A grabbing device for barrels of medium and low radioactive waste

A low-radioactive, grabbing device technology, applied in the mechanical field, can solve problems such as potential safety hazards, barrel wall rupture, and barrel wall tearing, and achieve the effects of improving the stability of clamping, avoiding damage, and improving the state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention are described in detail below, and the following embodiments are based on the technical solutions of the present invention, and provide detailed implementation methods and specific operation processes. It should be noted that any modification, equivalent replacement, variation and improvement made by those skilled in the art without departing from the concept of the present invention shall fall within the protection scope of the present invention.

[0040] This embodiment provides a grasping device for medium and low radioactive waste barrels, which not only improves the stress state of the waste barrels, improves the stability of the waste barrels in the process of handling and moving, but also realizes The device can automatically center the waste bucket.

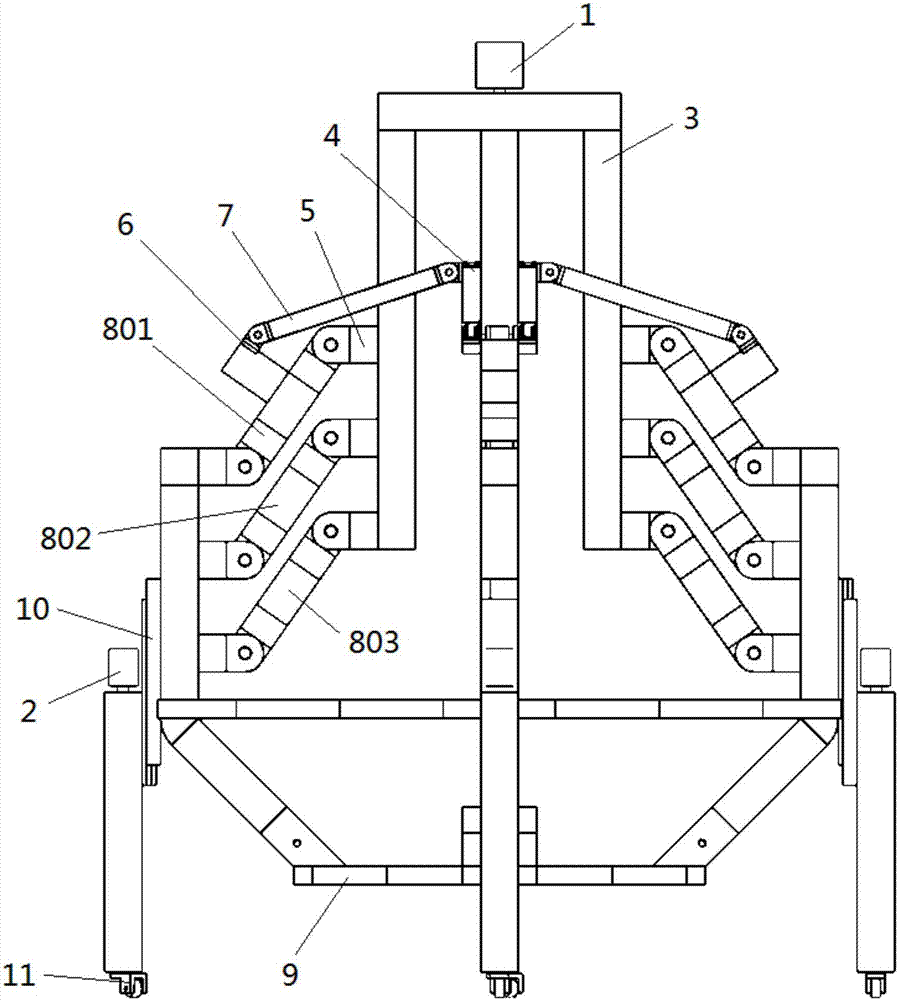

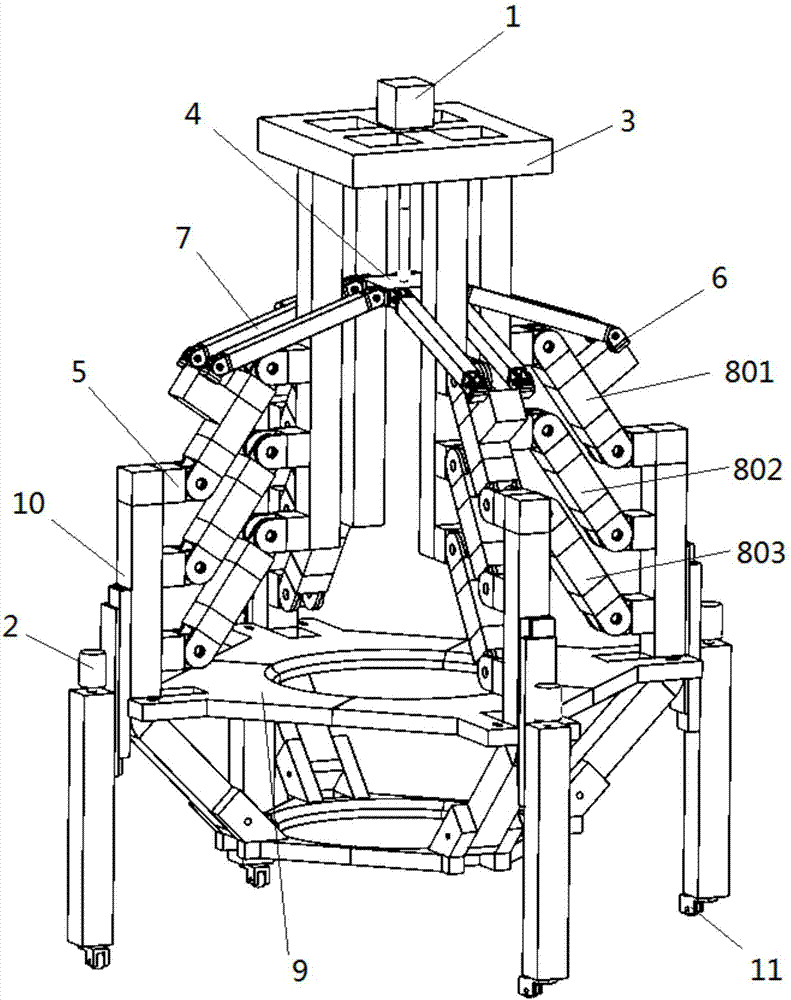

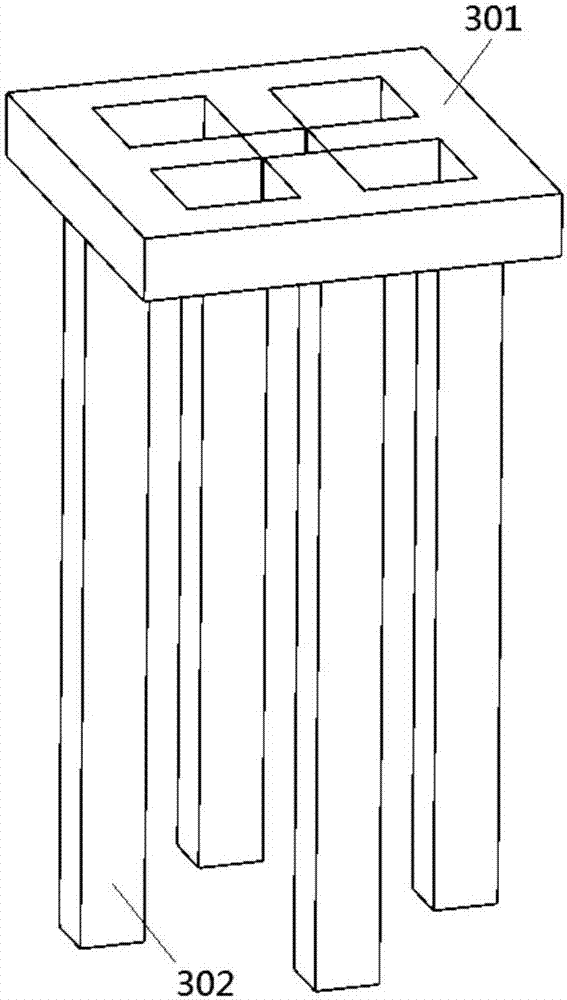

[0041] Please refer to figure 1 and figure 2 , The grasping device described in this embodiment includes a main bracket 3, a grasping motor screw 1, a drive nut plate 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com