Patents

Literature

116results about How to "Large injection volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

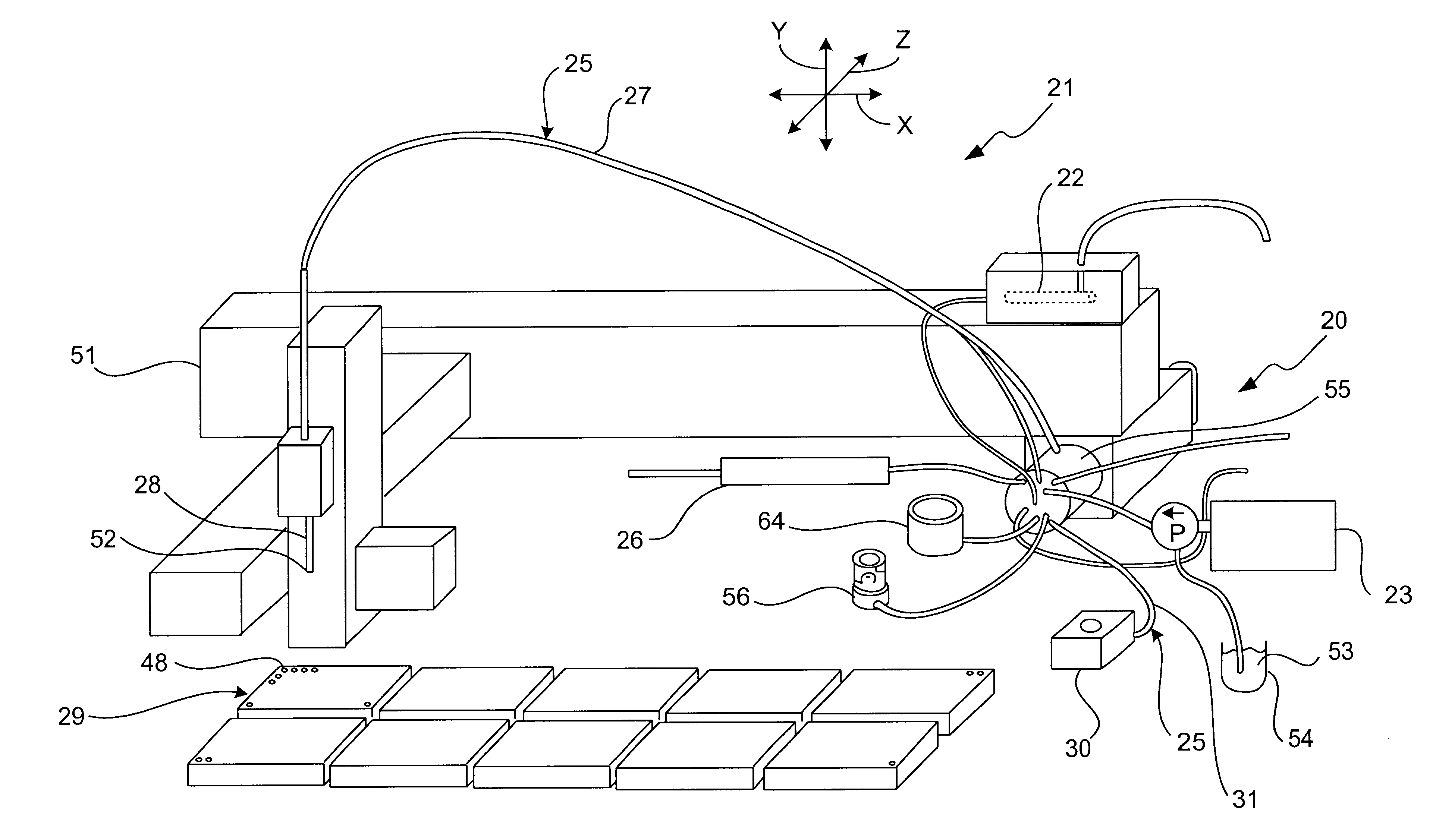

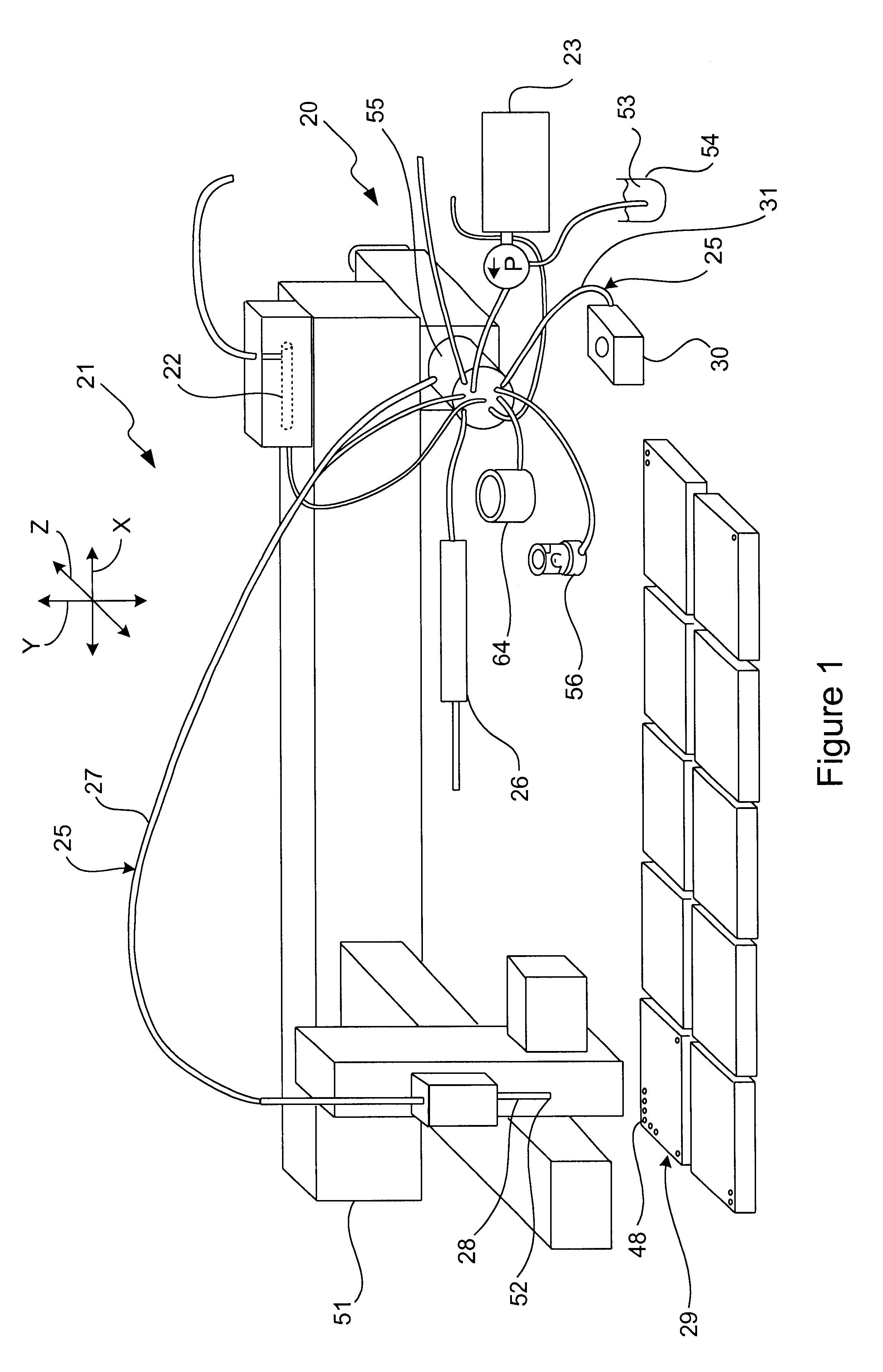

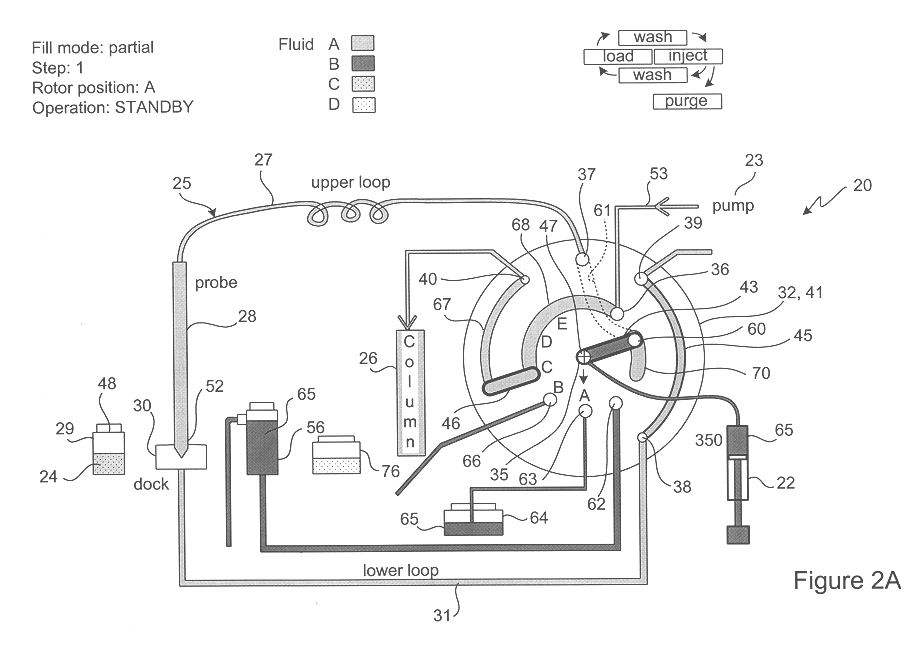

Multi-valving sample injection apparatus

A multi-function valve apparatus for use with a Probe-In-Loop (PIL) architecture sample injection assembly which enables both Partial-Fill and Complete-Fill injections. The rotor element is rotatable about a rotation axis relative the stator between: a Load Position, an Overfill Position, and an Injection Position. In the Load Position, a first bridge channel fluidly couples a metering syringe to the sample loop assembly enabling the probe to aspirate one of a discrete volume of sample into the probe, during a Partial-Fill Mode, and a second volume of sample into the probe, during a Complete-Fill Mode. In the Overfill Position, in the Complete-Fill Mode, a second bridge channel fluidly couples a downstream loop portion to a waste port, and the first bridge channel fluidly couples the metering syringe to an upstream loop portion of the sample loop assembly. This enables the metering pump to dispense the sample from the probe into the downstream loop portion and out the waste port to completely fill the downstream loop portion and the second bridge channel with a substantially precise known volume. In the Injection Position, the second bridge channel fluidly couples the downstream loop portion to the analyzing device to inject the sample into the analyzing device, in either the Partial-Fill Mode or and the Complete-Fill Mode.

Owner:IDEX HEALTH & SCI

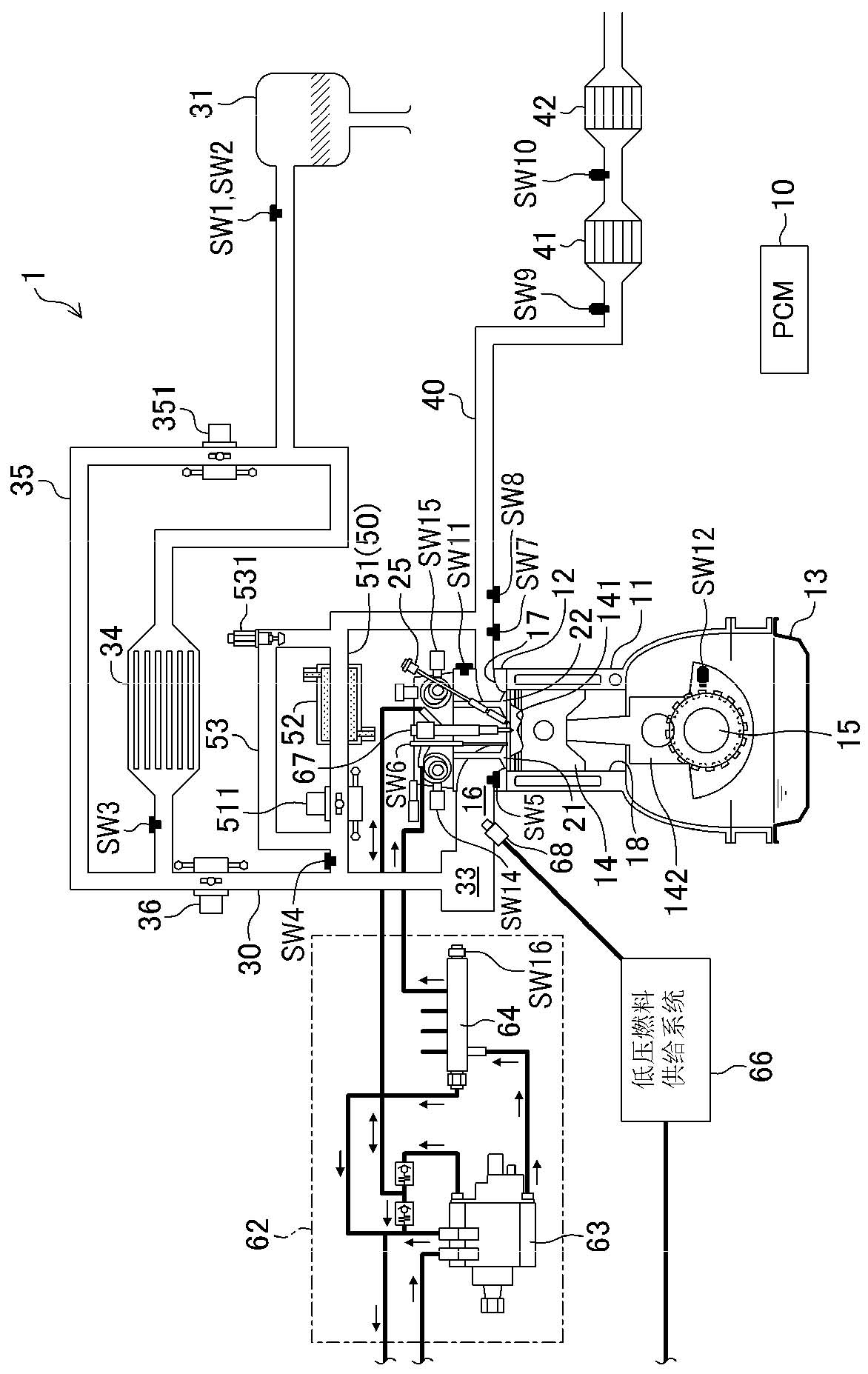

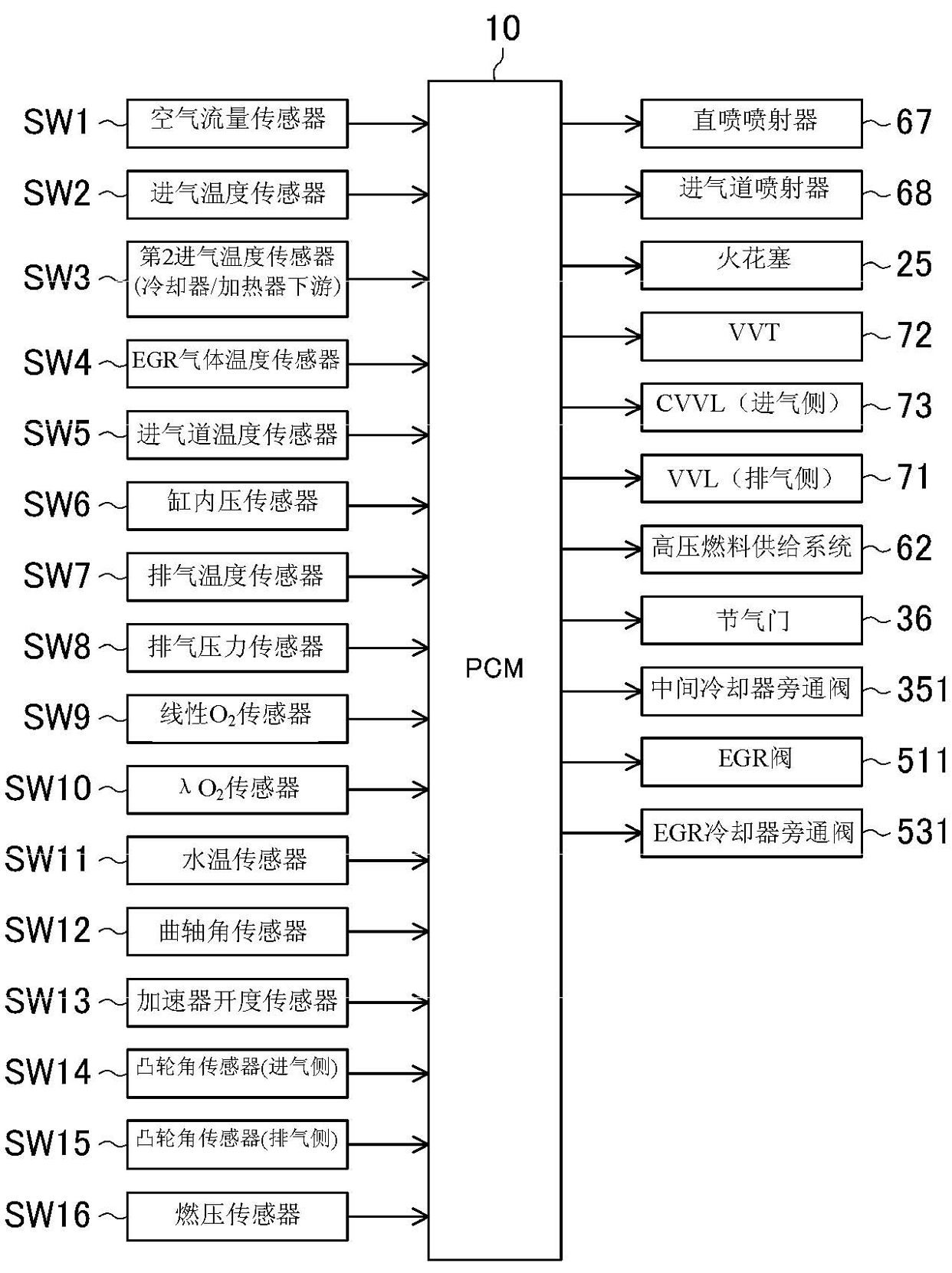

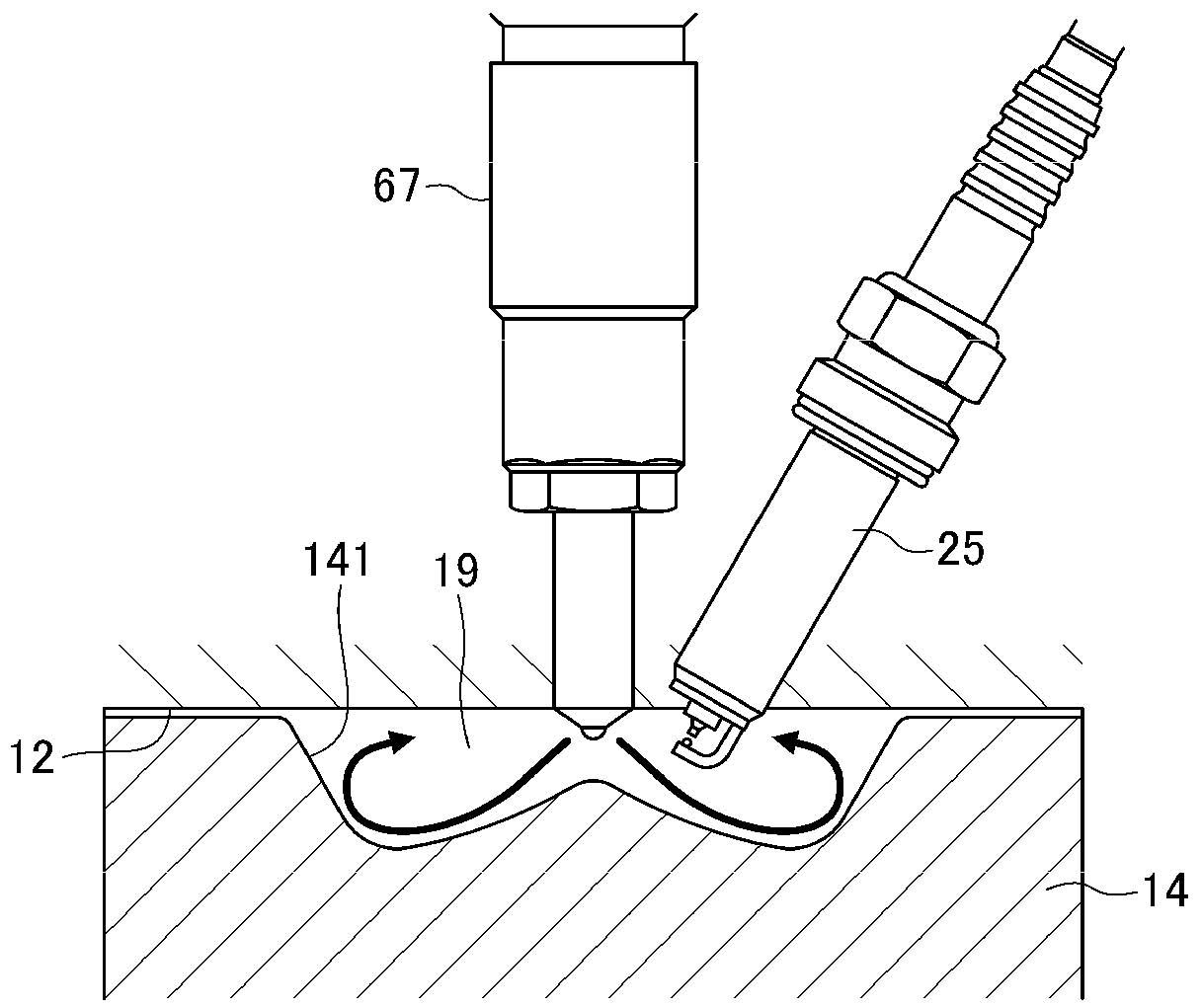

Control device of spark-ignition gasoline engine

InactiveCN102650239ALarge injection volumeShorten the formation periodElectrical controlInternal combustion piston enginesInjectorFuel supply

The disclosure provides a control device of a spark-ignition gasoline engine. According to the invention, in a spark-ignition gasoline engine (1) with a higher high compression ratio, abnormal burning in a high load area can be avoided. When an operating state of an engine body is within a low engine speed range, a controller (PCM 10) operates a fuel pressure variable mechanism (a high pressure fuel supply system 62) so that a fuel pressure is higher within a high engine load range compared to a low engine load range, the controller operates, within the high engine load range, a fuel injection mechanism to perform at least a fuel injection into the cylinder by a cylinder internal injection valve (a straight spray injector 67) at a timing during a retard period from a late stage of a compression stroke to an early stage of an expansion stroke, and the controller (10) operates, within the high engine load range, an ignition plug to ignite at a timing during the retard period and after the fuel injection.

Owner:MAZDA MOTOR CORP

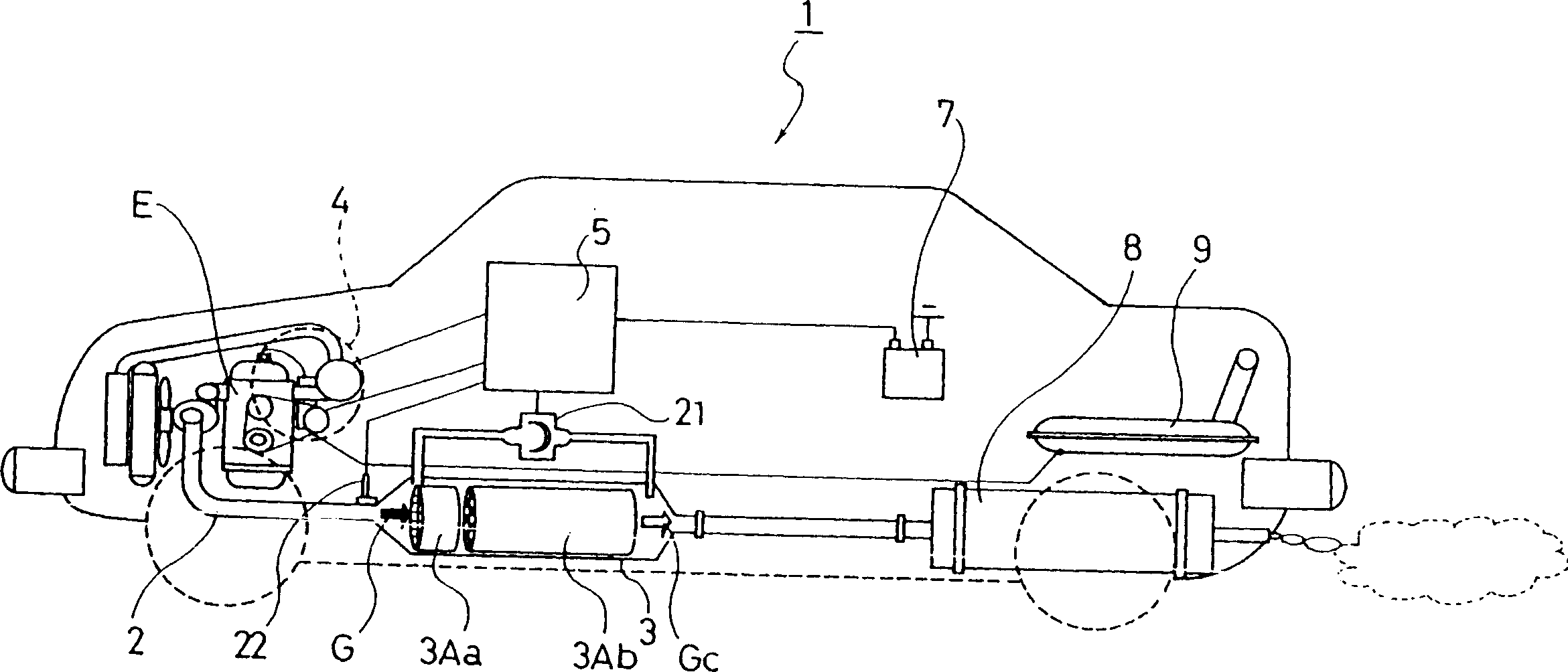

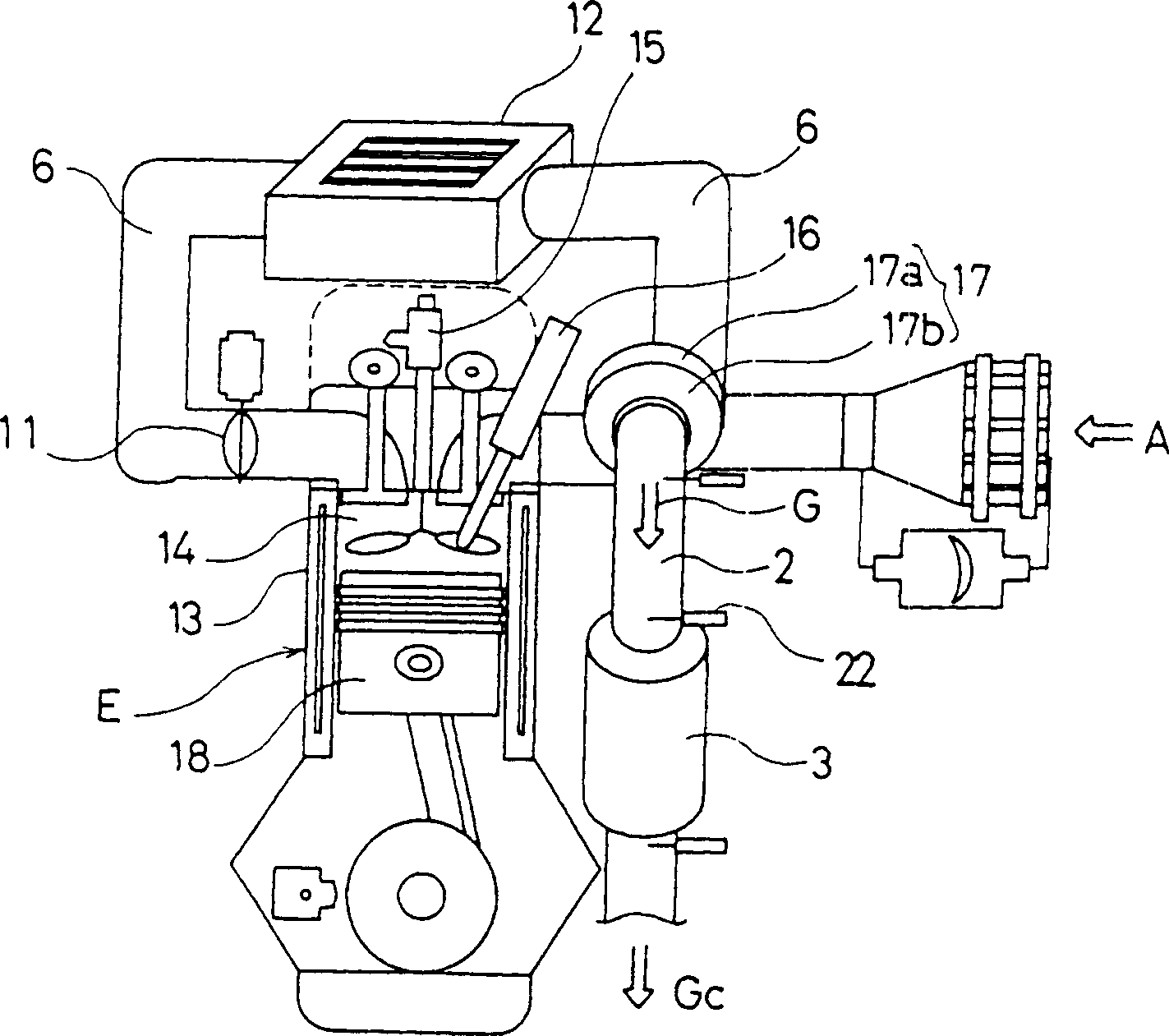

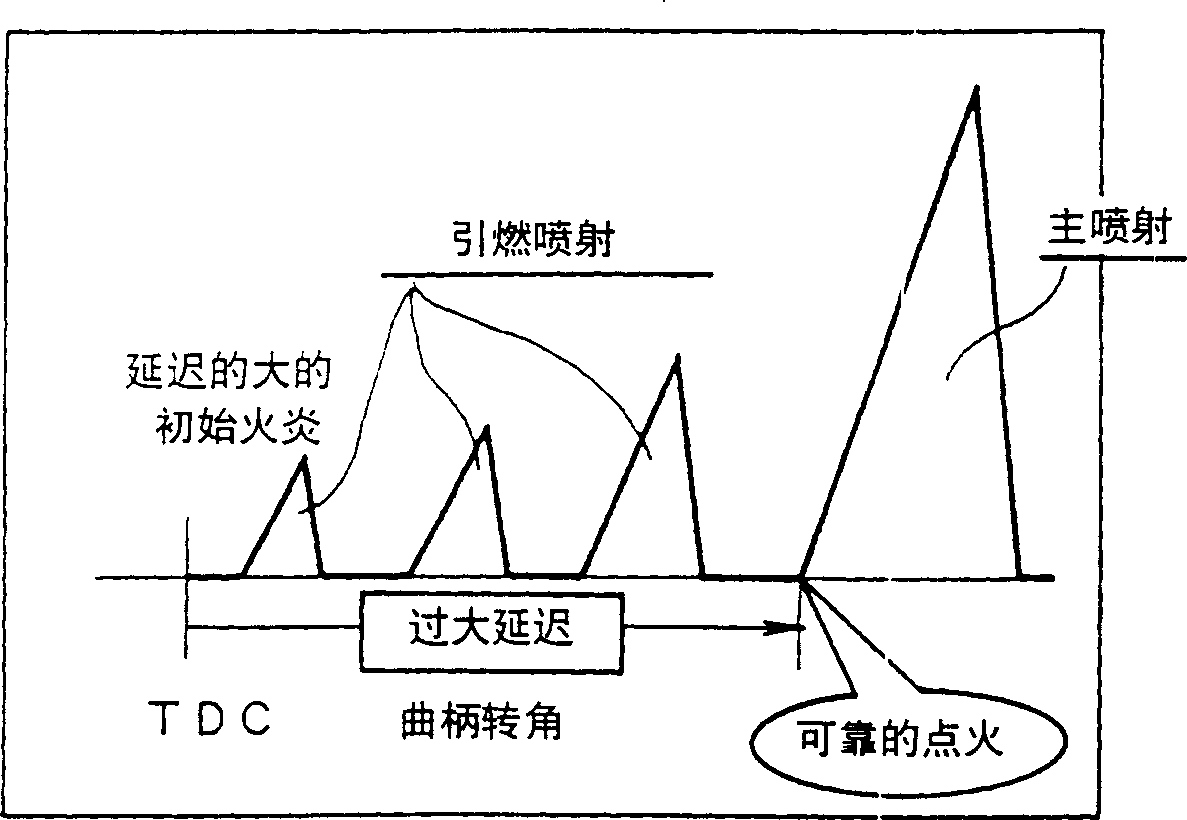

Waste gas purification system

InactiveCN1517526ALarge injection volumeDoes not affect the productionElectrical controlInternal combustion piston enginesExhaust fumesEngineering

