Machine tool spindle trial run platform capable of simulating working conditions

A technology of machine tool spindle and working conditions, which is used in the testing of mechanical components, the testing of machine/structural components, and metal processing mechanical parts, etc. It can solve the problem of not being able to test the dynamic performance of the spindle, and save testing time and processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

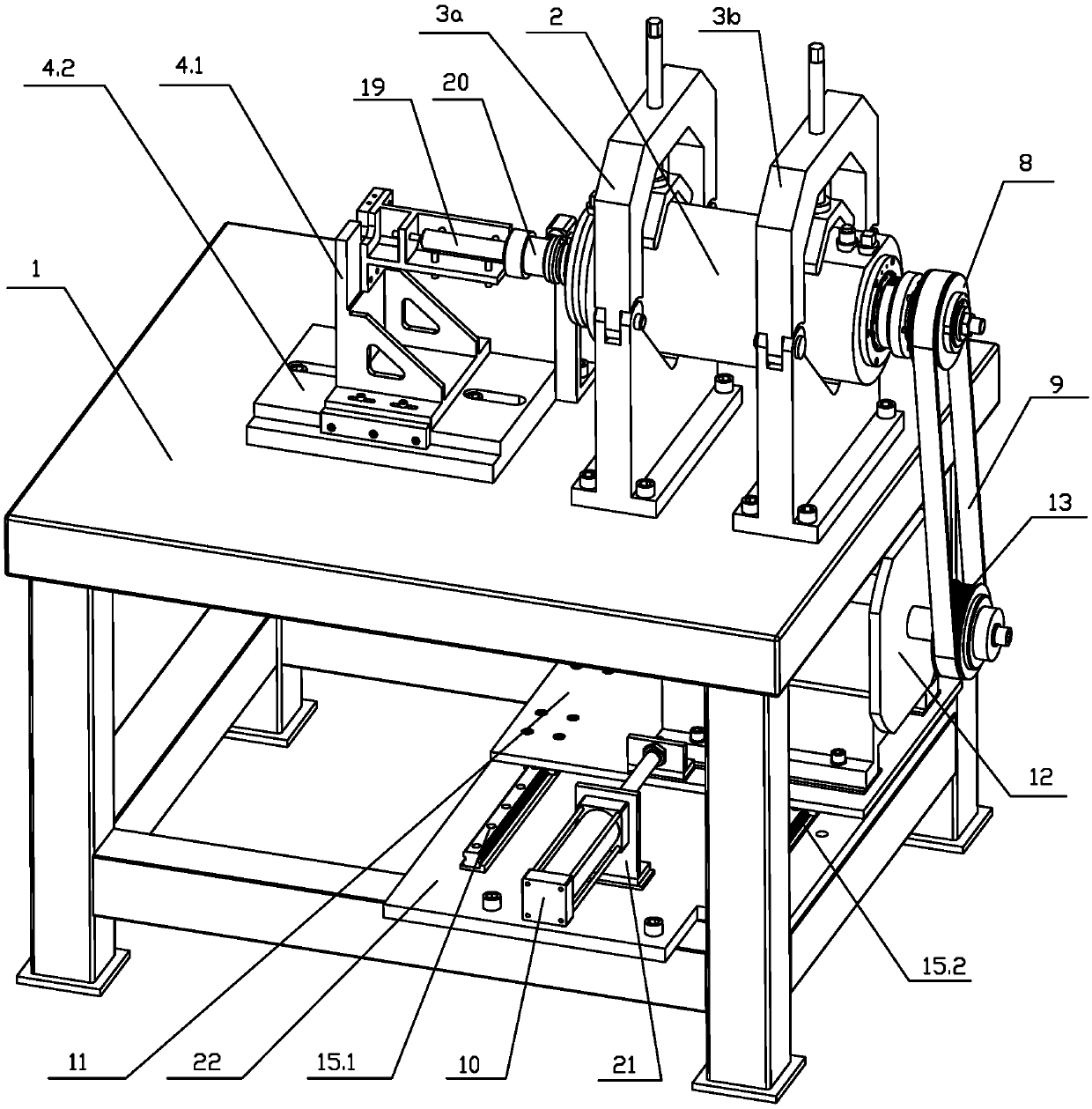

