Automobile instrument panel vacuum-absorption forming integrated mould

A technology of vacuum adsorption molding and automobile instrument panel, which is applied in the field of machinery, can solve the problems of high mold cost and long production cycle, and achieve the effect of overcoming large land occupation, safety assurance of maintenance and inspection, and safe and convenient maintenance and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The integrated mold for vacuum adsorption forming of the automobile instrument panel of the present invention will be further described in detail below in conjunction with the accompanying drawings.

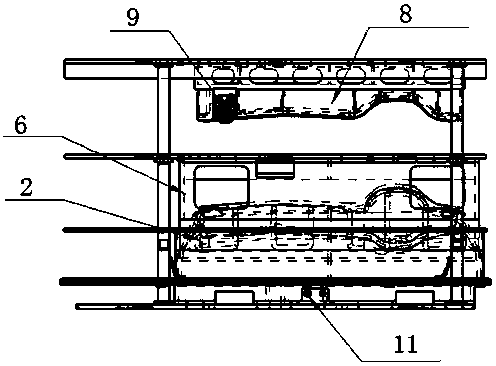

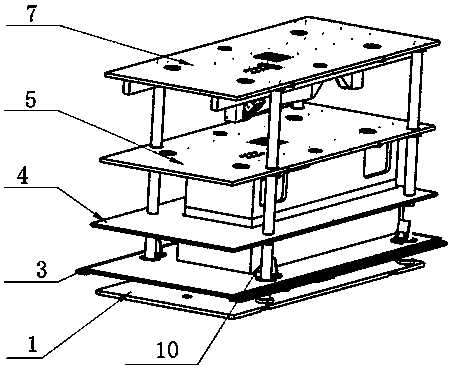

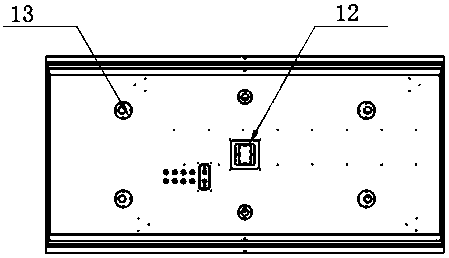

[0017] Such as Figure 1 ~ Figure 3 As shown, the automobile instrument panel vacuum adsorption forming integrated mold of the present invention, the upper template 7 is mainly equipped with a suture groove hot pressing die 8 and a hot stamping die 9 as the upper die, and the hot pressing die 8 and the hot stamping die 9 are integrated. The blade that the cutter plate 5 is installed and cuts the skin is the cutter die 6. The upper pressing frame 4 and the lower pressing frame 3 form a closed space for vacuum adsorption in order to clamp the epidermis. A vacuum suction mold body 2 is installed on the base plate 1, which is a vacuum mold. The waterway joint 11 is a quick-plug standard part heated by water, which heats the mold body. Harding joint 12 is the fast plug-in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com