An exhaust gas purifying system (1) aving a continuous regeneration DPF (3) installed in the exhaust passage (2) of a diesel engine (E) provided with a glow plug (16) and a regeneration control means for regenerating the continuous regeneration DPF (3), is constituted so that the regeneration control means performs retarded injection or post-injection in the control of fuel injection into a cylinder (13) and heating the inside of the cylinder (13) by the glow plug (16) for regenerating the continuous regeneration DPF (3). Thereby, when raising the temperature of exhaust gas in the regeneration of the continuous regeneration DPF (3), it is possible to prevent the generation of white fumes and misfire and to raise the exhaust gas temperature efficiently and substantially. Therefore, it is possible to prevent the temperature of a catalyst and a DPF from being abnormal high and to prevent the deterioration and the melt down of the catalyst.

Owner:ISUZU MOTORS LTD

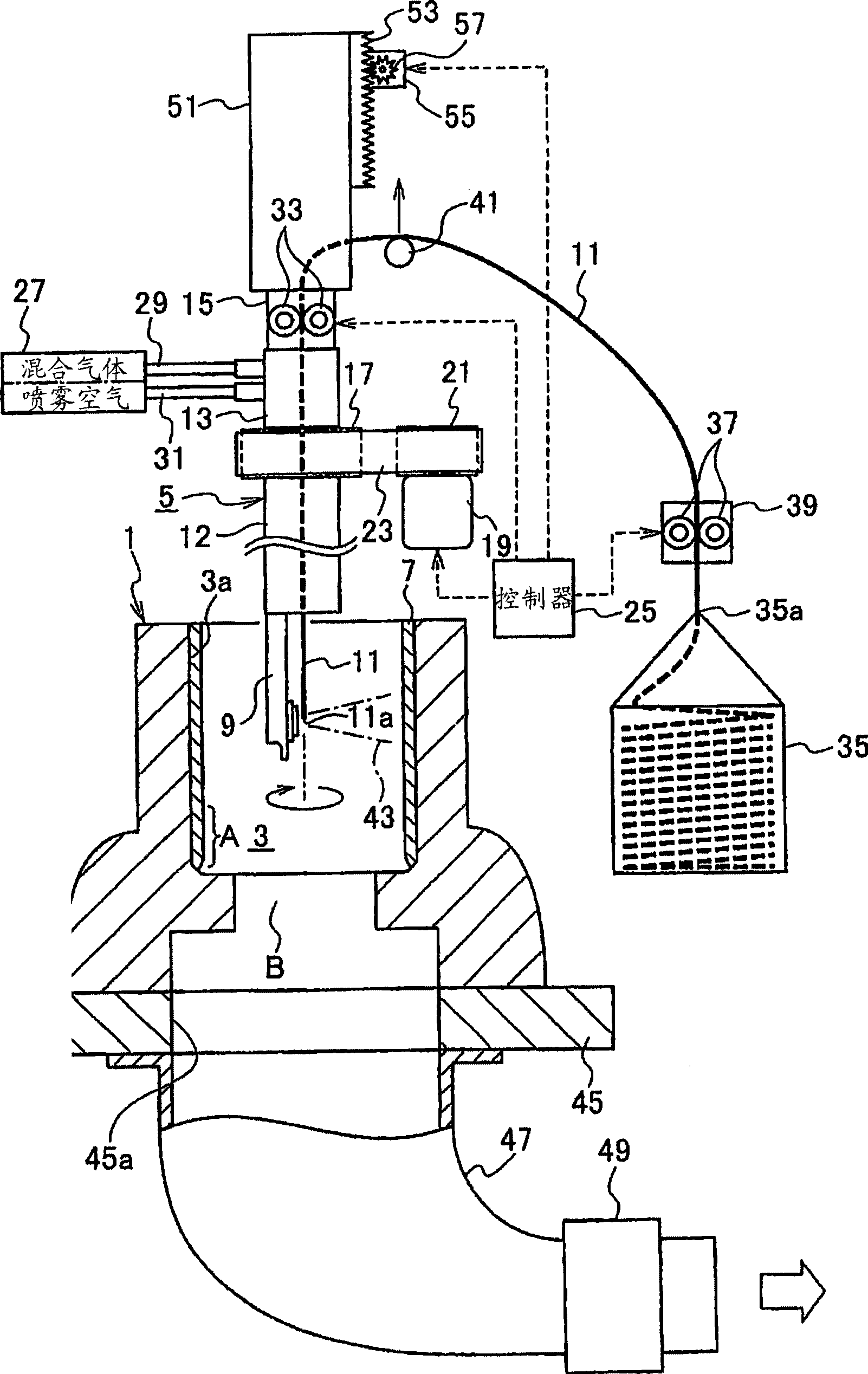

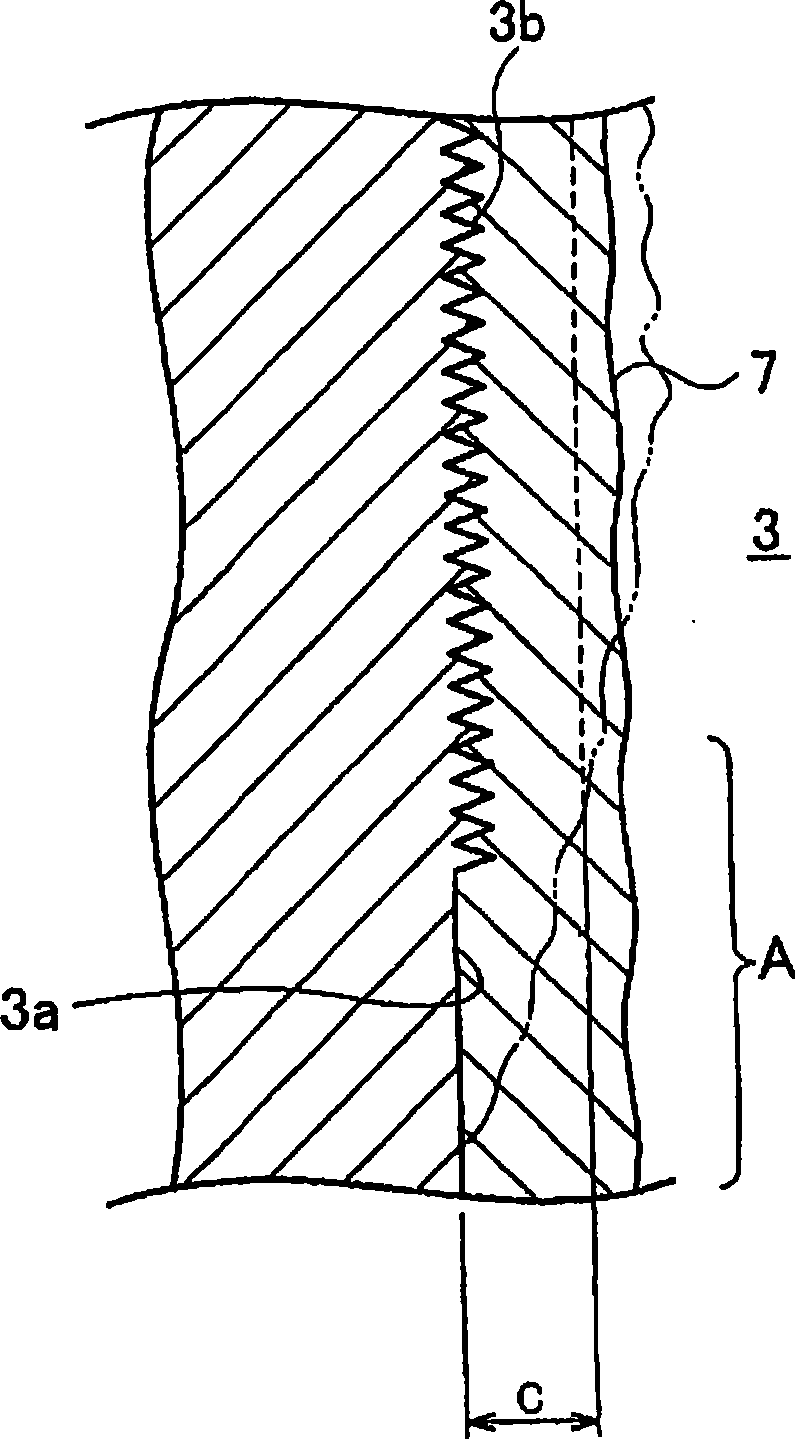

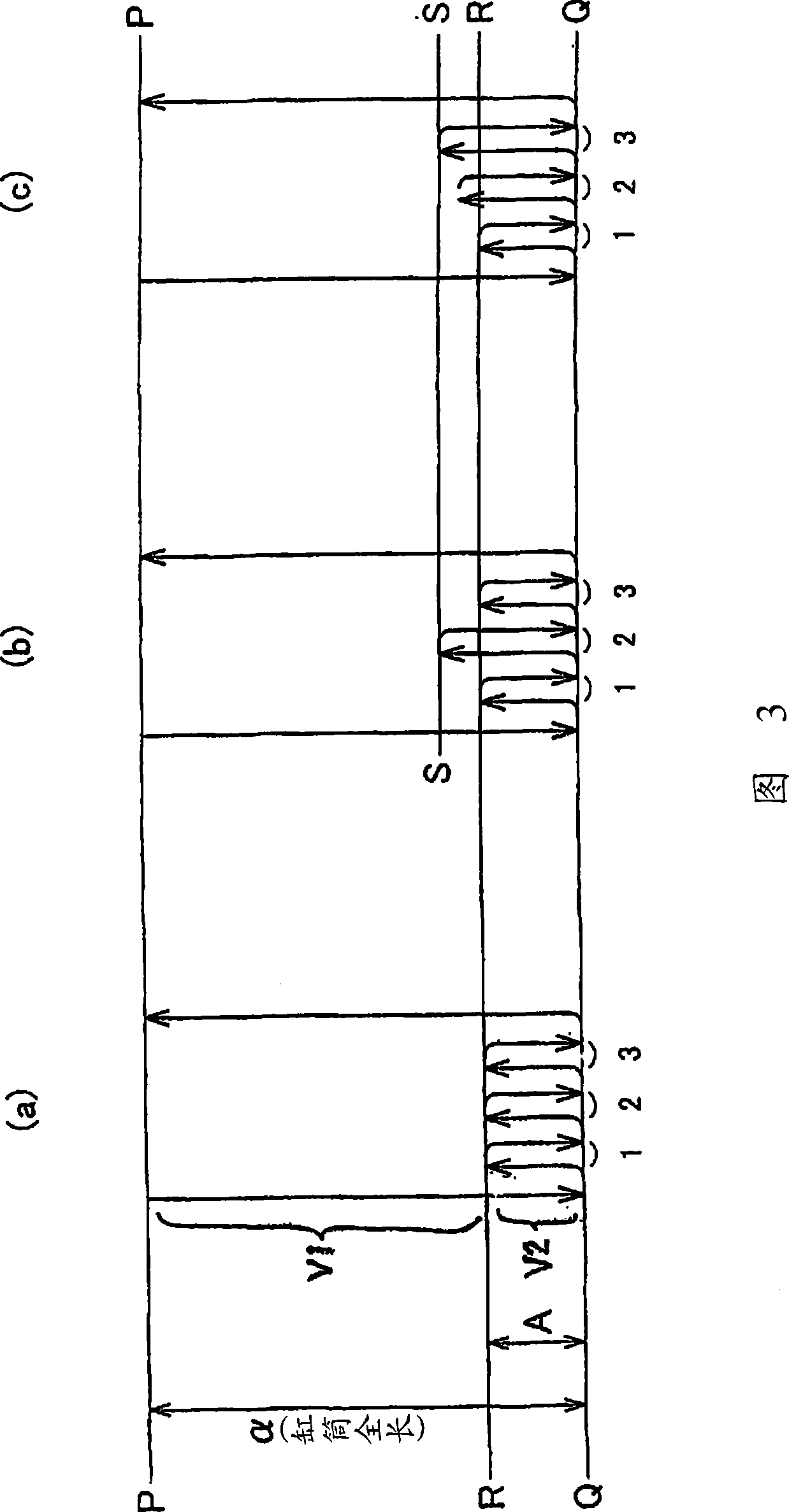

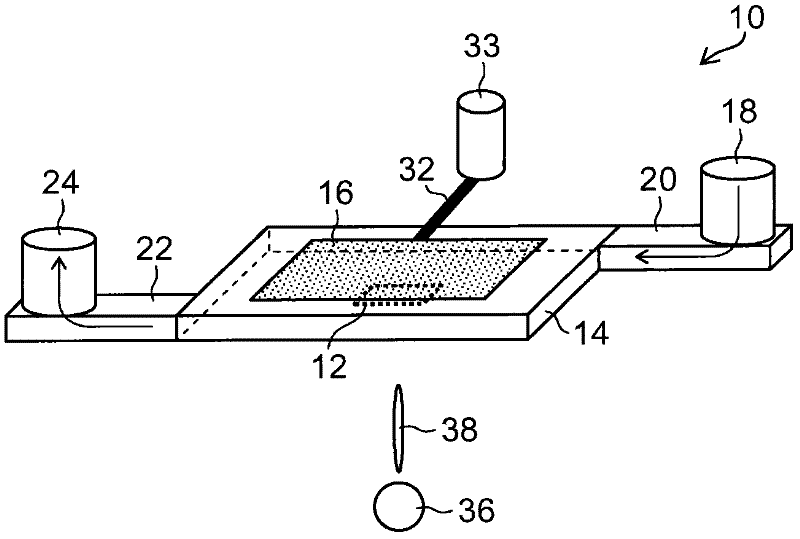

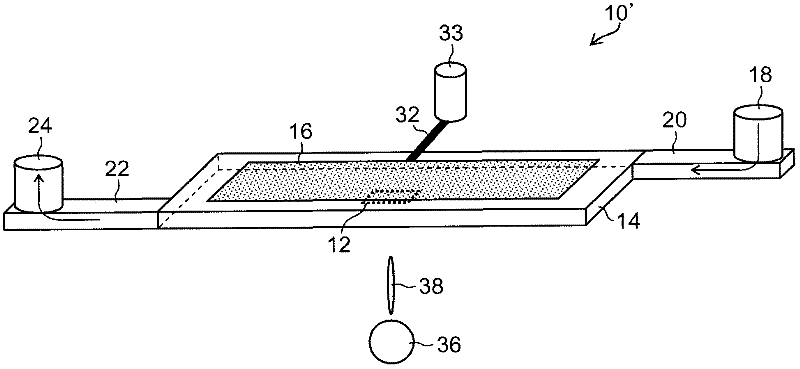

Sprayed film forming method and apparatus

ActiveCN101418426ALarge injection volumeIncrease the plating timeMolten spray coatingForeign matterElectrical and Electronics engineering

The present invention provides a method for forming sprayed film and a device thereof, which can restrain the operating time and the increase of material used for spraying, and furthermore the film thickness of the axial end of the round hole is equal with that of other part. The device for forming sprayed film causes that a spraying film (7) is formed on the inner surface (3a) of the cylinder at a state that a spraying gun (5) rotates and axially moves simultaneously in the cylinder (3). Simultaneously a sucking device (49) is used for sucking the air in the cylinder (3) for leading to the air flowing in the cylinder (3) for preventing the entering of foreign object into the spraying film (7). A tendency that the air velocity in the cylinder (3) is larger than the velocity of a preset area A at the axial end of the suction side exists. Under the influence of factors of higher velocity, cylinder shape, etc., the supplying velocity of metal wire (11) which is used as spraying material at the preset area A in which the thickness of spraying film (7) easily becomes thin to the spraying gun (5) is higher than the supplying velocity of other component. Thereby, the film thickness of the spraying film (7) at the preset area A can be increased and the whole film thickness can be homogenized.

Owner:NISSAN MOTOR CO LTD

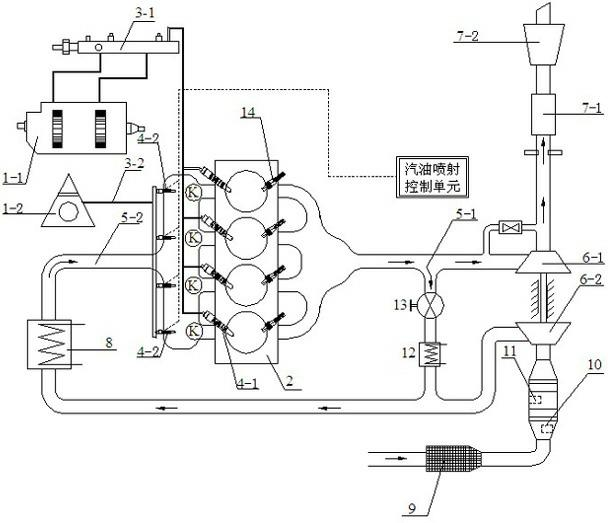

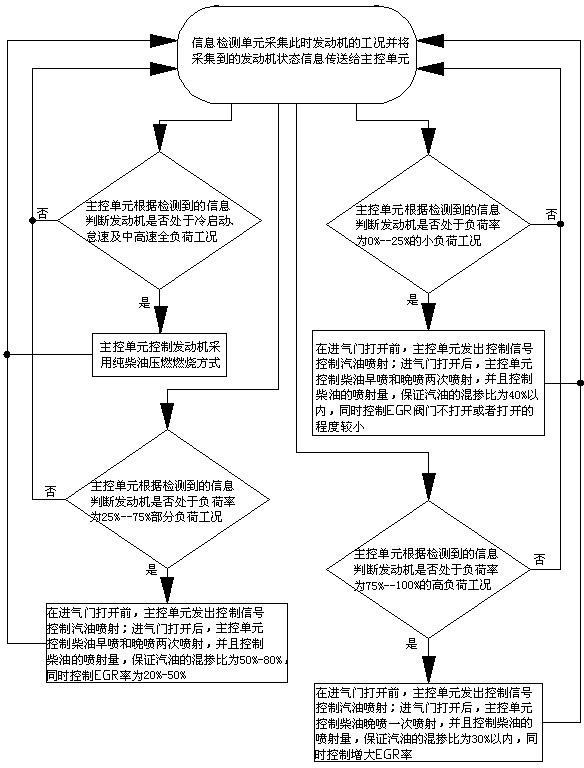

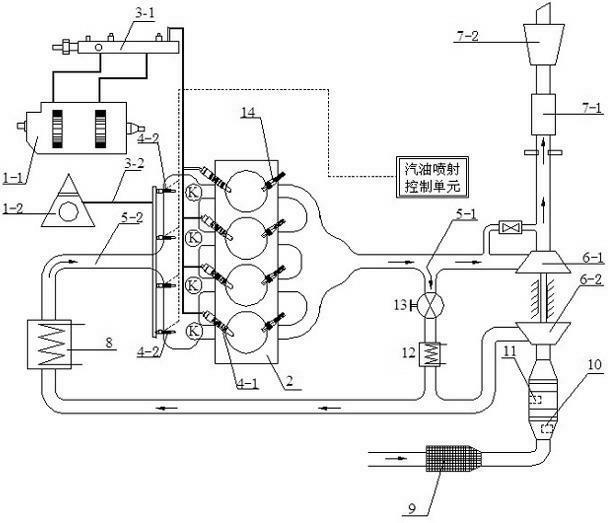

Gasoline premixing and diesel igniting engine as well as control method thereof

ActiveCN102678363AGuaranteed blending ratioImprove the exhaust effectElectrical controlMachines/enginesCommon railControl signal

The invention discloses a gasoline premixing and diesel igniting engine as well as control method thereof. The gasoline premixing and diesel igniting engine includes a diesel engine and a main control unit for controlling the action of the engine, wherein a control signal output end of the main control unit is connected with the diesel engine, at least one gasoline injector is arranged on an air inlet pipeline of the diesel engine, and the gasoline injectors are connected with a gasoline electronic pump through a gasoline common rail; the control method is as follows: the main control unit receives information acquired by an information acquisition unit; and further, the main control unit judges the working condition of the engine as per various received information, and selects corresponding ignition mode to start the engine. The gasoline premixing and diesel igniting engine has simple structure and low cost, only requires arrangement of multiple gasoline injectors on the air inlet pipeline of the existing diesel engine, and meanwhile, can efficiently lower the oil consumption and reduce emission of harmful substances. The gasoline premixing and diesel igniting engine is applicable to engines used in fields of automobiles, locomotives, steamships, farm machinery, engineering machinery and the like.

Owner:GREAT WALL MOTOR CO LTD

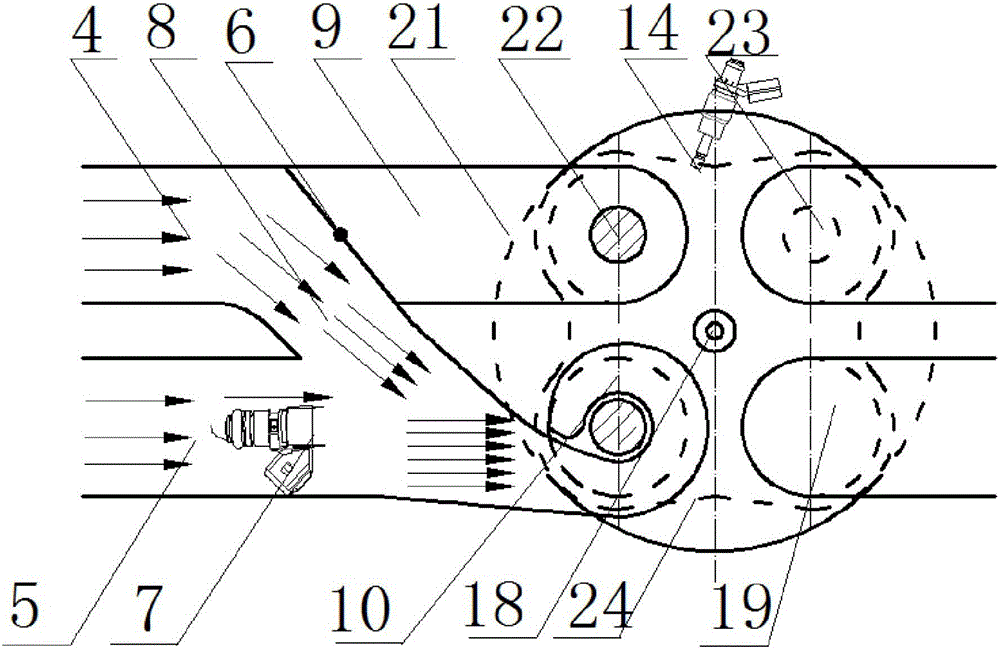

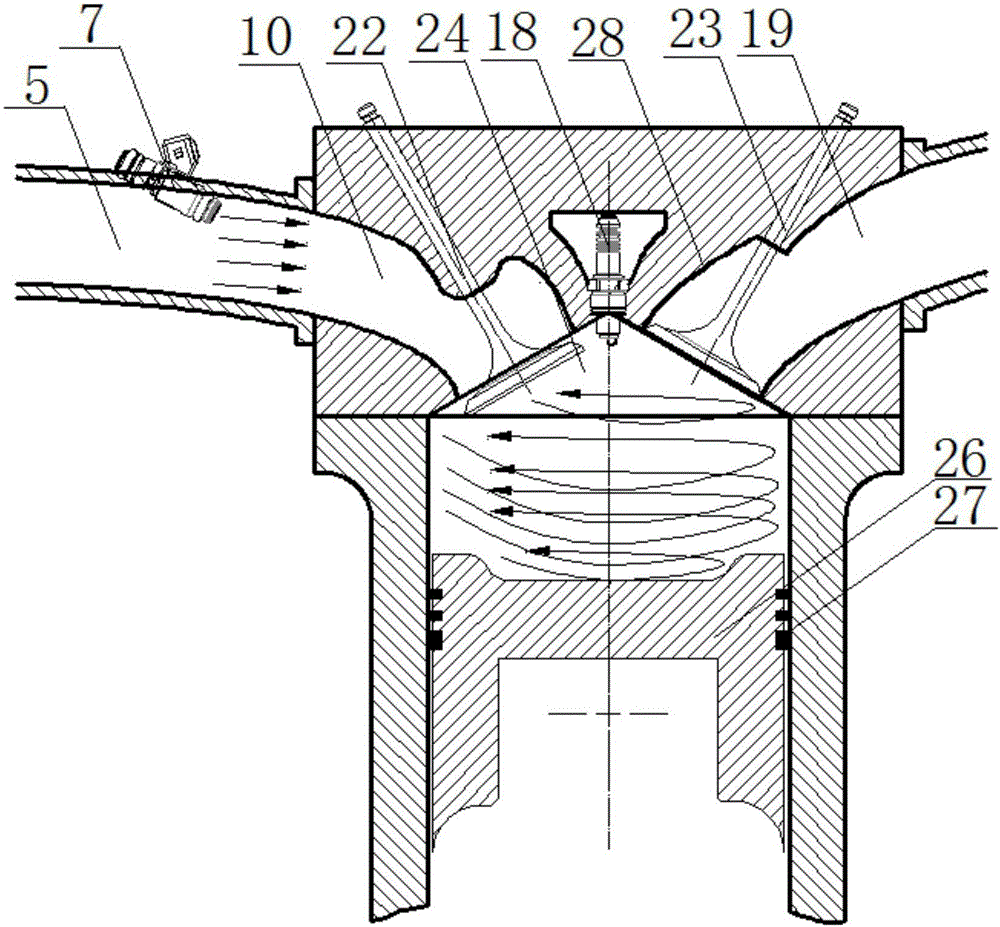

Dual-fuel spark-ignition internal combustion engine based on variable air channel, and control method

InactiveCN105715367ABurn fasterImprove economyInternal combustion piston enginesAir intakes for fuelCombustionInternal combustion engine

The invention designs a dual-fuel spark-ignition internal combustion engine based on a variable air channel, and a control method, aims at solving the problem that effective adjustment cannot be carried out on an intake flow and an airflow direction in an air channel, of an internal combustion engine adopting the traditional intake structure, and in particular, an internal combustion engine adopting a four-valve structure, and solving the problems of instable combustion, difficult ignition, fire and the like generated during lean combustion, and develops a dual-fuel spark-ignition internal combustion engine based on a variable air channel, and a control method. The invention provides a variable intake system. According to the variable intake system, the optimal airflow movement under different working conditions is obtained through control for the opening and closing of a swirl control valve, and in combination with a piston top surface with a special shape. The invention discloses a combined internal combustion engine technology for carrying out in-cylinder direct injection and intake channel injection respectively on the basis of two fuels. The different combustion modes of an in-cylinder mixed gas are realized through control for an injection time and an injection pulse width, and in combination with an airflow movement, and then the working efficiency of the internal combustion engine under different working conditions is improved, and oil consumption and emission are reduced.

