Novel converter for metal smelting

A new type of metal smelting technology, applied in the field of new metal smelting converters, can solve the problems of fuel consumption, limited and serious air feeding, and achieve the effects of increasing heating speed, enhancing combustion effect, and enhancing combustion temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

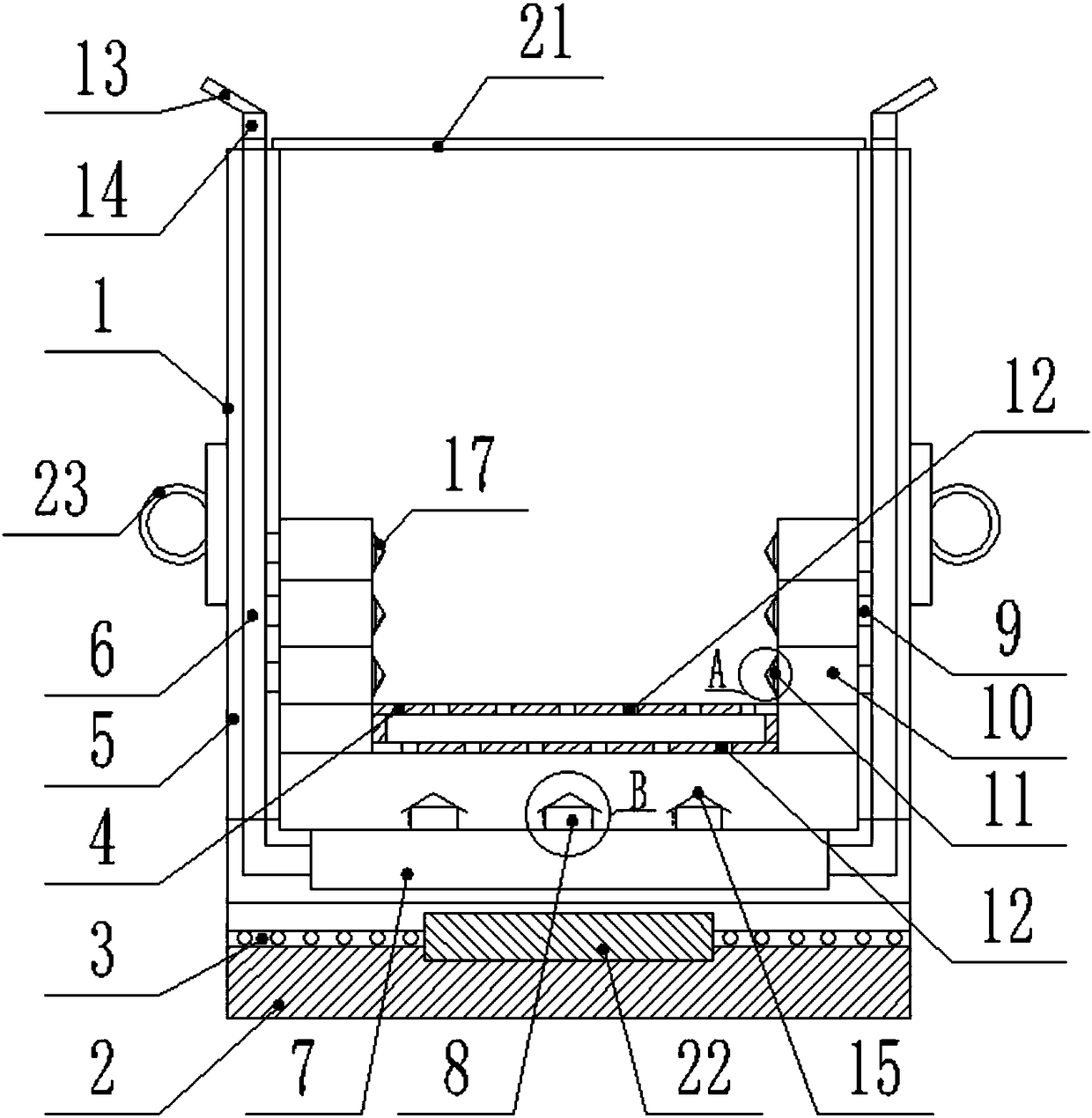

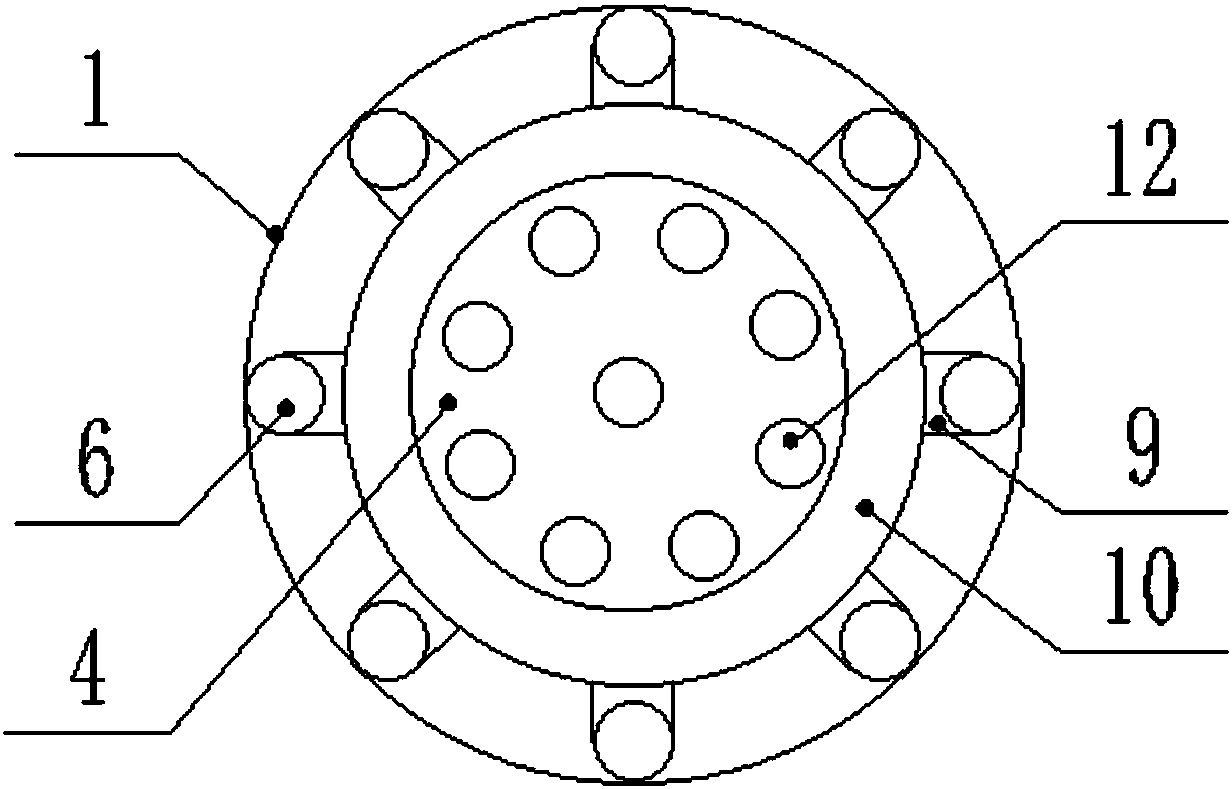

[0033] Such as Figure 1-4As shown, a new converter for metal smelting includes a furnace body 1 and a furnace base 2, the furnace body 1 and the furnace base 2 are connected by a bearing 3, and a positioning shaft 22 is arranged between the furnace body 1 and the base The bottom of the furnace body 1 and the top of the furnace base 2 are respectively provided with grooves matched with the positioning shaft 22, and the positioning shaft 22 is arranged on the groove at the bottom of the furnace body 1 and the concave groove on the top of the furnace base 2. in the space formed by the groove. The positioning shaft 22 makes the furnace body 1 more stable when rotating on the furnace base 2 . The furnace body 1 is provided with a ventilation assembly and a combustion rack 4 for placing fuel; the side wall of the furnace body 1 is provided with several cavities 5; the top of the furnace body 1 is provided with a furnace cover 21, The furnace cover 21 is movably connected with the...

