Smoke combustion chamber and environment-friendly household garbage incineration system

A flue gas combustion chamber and garbage technology, applied in the direction of combustion types, combustion methods, incinerators, etc., can solve the problems of ineffective decomposition of dioxins, weaken the environmental conditions of dioxins, add combustion-supporting materials, etc., and achieve the reduction of dioxins Synthesis of dioxins, preventing the regeneration of dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

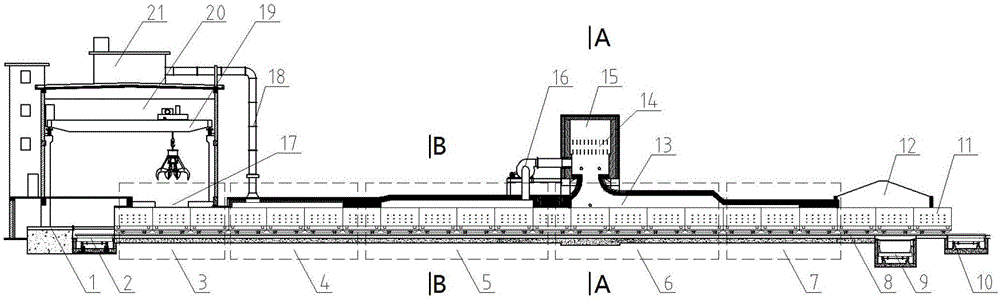

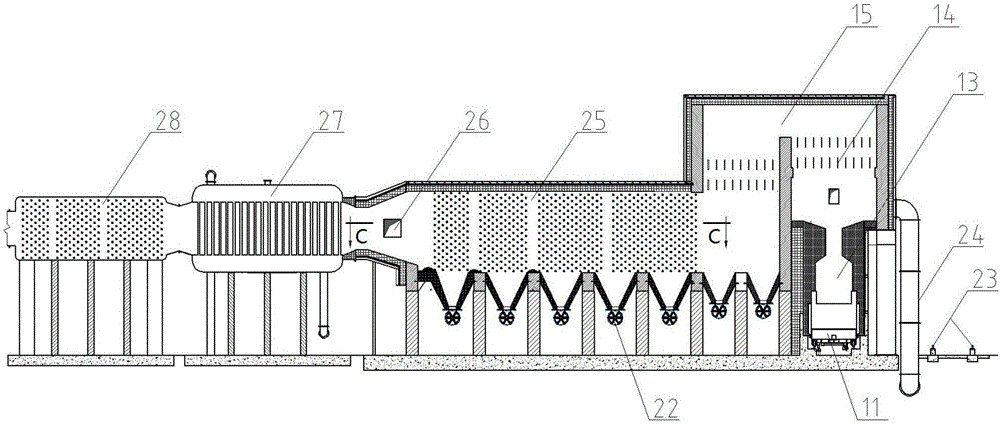

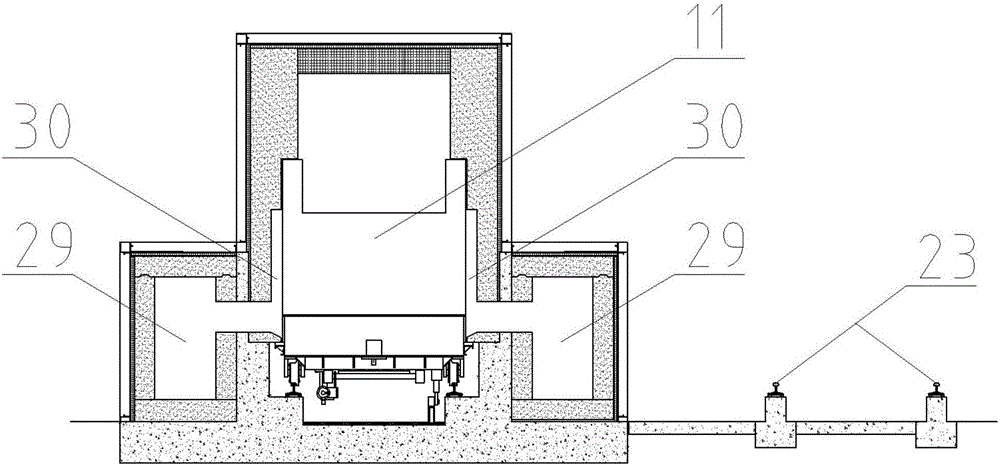

[0032] like figure 1 As shown, the environment-friendly domestic waste incineration system of this example is built on a flat site, consisting of a garbage storage 20, a horizontal tunnel furnace body, a waste incineration vehicle 11, an automatic dispatching system for an incineration vehicle, a flue gas combustion chamber 15, and a steam removal system. Odor purification system 21, flue gas heat exchange cooling system, flue gas purification system, ash truck 9, induced draft fan 16, chimney and other equipment.

[0033] The garbage storage 20 is provided with a bridge type grab crane 19, and the garbage storage 20 top is provided with a steam deodorization and purification system 21 (existing steam deodorization and purification systems such as ultraviolet photolysis ozone purifiers can be used). It is used to purify the steam evaporated from the garbage in the drying section 4, and to purify the steam evaporated from the fermentation of garbage in the garbage storage 20 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com