Pneumatic control assembling device of swivel joint

An assembly device and rotary joint technology, which is applied in the manufacture of tools, metal processing equipment, metal processing, etc., can solve the problems of low production efficiency, difficulty in centering, high risk factor, etc., and achieve easy operation, save manpower, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

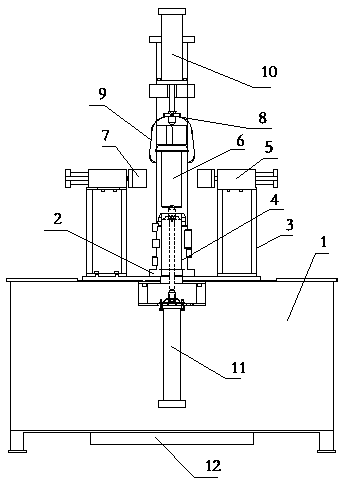

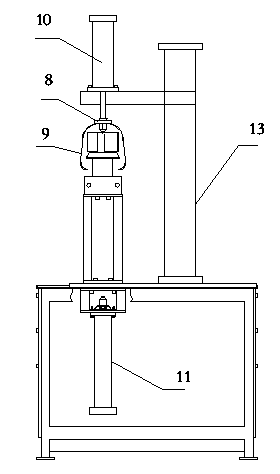

[0016] Such as figure 1 , 2 As shown, a rotary joint pneumatic control assembly device of the present invention includes a workbench 1 and a rocker arm, and an annular shell centering seat 2 is arranged on the table surface of the workbench 1 . The rotary housing 4 is placed on the housing centering seat 2, the center of the rotary housing 4 coincides with the center of the housing centering seat 2, and the rotary housing 4 is prevented from moving at the same time. The center of the centering seat 2 of the housing is provided with a central through hole passing through the table of the workbench 1. A cylinder I11 is vertically provided directly below the central through hole, and a cylinder II10 connected to the rocker arm is vertically provided directly above the central through hole. , The piston rod of cylinder I11 is opposite to the piston rod of cylinder II10. The rocker arm can move up and down, which not only saves the required space but also solves the problem that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com