Efficient jujube harvesting robot

A technology of robots and jujubes, applied to harvesters, picking machines, agricultural machinery and equipment, etc., can solve the problems of inconvenient collection of jujubes and falling of jujubes, reduce manual fatigue, increase rolling speed, and prevent jujubes from being damaged Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

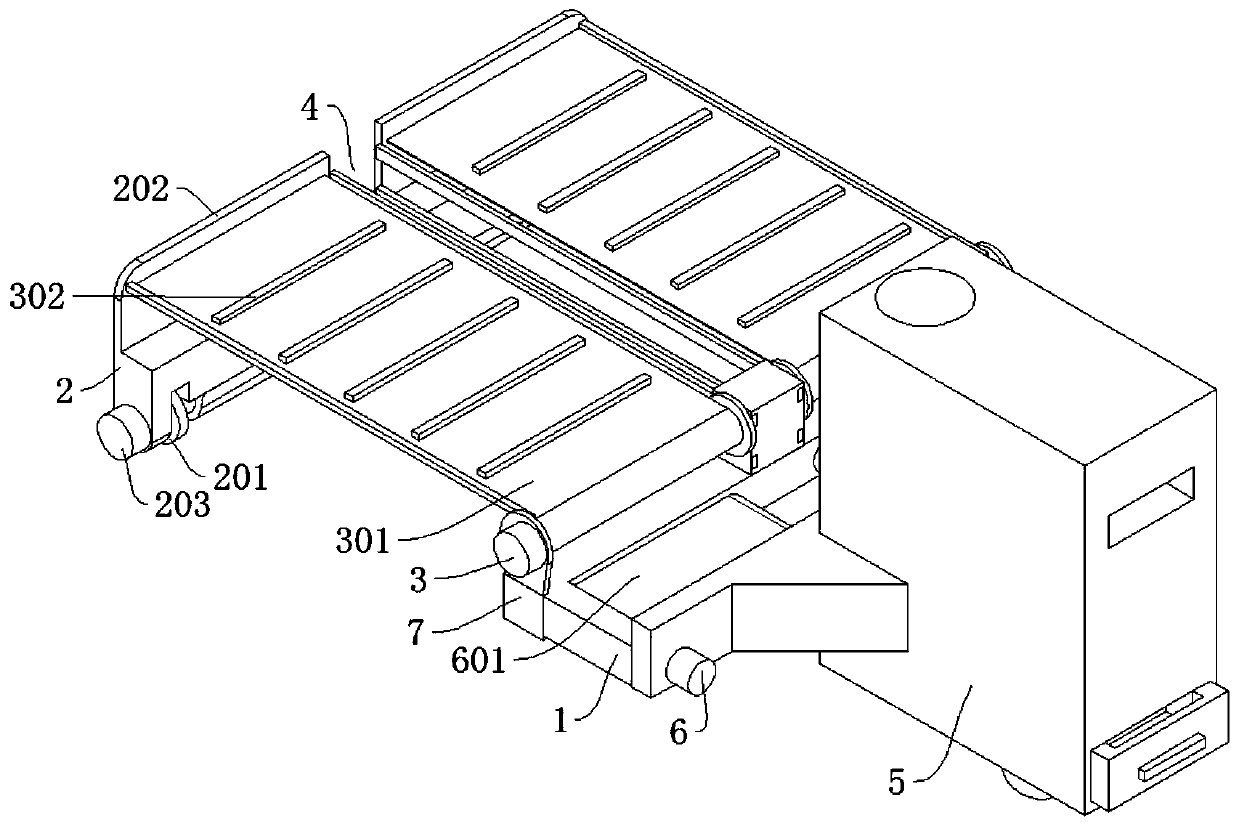

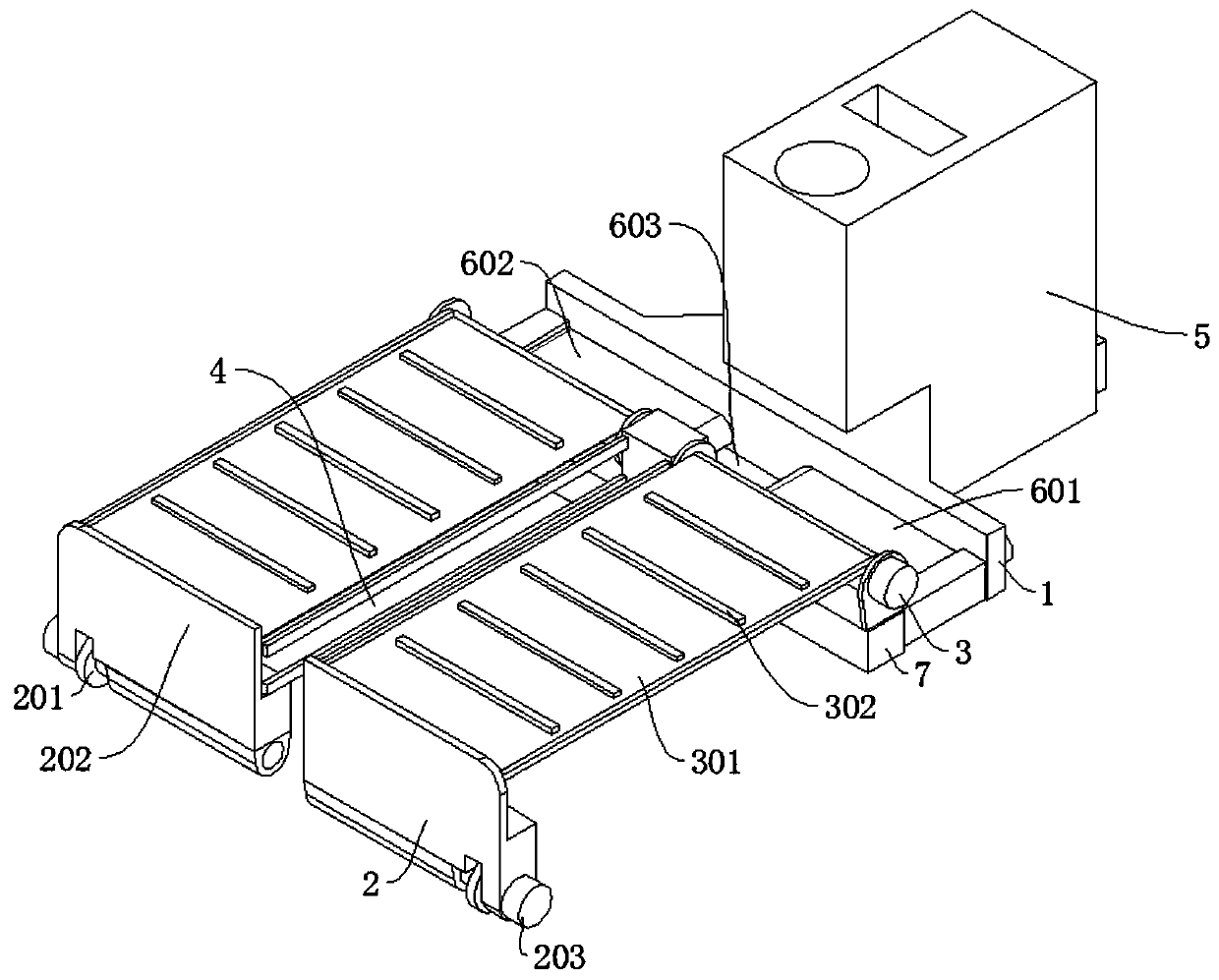

[0031] refer to Figure 1-4 , in order to solve the problem that red jujubes fall after hitting or mechanically vibrating the fruit trees, and it is inconvenient to collect red dates in a concentrated manner, the application adopts the following technical means: including base 1; moving seat 2, moving seat 2 and base 1 The position of the collection cloth 301 can be changed; one end of the collection cloth 301 is connected with the base 1, and the other end is connected with the mobile seat 2; wherein, the base 1 is connected with a winding mechanism corresponding to the collection cloth 301; the quantity of the mobile seat 2 and the collection cloth 301 is the same It is two and symmetrical to each other, and there is a space 4 for accommodating the trunk in the middle; the driving part that drives the moving seat 2 is connected to the mobile seat 2; the collection port 603 is opened on the base 1; Jujubes are transported to the collecting port 603 on the base 1; the separati...

