Pneumatic abrasion-resisting angle stop valve

An angle-type globe valve and valve body technology, applied in the field of globe valves, can solve the problems of high labor intensity, inconvenient installation and disassembly, complicated valve structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

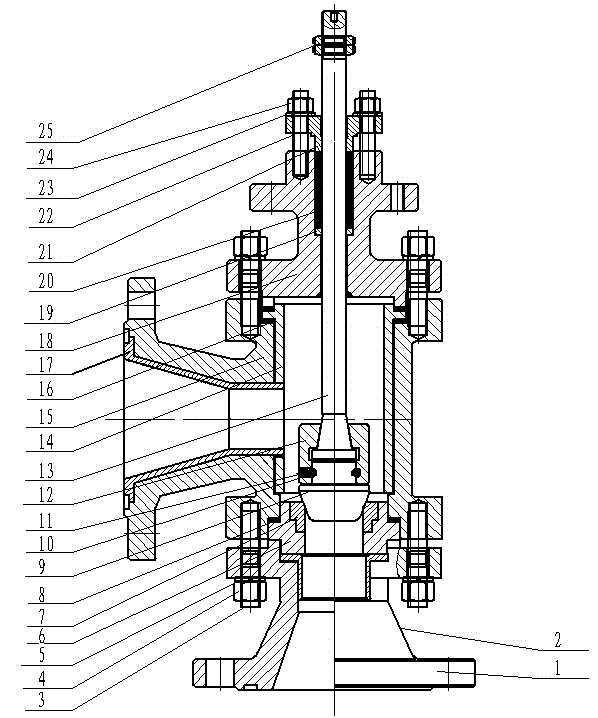

[0020] As shown in the figure, the wear-resistant angle stop valve includes a three-way valve body 15, flange holes are arranged at the upper and lower ends of the valve body 15, and the left side is a concave flange, and the left side inner protection is arranged inside the concave flange. Cover 17, the valve body 15 lower opening is provided with a valve body jacket 6 made of alloy steel, a metal winding pad 8 is arranged therebetween, the valve body jacket 6 is inlaid with a valve seat 7, and the valve body 15 lower end surface is passed through a double-ended stud. 3. The hexagonal nut 4 and the spring washer 5 are installed with the flange joint 1, the inner stop of the flange joint 1 is provided with the inner sheath 2 at the lower end, and the upper end of the inner sheath 2 is press-fitted between the valve seat jacket 6 and the flange joint 1, On the upper opening of the valve body 15, a bonnet 18 with a central through hole is installed in the middle through a stud 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com