040] Such as figure 1 As shown, a low-temperature pyrolysis process for treating low- and medium-level radioactive degradable wastes, the process is as follows:

[0041] A process for low-temperature pyrolysis treatment of low- and medium-level radioactive degradable waste, the process is as follows:

[0042] (1) Low-temperature pyrolysis treatment: carry out negative-pressure pyrolysis reaction on low- and medium-level radioactive degradable waste to convert it into small molecule combustible gas and solid ash. The low-temperature pyrolysis treatment pressure is -250Pa and the temperature is 400°C;

[0043] (2) Thermal oxidation treatment: The small molecular combustible gas obtained by low-temperature pyrolysis treatment is subjected to thermal oxidation treatment, and through a sufficient reaction with oxygen, it is converted into tail gas and a small part of residues including carbon dioxide, nitrogen oxides, and sulfides. is 1000°C;

[0044] (3) Tail gas purification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com