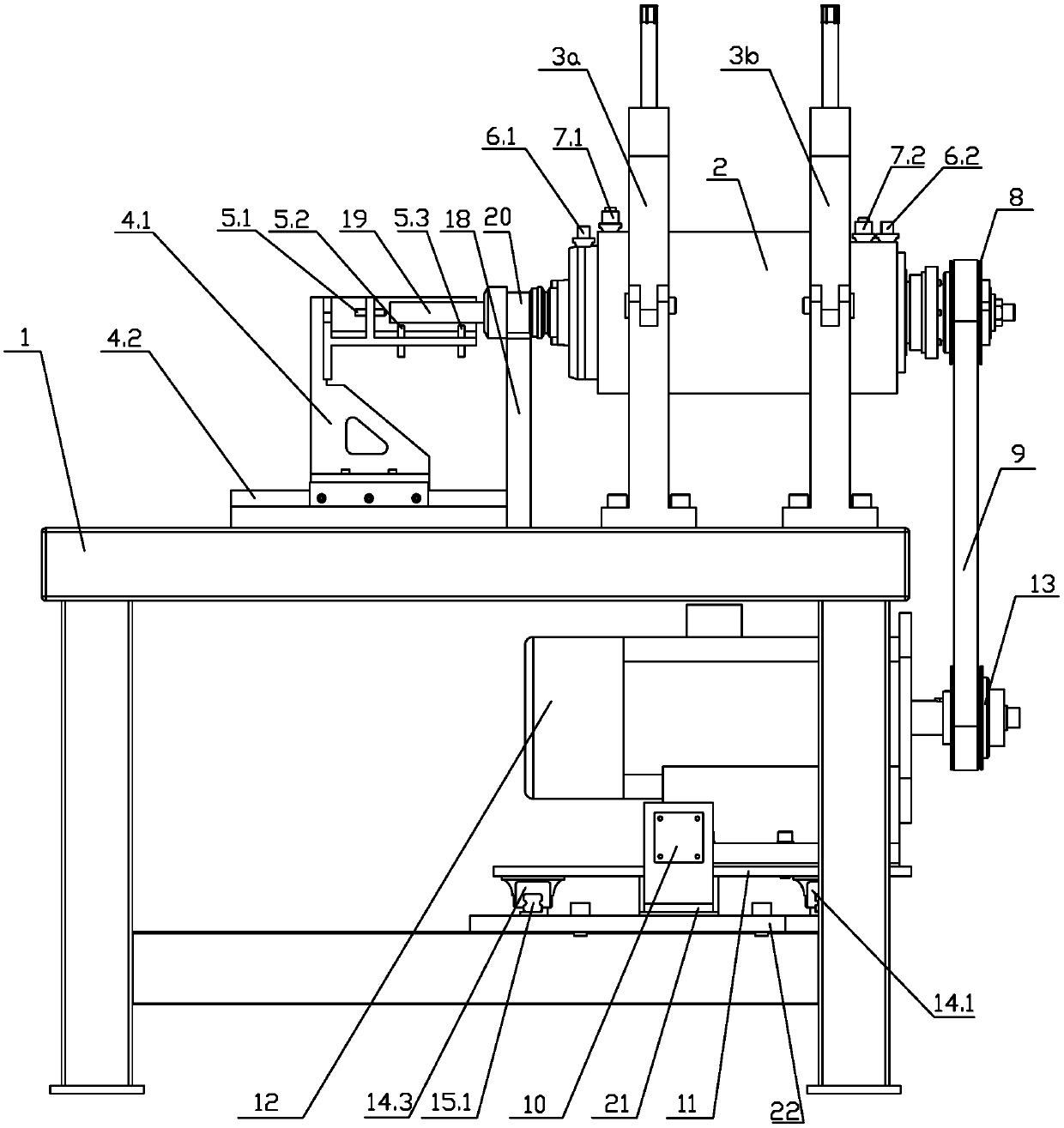

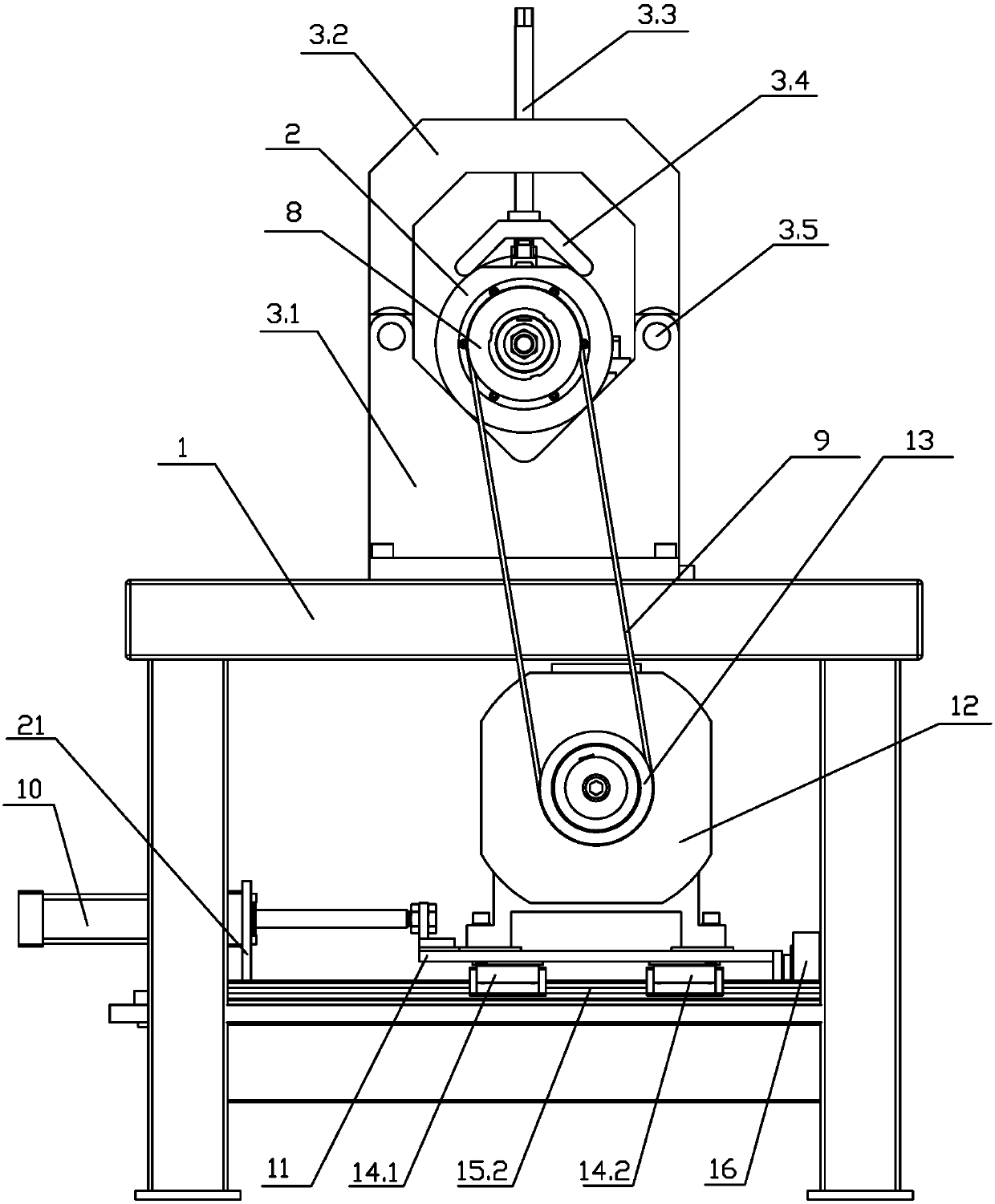

[0045] A machine tool spindle test run platform capable of simulating working conditions of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0046] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a machine tool spindle test run platform capable of simulating working conditions of the present invention includes a workbench 1, and front spindle fixings for correspondingly supporting the front and rear of the spindle 2 to be tested are arranged side by side on the workbench 1. The support 3a and the rear spindle fixing bracket 3b, the inspection rod 19 and the spindle handle 20 corresponding to the front end of the main shaft 2 to be measured on the workbench 1 are respectively provided with a displacement information collection mechanism for obtaining the displacement information of the inspection rod 19, and for An angle / velocity information acquisition mechanism for obtaining the rotation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com