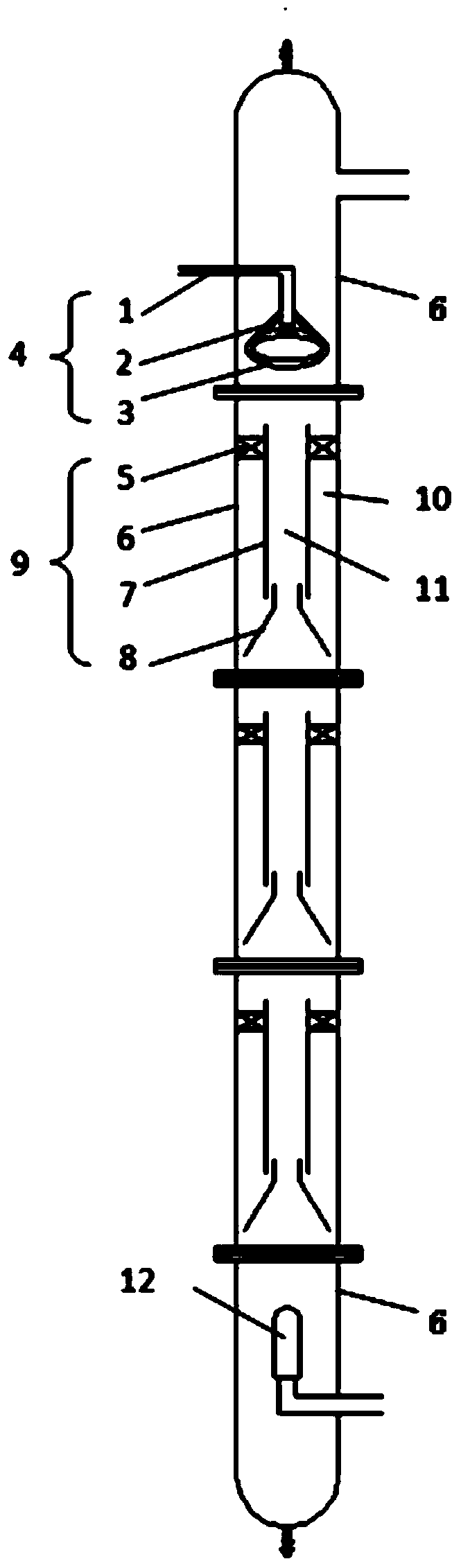

Oil-water separating tower

A technology of oil-water separation and tower section, which is applied in the field of oil-water separation tower and oil-water separation process. It can solve the problems of easy plugging of fillers, short liquid residence time, secondary pollution, etc., to increase residence time, increase separation effect, and improve mutual contact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