Owner:JILIN UNIV

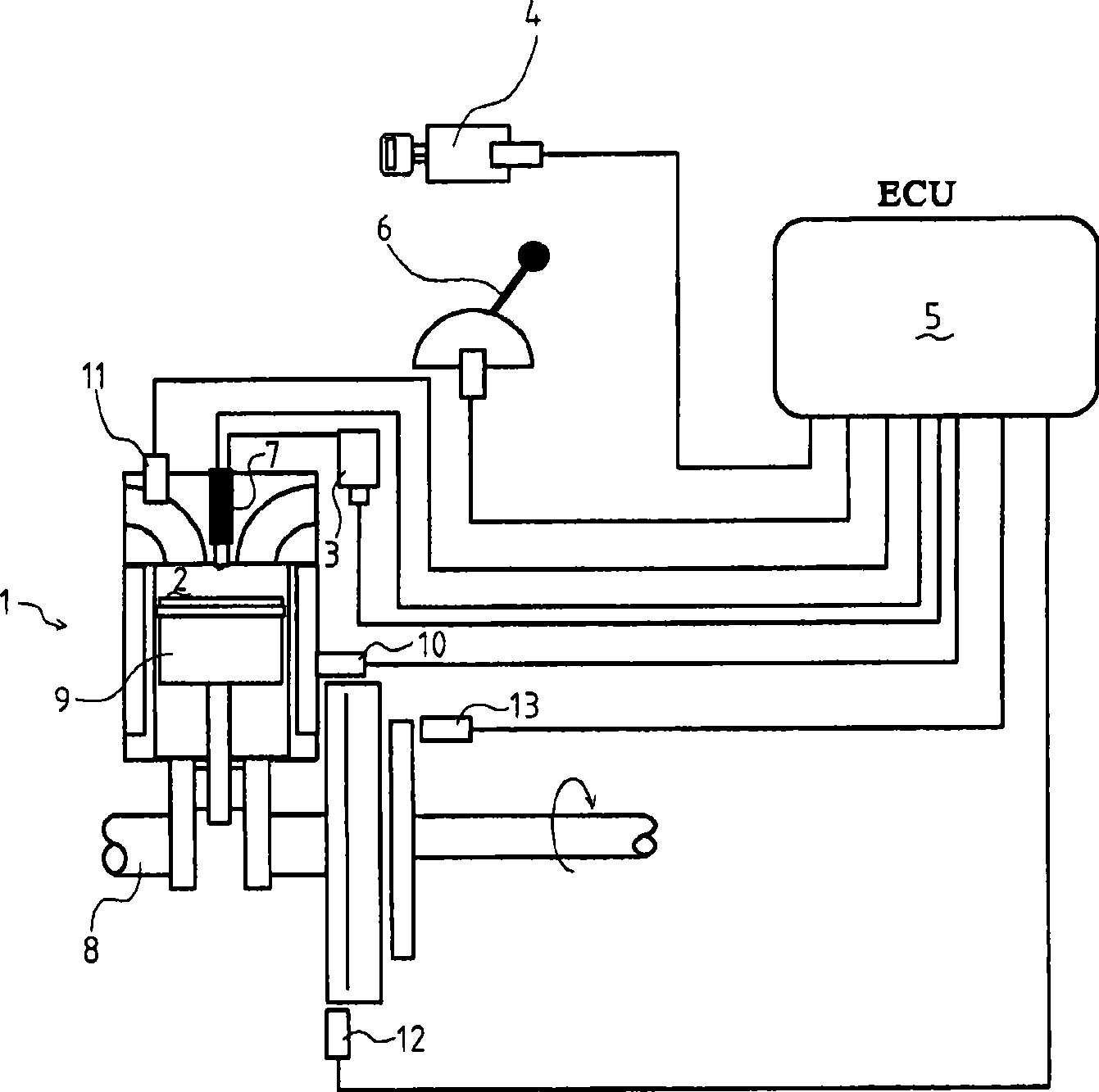

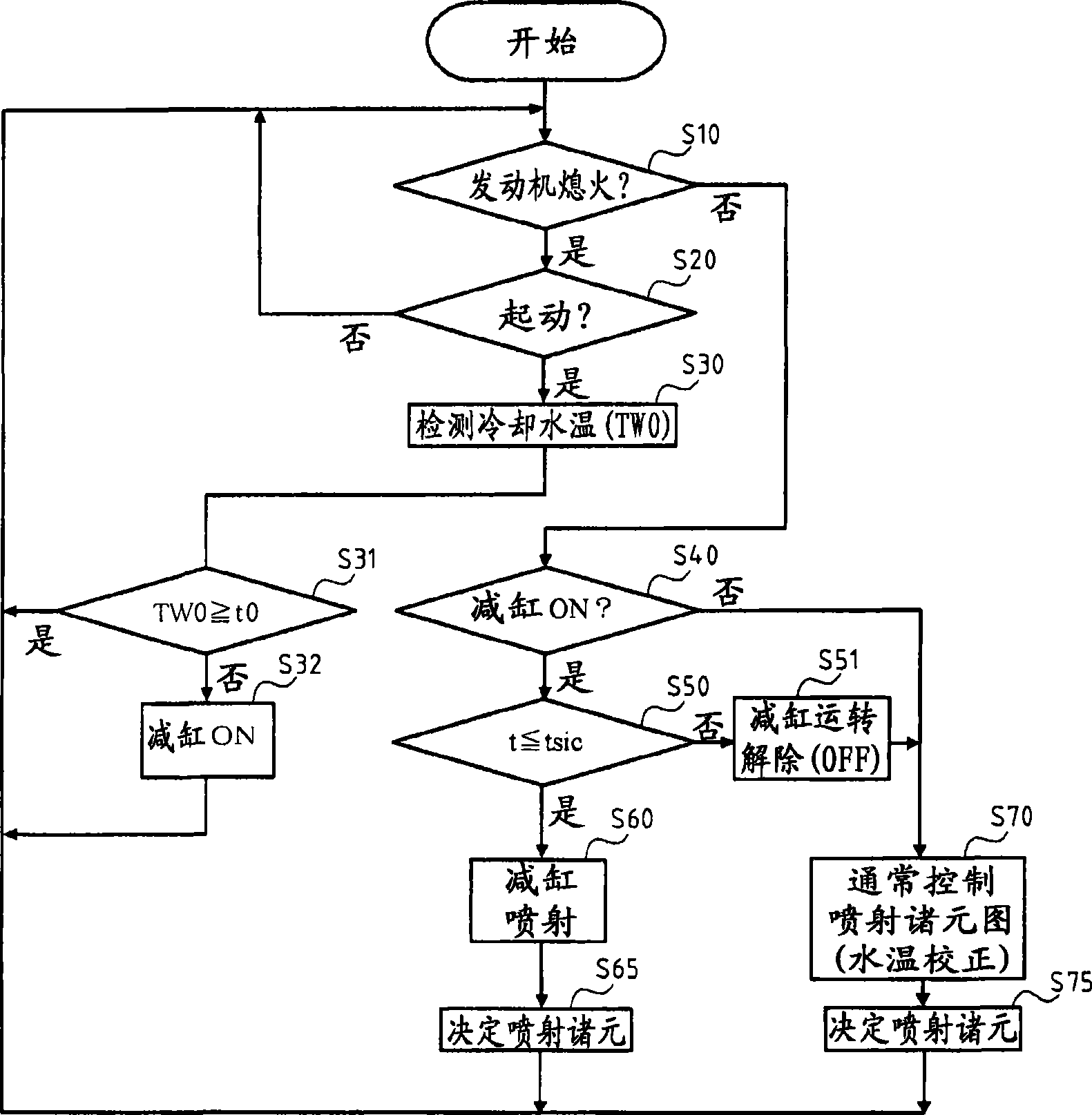

Method of controlling internal combustion engine

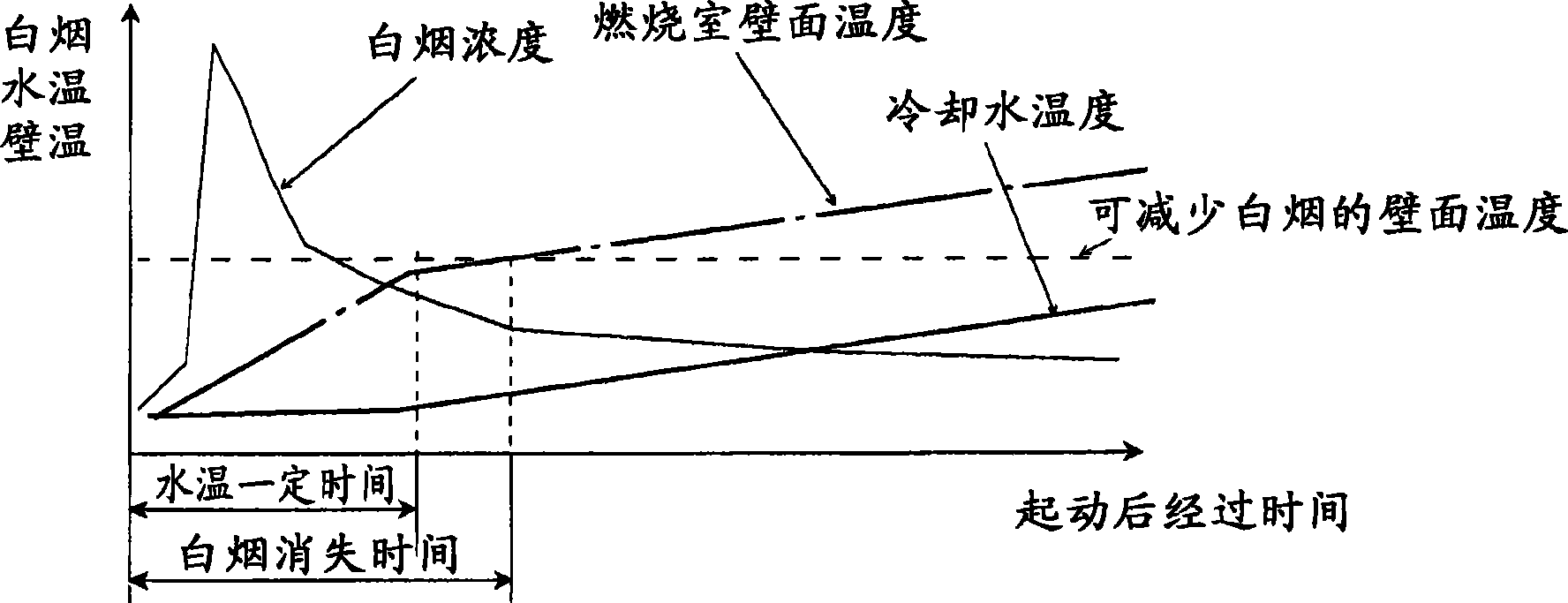

InactiveCN101535614ALarge injection volumeRaise the combustion temperatureElectrical controlInternal combustion piston enginesTime lagExternal combustion engine

A method of controlling an internal combustion engine, in which engine operation with a reduced number of cylinders is controlled according to an idling speed after starting the engine to thereby minimize discharge of white smoke during a time lag for temperature equilibrium immediately after a cold start. The method uses a coolant temperature detection means (10) for detecting the temperature of the coolant of the internal combustion engine (1), an engine speed detection means (12) for detecting the speed of the engine, and control means (5) for controlling operation of the engine according to the temperature of the coolant and the engine speed. When the engine is determined to be in a cold start, engine operation with a reduced number of cylinders is started, and in this engine operation, fuel is injected into the cylinders for a predetermined time period after the speed of the engine reaches a predetermined level after the start of the engine.

Owner:YANMAR POWER TECHNOLOGY CO LTD

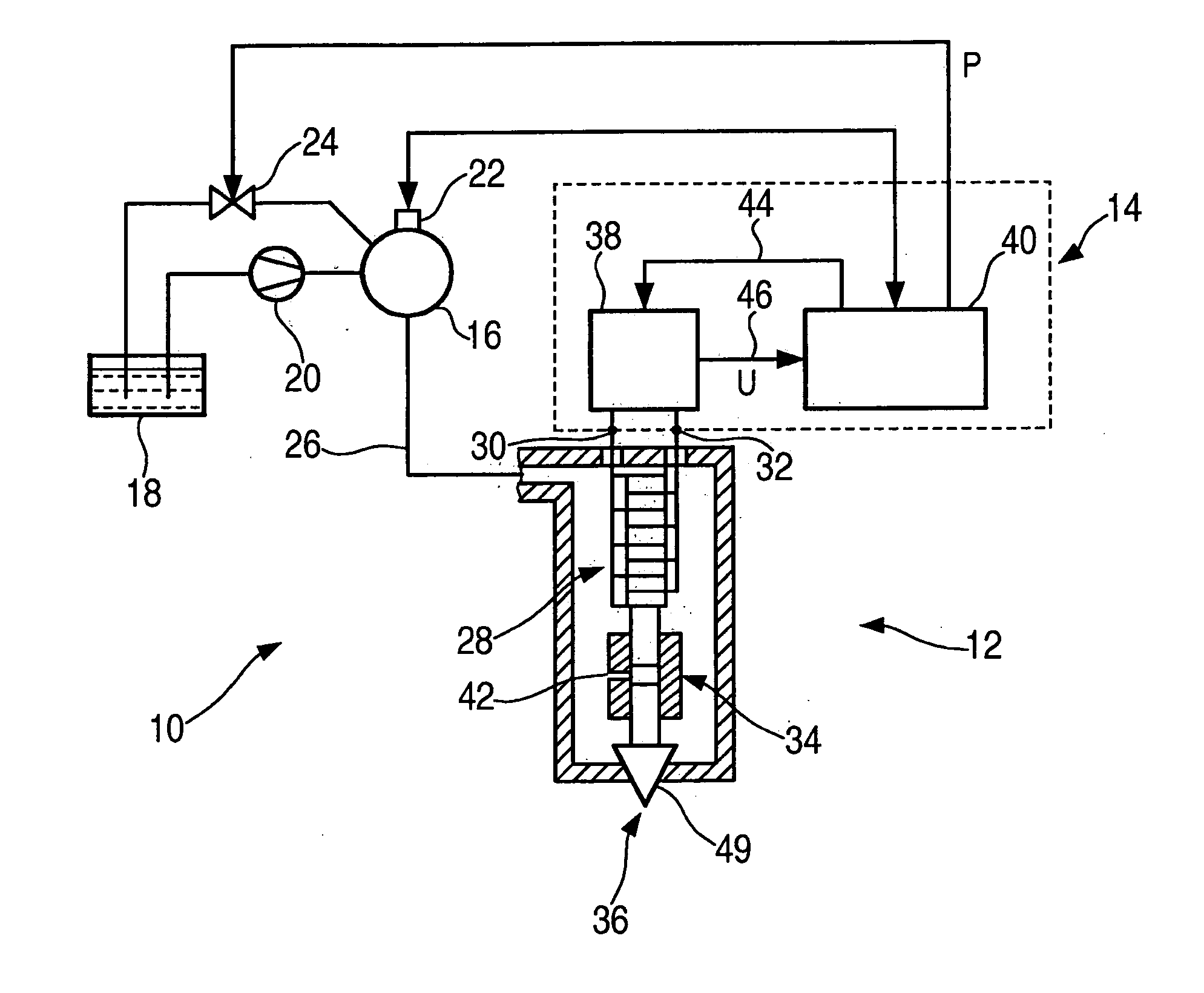

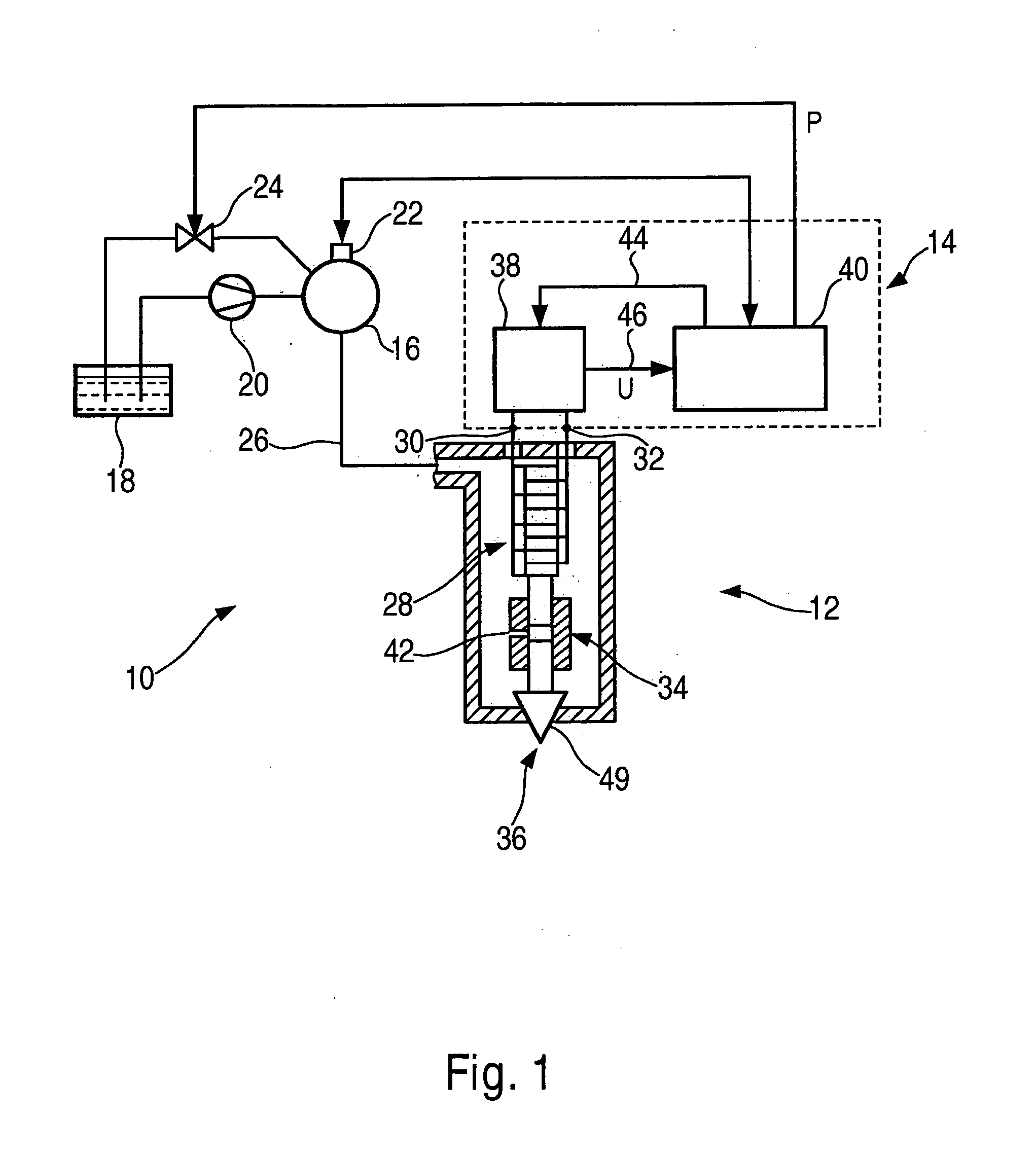

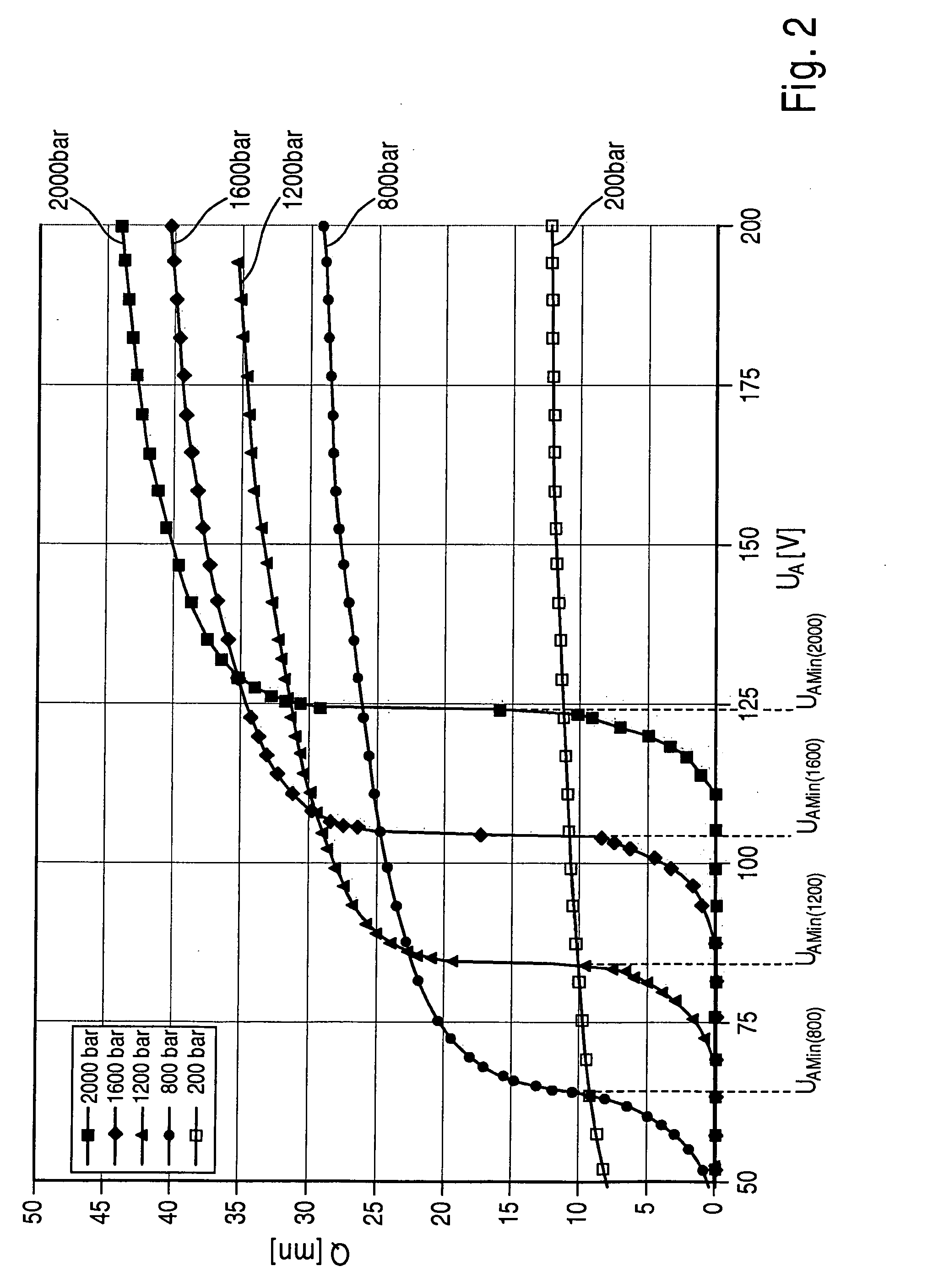

Method for Determining an Opening Voltage of a Piezoelectric Injector

InactiveUS20100275885A1Reduce voltageLarge injection volumeInternal-combustion engine testingElectrical controlElectricityPiezoelectric actuators

A method for determining an opening voltage of an injector having a piezo actuator, in particular an injector of an internal combustion engine, in which an output voltage is applied at the piezo actuator in the closed state of the injector, and the voltage is lowered by energizing the piezo actuator so as to open the injector. The energy supply is interrupted at a holding voltage and the voltage change present at the piezo actuator is then measured over the time, the reaching of the opening voltage being inferred in the case of a voltage rise.

Owner:ROBERT BOSCH GMBH

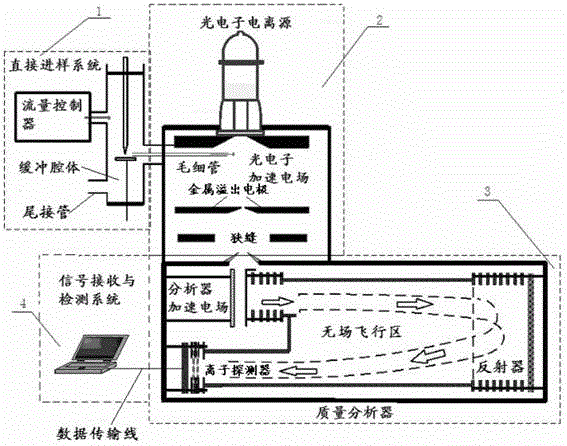

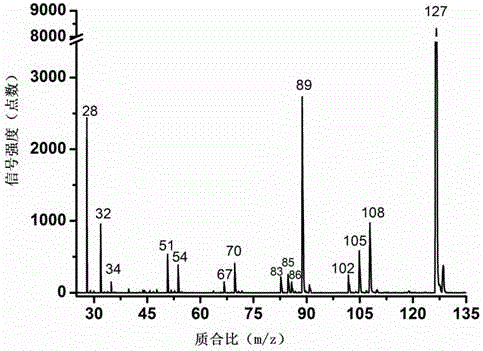

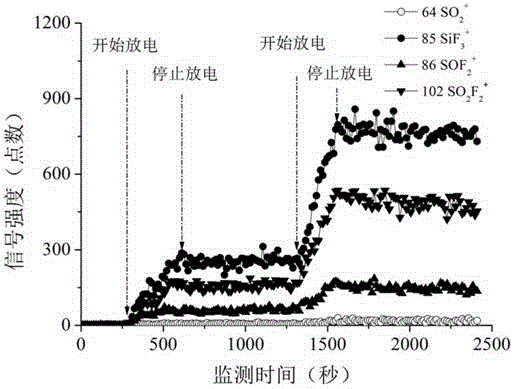

On-line detection method for SF6 gas in electrical equipment

The invention discloses an on-line detection method for SF6 gas in electrical equipment. On-line mass spectrometer is employed for detection analysis. An employed ionization source of the on-line mass spectrometer is a photoelectron ionization source. A sample gas is firstly subjected to dedusting processing before being introduced, and directly enters a sample-introduction system, and is introduced to the on-line mass spectrometer under the condition of constant temperature by a capillary. The method does not need any sampled subjected to pretreatment, the detection speed is fast, the analysis time and the processing time are in 1 min, the sensitivity is high, and the method is suitable for on-site direct detection on SF6 gas in electrical equipment.

