Method for reducing nitrogen oxide generated by combustion of boiler

A technology of nitrogen oxides and boiler combustion, which is applied in the field of boiler combustion technology, can solve the problems of reducing boiler efficiency, furnace flame upward movement, affecting boiler operation reliability, and increasing fly ash combustibles, etc., to reduce mechanical incomplete combustion losses, Effect of reducing chemical incomplete combustion loss and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

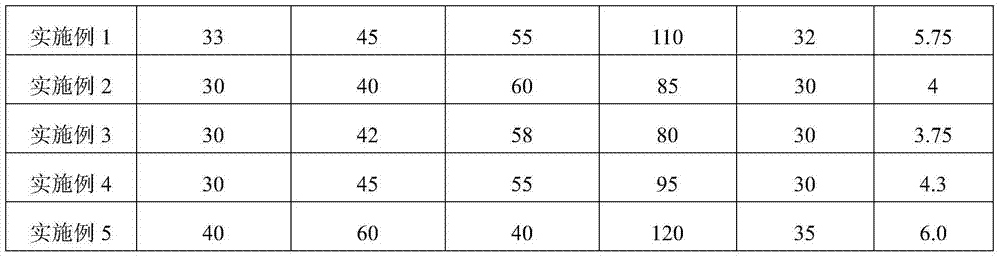

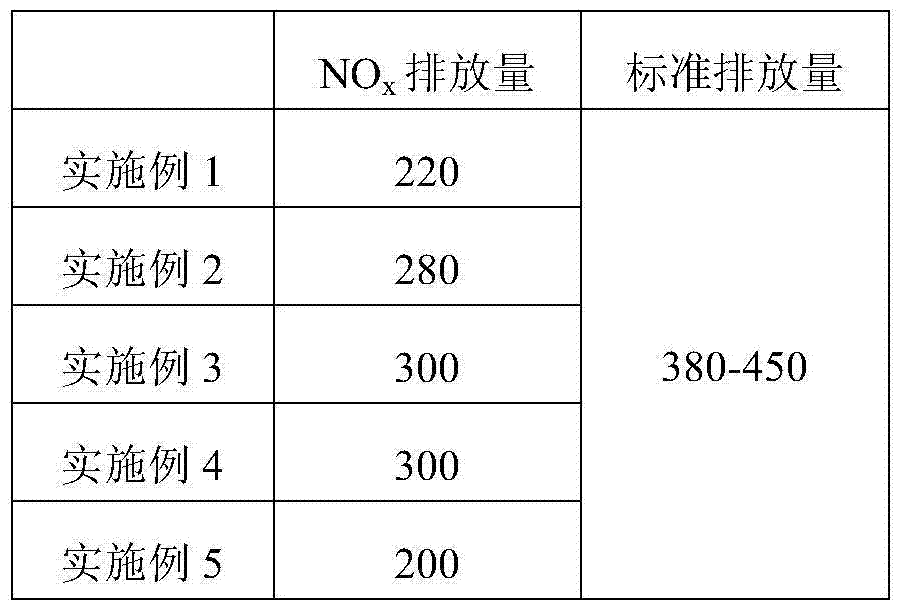

[0025] The method for reducing nitrogen oxides produced by boiler combustion according to the present invention will be further described below according to specific examples and accompanying drawings, but the specific examples and related descriptions do not constitute improper limitations to the technical solution of the present invention.

[0026] In embodiment 1-5, the method for reducing the nitrogen oxides produced by boiler combustion comprises the following steps:

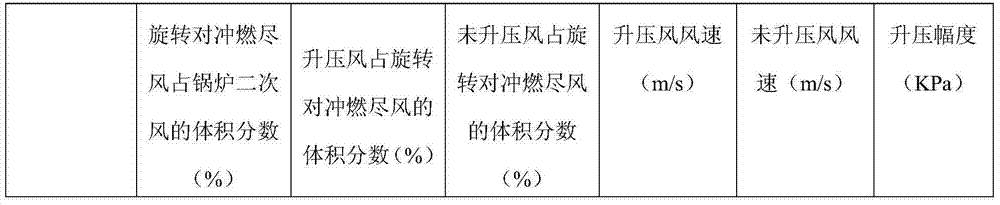

[0027] 1) Extract about 20%-40% of its volume fraction from the secondary air of the boiler as the rotating hedging burnout air;

[0028] 2) Redistribute the rotating hedging overburning air, and divide it into the first part and the second part, wherein the first part accounts for 40%-70% of the total rotating hedging overburning air (by volume fraction), while the second part The second part accounts for 30%-60% of the total amount of rotary hedging overfire air (by volume fraction);

[0029] 3) At a spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com