Large complex mold element separating and combining method and device

A combination method and unit group technology, applied in the direction of coating, etc., can solve the problems of surface defects, design and processing difficulties, and low molding efficiency of products, so as to facilitate mold clamping, installation and demoulding, and reduce processing difficulty. The effect of convenient installation and combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

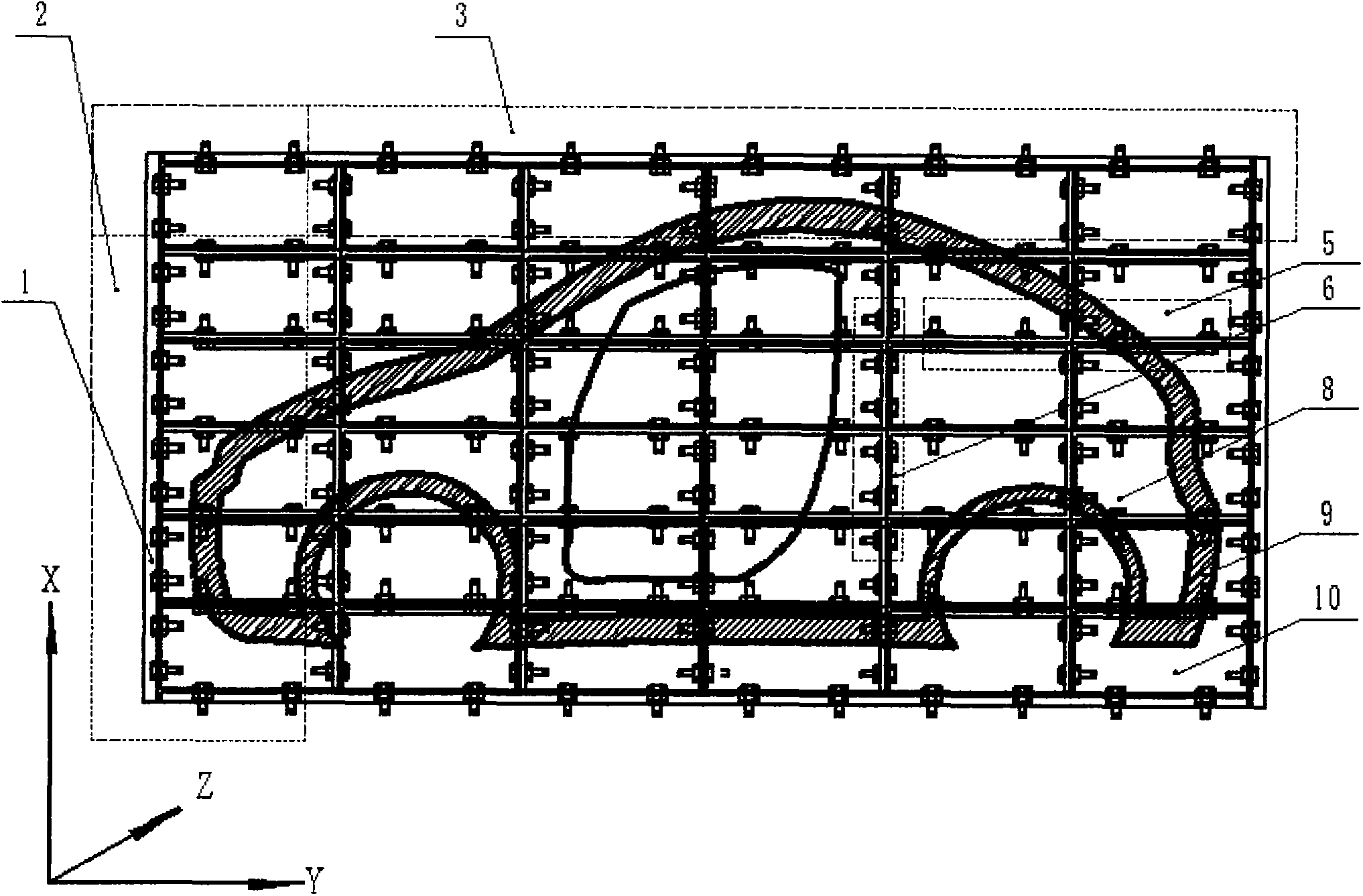

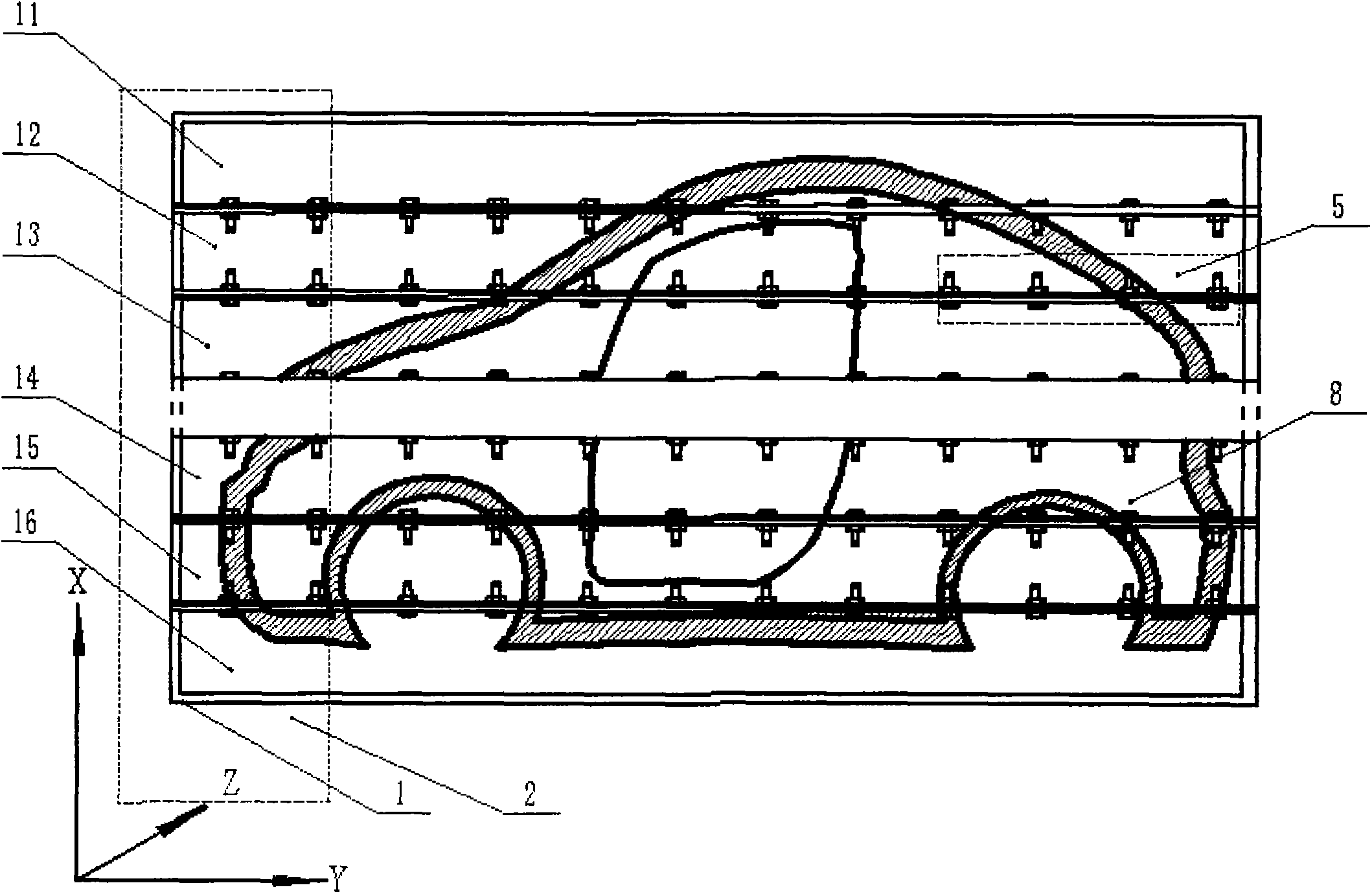

[0028] A large and complex mold unit segmentation and combination method and device of the present invention are segmented effect diagrams along the X direction, such as image 3 with Figure 4 As shown, when the shape and size of the mold to be processed are suitable for unit block along the X direction, 1 can be used # Combination of die unit group 2, 1 # Die unit group 2 mainly includes: X n Die Micron 11, X (n-1) Die Micron 12, X (n-2) Mold microelement 13,...,X 3 Die Micron 14, X 2 Die Micron 15, X 1 There are 16 mold elements, and each mold element in the X direction passes through 1 # The bolt assembly 5 is connected and fixed. If the mold needs to be opened and closed, the matching plane of the two mold elements can be selected according to the shape of the product, the precision of the processed product, and the difficulty of the mold opening and closing station. Actions, e.g. select X (n-2) Mold Micron 13 with X 3 Die micro-unit 14 is used for opening and c...

Embodiment 2

[0030] A large and complex mold unit segmentation and combination method and device of the present invention segmentation effect diagram along the Y direction, as shown Figure 5 As shown, when the shape and size of the mold to be processed are suitable for unit block along the Y direction, 2 can be used # Combination of die unit group 3, 2 # Die unit group 3 mainly includes Y 1 Mold Microelement 17, Y 2 Die micro-element 18,...,Y 3 Mold Microelement 19, Y (n-2) Mold Microelement 20, Y (n-1) Mold Microelement 21, Y n Die micro-units 22, and each mold micro-unit in the Y direction passes through 2 # The bolt assembly 6 is connected and fixed. If it is necessary to open and close the mold, the matching plane of the two mold elements can be selected according to the shape of the product, the precision of the processed product, and the difficulty of the mold opening and closing station. Actions, e.g. select Y 3 Mold Microelement 19 and Y (n-2) Mold micro-element 20 is use...

