A secondary combustion system

A secondary combustion and burner technology, which is applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of insufficient combustion and environmental impact, and achieve complete combustion, good environmental protection, and obvious separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

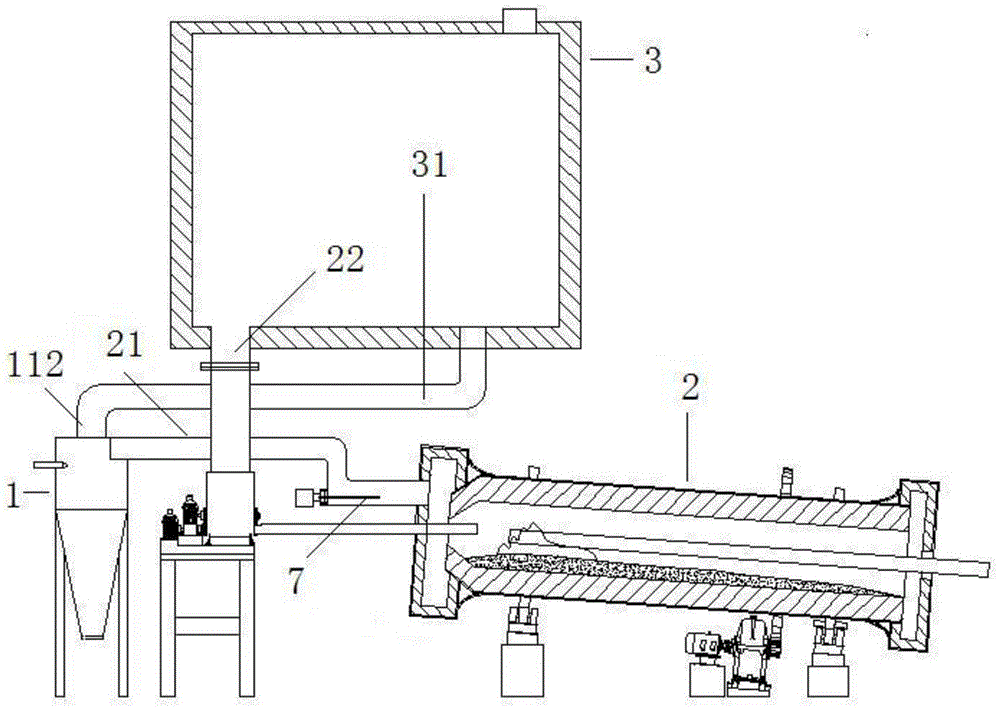

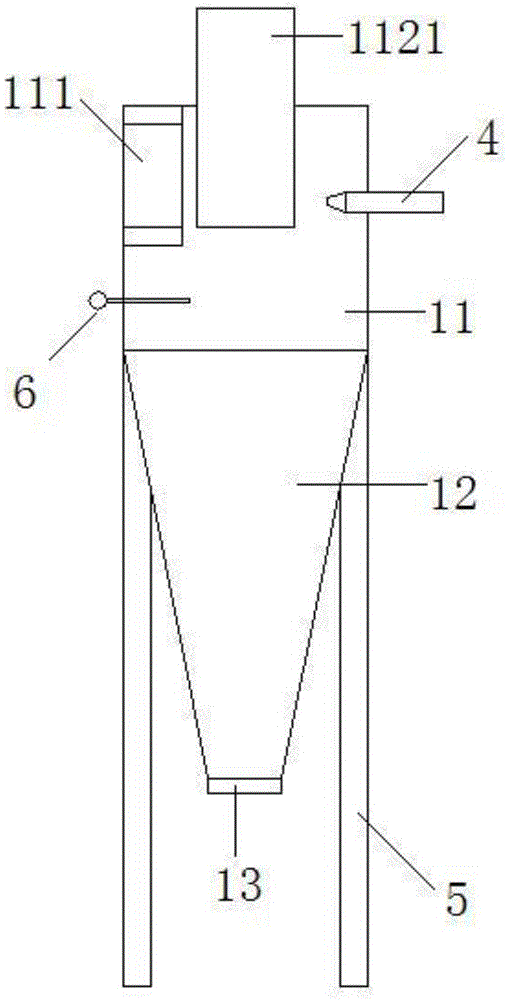

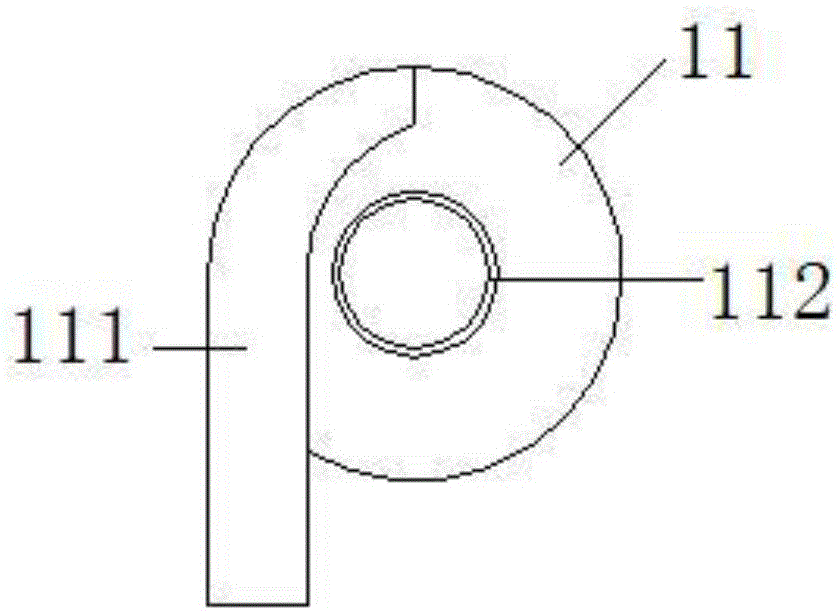

[0020] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In the shown embodiment, a secondary combustion system includes a secondary combustion chamber 1, a hot flue gas return pipe 21 communicating with the kiln tail of the rotary kiln 2, and the rotary kiln 2 is connected to the drying chamber through a feed pipe 22. chamber 3, the upper part of the side wall of the second combustion chamber 1 is provided with a smoke inlet 111, and the smoke inlet 111 is connected to the hot flue gas return pipe 21, and the second combustion chamber 1 is provided with a head extending into the second The burner 4 in the combustion chamber 1, the described secondary combustion chamber 1 includes a cylindrical main combustion chamber 11 and a deposition recovery chamber 12 connected below the main combustion chamber 11, the cross-sectional diameter of the deposition recovery chamber 12 is determined by Decreasing from top to bottom, the bottom of the second combusti...

Embodiment 2

[0023] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 6 As shown: the air outlet 31 is provided with a depressurizing part 32 with a diameter larger than that of the air outlet 31, and the air outlet 31 is provided with an air pump 8, and the air pump 8 is located between the drying chamber 3 and the air outlet. Between the pressing parts 32.

[0024] The pressure-reducing part 32 has a relatively large caliber, which can reduce the instantaneous air pressure of the purified hot flue gas after reaching here, so that the airflow can enter smoothly, so that the airflow in the section of the air outlet 31 before the pressure-reducing part 32 can be more smoothly. Supplemented by the suction of the air pump 8, the smooth flow of the air flow in the entire air outlet can be guaranteed, thereby avoiding the air flow block at the air outlet 112, so that the purified hot flue gas can leave t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com