Owner:GUANGXI POWER GRID ELECTRIC POWER RES INST +1

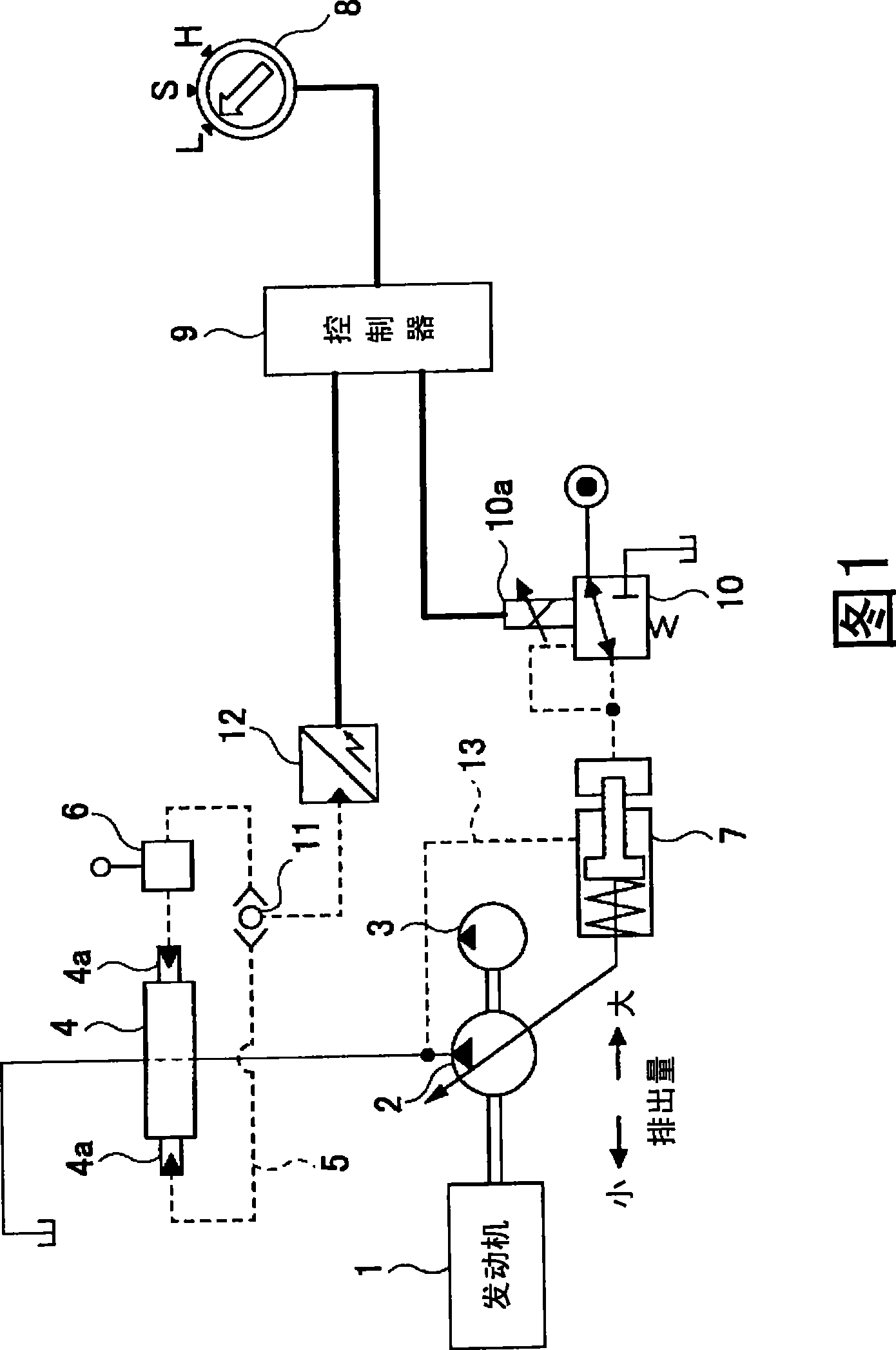

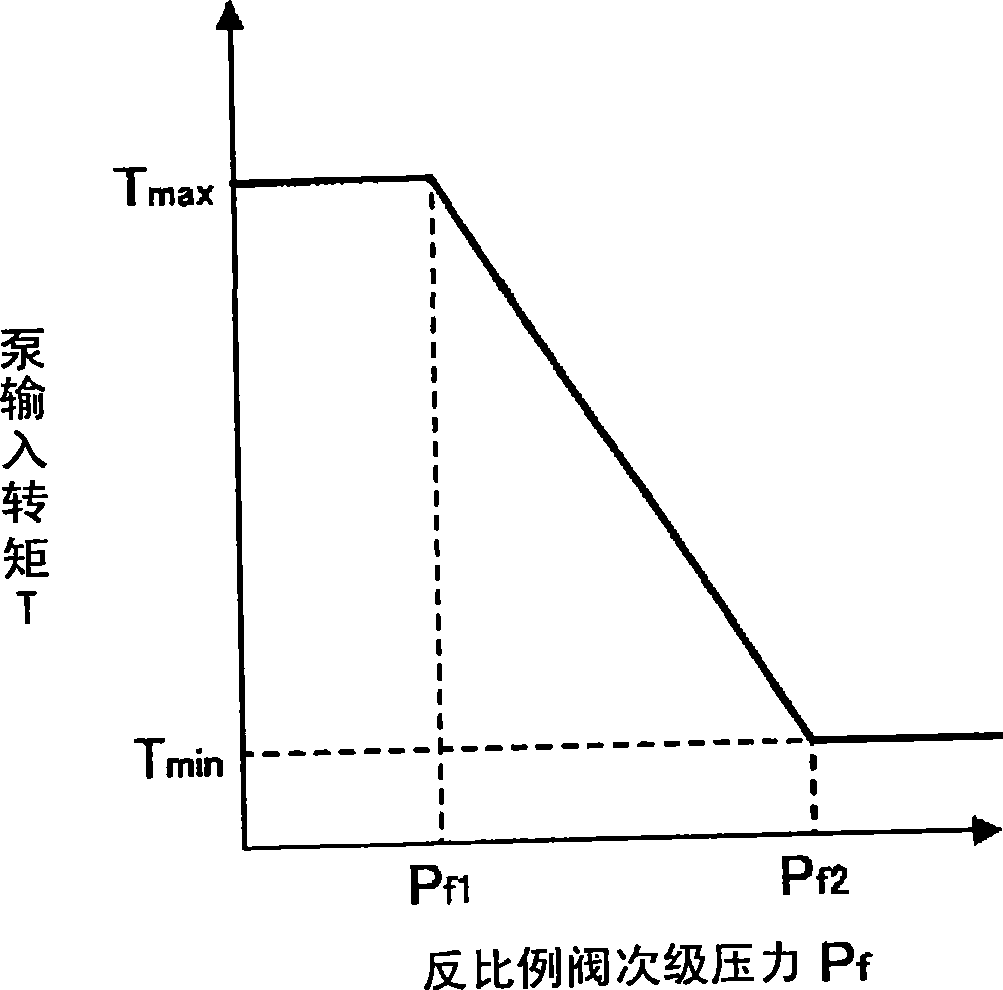

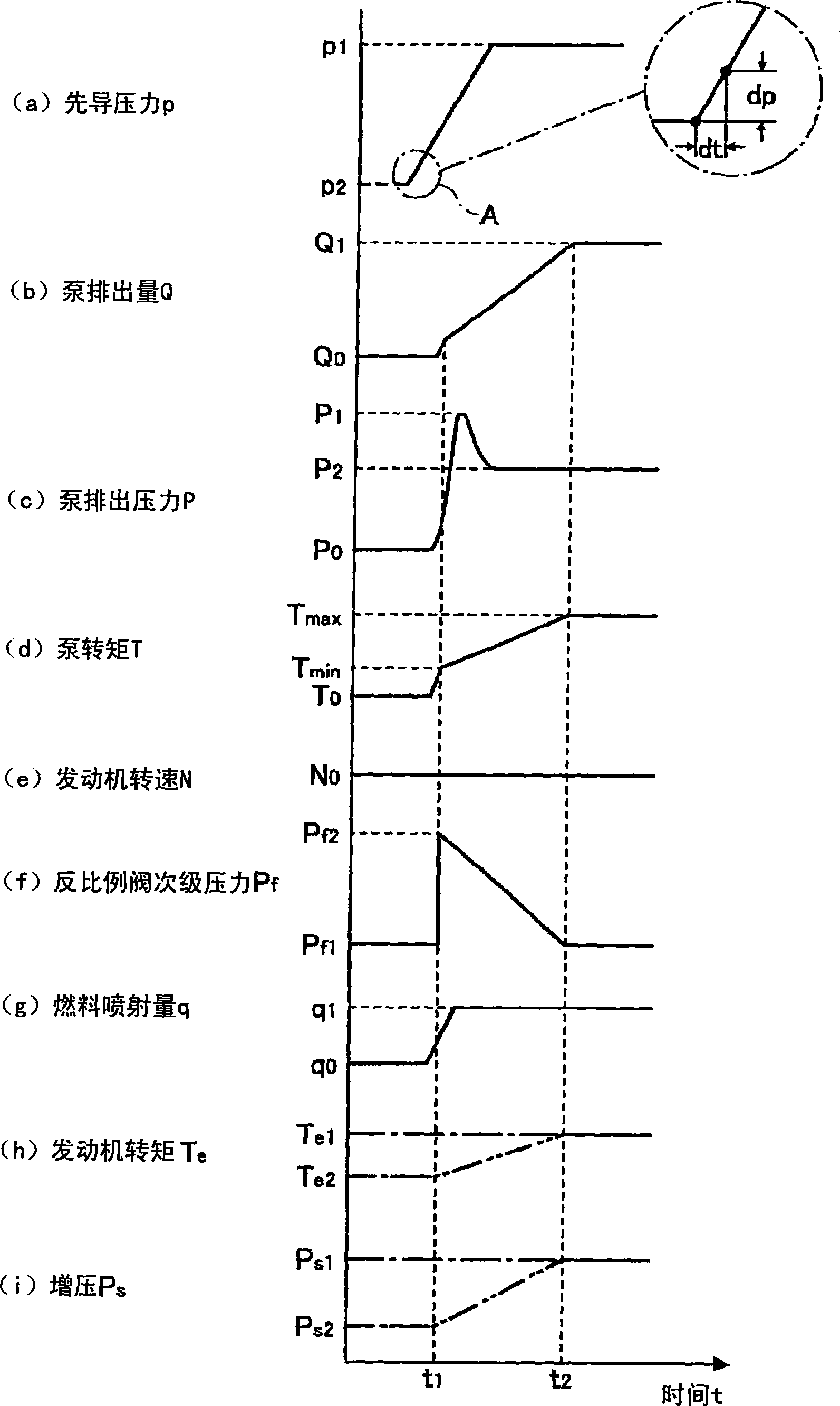

Overload prevention device for construction machine

ActiveCN101432529AEliminate loading slowdownsEliminate consumptionServomotorsServometer circuitsControl signalHydraulic pump

An overload prevention device for a construction machine, preventing occurrence of engine lag down in a sharp rise of discharge pressure of a hydraulic pump to prevent the amount of fuel injection of an internal combustion engine from increasing sharply, thereby reducing fuel consumption in the entire work of the construction machine and improving operability of a hydraulic actuator etc. The overload prevention device has operating condition detection means and control means. The operating condition detection means detects operating conditions of an operation lever. When the control means determines, based on the operating conditions detected by the operating condition detection means, that the lever is operated at a speed higher than a predetermined speed, the control means outputs to discharge amount control means a control signal for setting input torque of a hydraulic pump at a minimum torque value in constant-torque control, and after that, the control means changes the level of the control signal according to a predetermined control pattern to increase the input torque of the hydraulic pump to a maximum torque value in the constant-torque control.

Owner:SUMITOMO CONSTRUCTION MACHINERY

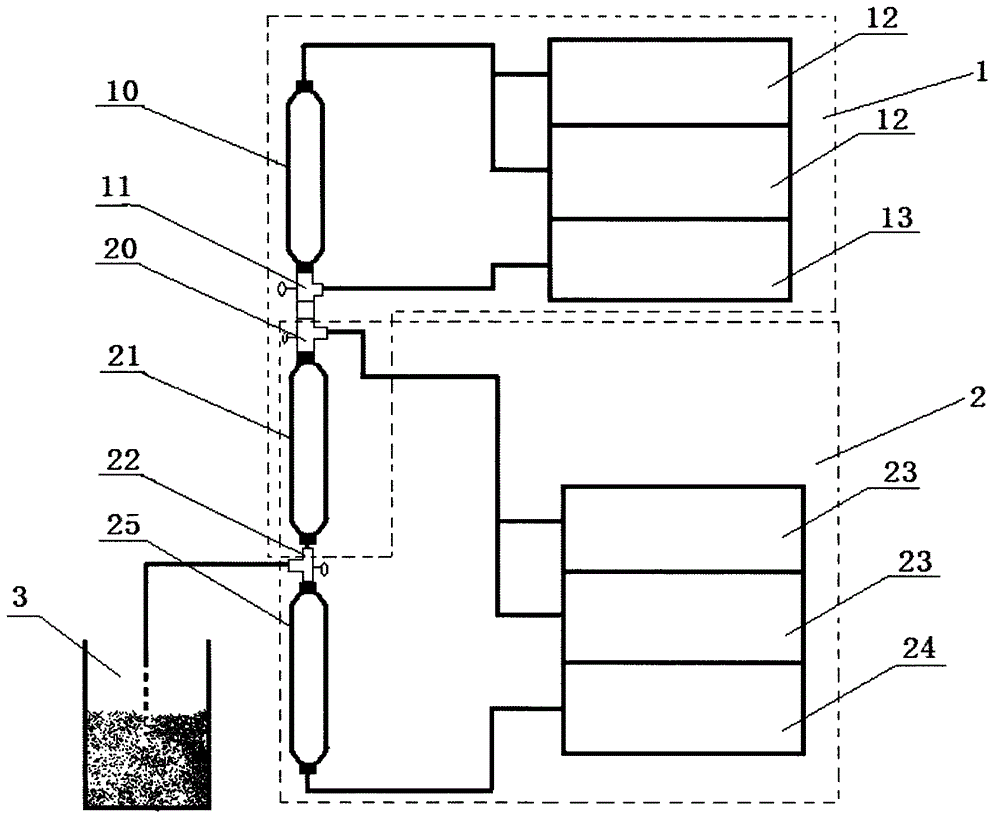

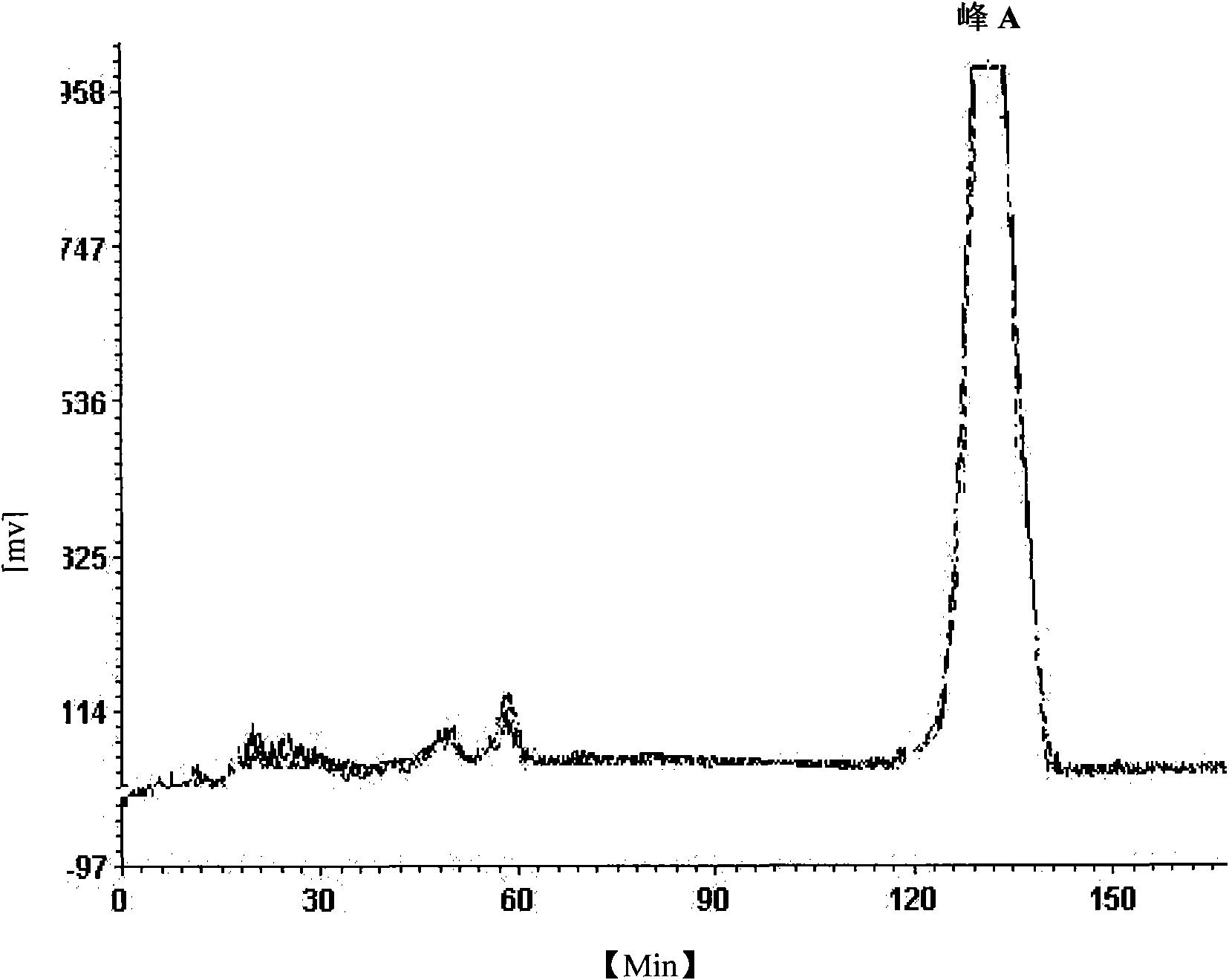

Three-section two-dimensional liquid chromatogram system and application method thereof

InactiveCN102879498AImprove separation efficiencyLarge injection volumeComponent separationHigh pressureLarge sample

The invention discloses a three-section two-dimensional liquid chromatogram system and an application method thereof. The three-section two-dimensional liquid chromatogram system comprises a first dimensional separation detection system and a second dimensional separation detection system. A first chromatographic column is connected with a second chromatographic column through a first three-way valve and a second three-way valve; the second chromatographic column is connected with a third chromatographic column through a third three-way valve; a first infusion device is connected with the sample-introducing end of the first chromatographic column; the first three-way valve is connected with a first detector; the second three-way valve is connected with a second infusion device; and the sample-outputting end of a third chromatographic column is connected with a second detector. The system achieves separation capability of a high-pressure preparative liquid chromatography system and a medium-pressure preparative liquid chromatography system by combining two medium-pressure preparative liquid chromatography systems or low-pressure preparative liquid chromatography systems, has the advantage of large sample capacity of the low-pressure system and the medium-pressure system, and prolongs the service of the chromatogram columns. The system is simple in structure and wide in application range.

Owner:SOOCHOW HIGH TECH CHROMATOGRAPHY

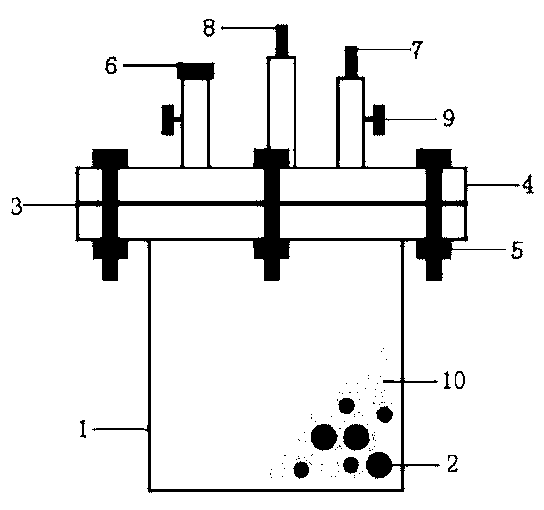

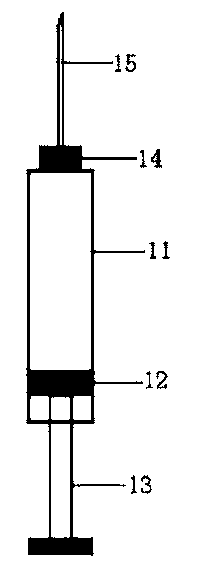

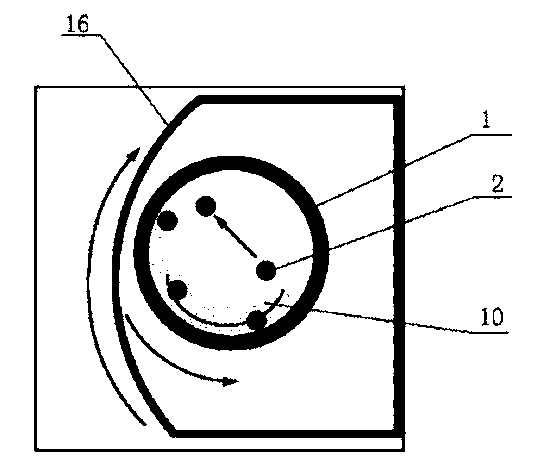

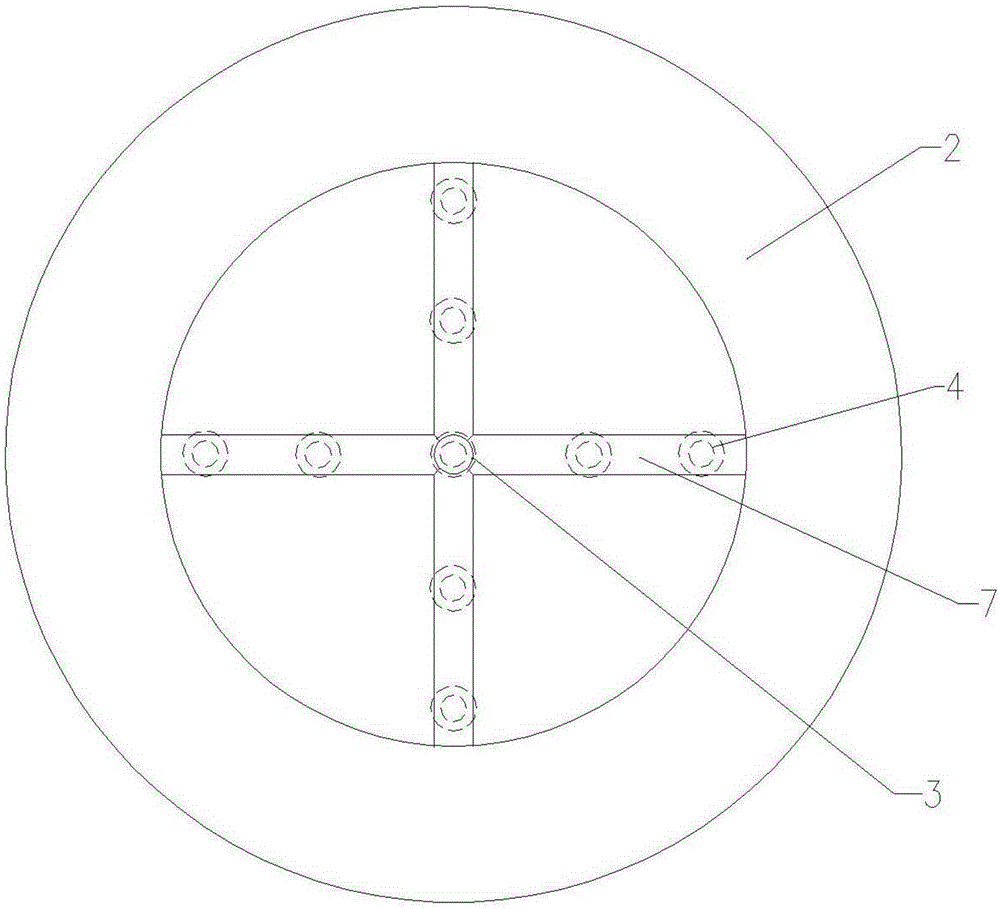

Rock analysis gas high-vacuum degassing and gas-collecting device

InactiveCN103698166AGood effectAnalytical gas volume is largeWithdrawing sample devicesThermodynamicsEngineering

The invention relates to a rock analysis gas high-vacuum degassing and gas-collecting device. The device comprises a degassing device and a gas collecting device. The degassing device comprises a stainless steel tank body and a gas pressure detector. Stainless steel balls are disposed in the stainless steel tank body. A stainless steel sealed cap is disposed on the upper portion of the stainless steel tank body. An analysis gas collecting port, a vacuum pump connecting port and the gas pressure detector are respectively disposed on the stainless steel sealed cap. The gas collecting device comprises a glass tank body, a push rod and a needle tube, wherein a sealed piston is arranged on the end portion of the push rod. The push rod is disposed at one end of the glass tank body and the needle tube is disposed at the other end of the glass tank body. The sealed piston is disposed in the glass tank body. The rock analysis gas high-vacuum degassing and gas-collecting device is wide in application range, large in the amount of obtained analysis gas, short in vacuum broken time and low in temperature, and effectively improves the precision and reliability of component data of the analysis gas and isotope composition data.

Owner:LANZHOU CENT FOR OIL & GAS RESOURCES INST OF GEOLOGY & GEOPHYSICS CAS

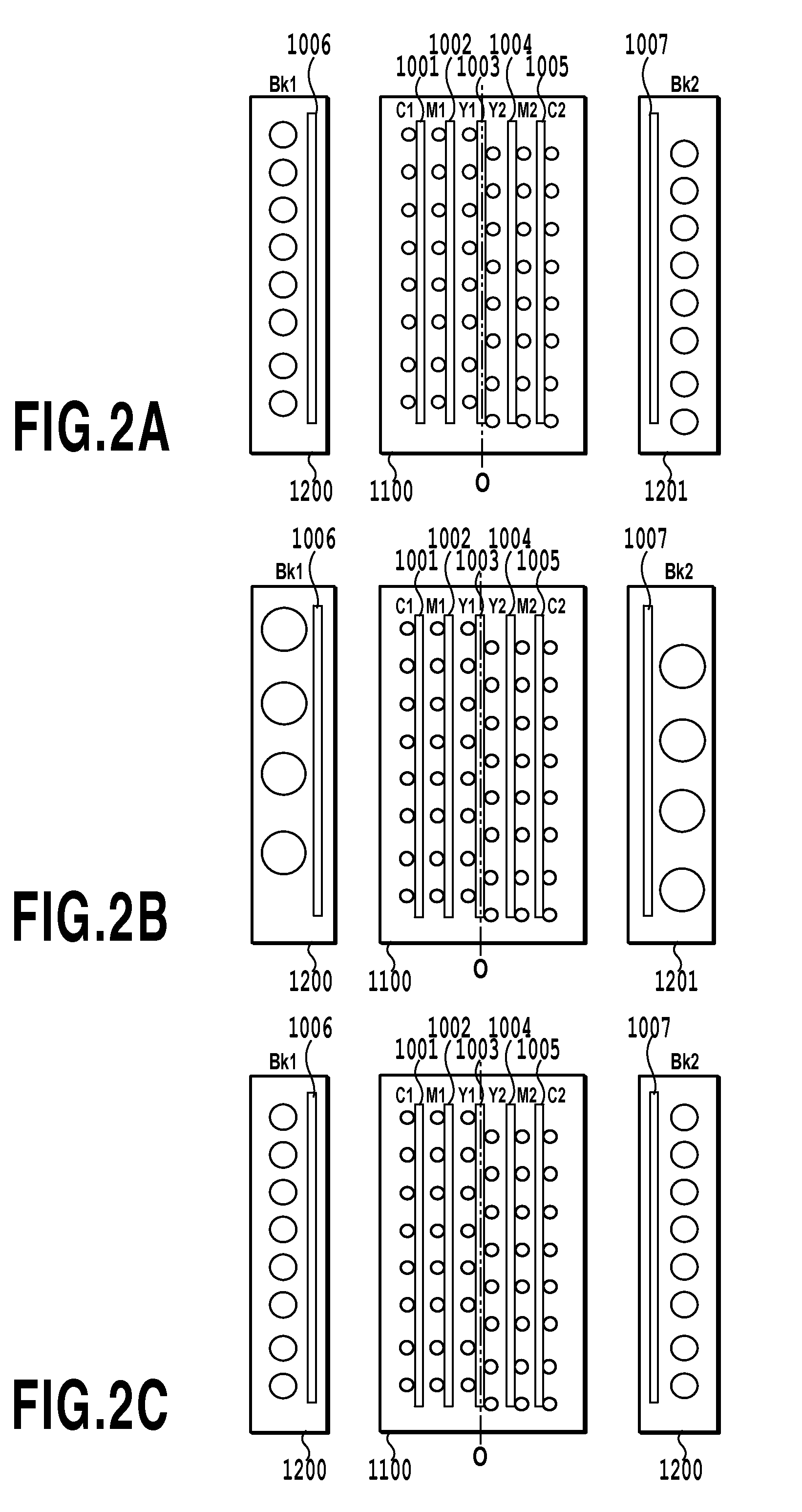

Liquid ejection head, liquid ejection apparatus and inkjet printing apparatus

InactiveCN102310656ASimple compositionLarge injection volumeInking apparatusLiquid jetImage formation

The invention provides a liquid ejection head, a liquid ejection apparatus and an inkjet printing apparatus. The liquid ejection head has a recording element including a set of ejection elements. Each of the ejection elements includes a pressure chamber, a supply flow channel connected to the pressure chamber, an ejection energy generating device arranged correspondingly to the pressure chamber, and an ejection port connected to the pressure chamber. The ejection elements constituting the same set have identical ejection operation characteristics. The ejection energy generating devices included in the ejection elements constituting the same set are connected to a common signal wire, and are configured to be applied with the same drive signal through the common signal wire to be simultaneously driven. In the ejection elements constituting the same set, when the ejection energy generating devices are simultaneously driven, liquids are ejected from the pressure chambers through the ejection ports and deposited to a same pixel on an image formation medium in an image formation operation.

Owner:FUJIFILM CORP

Method for measuring residual solvent in tetracycline hydrochloride bulk drug by utilizing headspace gas chromatography

The invention relates to a method for measuring a residual solvent in a tetracycline hydrochloride bulk drug by utilizing headspace gas chromatography. The method comprises the following steps of: preparing tetracycline hydrochloride into a solution and placing the solution into a headspace bottle; heating the solution, and volatilizing a volatile organic solvent from the solution; after balance is achieved, taking a gas at the upper part in the headspace bottle, and injecting the gas into a gas chromatograph for separation and measurement. The method for measuring the residual solvent in the tetracycline hydrochloride bulk drug by utilizing headspace gas chromatography can prevent solid tetracycline hydrochloride from remaining at an injection port of a gas chromatographic column, the chromatographic column can not be affected, thus the service life of the chromatographic column is prolonged, also the interference factors are less, the measured result is accurate, and the detection limit is high because of great sample size.