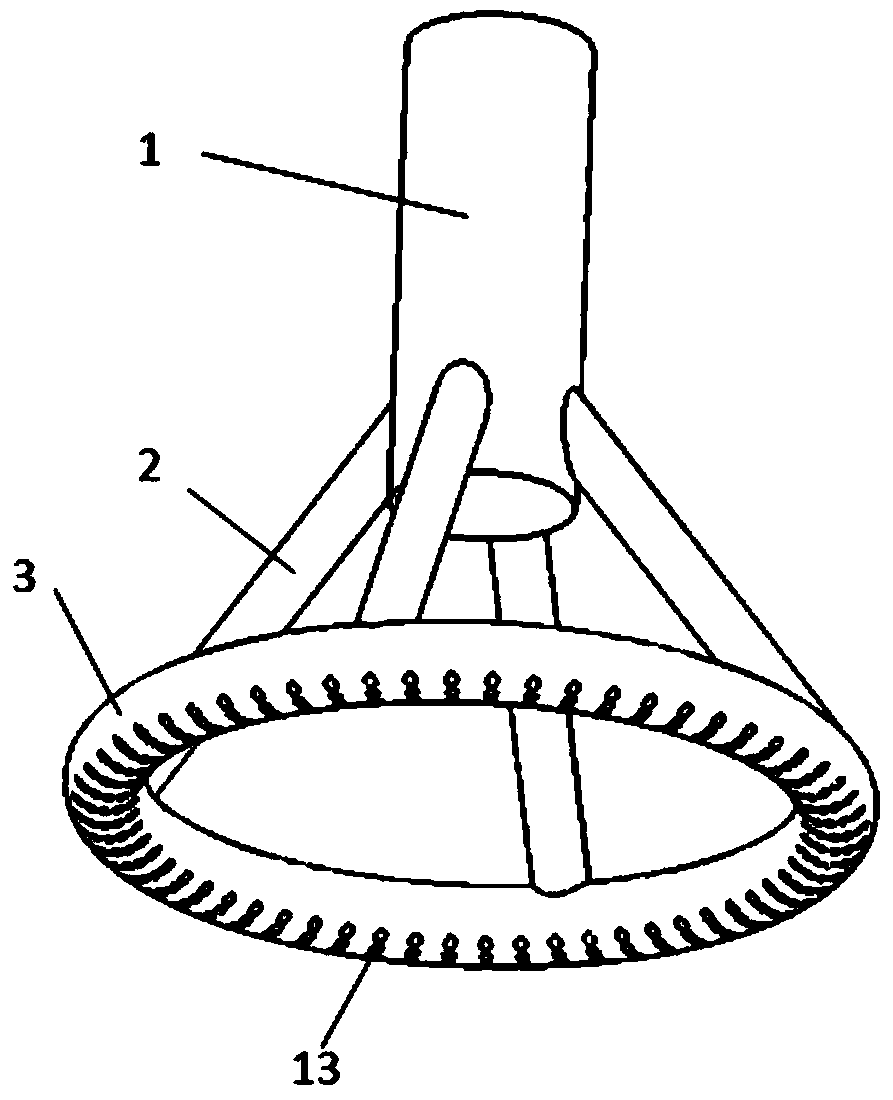

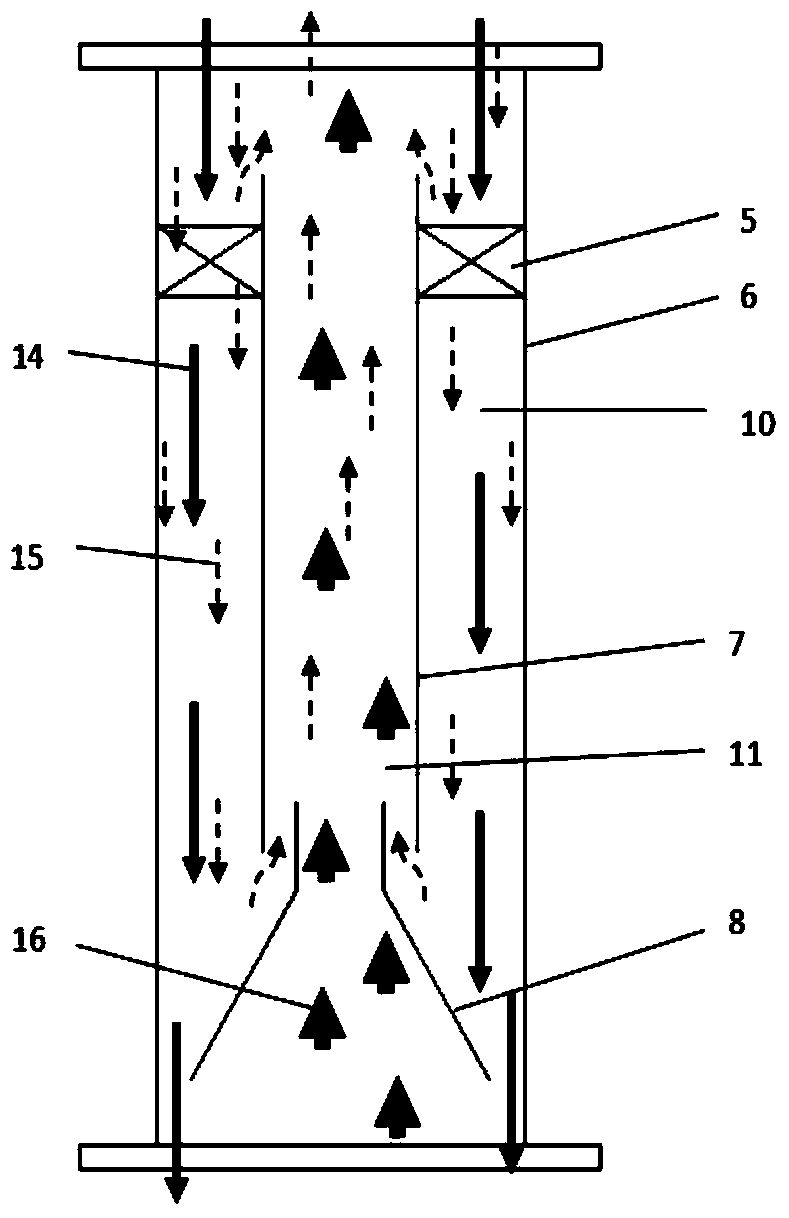

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Use the above-mentioned experimental equipment to separate oil and water from industrial waste liquid. The process is as follows: fill the device with industrial waste liquid at normal temperature and pressure, then introduce microbubble gas into the device, adjust the two-phase flow rate to be stable, and carry out Continuous and stable operation. The operating industrial waste liquid flow rate is 1t / h, the main component is the emulsion of organic oil phase and water, of which the oil phase content is 70%; the gas flow rate is 20m 3 / h. By adopting the oil-water separation tower of the present invention, the yield of oil is 97%, which is 25% higher than that of other processes.

Embodiment 2

[0028] Example 2: Use the above-mentioned experimental equipment to separate oil and water from industrial waste liquid. The process is as follows: fill the device with industrial waste liquid at normal temperature and pressure, then introduce microbubble gas into the device, adjust the two-phase flow rate to be stable, and carry out Continuous and stable operation. The flow rate of industrial waste liquid is 2t / h, the main component is the emulsion of organic oil phase and water, of which the oil phase content is 60%; the gas flow rate is 25m 3 / h. By adopting the oil-water separation tower of the present invention, the yield of oil is 97%, which is 25% higher than that of other processes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com