Reactor pool cleaning method used for miniature neutron source reactor decommissioning

A cleaning method and pool pool technology, applied in the field of reactor engineering, can solve the problems of waste mixing and taking up a lot of time, and achieve the effect of reducing cleaning, avoiding waste mixing, and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

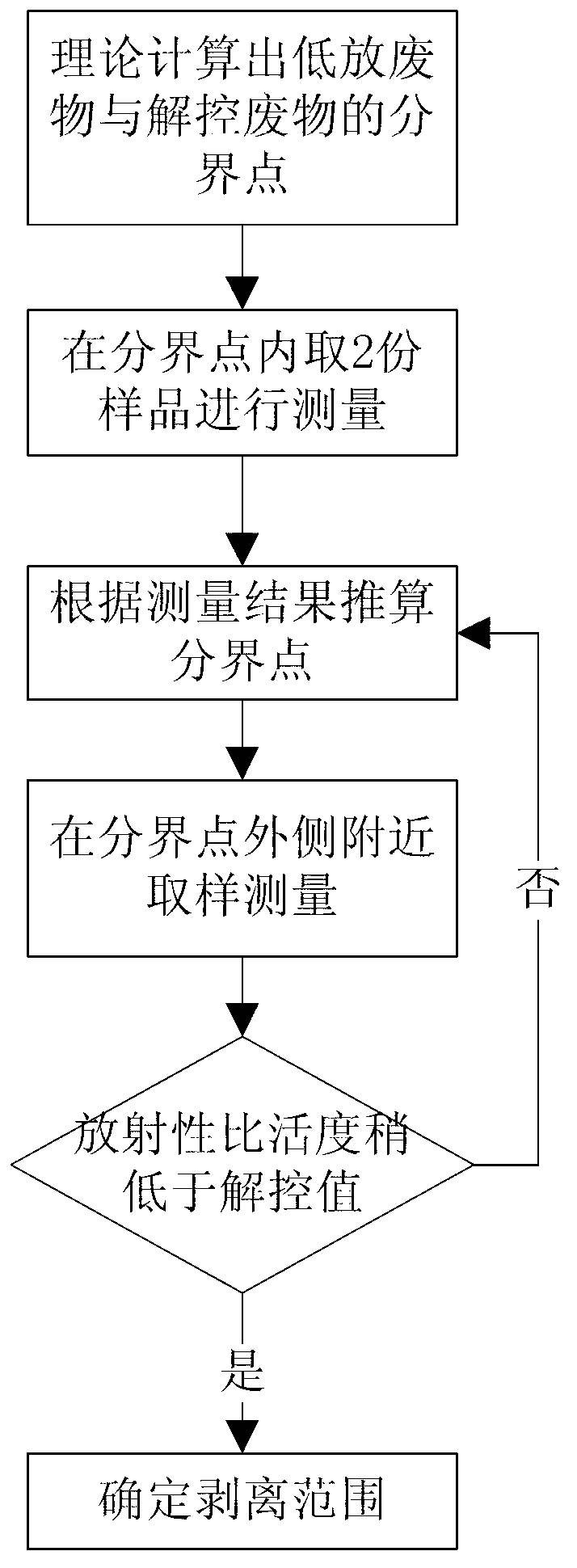

Method used

Image

Examples

Embodiment 1

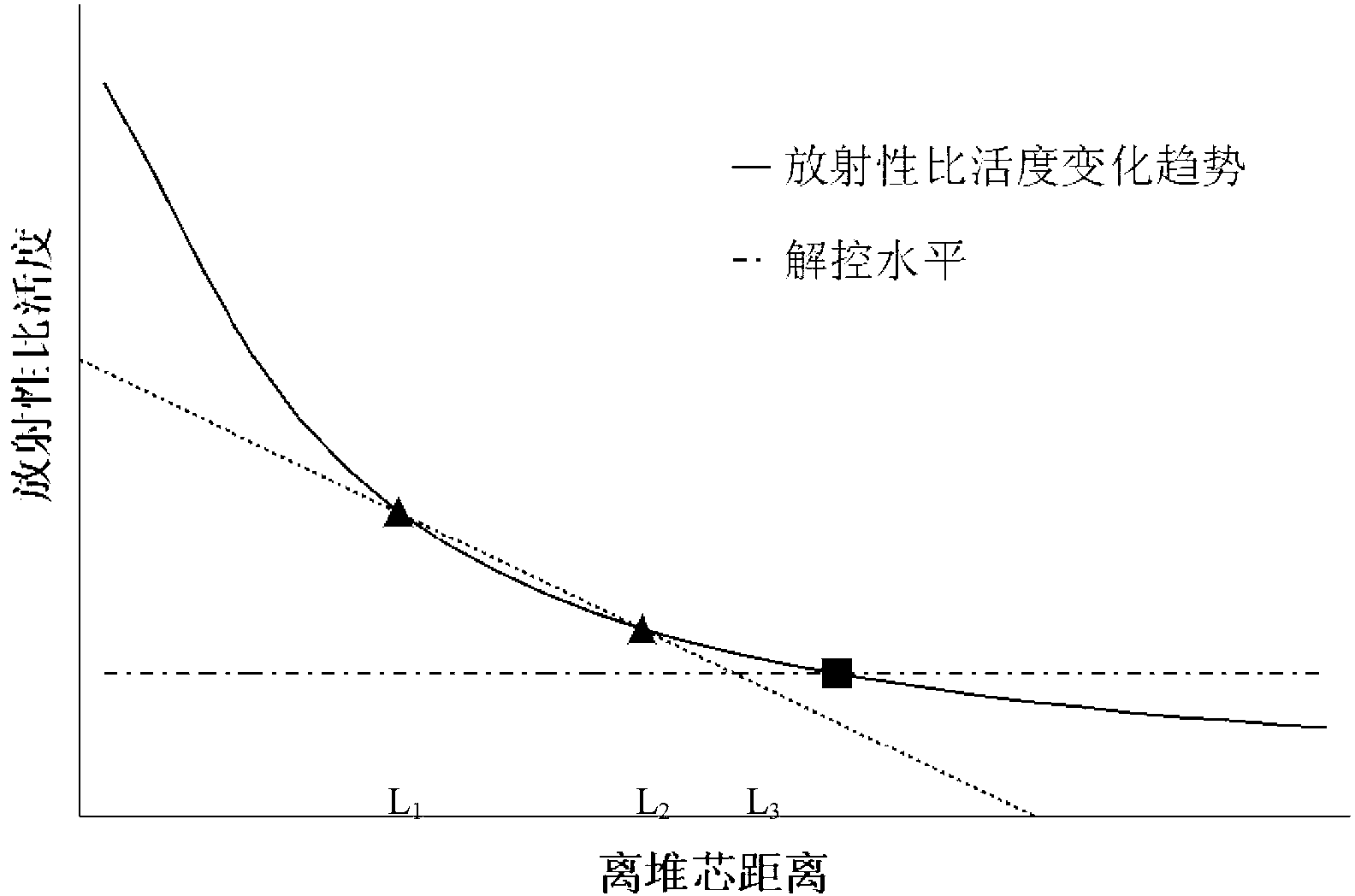

[0029] The present invention is used for the cleaning of the bottom of the Jinan heap pool, and the bottom of the Jinan heap pool is as follows Figure 4 As shown, the big circle is the bottom of the reactor pool, and the small circle is the projection of the reactor core on the bottom of the pool. When stripping the bottom of the pool, according to this method, the demarcation point between low release and release control is determined from both horizontal and vertical directions. In this embodiment, the vertical direction is taken as an example for illustration.