Owner:NINGXIA QIYUAN PHARMA

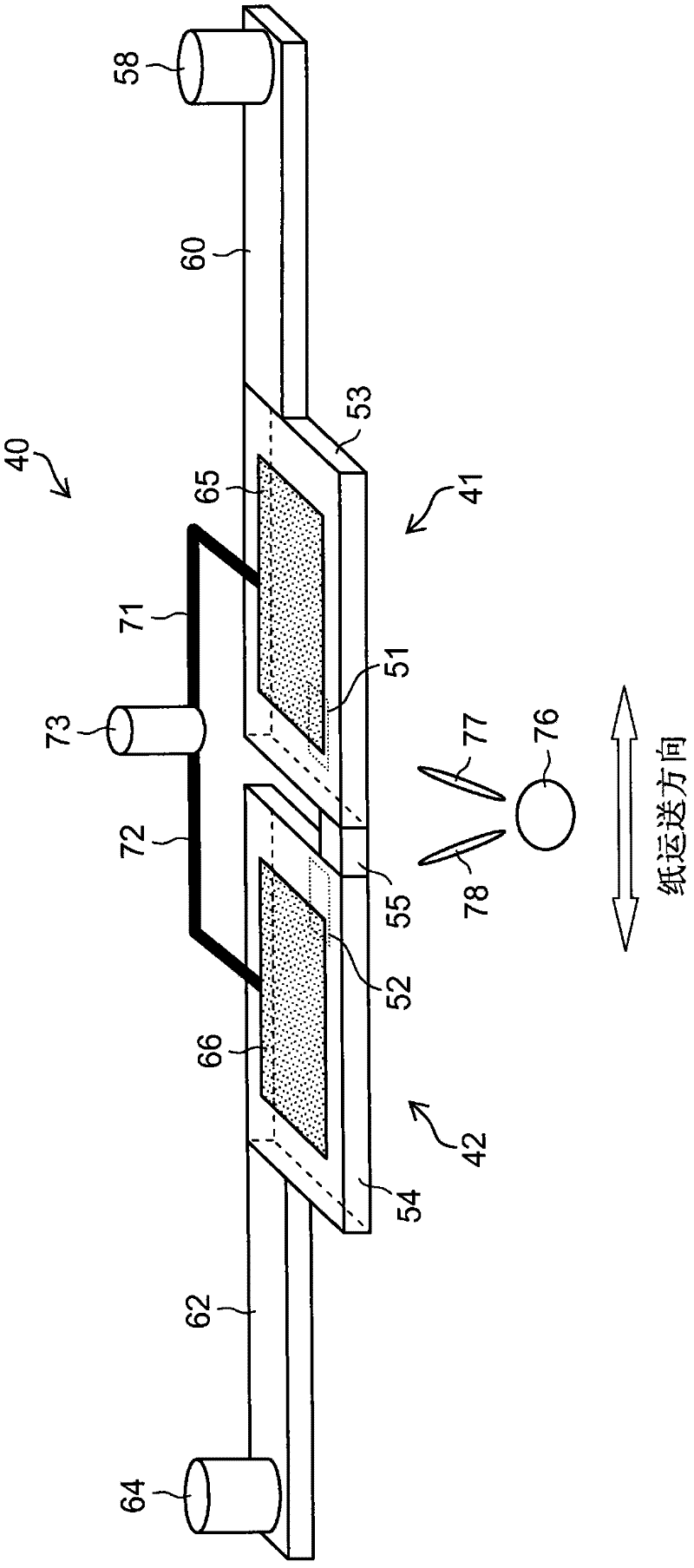

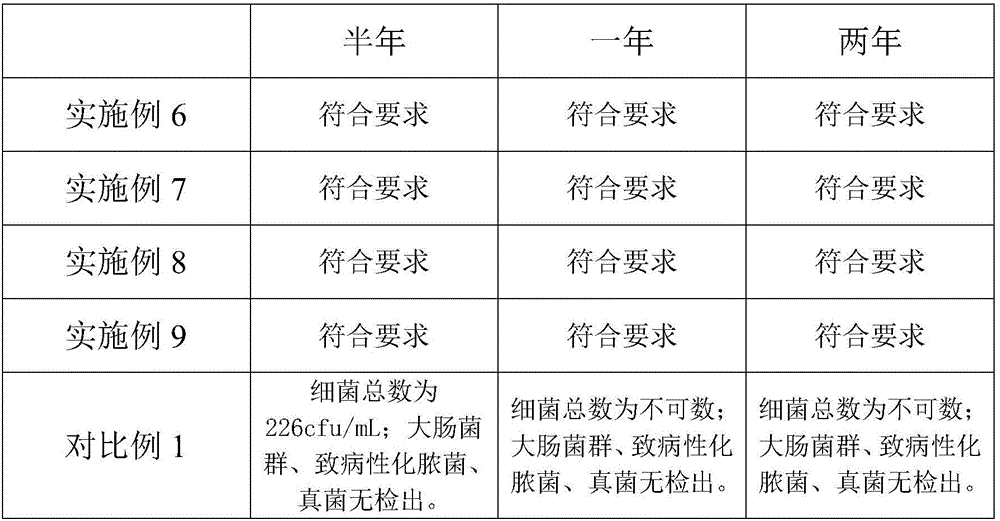

Saline nasal sprayer

ActiveCN106110453AGuaranteed effective usePrevent bacterial growthAntibacterial agentsAntisepticsSaline nasalMicrometer

The invention discloses a saline nasal sprayer which comprises a bottle body, a pump and a bottle cap. The pump is installed on the bottle body and used for pumping liquid in the bottle body. The bottle cap is buckled with the bottle body to form a closed containing cavity. The pump is located in the containing cavity. The pump comprises a spray pipe which is provided with a bacteria filtering membrane used for preventing bacteria from entering the bottle body, and the pore diameter of the bacteria filtering membrane is smaller than or equal to 0.22 micrometer. According to the saline nasal sprayer, the bacteria filtering membrane for preventing sucking bacteria back is arranged in the spray pipe, and the diameter of the bacteria filtering membrane is smaller than or equal to 0.22 micrometer so that the liquid can be effectively prevented from being sucked back, and bacteria can be filtered away to prevent secondary pollution.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

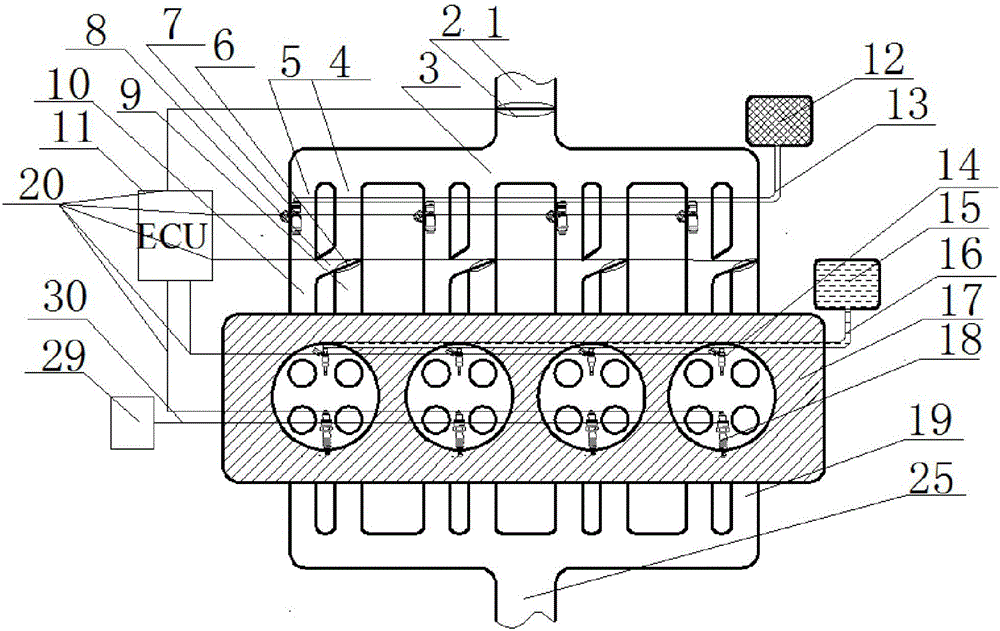

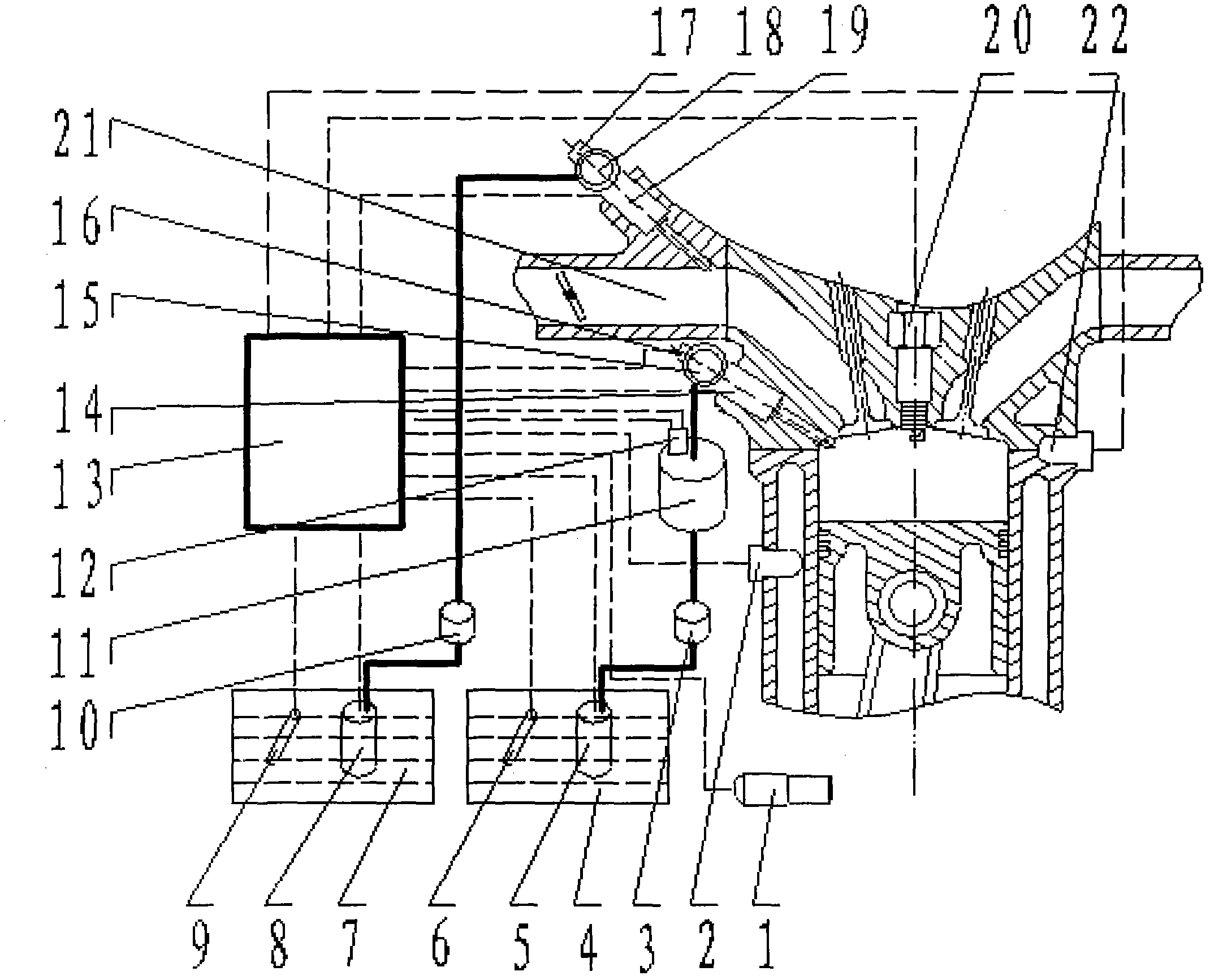

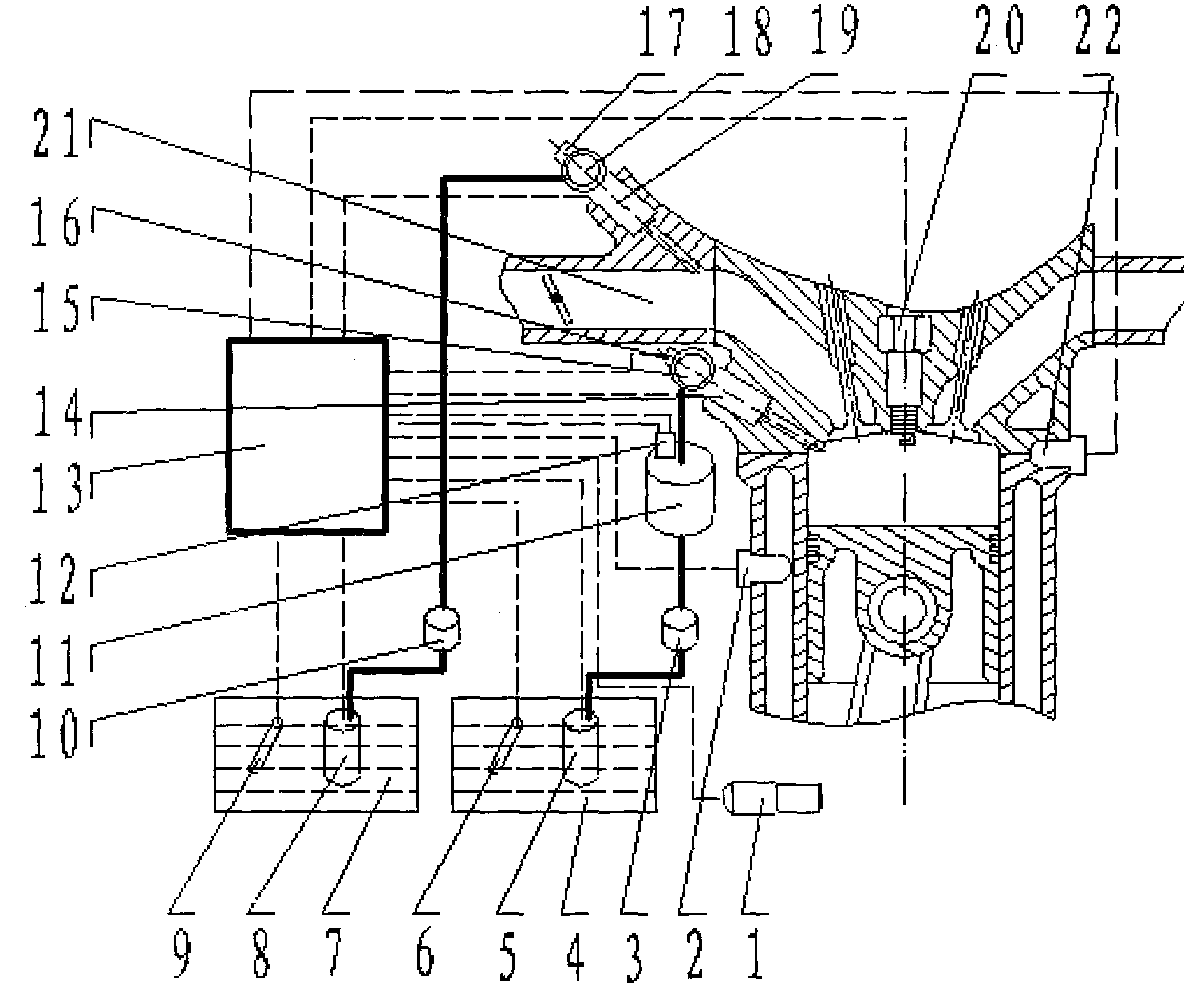

Fuel injection control system of flexible fuel engine

InactiveCN102418614ALarge injection volumeImprove emission effectElectrical controlMachines/enginesInjectorLiquid level sensor

The invention provides a fuel injection control system of a flexible fuel engine and belongs to the field of control of engines. The system is characterized in that the flexible fuel engine with an independent PI (port injection) system and an independent DI (direct injection) system is coordinatively controlled through an electronic control unit, so that the PI system and the DI system can operate simultaneously and also can operate independently; when the engine is started, the PI system operates independently; through detecting signals of a liquid level sensor I, an engine temperature sensor and a crank shaft position sensor, the electronic control unit judges whether the DI system operates or not, if conditions are met, the DI system can operate normally; the fuel injection amount and injection timing of the PI system and the DI system as well as the ignition timing and ignition energy storage period of a spark plug are regulated; through the principle of calibrating the fuel charge pulse spectrum of the PI system and the DI system based on equal heat energy of a gasoline engine with an equal output volume and by virtue of the accurate design and assembly of installation positions of a DI fuel injector and the spark plug as well as a corresponding control strategy, thin and layered combustion can be realized, detonation can be avoided, the fuel economy is improved and the emission is reduced.

Owner:镇江恒驰科技有限公司

Method for preparing usnic acid

ActiveCN101891722ALarge injection volumeStrong separation abilityOrganic chemistryCounter currentChemistry

The invention discloses a method for preparing usnic acid. The method comprises the following steps of: 1) crushing usnea longissima and blending the crushed usnea longissima with an organic solvent, and performing refluxing extraction to obtain usnic acid crude extracts; and 2) selecting a two-phase solvent system to separate the usnic acid crude extracts obtained by step 1) by high speed counter-current chromatography to obtain the usnic acid. The method adopts the high speed counter-current chromatography for separating the usnic acid; and compared with conventional experimental preparation method, the method has the obvious advantages of large sample volume at one time, high separation capability, short separation time, small sample loss and synchronous completion of separation and purification. The method provided by the invention is suitable for a high speed counter-current chromatograph with the column capacity of 325ml, and the usnic acid prepared by the method has a purity of up to 99 percent and a very important application value.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

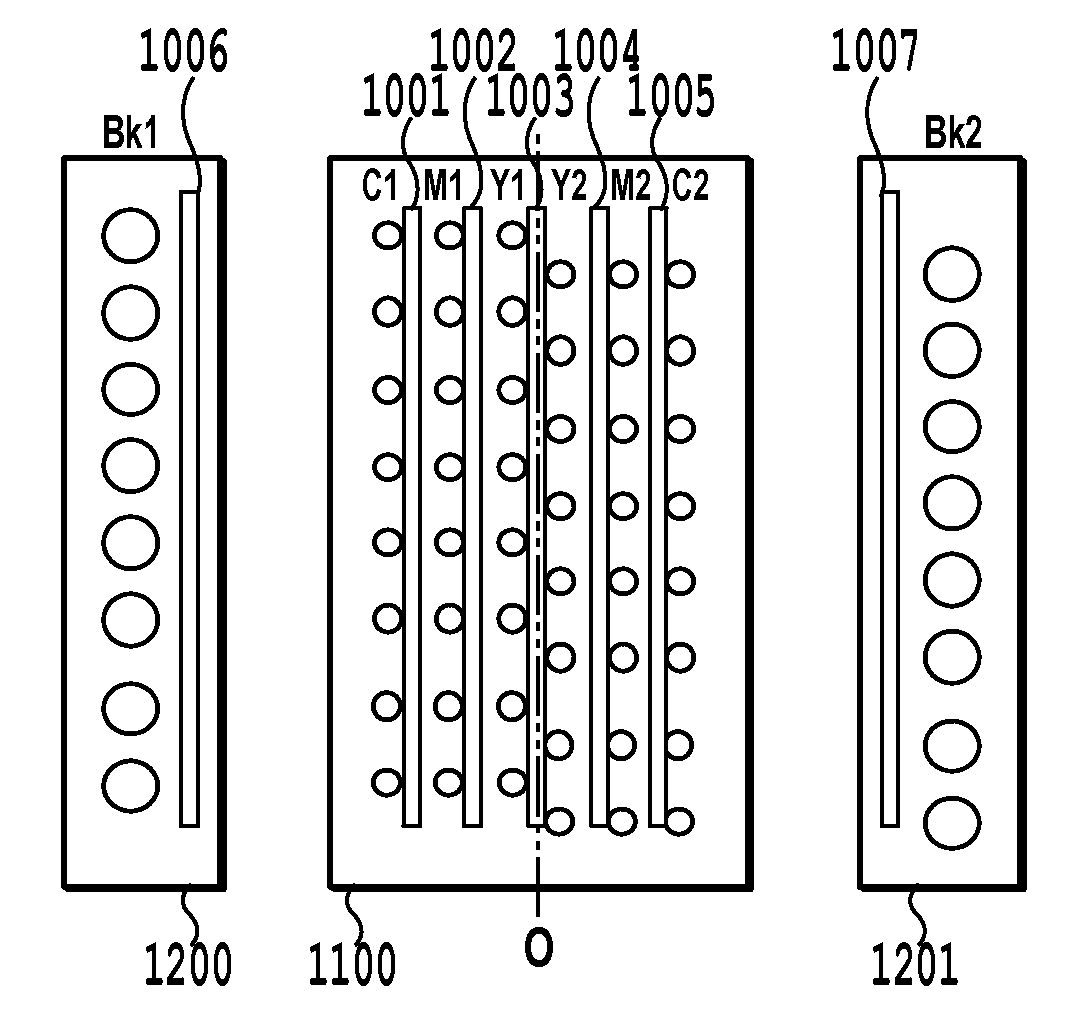

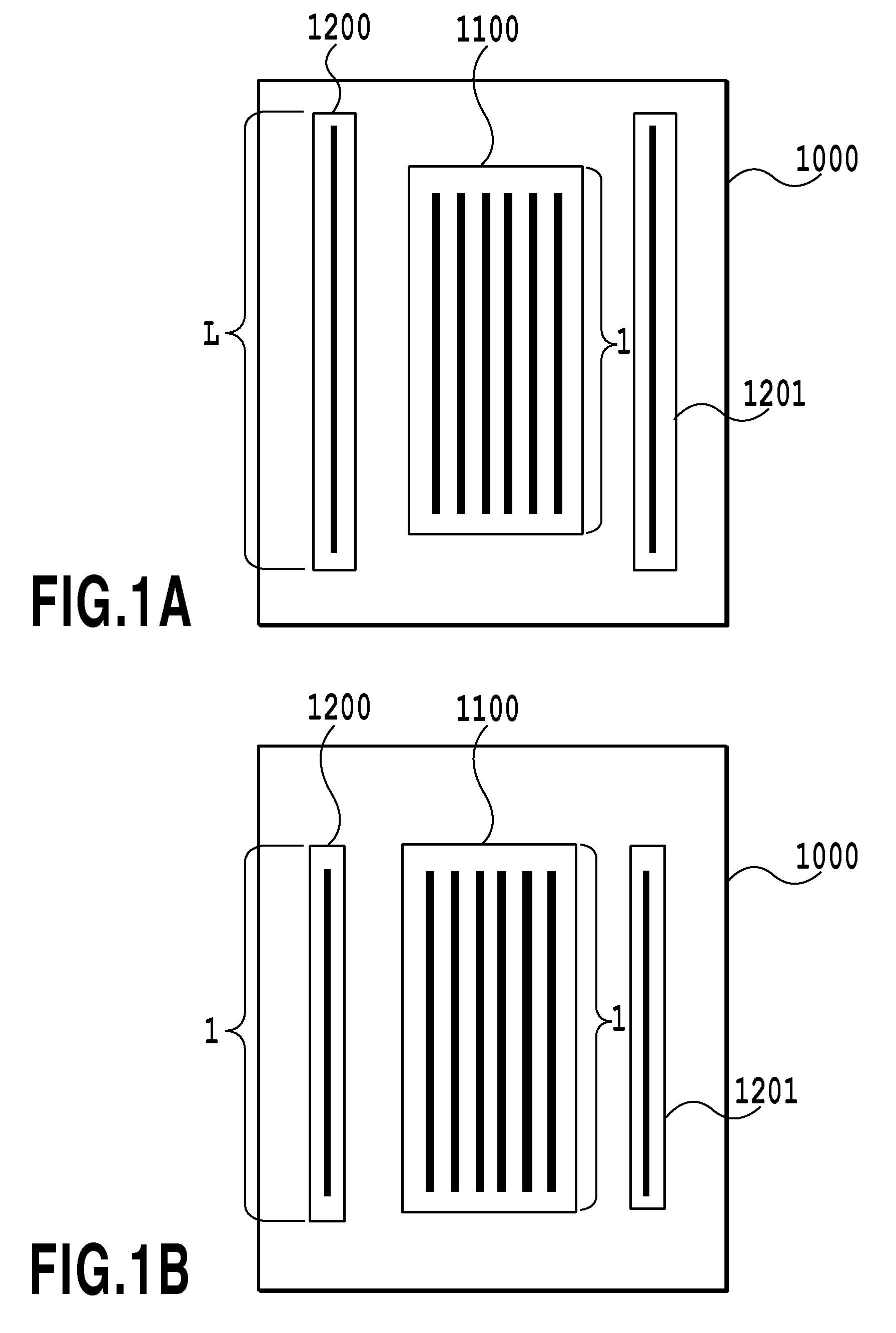

Ink jet print head and printing method and apparatus using the same

The present invention relates to measures for preventing end deviation that may occur during high-duty printing such as one-pass printing, and in particular, to measures for preventing density unevenness (white stripes) in the case of ink with a low lightness such as black ink. According to the present invention, the amount of black ink ejected through the corresponding ejection ports is set to be larger than that of color ink ejected through the corresponding ejection ports. Two black ink ejection chips each having at least one black ink ejection port row are arranged on the respective sides of a color ink ejection chip.