Embodiment 2

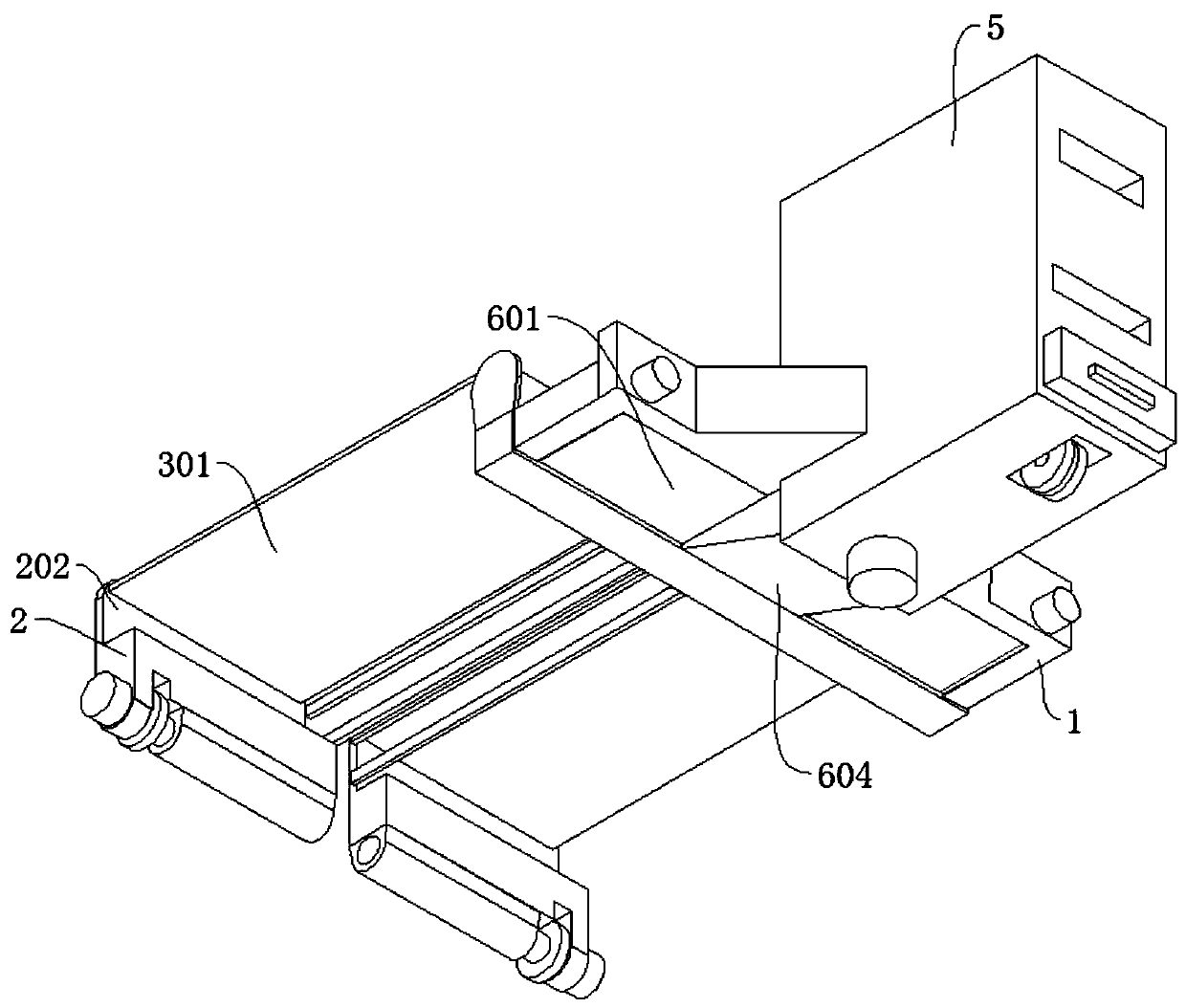

[0033] refer to Figure 1-3, which is basically the same as that of Example 1. Furthermore, this implementation is a specific implementation of the winding mechanism, and the winding mechanism includes two brackets 703, and the base 1 is fixedly connected with the box body 7, so The two-way screw rod 702 connected with oil is rotated in the box body 7, and the two brackets are threadedly connected with the two-way screw rod 702. The top of the box body 7 is provided with a chute 704, and the two brackets 703 are slidably connected in the chute 704. The side wall of the box body 7 is connected with a motor E701, the output end of the motor E701 is fixedly connected with the two-way screw 702, the side wall of the support plate 703 is connected with a motor A3, and the output end of the motor A3 is connected with a rotating shaft A, The collecting cloth is wound and connected to the rotating shaft A, and the air motor E701 drives the two-way screw 702 to rotate, thereby driving ...

Embodiment 3

[0036] refer to Figure 1-3 , is basically the same as Embodiment 1, and furthermore, this implementation is a specific embodiment of the driving part, which includes a rotating shaft B that is rotatably connected to the bottom of the moving base 2, and the rotating shaft B is fixedly connected with a road wheel 201, and the moving base 2 The side wall is connected with a motor B203, the output end of the motor B203 is connected with the rotating shaft B, the moving seat 2 is provided with a connecting plate 202, the end of the collecting cloth 301 away from the winding mechanism is connected with the connecting plate 202, and the rotating shaft B is driven by the motor B203 to rotate, Therefore, the traveling wheel 201 is rotated, the moving seat 2 is separated from the base 1, and the collecting cloth 301 is unfolded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com