Method for rapidly detecting main component in active lime and passivated lime

An active lime, rapid determination technology, applied in the field of analytical chemistry, can solve the problems of titration error amplification, increase of analytical test uncertainty, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

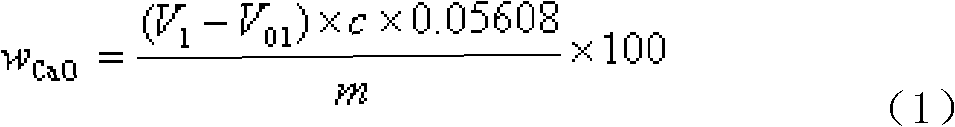

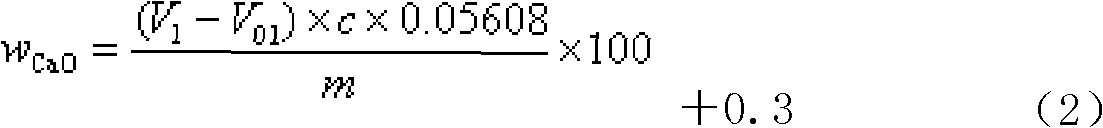

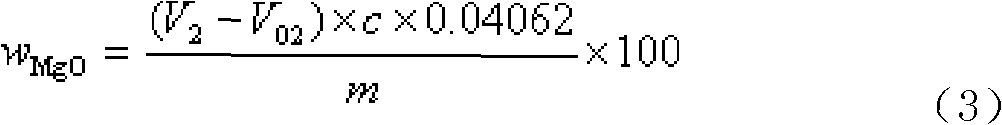

[0068] Weigh 0.1g to 0.50g, preferably 0.5000g, (accurate to 0.0001g) active lime and passivated lime samples that have been prepared to have a particle size of less than 0.125mm and placed in a sealed bottle, and carry out a blank test along with the sample. Place in a 100mL-250mL heating container, preferably a 150mL beaker for the heating container, add 30mL-100mL hydrochloric acid solution with a concentration ratio of 1:1 to 1:5, the sample size corresponds to the amount of hydrochloric acid, when When the sample volume is small, a small amount or low concentration ratio of hydrochloric acid solution should be used to dissolve the sample, preferably 100mL of hydrochloric acid with a concentration of 1:3. If the sample is not completely decomposed, 10mL of hydrochloric acid with a concentration of 1:3 can be added each time. Hydrochloric acid, or choose other concentrations of hydrochloric acid and dosage to dissolve the sample, decompose the sample on the heater until it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com