Embodiment 2

[0042] Such as Figure 1-4 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, the first output The outlet end of the air duct 8 is provided with a first baffle plate 15 with a herringbone cross section, the top of the first air outlet duct 8 is embedded between the first baffle plates 15, and the side of the first air outlet duct 8 The wall is provided with a through first ventilation hole 16 . The air can escape from the first ventilation hole 16 and will not be blocked by residues on the air guide pipe 6 pipes. The first baffle plate 15 can solve the problem that the residue generated by fuel combustion blocks the air guide pipe 6 pipes and prevents the outside air from entering the air guide pipe 6. In the converter, the fuel is not in sufficient contact with the air, which affects the normal operation of the c...

Embodiment 3

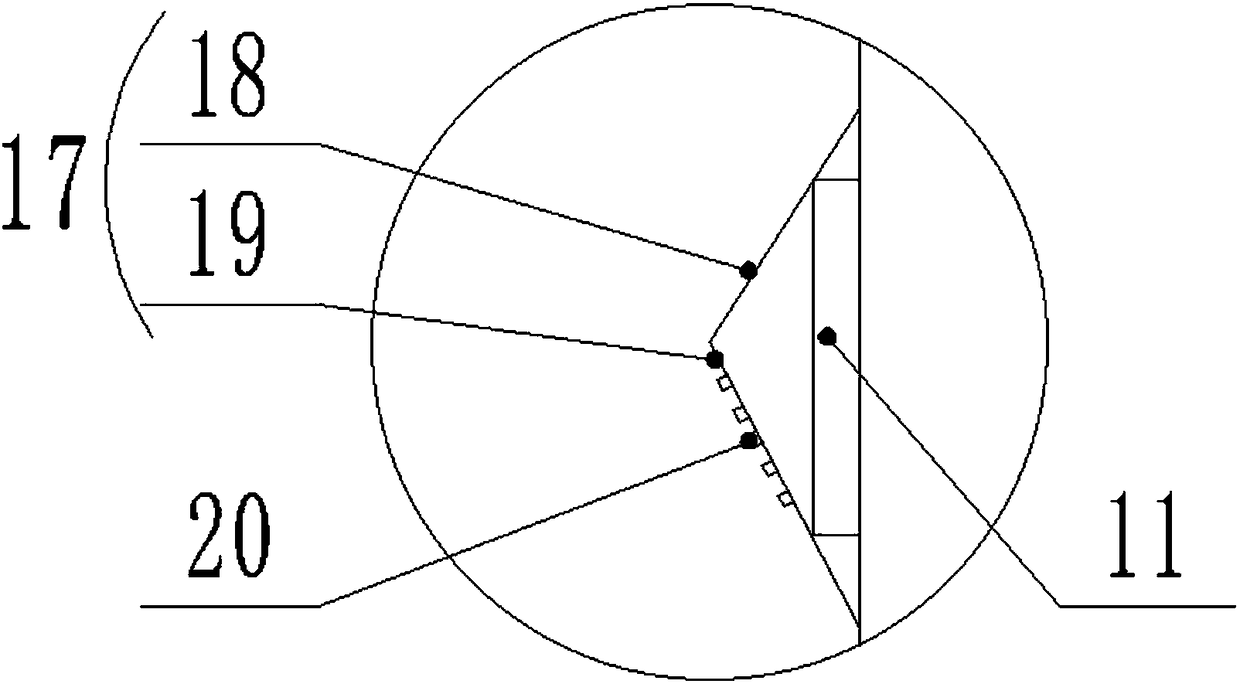

[0044] Such as Figure 1-4 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, the second output The outlet end of air duct 11 is provided with the second baffle plate 17 that cross-section is herringbone, and described second baffle plate 17 is made up of upper baffle plate 18 and lower baffle plate 19, and the upper baffle plate 18 and lower baffle plate 19 One end is connected, and the other ends of the upper baffle plate 18 and the lower baffle plate 19 are respectively connected with the side walls of the ventilation chamber 10 , and the lower baffle plate 19 is provided with a plurality of second ventilation holes 20 . The second ventilation hole 20 on the lower baffle plate 19 can diffuse the air in the ventilation chamber 10 into the body of heater 1, so that the fuel in the burning state on the combustion r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com