Arc gear and arc rack

An arc gear and tooth line technology, applied in the arc gear and arc rack field, can solve the problems of machining error, poor meshing quality, etc., and achieve the effects of easy assembly, uniform wear and easy gunning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

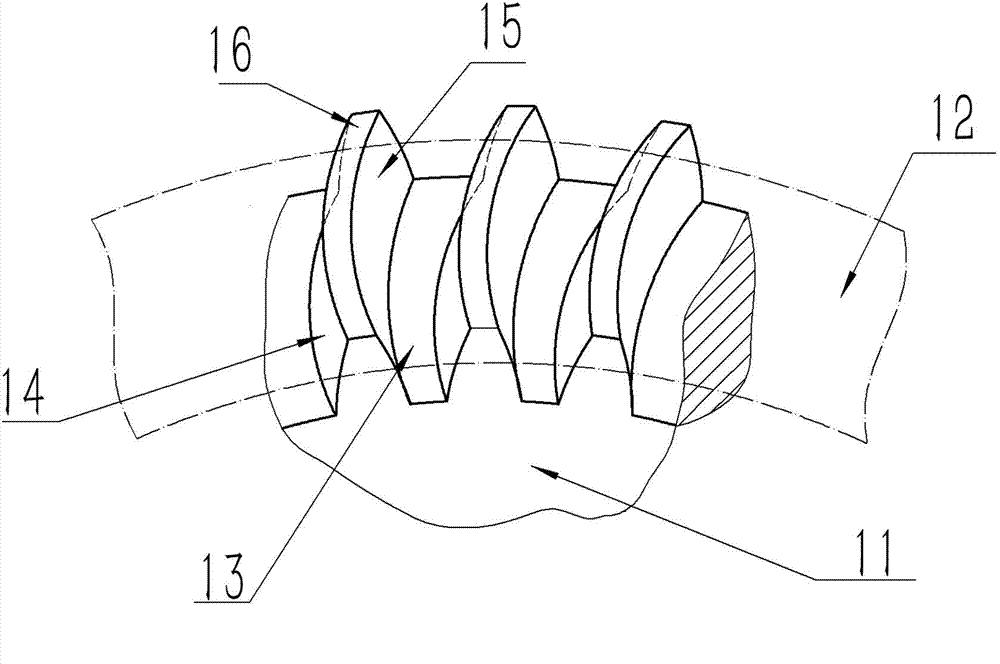

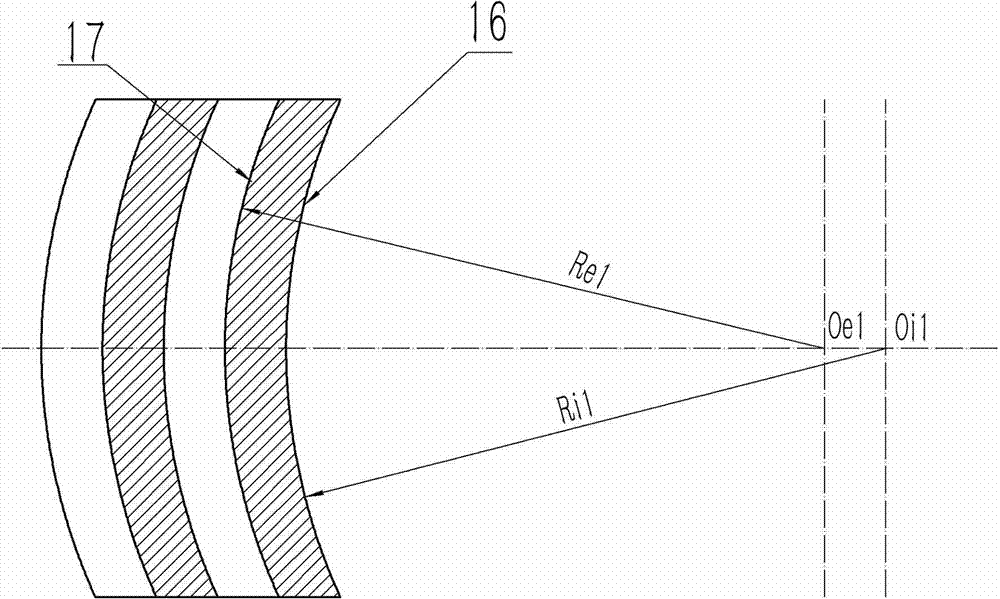

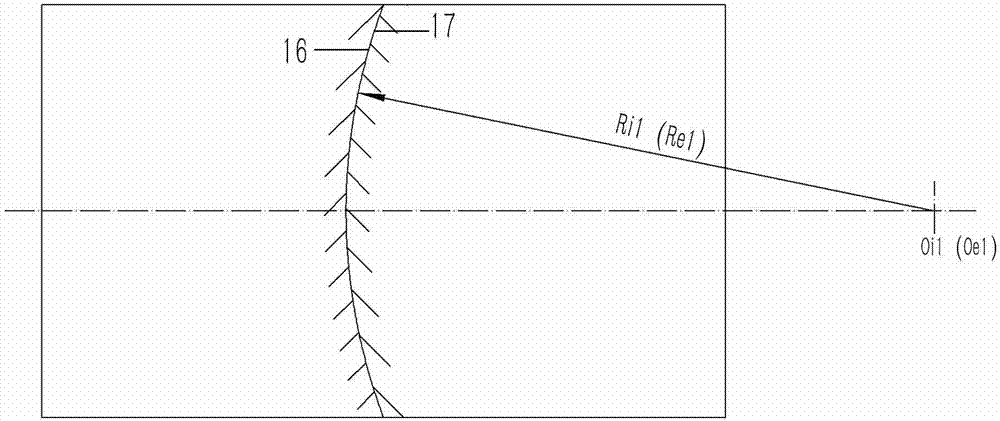

[0025] The embodiment of arc gear of the present invention: as Figure 5 to Figure 7 As shown, the arc gear is a kind of cylindrical gear with unequal diameter circular arc teeth. The arc-shaped tooth surfaces on the opposite sides of the tooth are respectively concave tooth surfaces and convex tooth surfaces, wherein the tooth lines of the convex tooth surfaces on the indexing cylinder surface are arc-shaped convex tooth lines 22, and the concave tooth surfaces are divided into The expanded tooth line on the degree cylindrical surface is an arc-shaped concave tooth line 21, the centers of the convex tooth line 22 and the concave tooth line 21 are on the symmetrical midline of the indexing cylindrical surface development surface, and the arc radius Re of the convex tooth line 22 is It is smaller than the arc radius Ri of the concave tooth line 21. Under the condition of maintaining the equal tooth thickness of the existing gear teeth, the spacing distance between the center O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com