Micro-organism eliminating method for contaminated underground water

A groundwater and organic matter technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Small footprint, overcoming the effect of long processing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

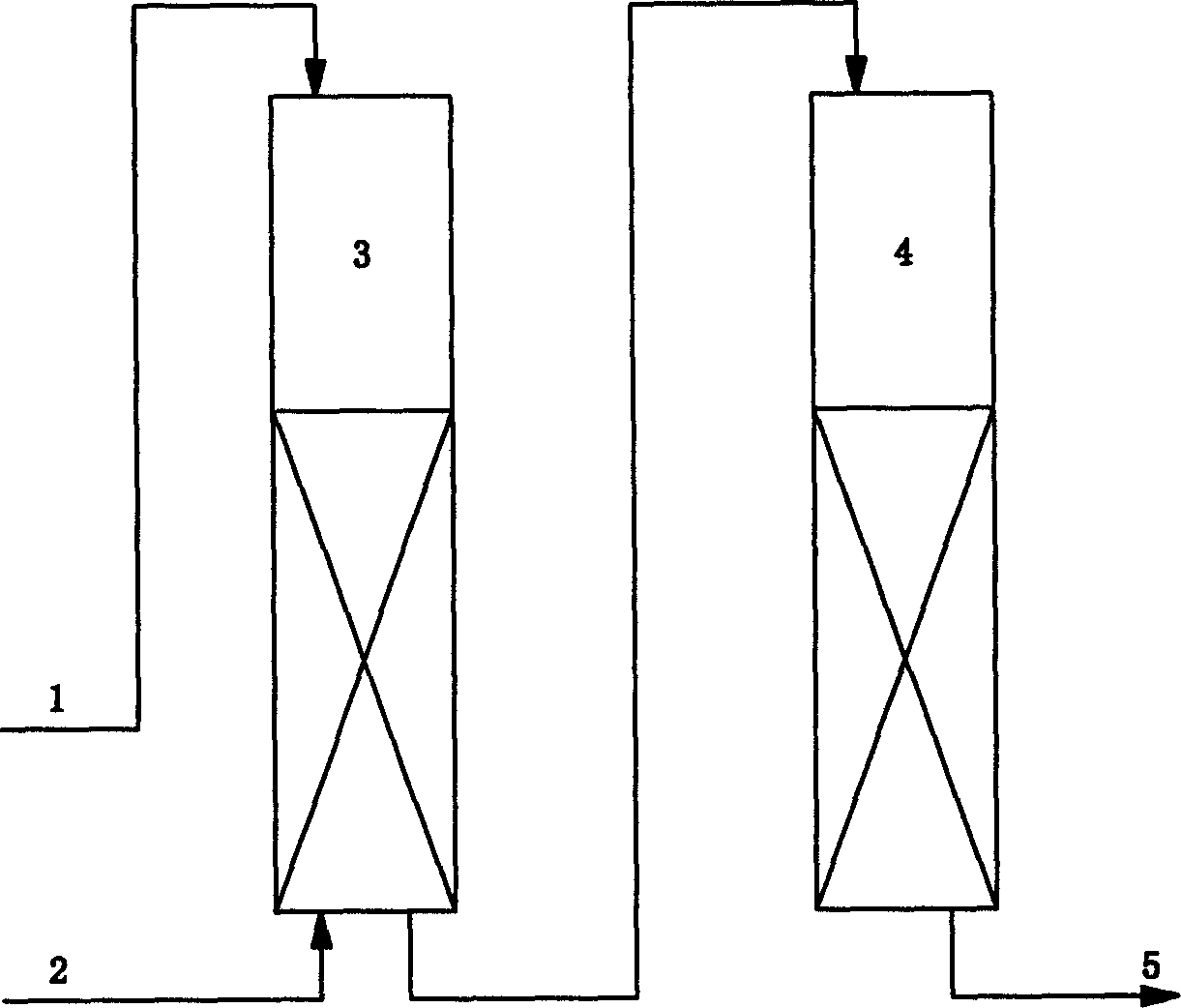

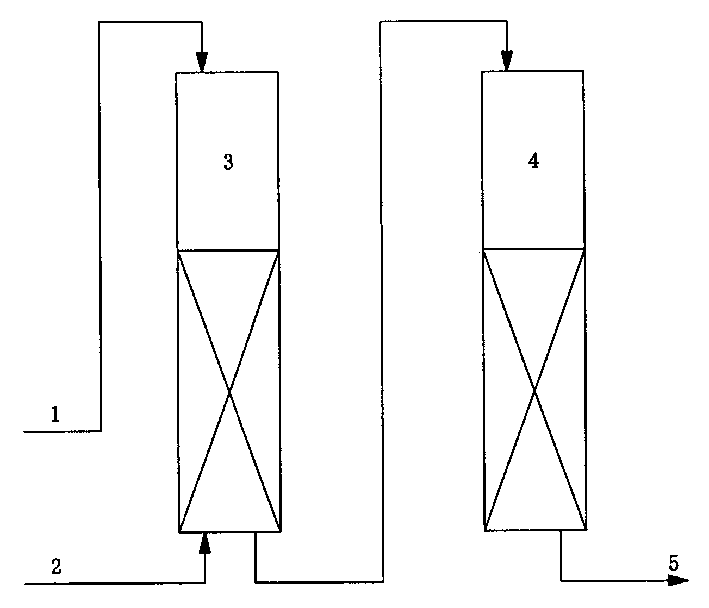

Image

Examples

Embodiment 1

[0019] The biological oxidation tower is equipped with biological filler ceramsite and supporting gravel. The ceramsite is a lightweight porous aggregate made from natural shale as the raw material and expanded by high temperature roasting (around 1000℃). The shale ceramsite is hard and porous. It is light in weight and does not contain heavy metals and other harmful substances harmful to the human body. Its main chemical components are:

[0020] Name SiO 2 Al 2 O 3 Fe 2 O 3 CaO MgO loss on ignition

[0021] Content% 61~65 19~24 4~9 0.5~1 1~2 5.0

[0022] The bulk density of ceramsite is 720Kg / m 3 , The total porosity is 75.6%, of which the open porosity is 47.2%, and the specific surface area is 3.99m 2 / g The oxygen required by the biological oxidation tower is supplied by compressed air to keep its dissolved oxygen above 2mg / L. The effluent from the biochemical tower is then pumped into the activated carbon adsorption tower, and the effluent from the activated carbon ...

Embodiment 2

[0039] Biochemical tower inlet water petroleum organic matter content 15mg / L, biochemical tower inlet water 4m 3 / h, hydraulic retention time 40min,

[0040] Activated carbon tower water intake 4m 3 / h, the hydraulic retention time is 35min, most of the organic matter in the effluent of the activated carbon tower is not detected, and the petroleum organic matter content is 0.15mg / L. Irregular nutshell activated carbon is used in the activated carbon packing tower, and the rest is the same as in Example 1.

Embodiment 3

[0042] The content of petroleum organic matter in the inlet water of the biochemical tower is 3mg / L, and the inlet water amount of the biochemical tower is 4.5m 3 / h, hydraulic retention time 15min, activated carbon tower water inlet 4.5m 3 / h, the hydraulic retention time is 8min, most of the organic matter in the effluent of the activated carbon tower is not detected, and the petroleum organic matter content is 0.10mg / L. The rest is the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com