Hyperbolic filler bending mold

A hyperbolic turning and mold technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting separation efficiency, affecting separation effect, and reducing production efficiency, so as to improve separation efficiency, improve separation effect, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

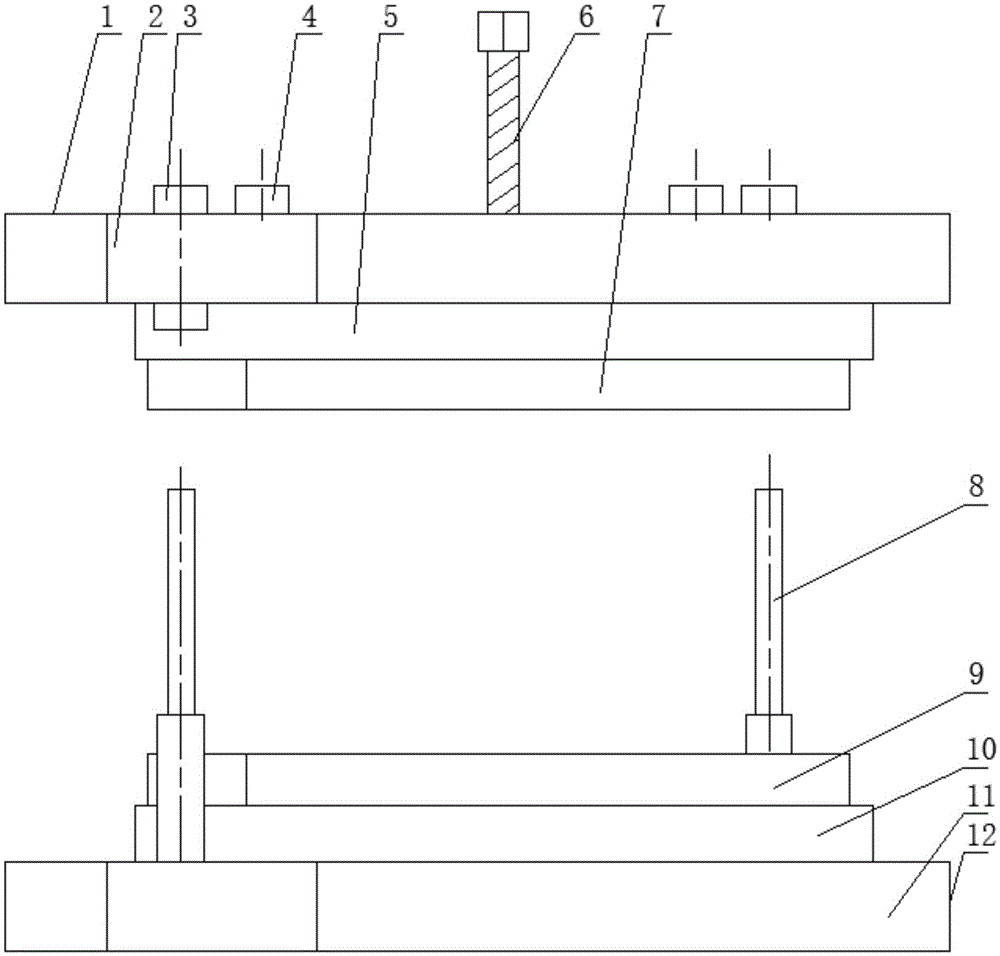

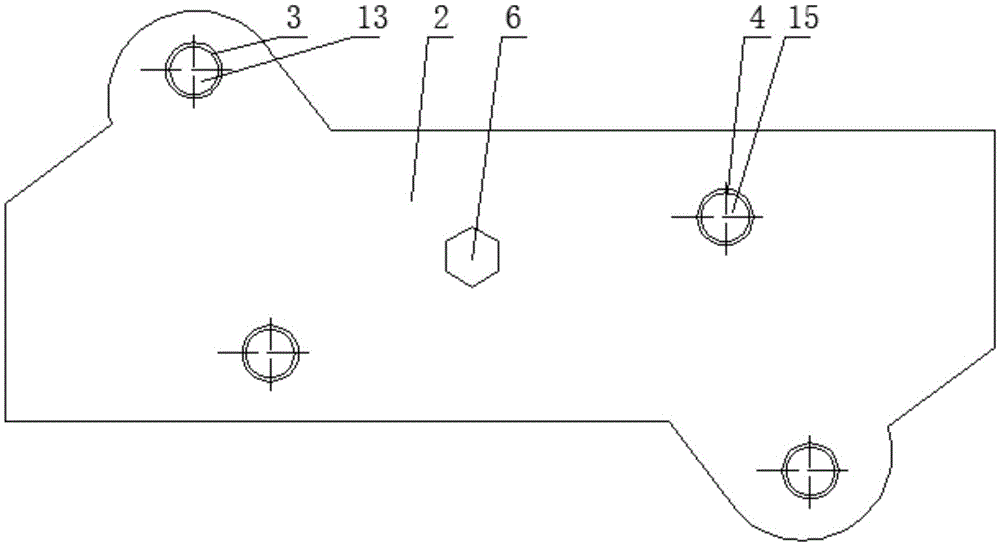

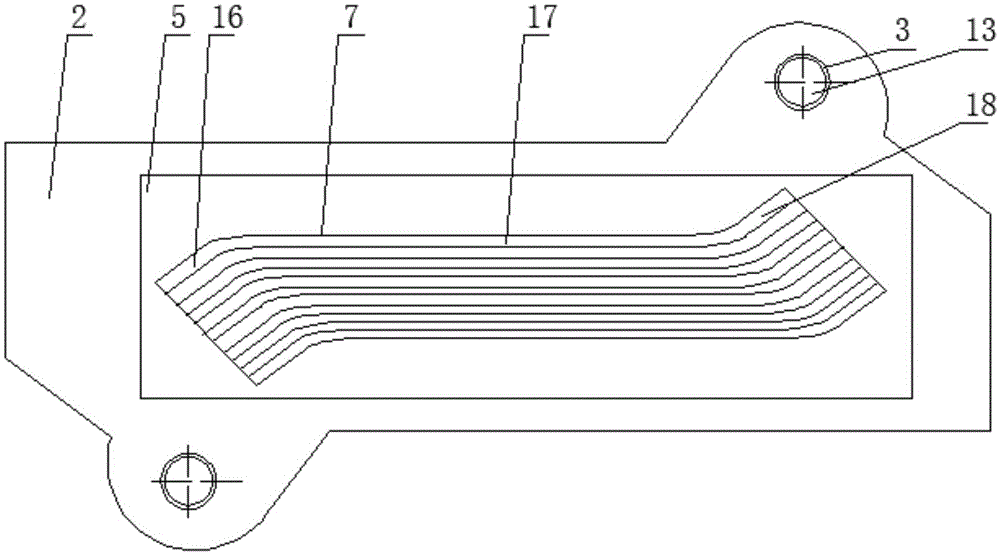

[0025] A hyperbolic packing bending die, such as figure 1 and figure 2 As shown, the mold includes an upper die 1 connected to the punch and a lower die 12 detachably arranged on the working platform of the punch press, and the upper die and the lower die are vertically oppositely arranged during use;

[0026] The upper mold includes a punch connecting part 2, an upper connecting plate 5 and an upper die pressing plate 7 which are connected in sequence, and the punch connecting part is fixed on the top surface of the upper connecting plate in parallel, and the upper connecting plate The upper molded plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com