Owner:CANON KK

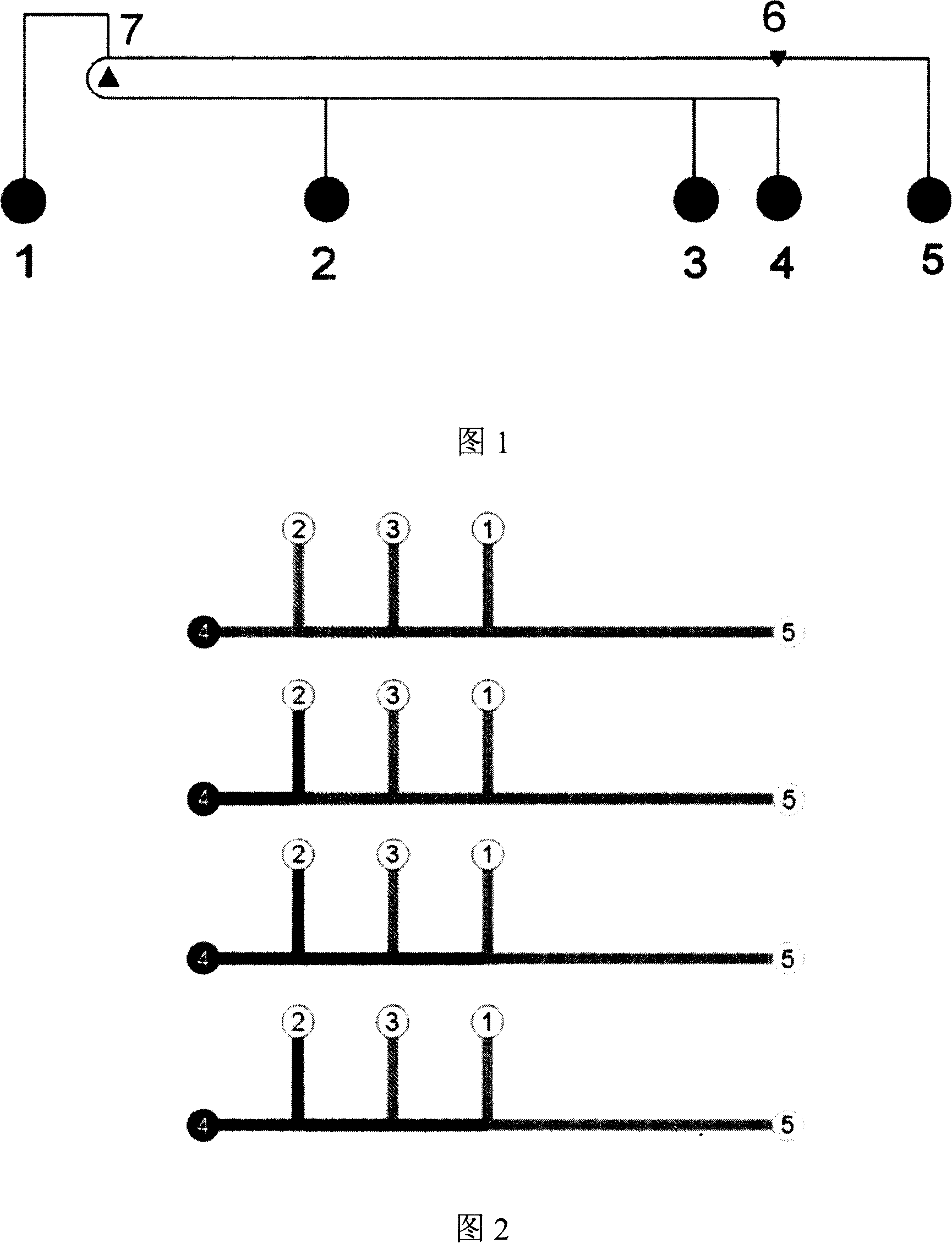

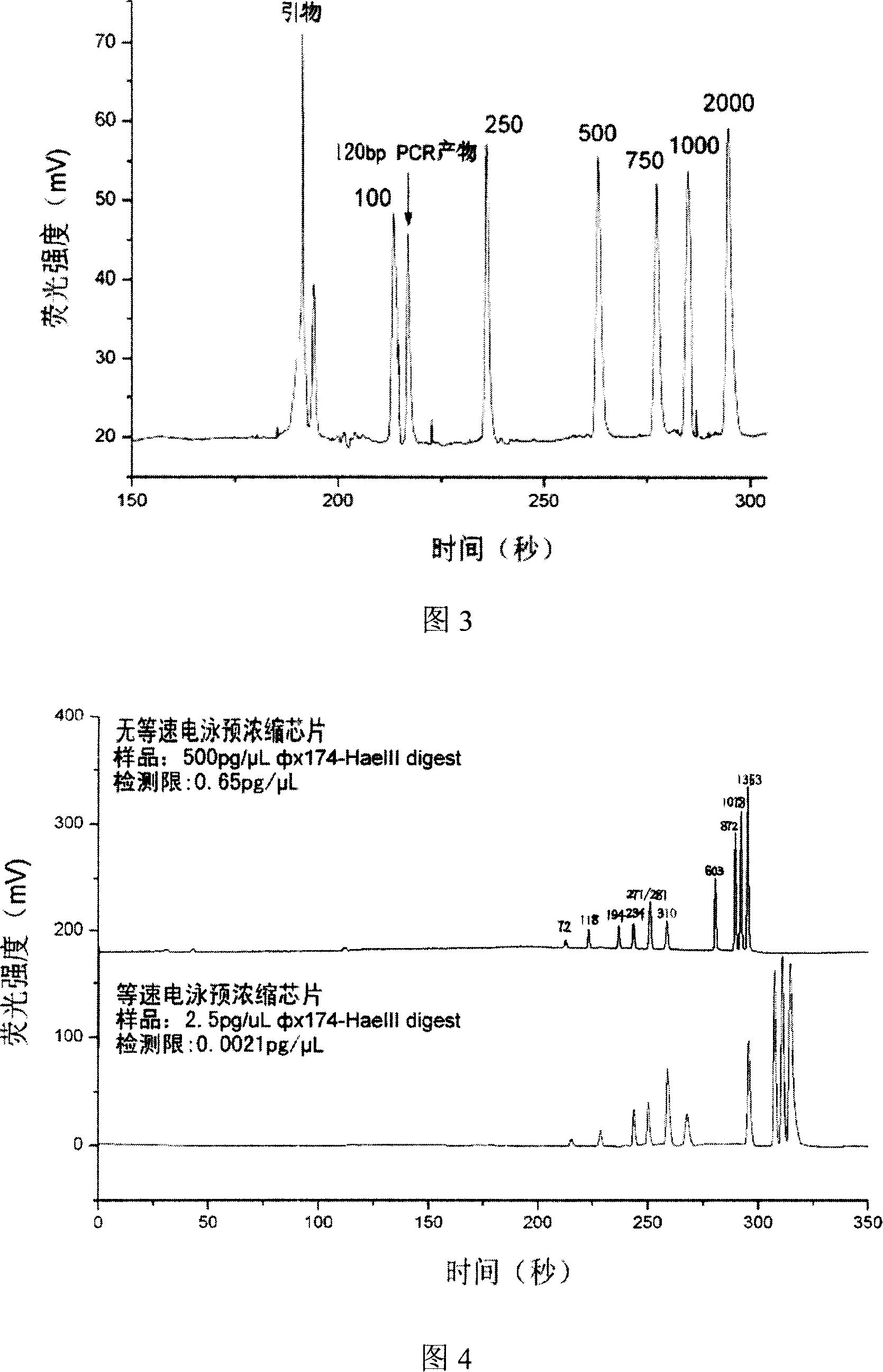

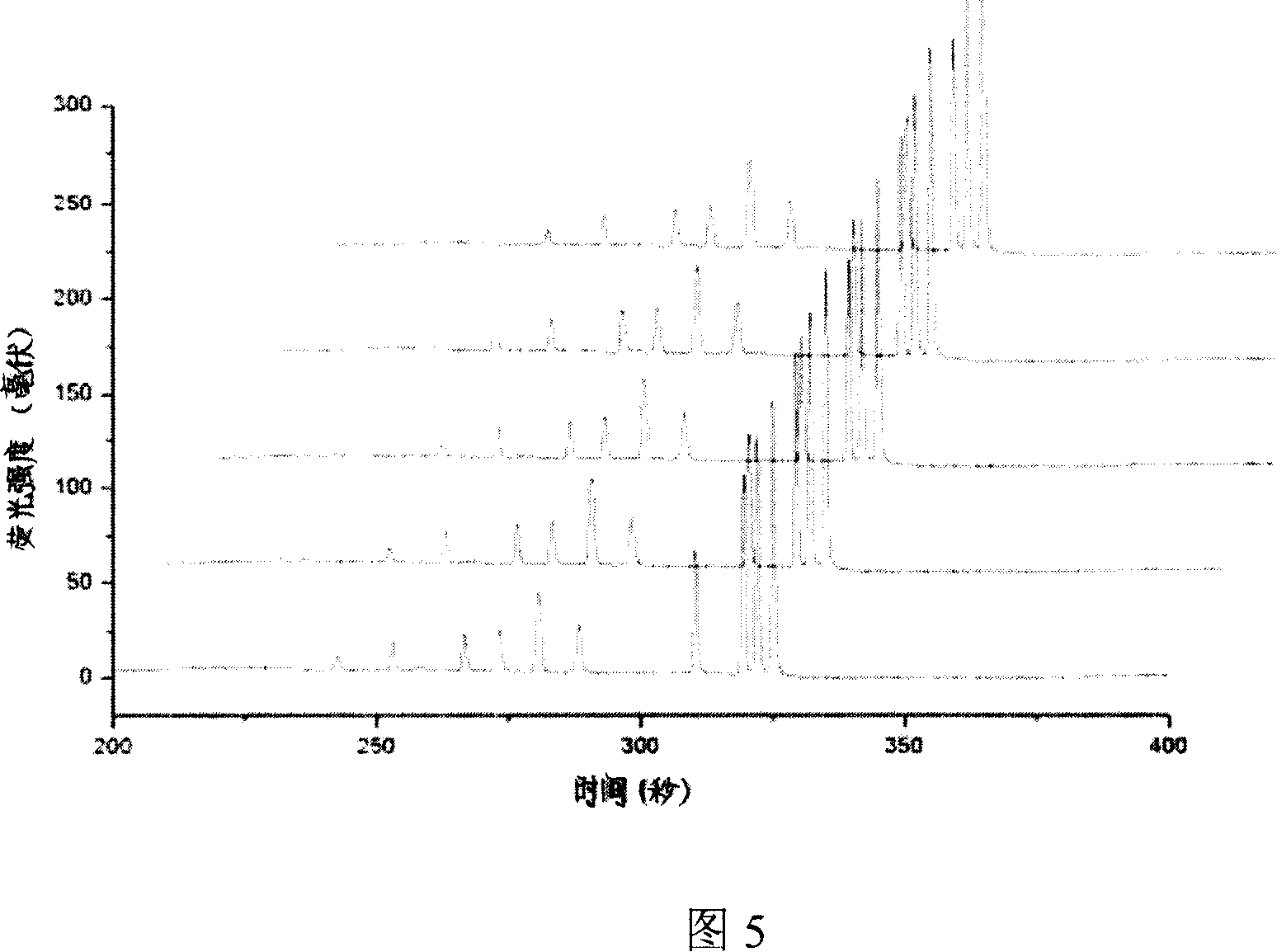

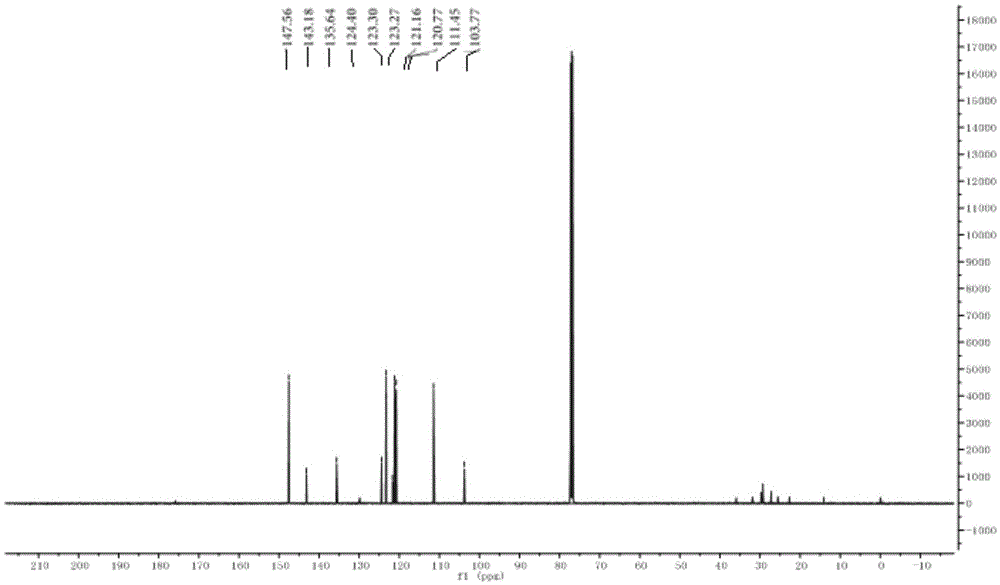

DNA on-line separating microcurrent control chip and analytical method thereof

InactiveCN101153281AFlexible designSimple processingMicrobiological testing/measurementDNA preparationMicrofluidic chipMicro fluidic

The present invention relates to a DNA separation technique, in particular to a micro-fluidic chip for online DNA pre-concentration and separation. The chip consists of a leading buffer pool, a sample pool, a sample waste liquid pool, a buffer waste liquid pool, a terminating buffer pool and channels between the pools, wherein, the terminating buffer pool is arranged at the outer side of the sample pool, and the leading buffer pool is arranged between the sample pool and the buffer waste liquid pool. A separation detection point is arranged near the inside of the buffer waste liquid pool, and a pre-concentration detection point is arranged at the crossing point of an extending channel and a separation channel of the leading buffer pool. The present invention combines online electrophoresis pre-concentration and electrophoresis separation after concentration of DNA samples into the micro-fluidic chip which is of flexible design, simple processing, convenient operation, high sensitivity and extensive application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

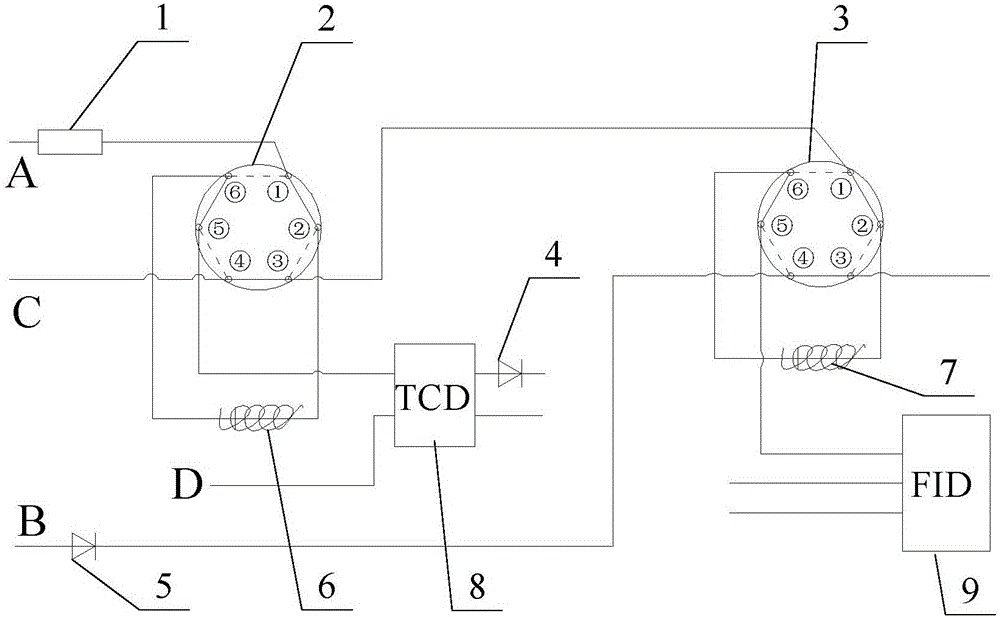

Two-dimensional back flush gas chromatograph gas circuit and analysis method thereof

The invention relates to a two-dimensional back flush gas chromatograph gas circuit and an analysis method thereof, and belongs to the technical field of gas chromatography in order to solve the problems of long analysis time and low detection ability of traditional analysis methods of an aniline and water blend system mixture in a diaminodiphenylmethane product. The gas circuit adopts a thermal conduction cell back flush system as a primary chromatograph and a hydrogen flame back flush system as a secondary chromatograph in order to obtain a two-dimensional back flush chromatograph. The analysis method realizes simultaneous analysis of tiny amounts of water and aniline in the diaminodiphenylmethane product through switching the connection state of a six-way valve 1 and a six-way valve 2. The gas circuit adopts a gas phase back flush technology in order to back flush impurities, so the analysis time is saved, and the sample size is increased in the same time, thereby the detection ability is improved. The gas circuit and the method are used for gas chromatography.

Owner:QIQIHAR UNIVERSITY

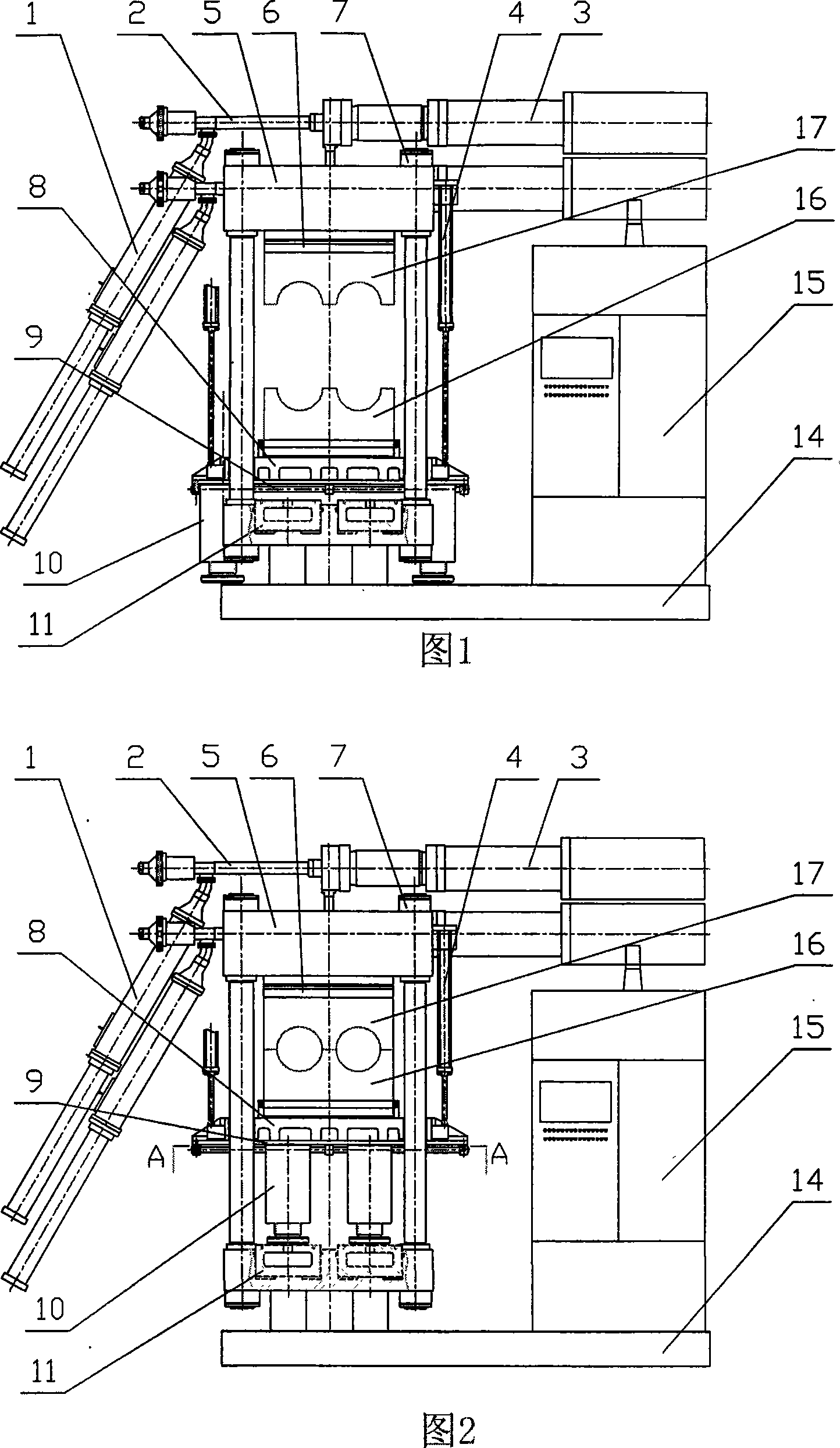

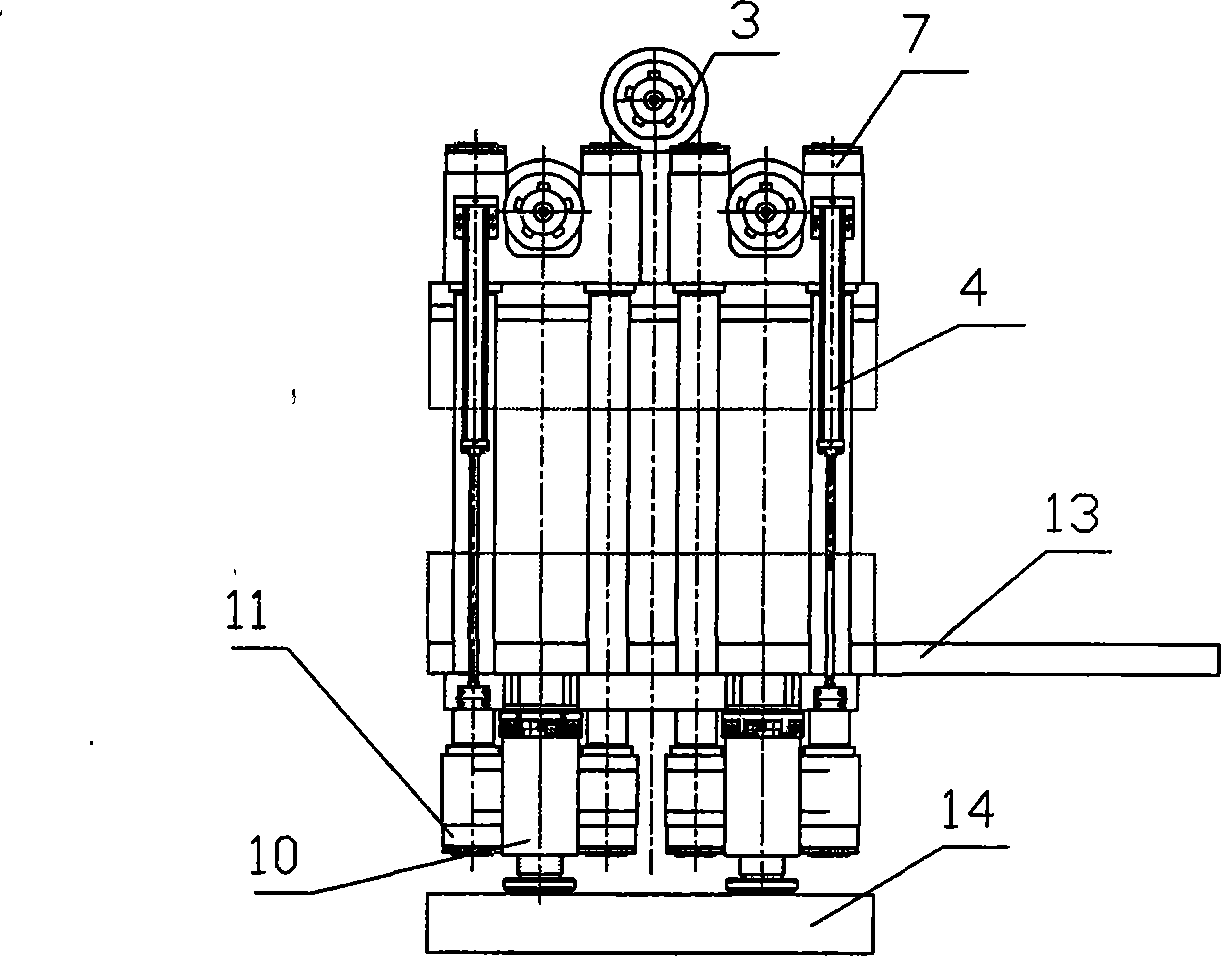

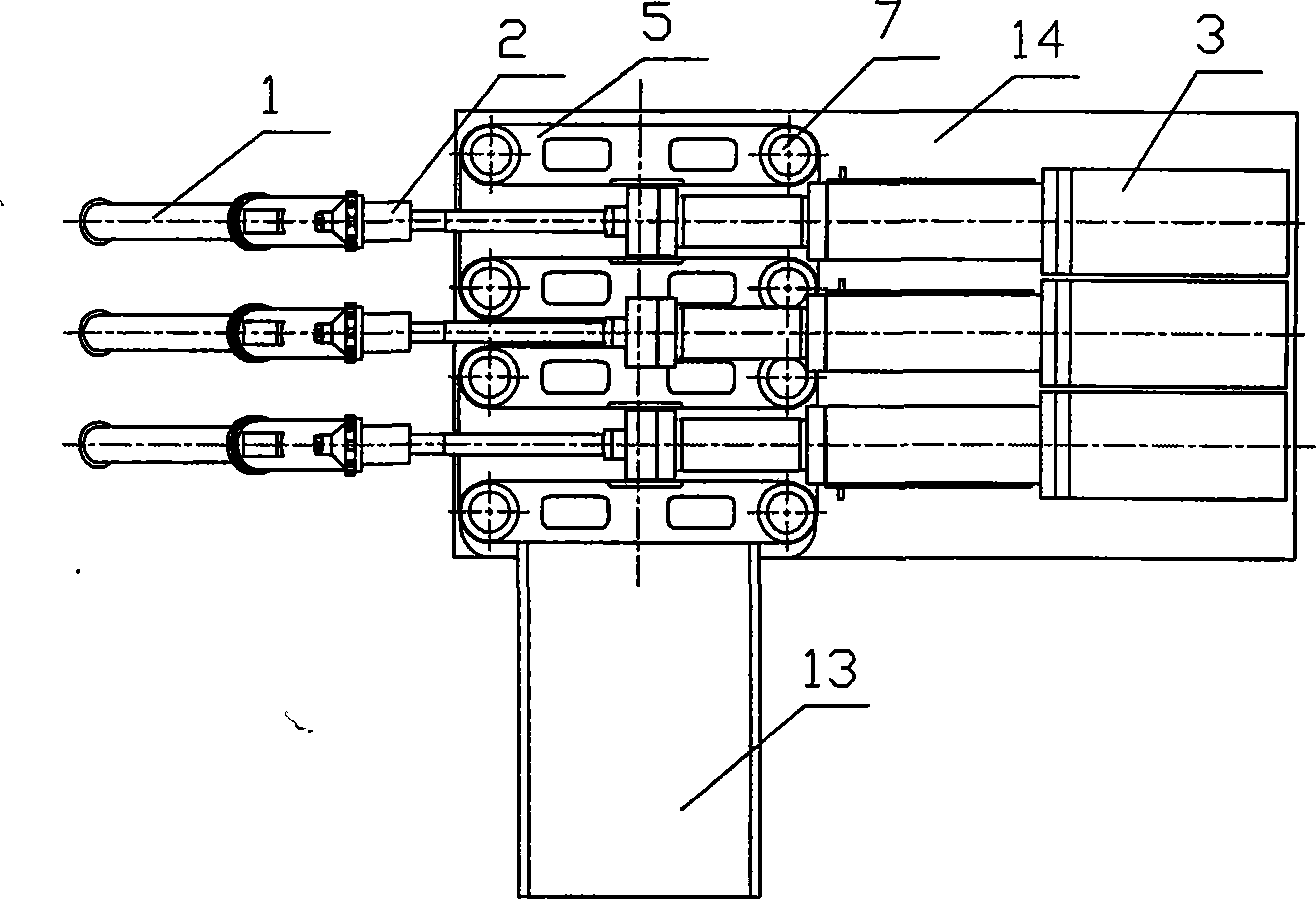

Large-scale injection machine

A major injection molding machine comprises a control system mounted on a base, and three injecting devices positioned above a control system and an upper mold plate and arranged in the shape of Chinese character Pin along the length direction of a mold. Each injecting device is provided with a plasticizing device and a feeding device; four mode-locked oil cylinders in a mode-locked part are arranged in a quadrangle shape, wherein, every two mode-locked oil cylinders share one cylinder body; eight tie bars are divided into two parts and respectively connected onto the cylinder body of a mode-locked oil cylinder and an upper mold plate; a moveable mold plate arranged between the upper mold plate and the cylinder body of the mode-locked oil cylinder slides up and down along a guide rail formed by the eight tie bars; a cold runner is fixed on the upper mold plate; the base of a mold stripping device is fixed on the moveable mold plate; four moveable cushion blocks and cushion block oil cylinders are connected under the moveable mold plate through the rail formed by the eight tie bars. The mold is divided into an upper mold and a lower mold, wherein the upper mold in fixed on the cold runner, and the lower mold is connected with the sliding plate of the mold stripping device.

Owner:HENGYANG HUAYI MACHINERY

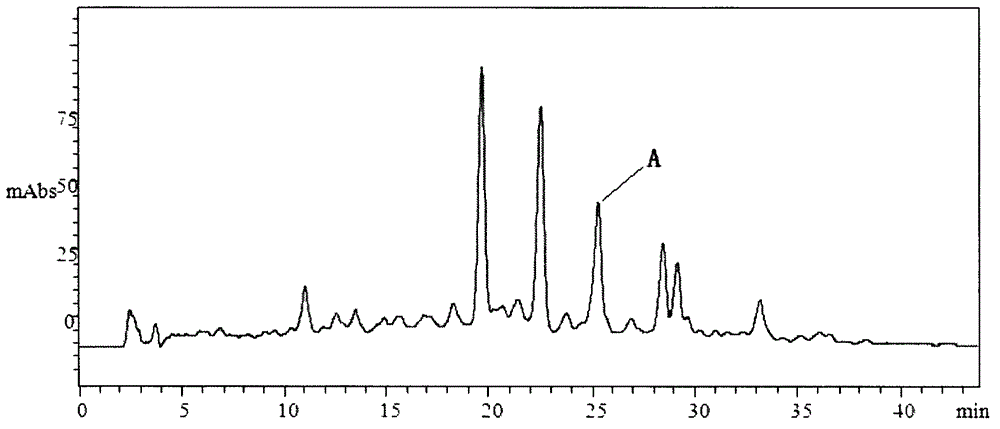

Fermentation preparation process of Streptomyces marinensis and secondary metabolite Streptochlorin thereof

InactiveCN105647828AHigh recovery rateLarge injection volumeBacteriaMicroorganism based processesMetaboliteCountercurrent chromatography

The invention discloses a fermentation preparation process of Streptomyces marinensis and a secondary metabolite thereof. The strain is characterized by having a preservation number of CGMCC No. 11468. The fermentation process specifically includes the steps of: inoculating Streptomyces marinensis to PDA, culturing in an incubator at 27.5 DEG C for 2 d; picking a single colony, inoculating to a seed culture medium, and culturing at 27.5 DEG C for 2 d; inoculating 5% by volume of a seed liquid to a fermentation medium, culturing at 27.5 DEG C for 11 d under the condition of 150 r / min; extracting a metabolite; and finally, separating and purifying a sampling liquid by a high-speed countercurrent chromatography to obtain a product. The process has the advantages of high preparation speed, and high product purity and yield.

