Method for separating anthocyanins monomer from lycium ruthenicum fruits

A technology of black fruit wolfberry and anthocyanin, which is applied in the field of separating and preparing anthocyanin monomers, can solve the problems of volatilization of chemical reagents, harm to operators, loss of anthocyanins, etc., and achieves the advantages of short separation time, safe operation, and prevention of degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

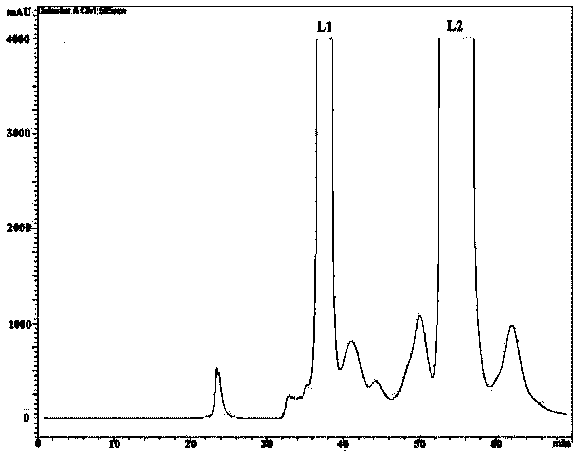

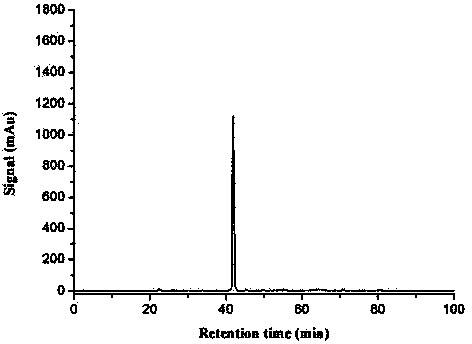

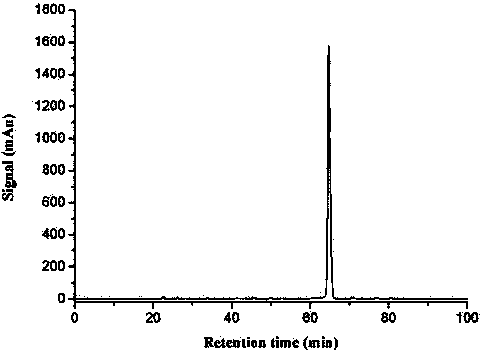

Image

Examples

Embodiment 1

[0029] Example 1 A method for isolating and preparing anthocyanin monomer from Lycium barbarum fruit, comprising the following steps:

[0030] (1) Raw material pretreatment: select the black fruit wolfberry fruit to remove impurities, wash it with water, and wash away the floating soil on the surface to obtain the processed black fruit wolfberry fruit.

[0031] (2) Prepare a methanol solution with a volume concentration of 2% formic acid: mix 200 mL of formic acid and 9800 mL of methanol evenly.

[0032] (3) Add the formic acid methanol solution obtained in step (2) to the fruit of Lycium ruthenicum fruit, and carry out normal temperature leaching at a ratio of 1 g: 1 mL at room temperature in the dark, and the extraction frequency is 1 time, 12 h each time, and combined to obtain the extract.

[0033] (4) Remove insoluble matter, protein, and polysaccharides from the extract with filter paper to obtain a filtrate, which is vacuum-evaporated on a rotary evaporator at 40...

Embodiment 2

[0042] Example 2 A method for isolating and preparing anthocyanin monomer from Lycium barbarum fruit, comprising the following steps:

[0043] ⑴Raw material pretreatment is the same as Example 1 .

[0044] ⑵Preparation volume concentration is 2% methanol solution of formic acid Example 1 .

[0045] (3) Add the formic acid methanol solution obtained in step (2) to the fruit of Lycium ruthenicum fruit, carry out normal temperature leaching at a ratio of 1 g: 5mL at room temperature in the dark, the extraction times are 3 times, each time for 24 h, combined to obtain extract.

[0046] (4) Remove insoluble matter, protein, and polysaccharides from the extract with filter paper to obtain a filtrate. The filtrate is vacuum evaporated and concentrated to a paste on a rotary evaporator at 50° C. to obtain anthocyanin extract from Lycium barbarum, and methanol is recovered.

[0047] ⑸The treatment of macroporous adsorption resin is the same as Example 1 .

[0048] (6) Re...

Embodiment 3

[0055] Example 3 A method for isolating and preparing anthocyanin monomer from Lycium barbarum fruit, comprising the following steps:

[0056] ⑴Raw material pretreatment is the same as Example 1 .

[0057] ⑵Preparation volume concentration is 2% methanol solution of formic acid Example 1 .

[0058] (3) Add the formic acid methanol solution obtained in step (2) to the fruit of Lycium ruthenicum fruit, and carry out normal temperature leaching at a ratio of 1 g: 3 mL at room temperature in the dark, and the extraction times are 2 times, each time for 18 h, and combined to obtain extract.

[0059] (4) Remove insoluble matter, protein, and polysaccharides from the extract with filter paper to obtain a filtrate, which is vacuum-evaporated on a rotary evaporator at 45°C and concentrated to a paste to obtain anthocyanin extract from Lycium ruthenicum, and recover methanol.

[0060] ⑸The treatment of macroporous adsorption resin is the same as Example 1 .

[0061] (6) R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com