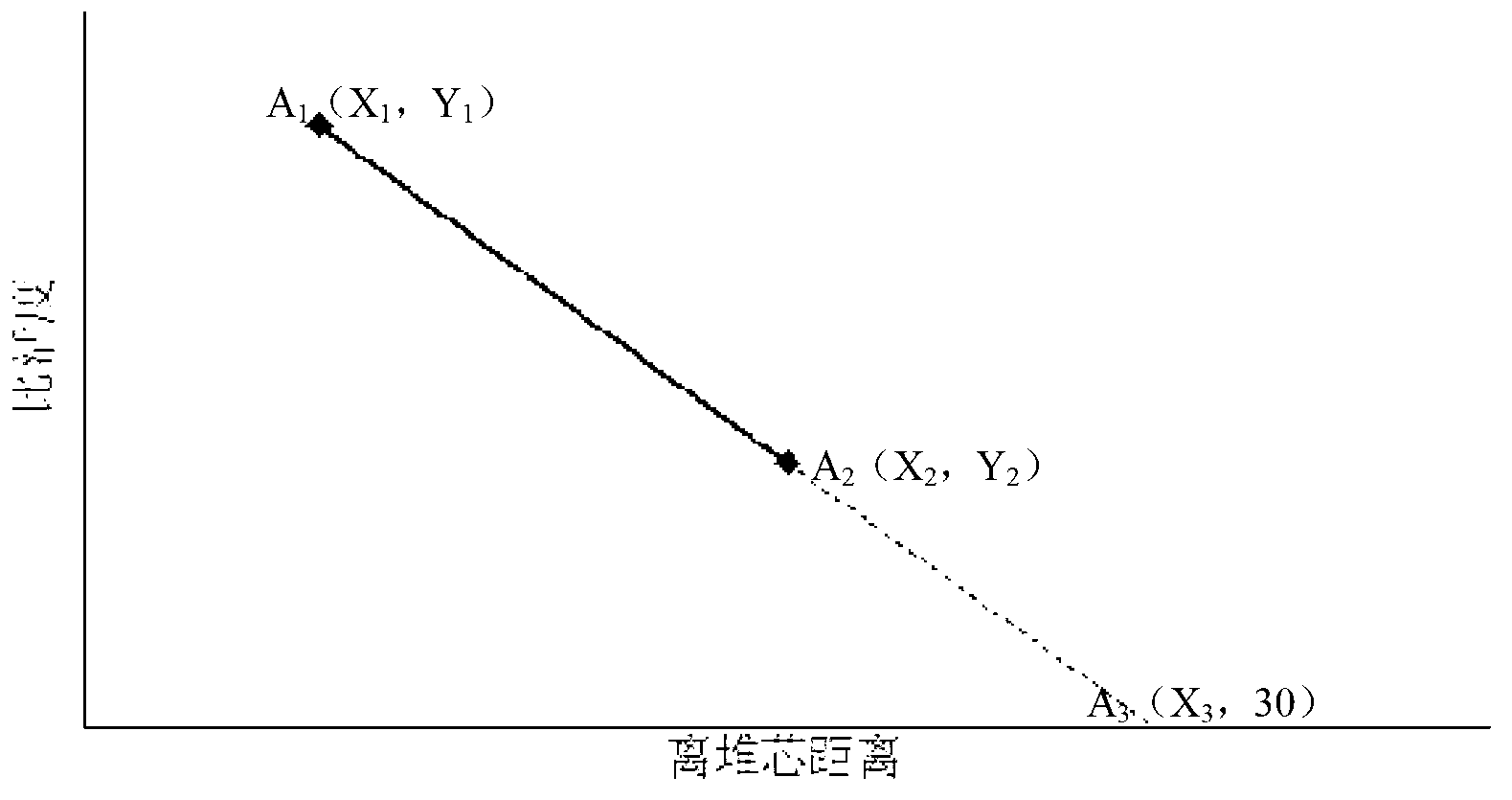

[0030] The release value of the reactor is required to be 60 Co specific activity is 30Bq / kg, 152 The specific activity of Eu is 100Bq / kg.

[0031] The design rated power of Jinan micro-reactor is 30kW, corresponding to the thermal neutron flux density of the inner irradiation seat is 1×10 12 n·cm ‐2 ·s ‐1 .

[0032] The first step: theoretical calculation:

[0033] Check the operation records of the Jinan ...

Embodiment 2

[0058] The present embodiment is the same as Embodiment 1, and its difference is that adopt this method to find the demarcation point in the horizontal direction at a distance of 90 cm from the projection center of the core at the bottom of the pool, and the demarcation point depth at 40 cm from the center is 40 cm, and the distance from the center is 40 cm. The depth of the demarcation point at 70cm is 15cm, and the peeling is carried out according to the above demarcation point. The section of the debonding part is as follows: Figure 5 shown.

[0059] During the decommissioning process of Jinan micro-pile, the total amount of waste cleaned by this method was 3.1 cubic meters, compared with 6.9 cubic meters of waste treated by other existing cleaning methods, the volume was reduced by more than half, and the secondary waste was greatly reduced. amount of radioactive waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com