Owner:NINGBO UNIV

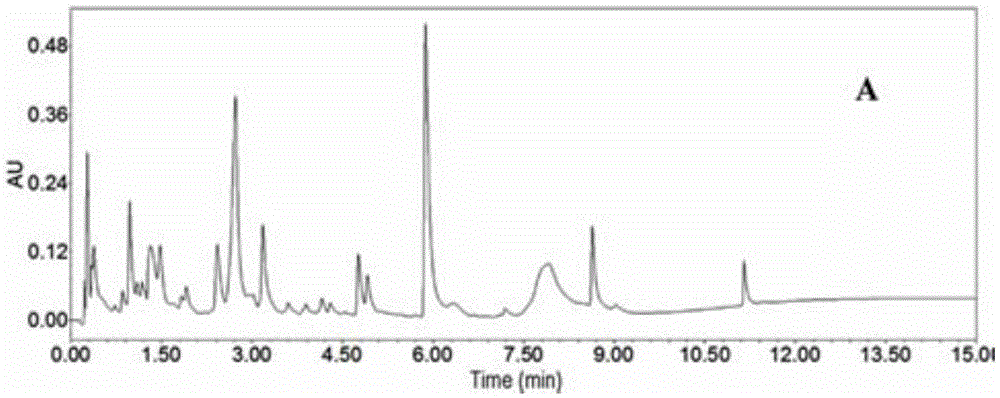

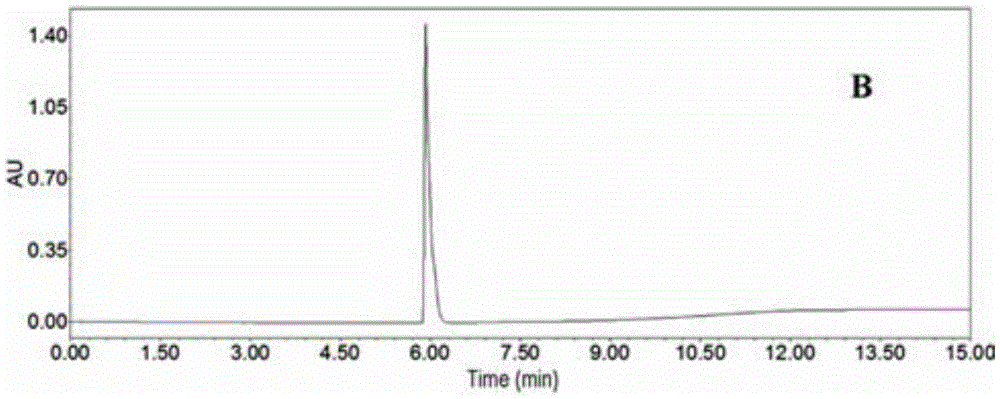

Method for separating and preparing ricinine

ActiveCN101544600AReduce lossesLarge injection volumeNervous disorderOrganic chemistryCastor SeedMethylene Dichloride

The invention discloses a method for separating and preparing ricinine, which comprises the following steps: 1) extracting castor meal of castor seeds by extract to obtain crude extract of the ricinine; and 2) selecting a two-phase solvent system and adopting a high-speed counter current chromatography to separate and purify the crude extract of the ricinine obtained in step 1) to obtain the ricinine, wherein the two-phase solvent system in step 2) is methylene dichloride / methanol / water, or 1,2-dichloroethane / methanol / water, or methenyl chloride / methanol / water, and is preferably the methenyl chloride / methanol / water in the ratio of 2:1:1; the top phase in the two phases is an immobile phase, and the bottom phase is a mobile phase; and the rotating speed of a separation column for separation and purification is between 500 and 1,000 rpm, the flow rate of the mobile phase in the separation column is between 3 and 6ml / min, and the temperature of the two-phase solvent system in the separation column is between 20 and 30 DEG C. The ricinine prepared by the method has the purity of 98 percent.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

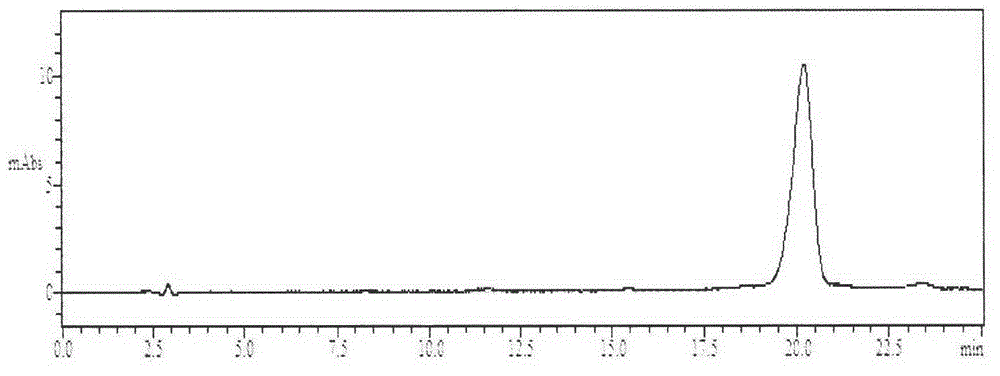

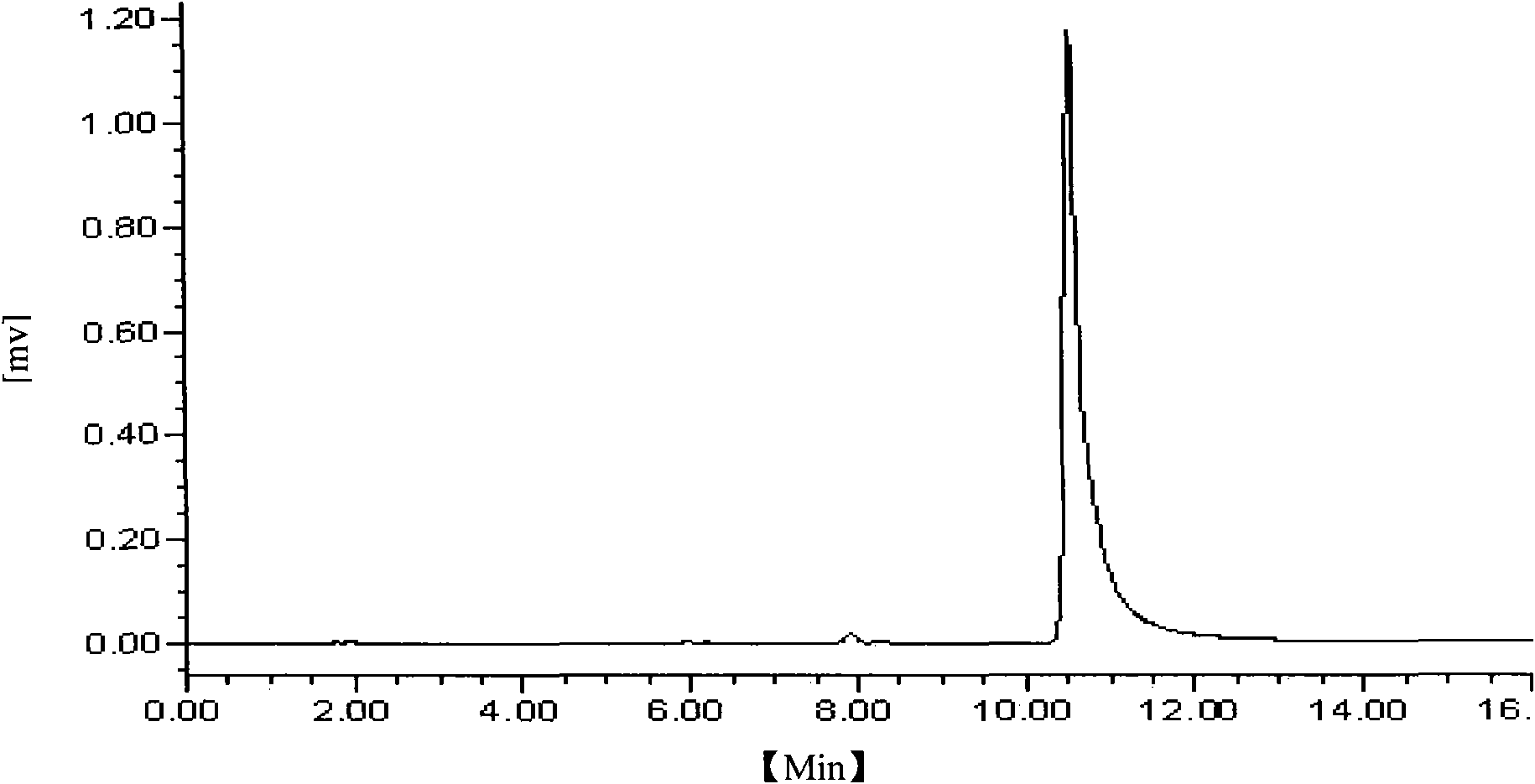

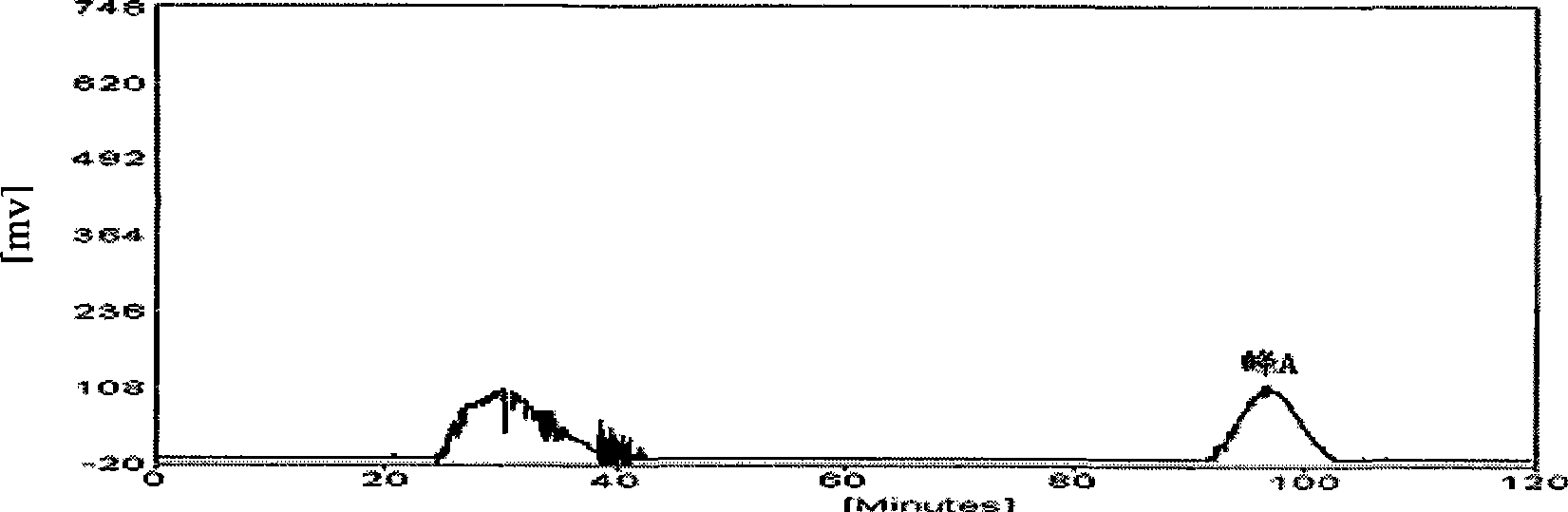

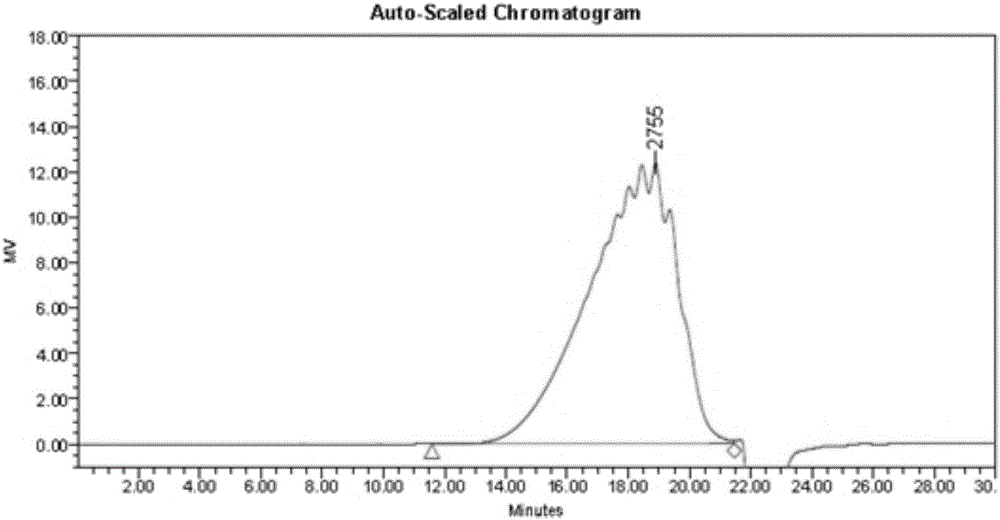

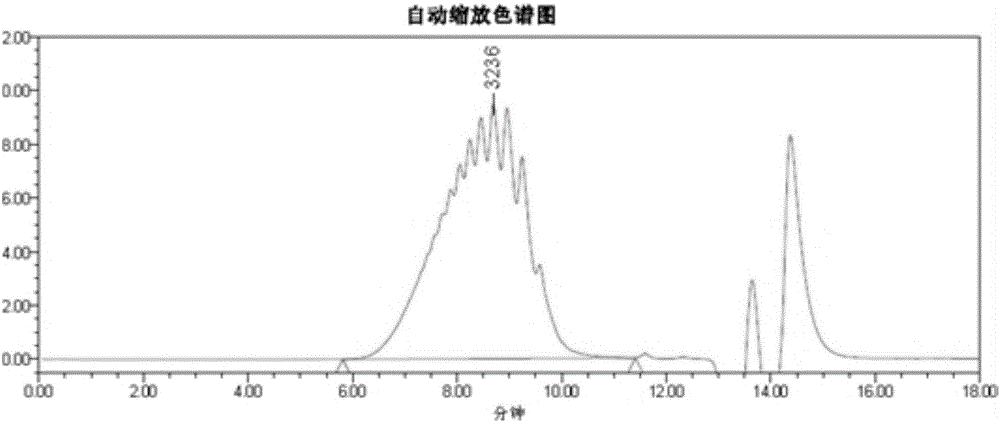

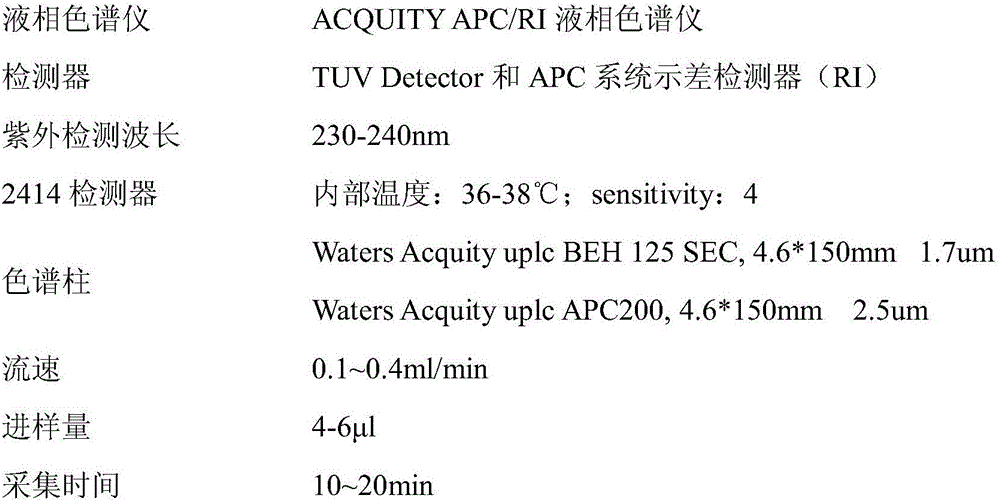

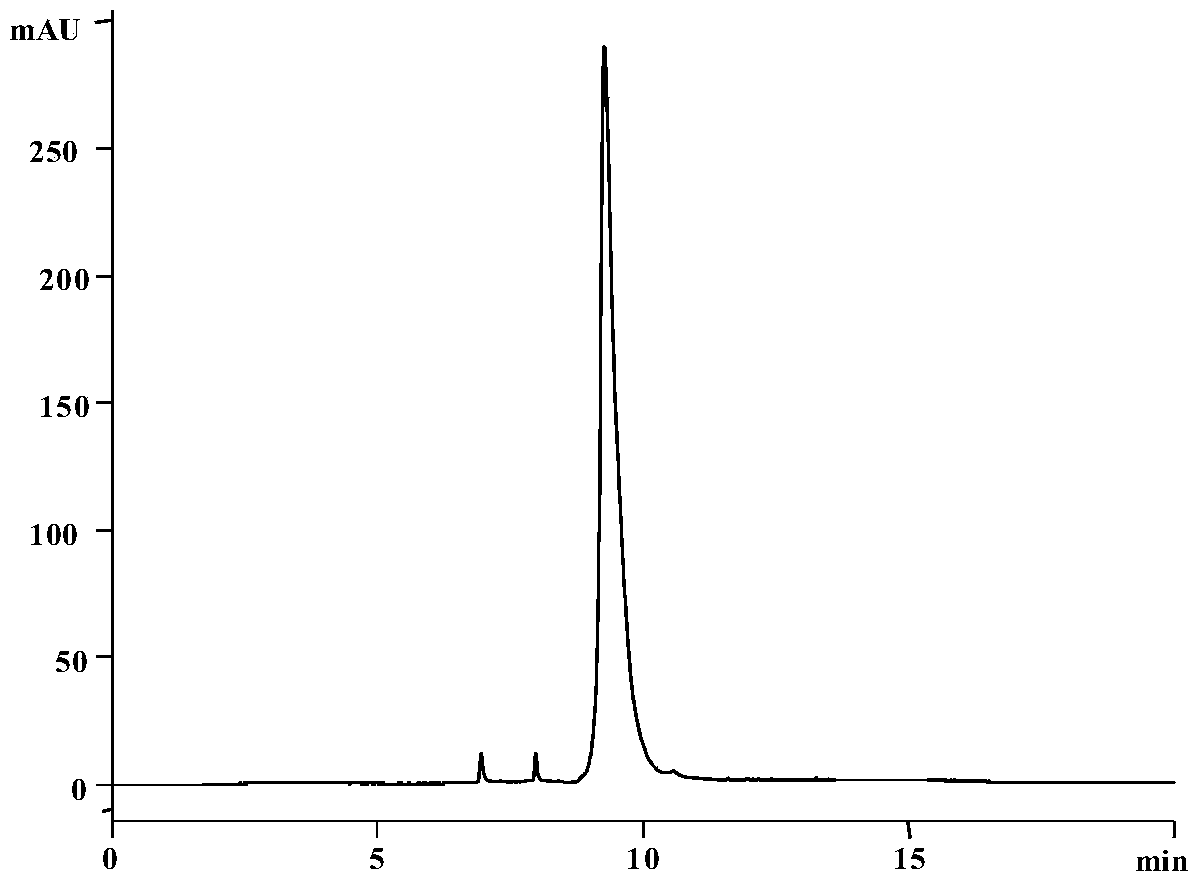

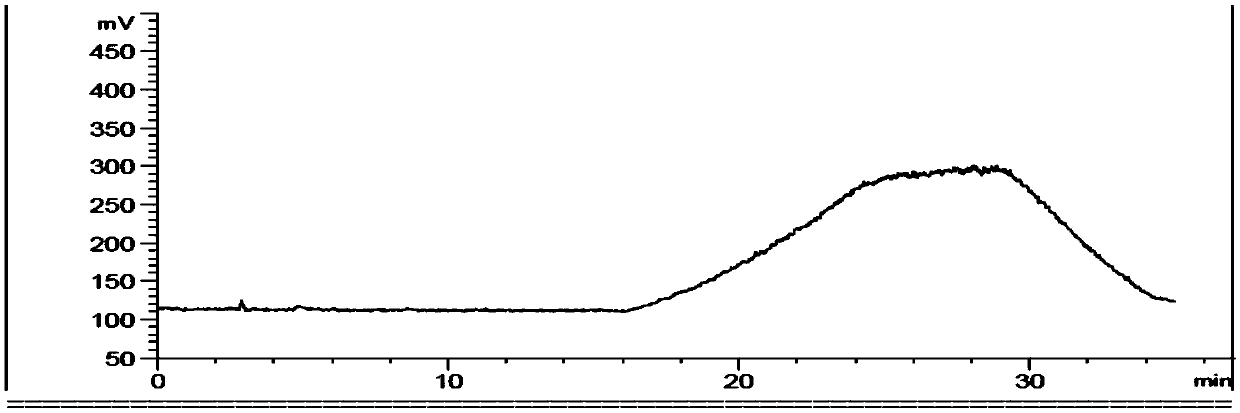

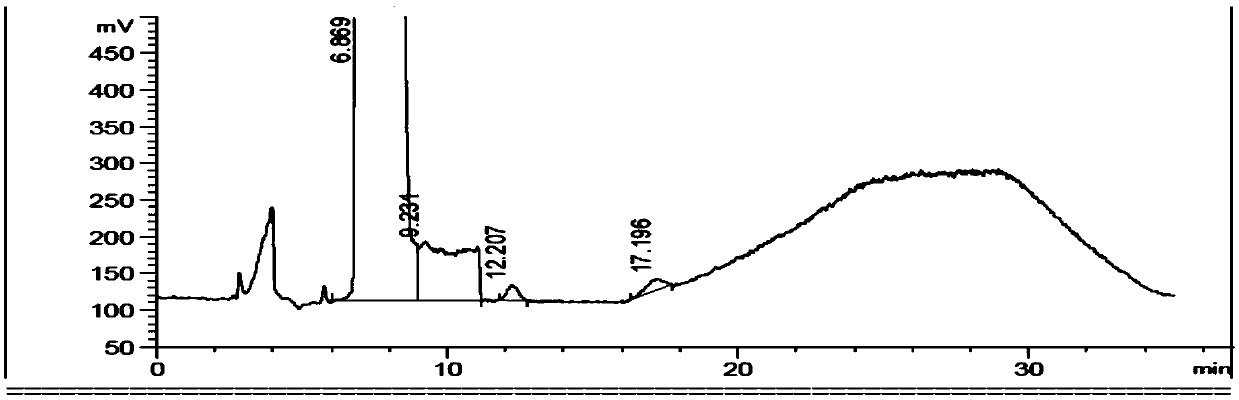

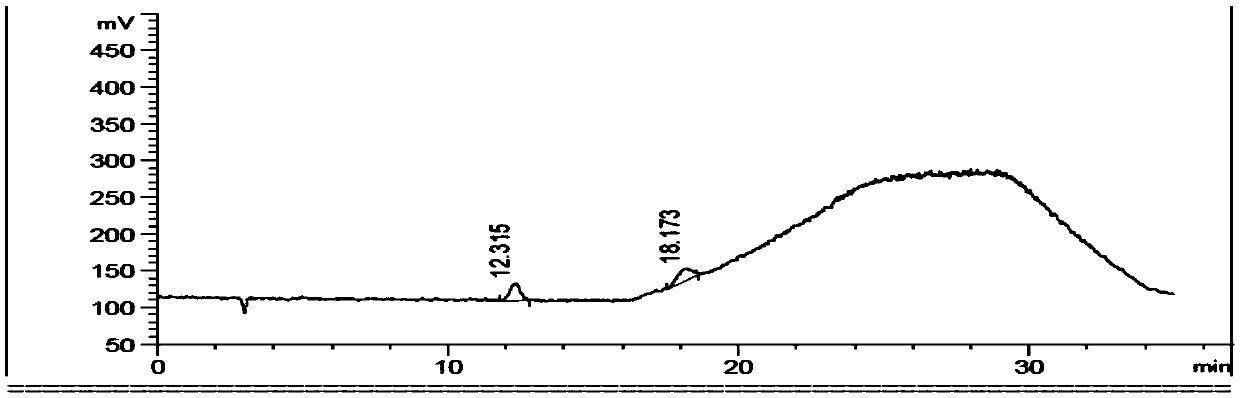

Low-molecular-weight heparin molecular weight and molecular weight distribution detection method

The invention relates to a low-molecular-weight heparin molecular weight and molecular weight distribution detection method. High performance liquid chromatography is used, the method includes the following steps that firstly, a low-molecular-weight heparin sodium standard substance solution is prepared; secondly, a low-molecular-weight heparin sodium molecular weight calibration standard solution is prepared; thirdly, a test sample solution is prepared; fourthly, a 0.01% sodium azide solution is prepared; fifthly, the 0.01% sodium azide solution, the low-molecular-weight heparin sodium standard substance solution, the low-molecular-weight heparin sodium molecular weight calibration standard solution and the test sample solution are injected into a high performance liquid chromatograph respectively to obtain a chromatogram, the molecular weight of a test sample is calculated and a molecular weight distribution result is obtained according to the chromatogram.

Owner:SHENZHEN TECHDOW PHARM CO LTD

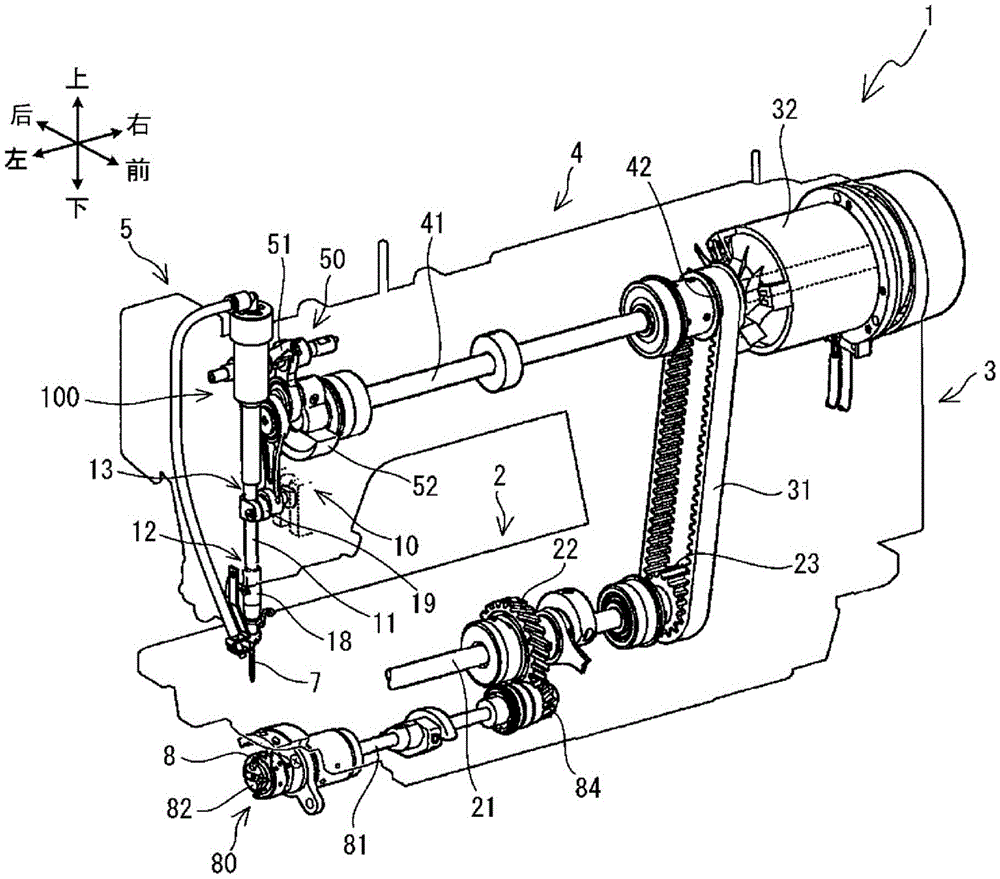

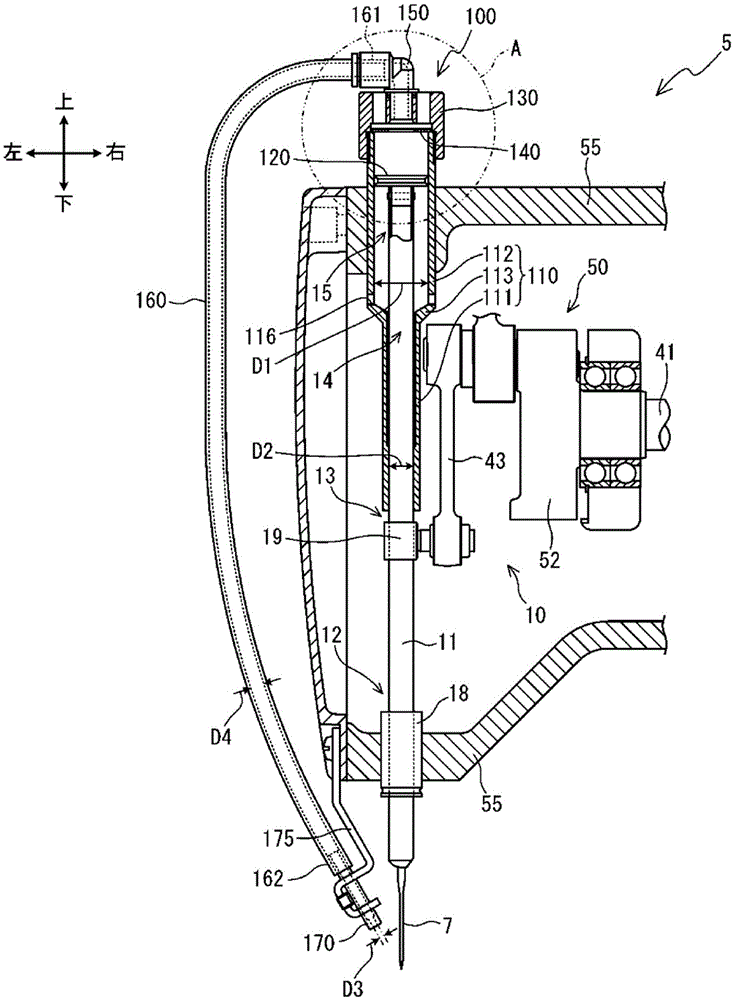

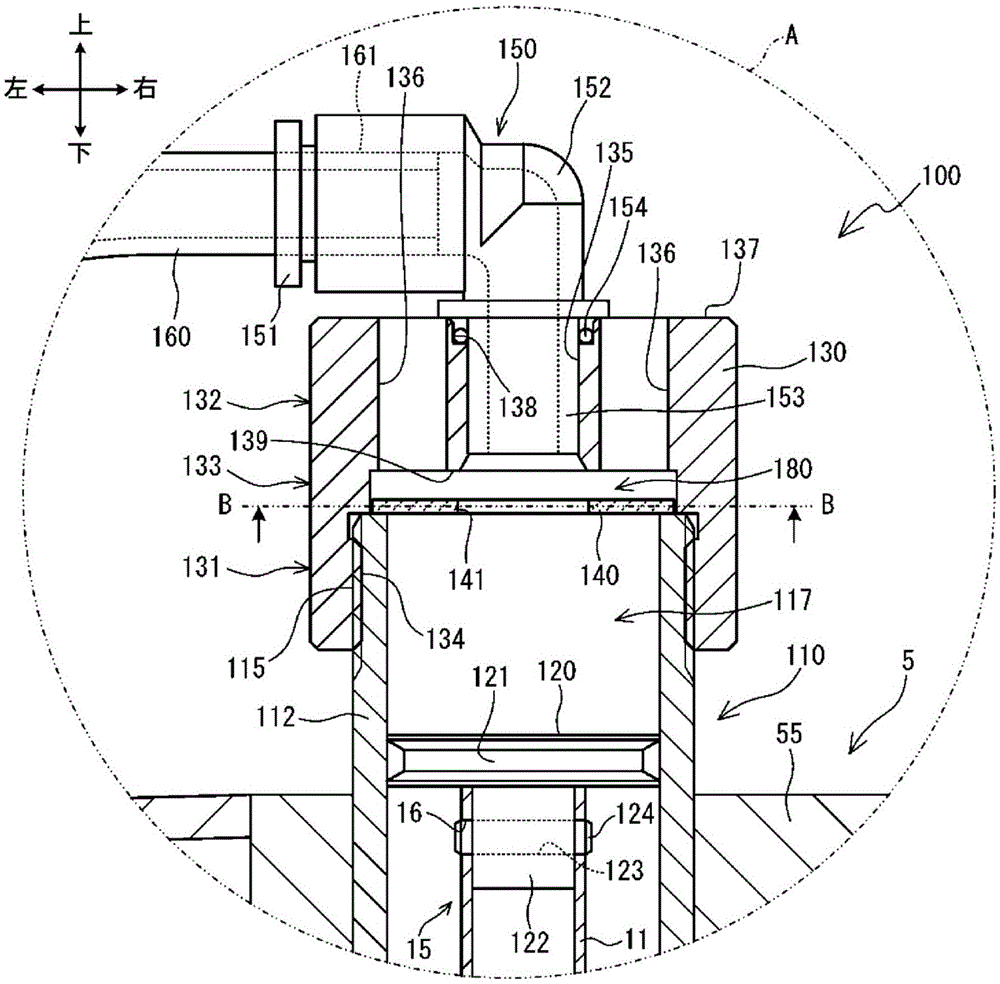

Machine needle cooling mechanism of sewing machine, sewing machine and air suction and exhaust mechanism

ActiveCN105734856AIncrease the internal volumeEfficient importLubrication/cooling devicesInjection airPiston

The invention relates to a machine needle cooling mechanism of a sewing machine, a sewing machine and an air suction and exhaust mechanism, wherein the air injection amount can be increased. According to the technical scheme of the invention, a cover part is covered onto a cylinder part. A valve chamber is formed between the cover part and the upper end of the cylinder part. The cover part is provided with a suction port and an exhaust port. The valve chamber is communicated with the outside via the suction port and the exhaust port. A circular ring-shaped valve core with a circulation port at the center thereof is arranged in the valve chamber. The valve core is in a non-fixed state in the valve chamber and is capable of moving up and down. A piston is arranged at the upper end portion of a needle bar. The needle bar moves up and down to drive the piston to move downwards, and the external air enters the valve chamber via the suction port to push the valve core downwards. The air that enters the valve chamber flows into a pump chamber via the circulating port of the valve core. When the piston moves upwards, the piston compresses the air the pump chamber. The compressed air pushes the valve core and then the valve core blocks the suction port. The compressed air is injected to the outside via a pipeline through the circulating port and the exhaust port, so that the machine needle of the sewing machine can be cooled.

