Engagement fixture for square steel blade milling

A milling and gnashing technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of long manufacturing cycle and difficult processing of blades, and achieve the goal of reducing the difficulty of manufacturing and processing, shortening the manufacturing cycle, reducing the Effects of processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

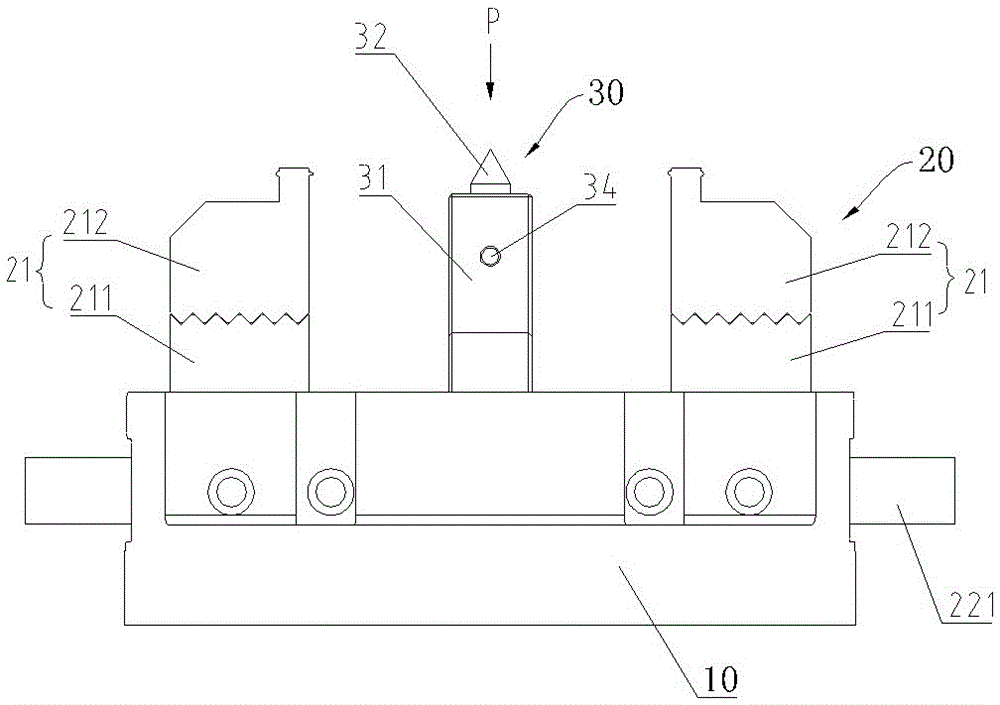

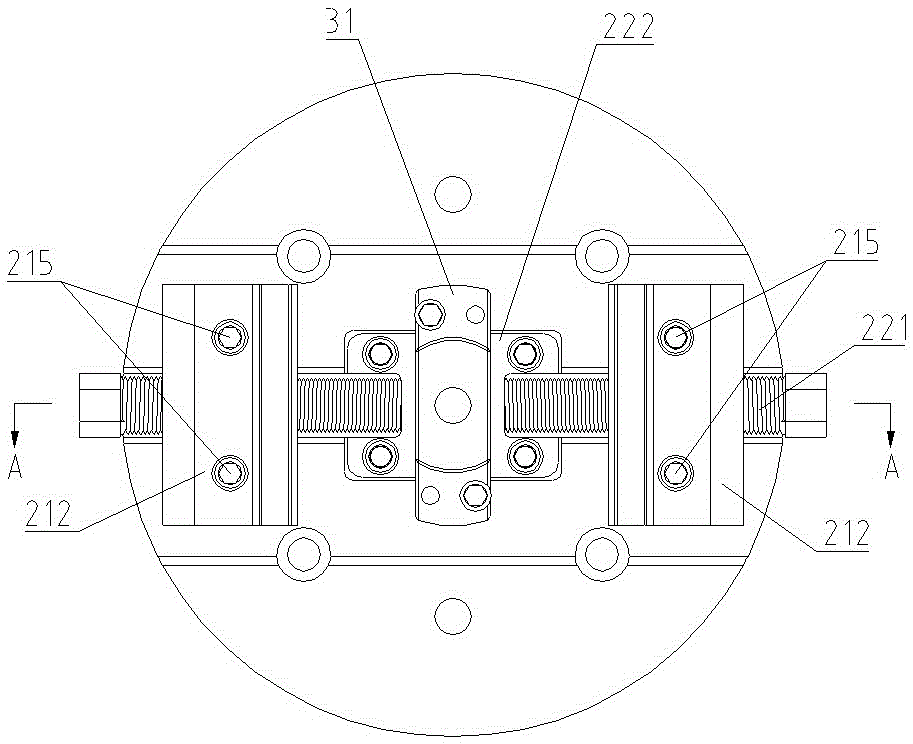

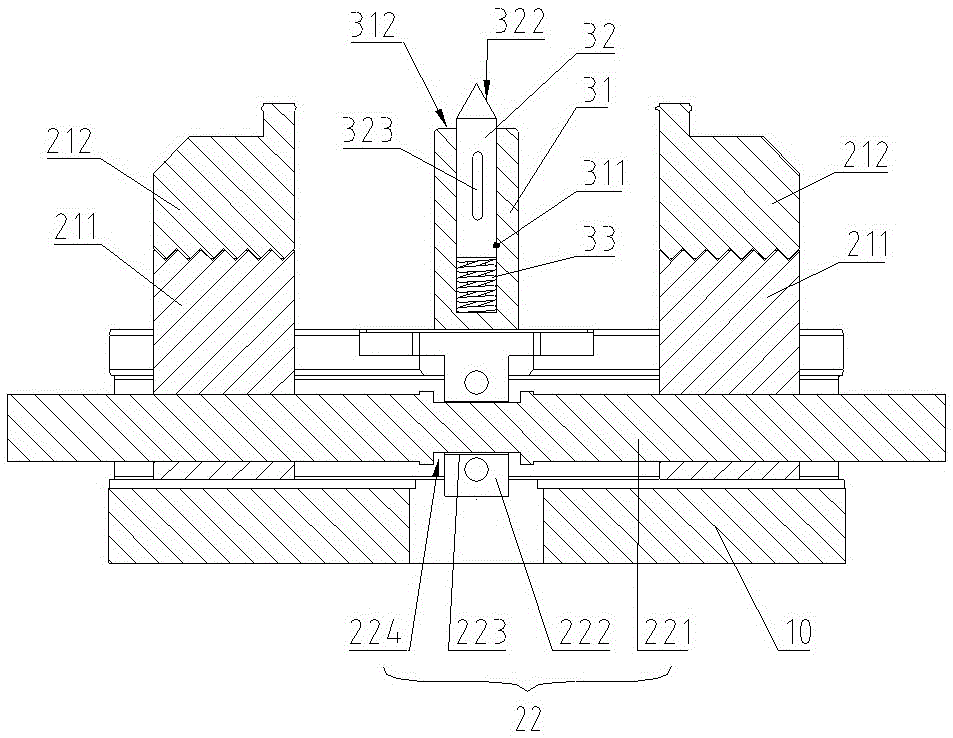

[0026] See Figure 1 ~ Figure 3 , the present invention includes a rotary disk 10, a tooth clamping mechanism 20 and a floating top mechanism 30, the tooth clamping mechanism 20 includes two tooth blocks 21 and a screw translation structure 22, and the screw translation structure 22 is installed on the rotary disk 10 Above, the floating top mechanism 30 is arranged at the center of the lead screw translation structure 20, and the two teeth blocks 21 are respectively installed on the screw translation structure 22 and located on both sides of the floating top mechanism 30, and the two teeth blocks 21 can The translational structure 22 along the lead screw moves toward or moves back.

[0027] Among them, the floating top mechanism 30 includes a top seat 31, a top 32 and a spring 33. A vertical blind hole groove 311 is provided in the top seat 31. A spring 33 is installed at the bottom of the vertical blind hole groove 311. The top 32 is also installed in a vertical In the blind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com