Embodiment 3

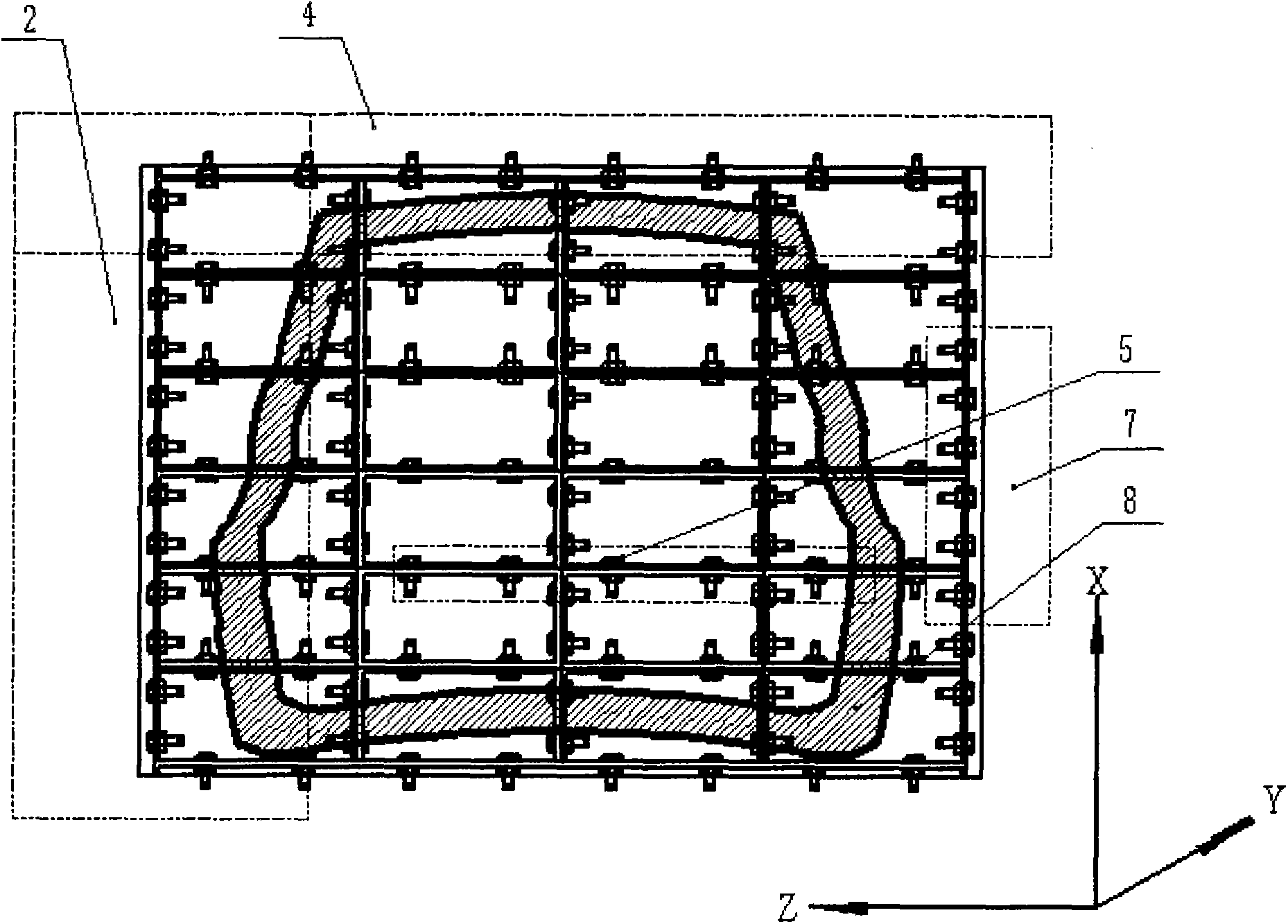

[0032] A large and complex mold unit segmentation and combination method and device of the present invention are segmented effect diagrams along the Z direction, such as Image 6 As shown, when the shape and size of the mold to be processed are suitable for unit block along the Z direction, 3 can be used # Combination of die unit groups 4, 3 # Die unit group 4 mainly includes: Z 1 Mold Microelement 23, Z 2 Mold Microelement 24,...,Z (n-1) Mold Microelement 25, Z n Die micro-units 26, and each mold micro-unit in the Z direction passes through 3 # The bolt assembly 7 is connected and fixed. If it is necessary to open and close the mold, the matching plane of the two micro-elements of the mold can be selected according to the shape of the product, the precision of the processed product, and the difficulty of the mold opening and closing station. Operation, for example: select Z 2 Mold Micron 24 with Z (n-1) Mold element 25 carries out opening and closing mould.

[0033] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com