Two-dimensional back flush gas chromatograph gas circuit and analysis method thereof

A technology of backflushing gas and chromatography, which is applied in the field of gas chromatography analysis, can solve the problems of low detection ability and long analysis time, and achieve the effects of strong detection ability, improved analysis efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

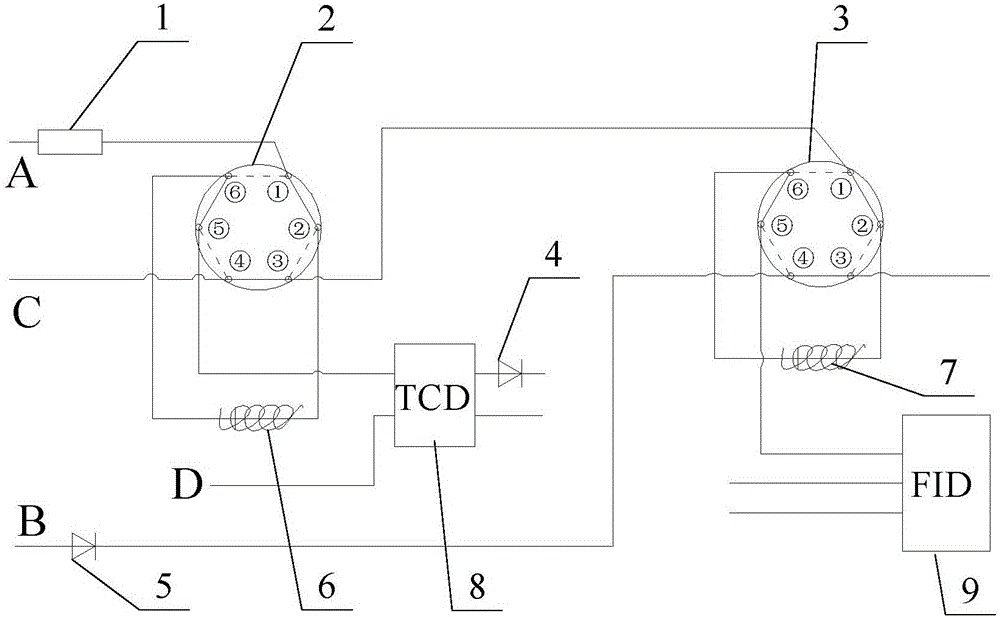

[0017] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the two-dimensional backflushing gas chromatography gas path described in this embodiment includes a vaporization chamber 1, and it also includes No. 1 six-way valve 2, No. 2 six-way valve 3, No. 1 cone valve 4, No. 2 No. 5 cone valve, No. 1 packed column 6, No. 2 packed column 7, thermal conductivity detector 8 and hydrogen flame detector 9,

[0018] The six interfaces of No. 1 six-way valve 2 and No. 2 six-way valve 3 are arranged clockwise;

[0019] The inlet A of the carrier gas source is connected to the inlet of the vaporization chamber 1, the outlet of the vaporization chamber 1 is connected to the ① port of the No. 1 six-way valve 2, and the ② port of the No. 1 six-way valve 2 is connected to the inlet of the No. 1 packed column 6. The No. 1 packed column The outlet of 6 is connected to the ⑥ interface of the No. 1 six-way valve 2, and the ⑤ interface of the No. 1 six...

specific Embodiment approach 2

[0025] Specific implementation mode two: the following combination figure 1 Describe this embodiment, a two-dimensional backflush gas chromatography analysis method described in this embodiment, the analysis method is realized based on the two-dimensional backflush gas chromatography gas path described in the first specific embodiment,

[0026] Connect the ① port of the No. 1 six-way valve 2 with the ② port, the ③ port with the ④ port, and the ⑤ port with the ⑥ port; , ⑤ interface and ⑥ interface are connected to form the initial state of No. 1 six-way valve 2 and No. 2 six-way valve 3;

[0027] The diaminodiphenylmethane product solution enters from the inlet A of the carrier gas source, and is vaporized into a gas through the vaporization chamber 1. Driven by the carrier gas A, it flows through the No. 1 six-way valve 2 and the No. 1 packed column 6, and then enters the thermal Conducting detector 8 carries out moisture analysis;

[0028] When the water peak is finished, s...

example 1

[0033] Example 1: Detection ability experiment

[0034] Using dried acetone as a solvent, prepare 7 standard samples of water with different concentrations and aniline standard samples with different concentrations, and label them. Inject and analyze 7 standard samples in sequence, record the peak height of the water peak in the TCD thermal conductivity detector, and the peak height of aniline in the FID hydrogen flame detector, and take the water / aniline content in the sample as the X-axis, the water / aniline peak The peak height signal value was used as the Y axis, and the standard curve was drawn respectively and its sensitivity, detection limit and lower limit of quantification were calculated.

[0035]The results show that: the water content is between 0.696mg / mL~4.667mg / mL, the linear correlation is good, the correlation coefficient is 0.9953, the sensitivity is 1250.8μV / mg·mL-1, and the detection limit of water is 14.42μg / mL, the lower limit of quantification is 52.23 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| detection limit | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com