Method for recovering magnesium alloy low-level waste

A recycling method and technology for magnesium alloys, applied in the direction of improving process efficiency, can solve problems such as aggravating the environment, complex chemical composition, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be further described below in conjunction with accompanying drawing:

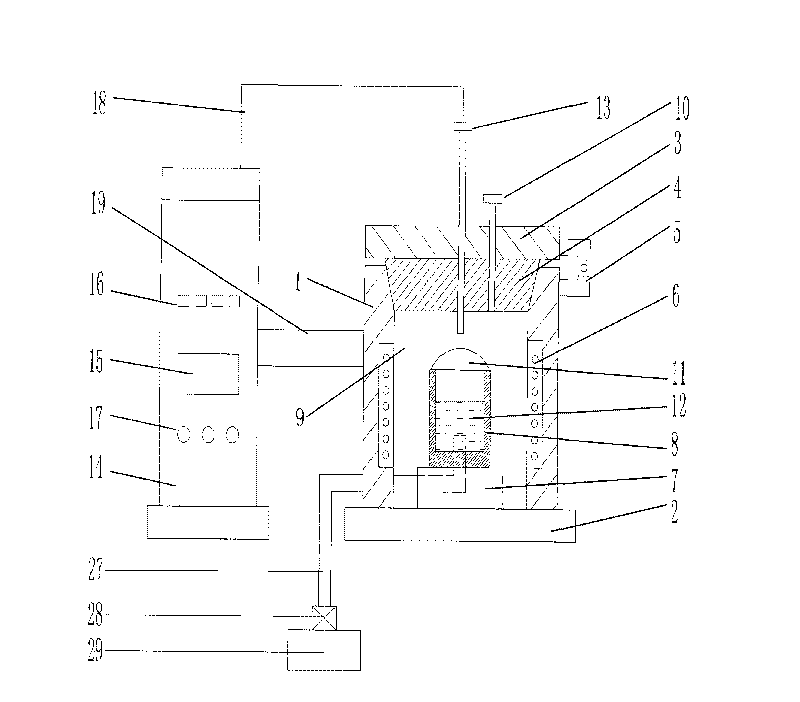

[0089] figure 1 As shown, it is the smelting and refining state diagram of the smelting furnace. The position and connection relationship of each part must be correct and the installation should be firm.

[0090] The thermocouple temperature measuring probe measures the melting temperature inside the furnace cavity, and transmits it to the electric control box for display.

[0091] The air outlet is a safe air hole for discharging the smelting gas in the furnace cavity.

[0092] To prepare the required raw materials, the amount of chemical substances is determined according to the preset amount, with grams, milliliters, and centimeters as the unit of measurement. When industrialized smelting, the units of measurement are kilograms, liters, and meters.

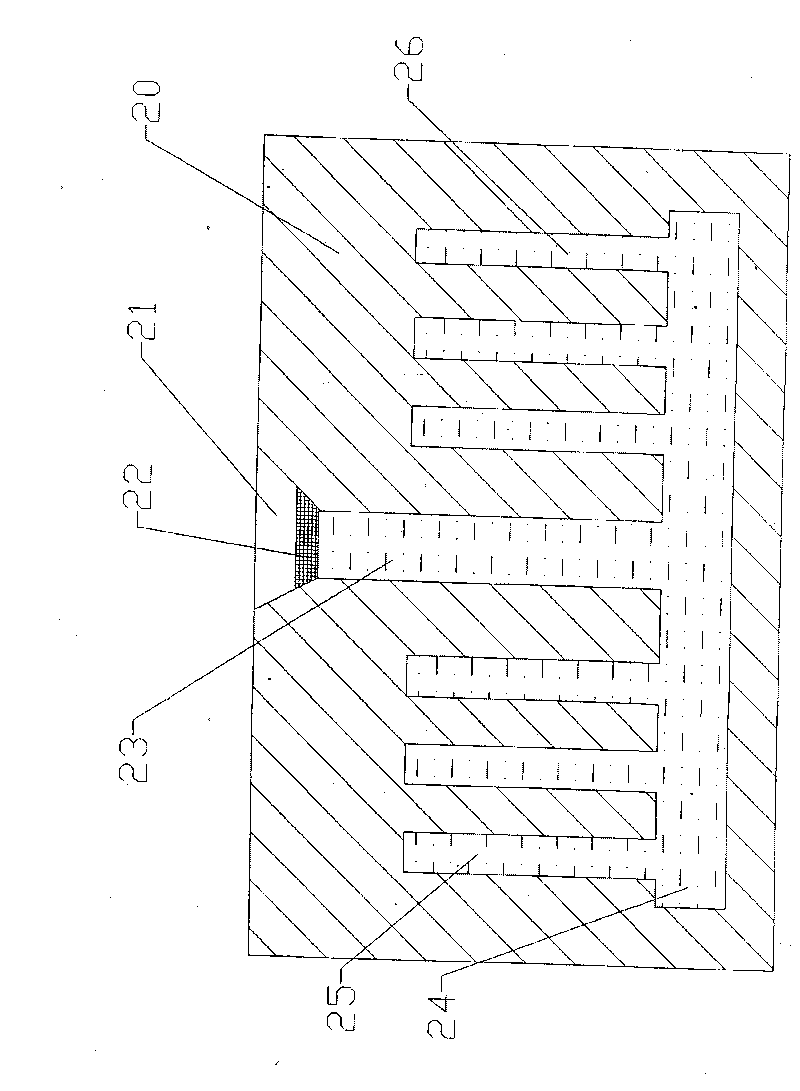

[0093] figure 2 As shown, it is the casting mold and the casting state diagram. The mold is open and close, the gate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com