Vertical mechanical microwave scanning active imaging personnel security inspection system

A mechanical scanning and microwave technology, applied in the field of personnel scanning imaging security inspection system, can solve the problems of high cost, storage, transportation, inconvenient installation, and large system space, achieve convenient maintenance, reduce related costs, and overcome the problem of large footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The preferred implementation examples of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

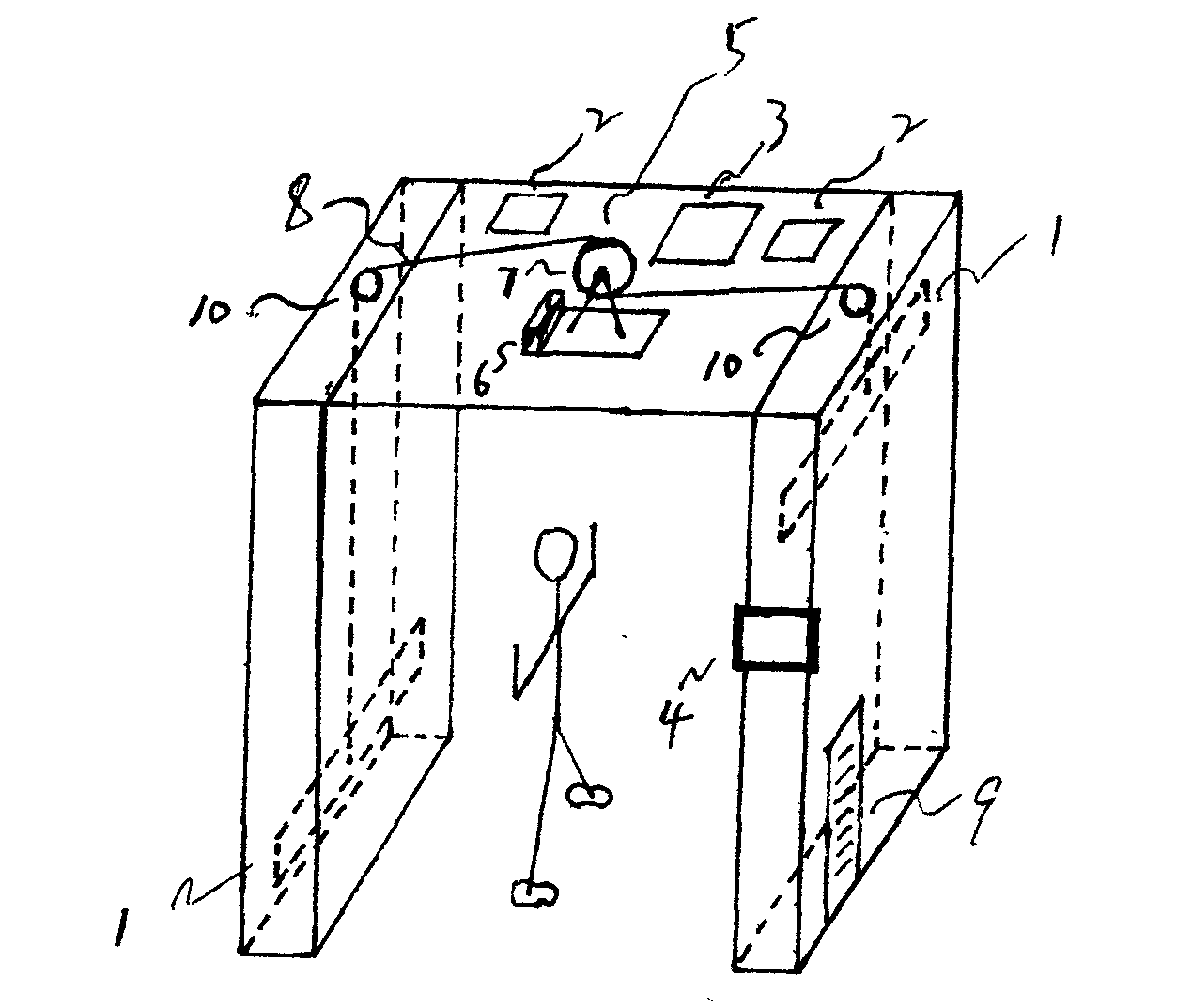

[0051] Such as figure 1 As shown, a millimeter-wave mechanical scanning human body imaging security inspection equipment uses a pair of horizontal detection arrays to scan vertically. The system consists of a pair of in-line detection arrays 1, a signal acquisition and processing unit 2, an imaging processing unit 3, a control display unit 4, Scanning unit 5 (including servo control 6, traction machine 7, traction rope 8, guide wheel 10, etc.) and power supply unit 9 are composed of parts. The inspected person enters the security inspection gate, stands facing forward at the designated position and raises his arm to keep still. The operator sends a scanning command through the control display unit, and the scanning servo mechanism drives the left and right detection arrays to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com