Hydraulic rapid automatic centering chuck

An automatic centering and collet technology, used in toolholder accessories, chucks, turning equipment, etc., can solve the problems of poor smooth performance, small jaw stroke, and easy wear and tear of components, and achieve good self-locking performance and operation. Smooth and increase the effect of rotating line speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

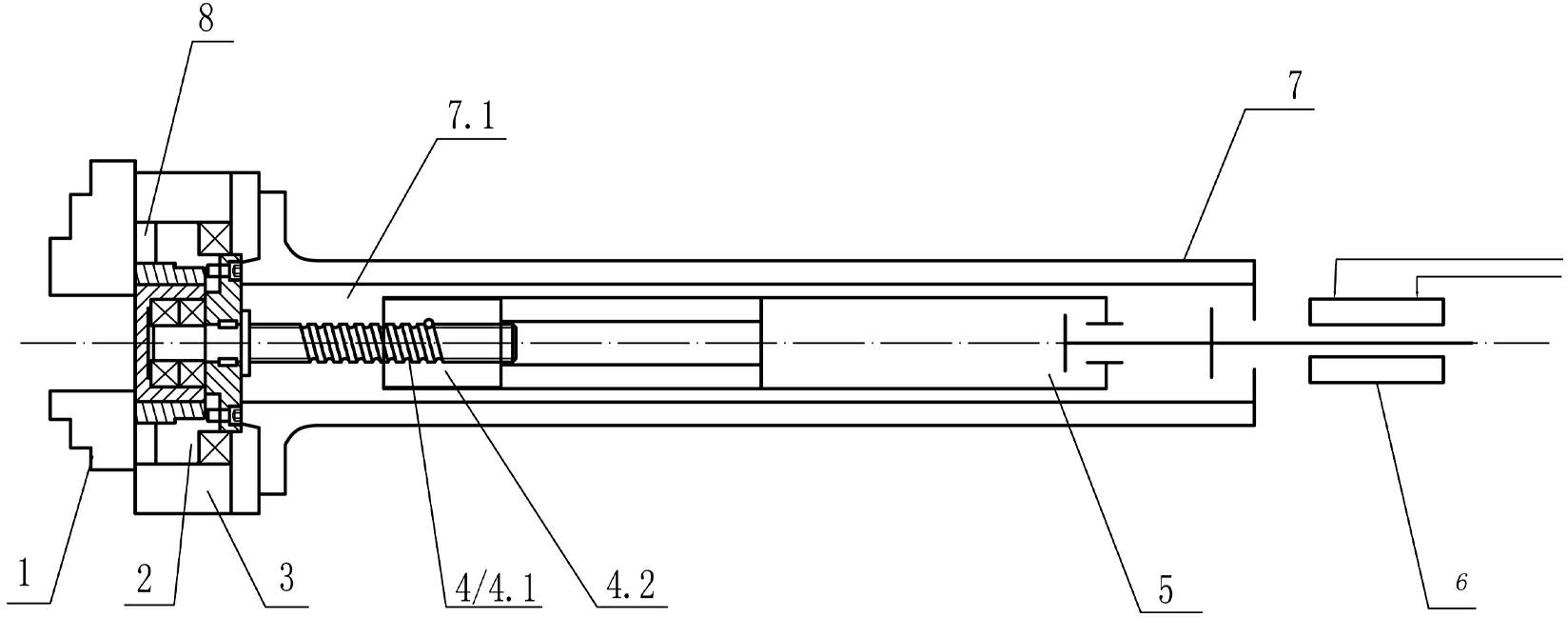

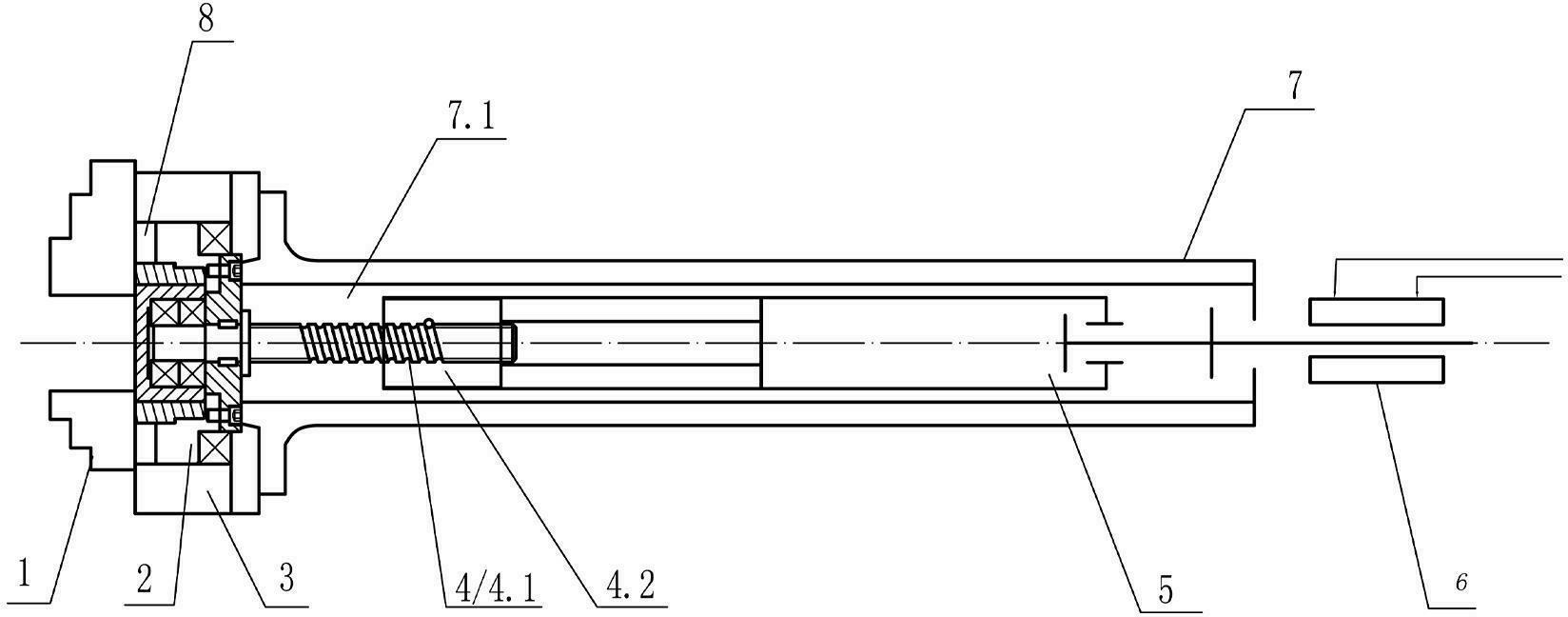

[0009] Such as figure 1 The illustrated embodiment, the hydraulic fast self-centering chuck, includes a jaw assembly 1 with three or four claws, a chuck body 3, a connector 2 placed in the chuck body 3, and a ball screw When the hydraulic transmission mechanism is in use, the chuck body 3 is installed on the flange of the machine tool spindle 7 . The ball screw hydraulic transmission mechanism includes a multi-start ball screw assembly 4 composed of a multi-start screw 4.1 and a ball nut 4.2, a hydraulic cylinder 5 and a hydraulic converter 6 connected to the hydraulic system. The hydraulic converter 6 is provided with a jacket made of polyimide and equipped with a wear-resistant and pressure-resistant FS seal and a rotating square ring, which can be purchased as a set in the market. The multi-head ball screw assembly 4 and the hydraulic cylinder 5 are placed in the spindle hole 7.1 of the machine tool, the hydraulic converter 6 is connected to the hydraulic cylinder 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com