Owner:BROTHER KOGYO KK

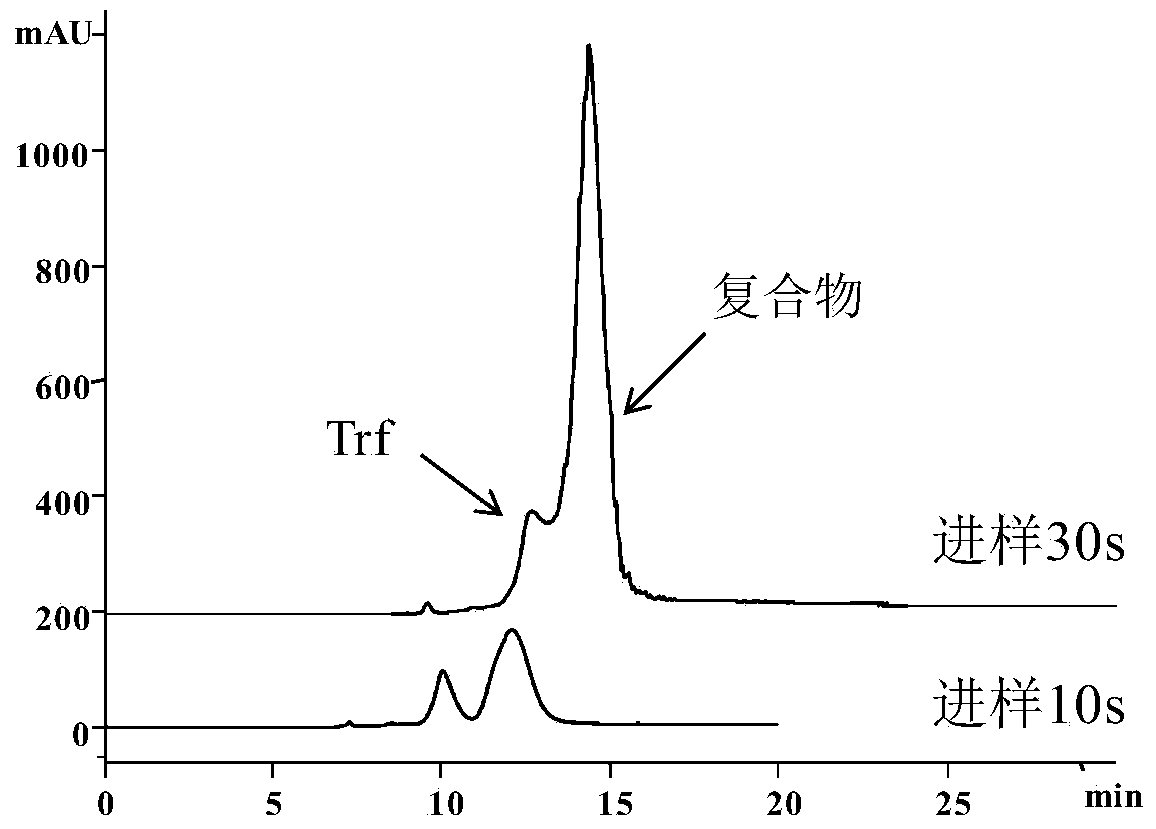

Compound collecting method based on low-pH-value capillary zone electrophresis

InactiveCN103551035AInhibition of adsorptionInhibition of electroosmotic flowDispersed particle separationElectrophoresisSingle strand dna

The invention relates to a compound collecting method based on low-pH-value capillary zone electrophresis, and belongs to the technical field of bio-separation and analysis. The method comprises the steps of incubating protein and a fluorescence labeling ssDNA (single-stranded DNA) library on ice after mixing; separating an incubated mixed sample by low-pH-value capillary zone electrophresis, wherein the pH value of electrophresis running buffer liquid is less than 3; in electrophresis separation, moving dissociated protein, dissociated ssDNA and a compound formed by the protein and the ssDNA in the mixed sample in the direction opposite to the charge characteristic according to charge characteristics of the dissociated protein, dissociated ssDNA and the compound formed by protein and ssDNA respectively; carrying out CE-LIF (capillary electrophresis laser induced fluorescence detector) analysis on collection collected at the outlet end and the inlet end of a capillary, and testing the method to be feasible. The method can inhibit electroosmotic flow and inhibit the adsorption of positive charge samples and alkaline protein on the inner wall of the capillary; the online separation of samples with different charge types is realized; the sample online enrichment amount can be increased through increasing the sample feed amount; more protein and ssDNA compounds can be obtained through analysis once.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Mixer

InactiveCN105195036AAvoid wasting jetsRadiation area is largeFlow mixersMixing methodsSilicon carbideNozzle

Provided is a mixer. The mixer comprises a mixing drum, a head cover is arranged on the mixing drum, a main pipe is installed on the head cover, a pressure type nozzle extending into the mixing drum is installed on the main pipe, a mist vent of the pressure type nozzle faces downwards, multiple mounting grooves which extend in the radial direction along the head cover and are evenly distributed in the circumferential direction are formed in the head cover, branched pipes which are communicated with the main pipe are installed in the mounting grooves, multiple pressure type nozzles extending into the mixing drum are installed on the branched pipes, mist vents of the multiple pressure type nozzles face downwards, the depths, extending into the mixing drum, of pressure type nozzles installed on the branched pipes are different from the depth, extending into the mixing drum, of the pressure type nozzle on the main pipe, head cover plates which cover the mounting grooves are arranged on the mounting grooves and hinged to the head cover, a big-end-down cone-shaped mist collecting cover is installed on the inner wall close to the edge of the head cover, and the diameter of the major diameter end is smaller than or equal to that of the head cover. According to the mixer, the radiating area can be larger when atomized absolute ethyl alcohol is sprayed out, the atomized absolute ethyl alcohol can make contact with carborundum in time to be mixed fully and evenly.

Owner:宁波天工机械密封有限公司

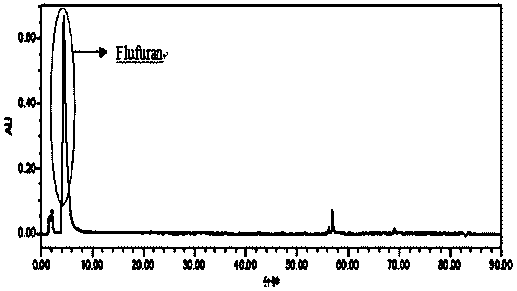

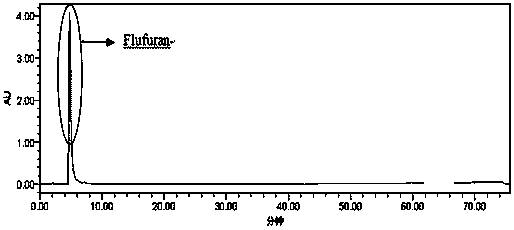

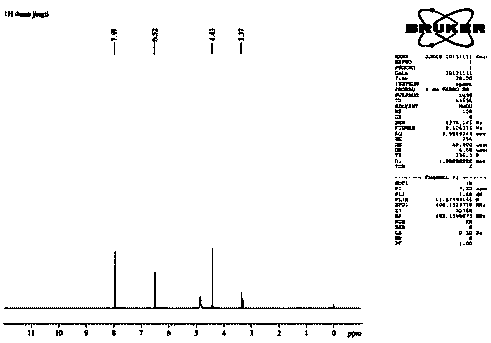

Fermentation process of ocean penicillium and secondary metabolite Flufuran thereof

ActiveCN104031845AIncrease productionLarge injection volumeFungiMicroorganism based processesBiotechnologySecondary metabolite

The invention discloses a fermentation process of ocean penicillium and secondary metabolite Flufuran thereof. The ocean penicillium is characterized in that the preservation number of penicillium is CCTCCM2014087, and the fermentation process of the penicillium comprises the following steps: inoculating PDA (Potato Dextrose Agar) with the ocean penicillium, culturing for 2 days in an incubator with the temperature of 25 DEG C, picking a single bacterial flora and then inoculating on a PDA culture medium, and culturing for 2 days at the temperature of 25 DEG C for later use; (2) inoculating PDB with the activated strain, culturing for 1 day at the temperature of 25 DEG C and at a rotating speed of 150rpm to obtain a seed solution; (3) inoculating the seed solution in a fermentation culture medium and culturing for 12 days at the temperature of 25 DEG C and at the rotating speed of 150rpm, wherein the inoculated amount of the seed solution is 5vol%,; (4) filtering a fermentation solution to obtain a supernatant liquor, extracting for three times by use of ethyl acetate, removing an organic phase, and dissolving again by use of methanol to obtain a sample introduction solution; (5) separating and purifying the sample introduction solution by adopting a high-speed counter-current chromatographic method to obtain a product, wherein the fermentation process has the advantages of high preparation speed and high product purity.

Owner:NINGBO XINUOYA MARINE BIOTECH CO LTD

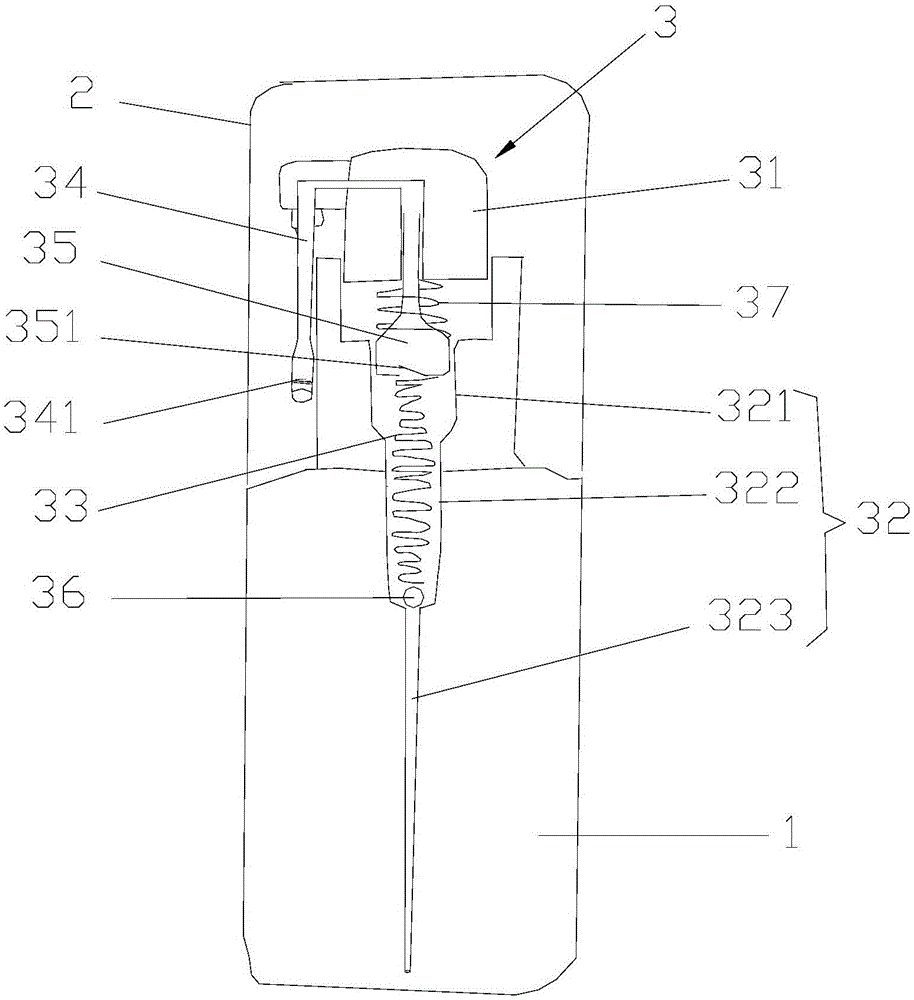

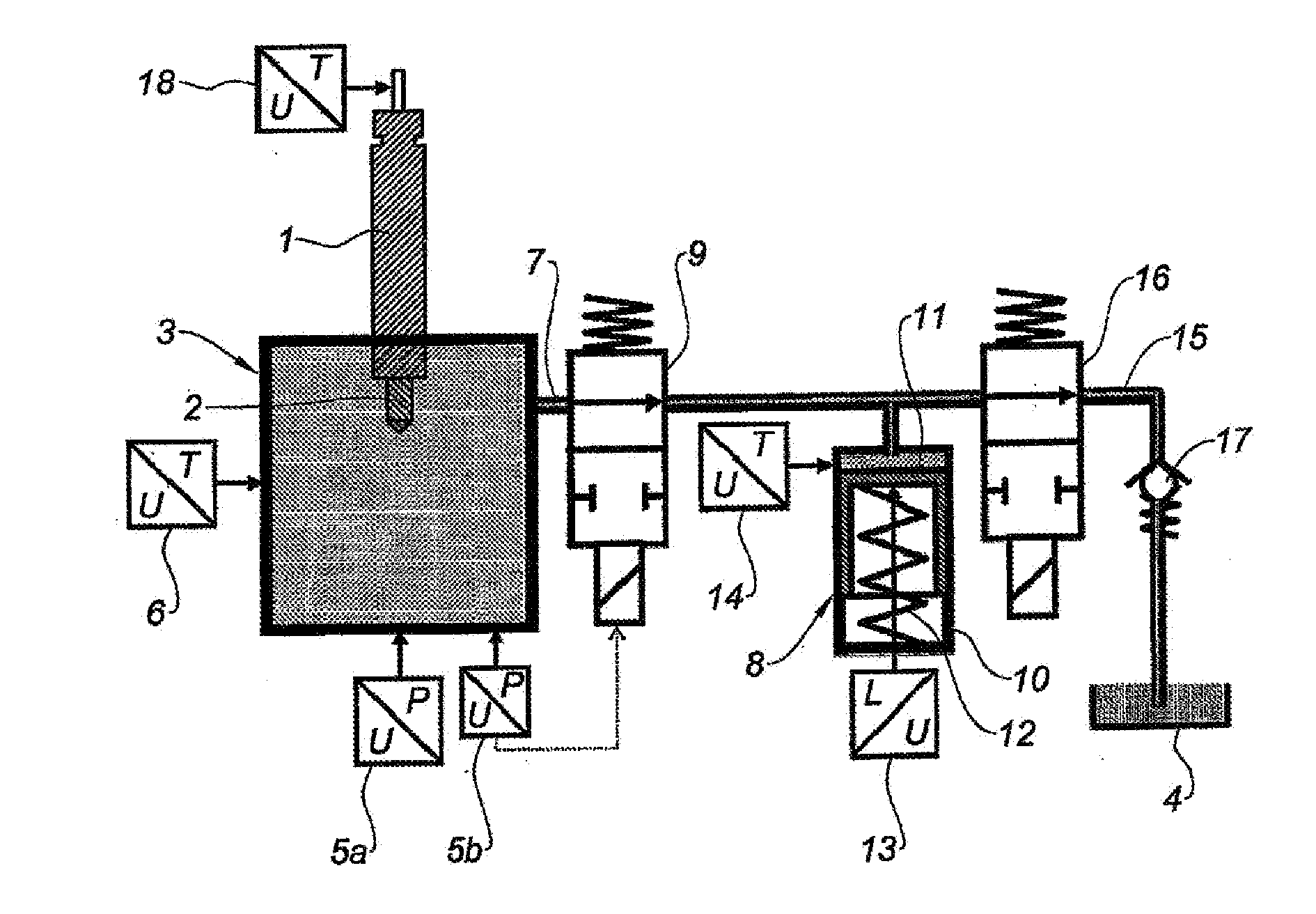

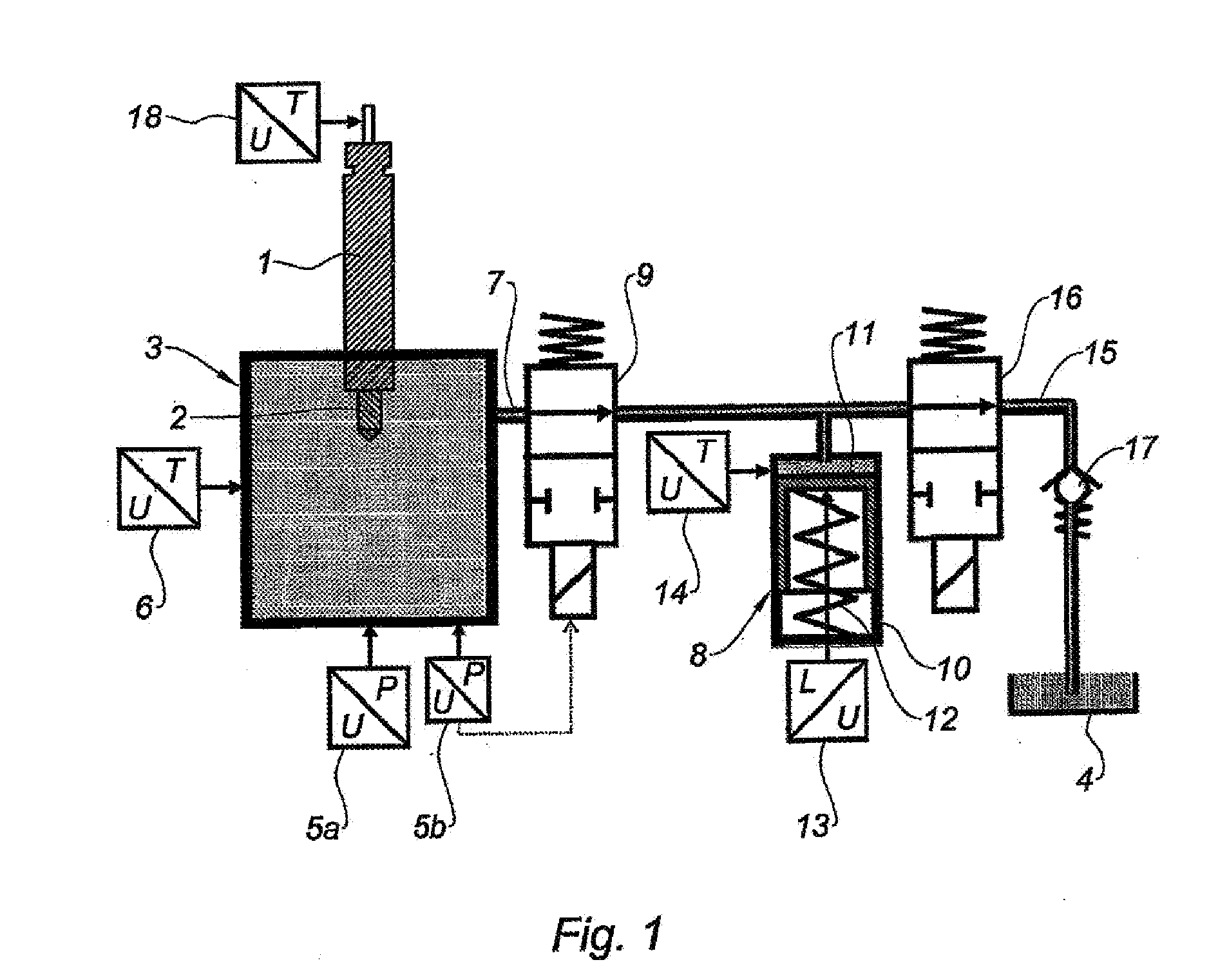

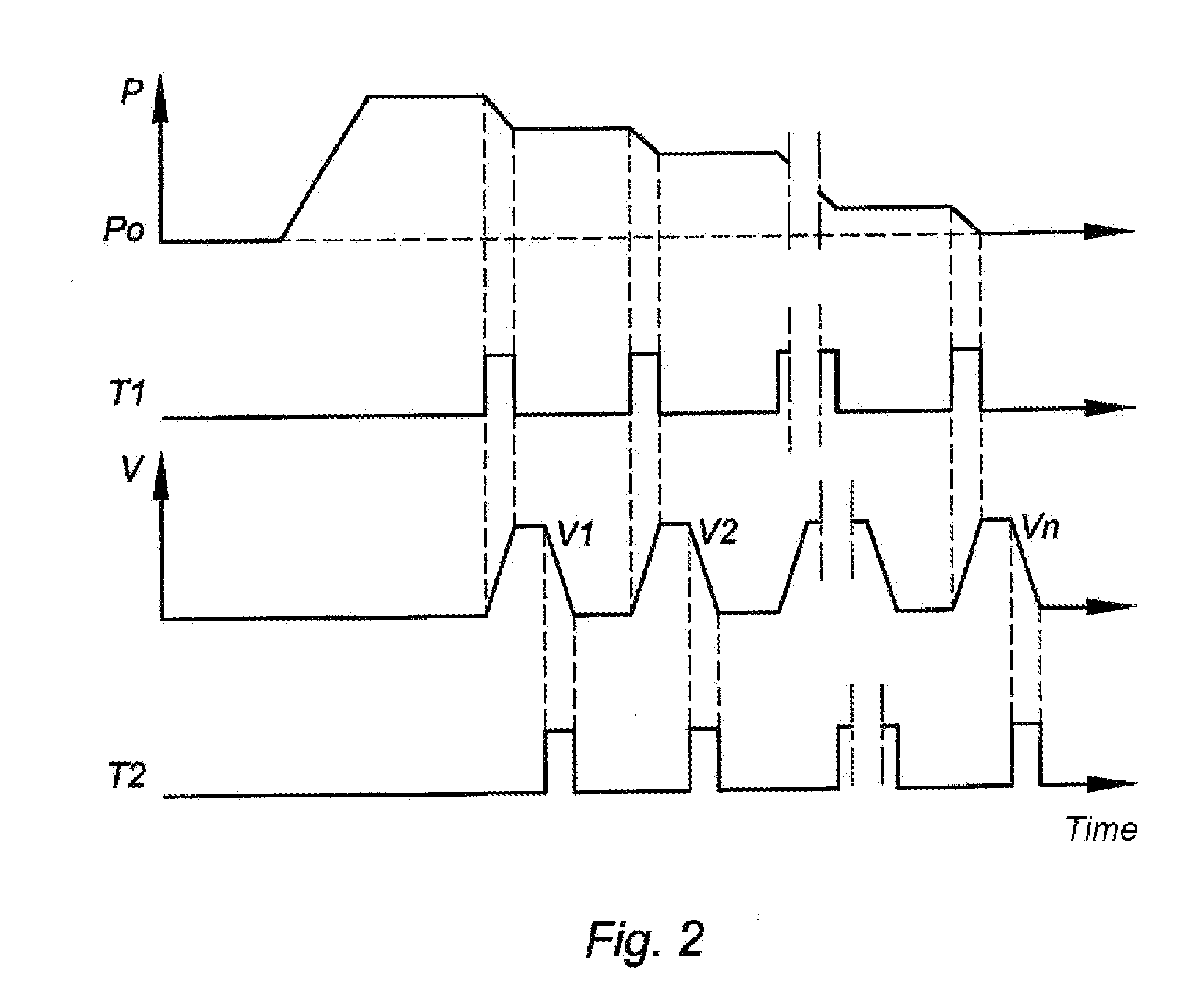

Method for analyzing the step-by-step injection rate provided by a fuel injection system used in a high power heat engine

InactiveUS20110185799A1Avoid difficultyInexpensive solutionEngine testingVolume/mass flow measurementEngineeringInjection rate

The method of the invention includes the injection of fuel in a first constant-volume measuring chamber (3) in which the pressure (P) and the temperature (T) are measured, and the partial draining of said first chamber into a second variable-volume measuring chamber (8) based on the movement of a piston (11), said movement being measured, wherein the partial draining of the first chamber into the second chamber after an injection is carried out until the pressure (Po) existing in the first chamber before the injection is recovered. The draining of the first chamber into the second after each injection is carried out several times consecutively, and the second chamber itself is drained each time. The volumetric measures made by moving the piston (11) for each filling / draining of the second chamber are added in order to obtain a total volume. The method is useful for high injection rates.

Owner:EFS SA

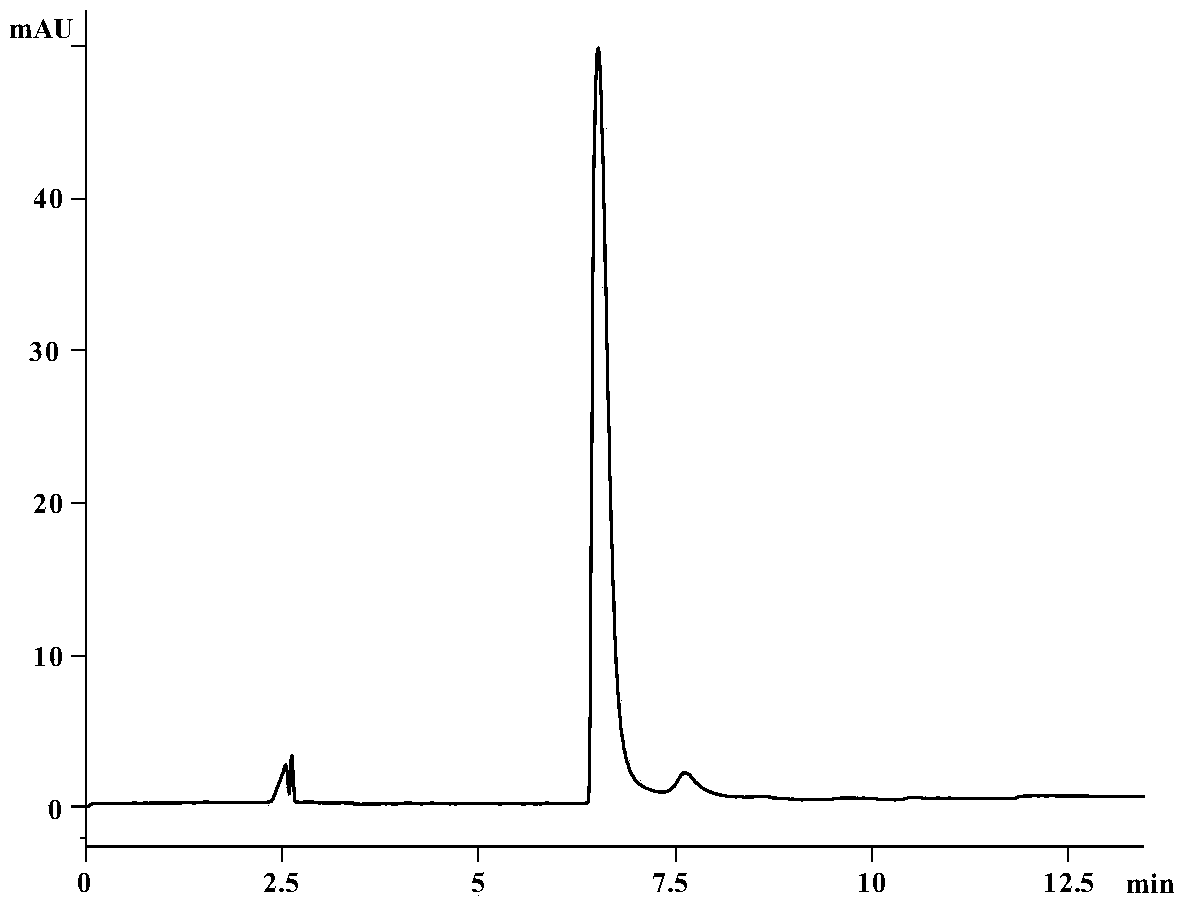

Detection method of relevant substances of ibuprofen injection

InactiveCN109521117AIncrease concentrationHigh detection sensitivityComponent separationIbuprofen InjectionSilica gel

The invention discloses a detection method of relevant substances of ibuprofen injection. The relevant substances comprise arginine. A high performance liquid chromatography method is used for detection; the relevant substances are subjected to qualitative or quantitative detection. The detection conditions comprise a detector being an ELSD detector, a chromatographic column being an alkyl silanebonded silica gel column or an amino column, flowing phases including an organic phase and a water phase at the volume ratio of (50 to 70):(50 to 30) (preferably 65:35). By using the method provided by the invention, the relevant substance of the arginine can be accurately monitored; the guarantee is provided for the quality and safety of the ibuprofen injection.

Owner:CHENGDU BRILLIANT PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com