Method for preparing usnic acid

A technology of Usnenic acid and Usnea longus, which is applied in the field of separation and preparation of natural antibiotics, can solve the problems of cumbersome and lengthy process, loss of target product, and lower yield, and achieve the advantages of short separation time, strong separation ability and small sample loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Weigh 100 g of Usnea longissima with a mesh size of 20 mesh after crushing, add 600 ml of petroleum ether with a boiling range of 60° C. to 90° C., reflux extraction for 6 hours, and suction filter. Repeat the above reflux extraction step 3 times. The combined filtrates were concentrated to 15 ml at 45° C. under vacuum (vacuum degree of 0 MPa), and allowed to stand at room temperature overnight to obtain a crude extract of usnic acid.

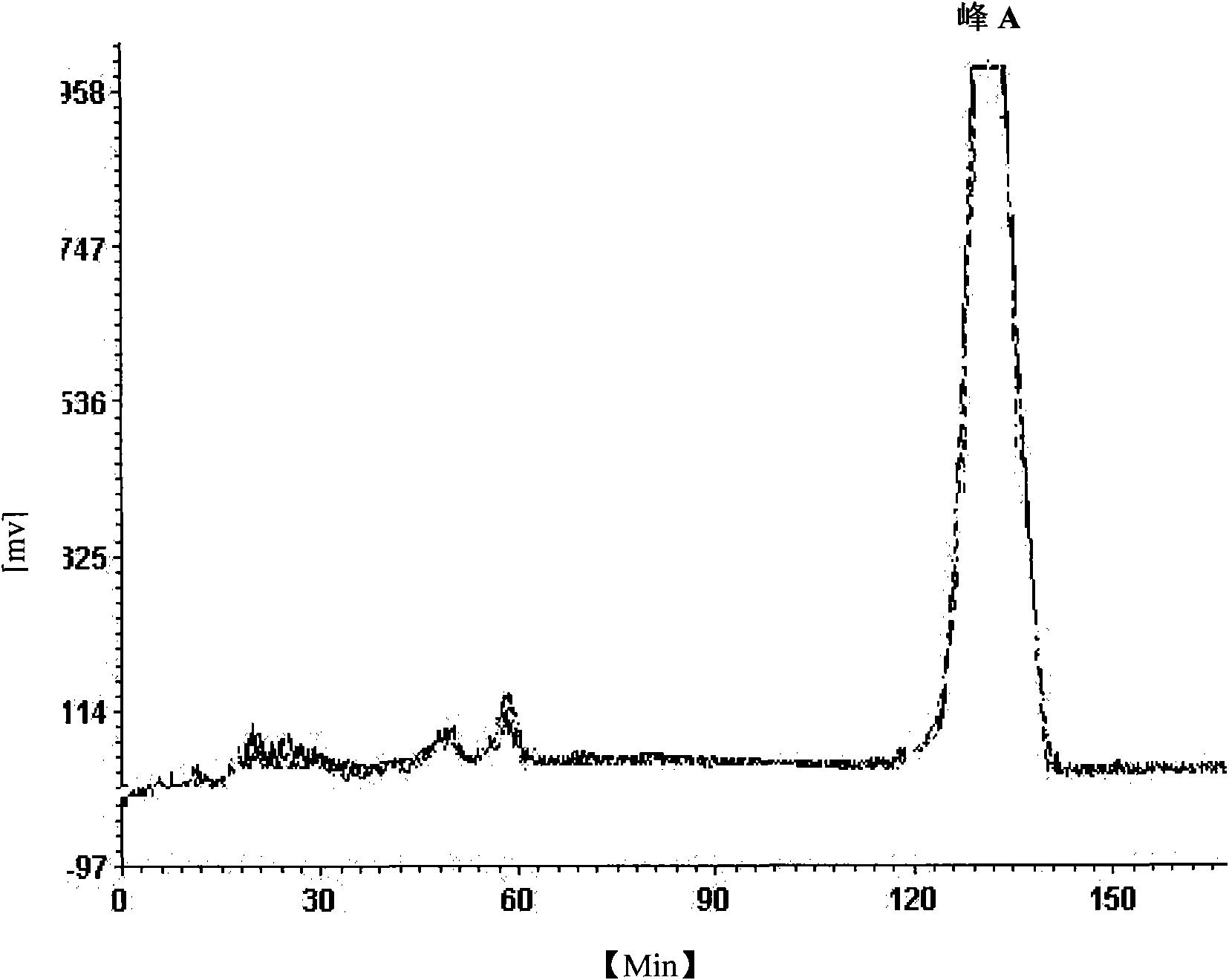

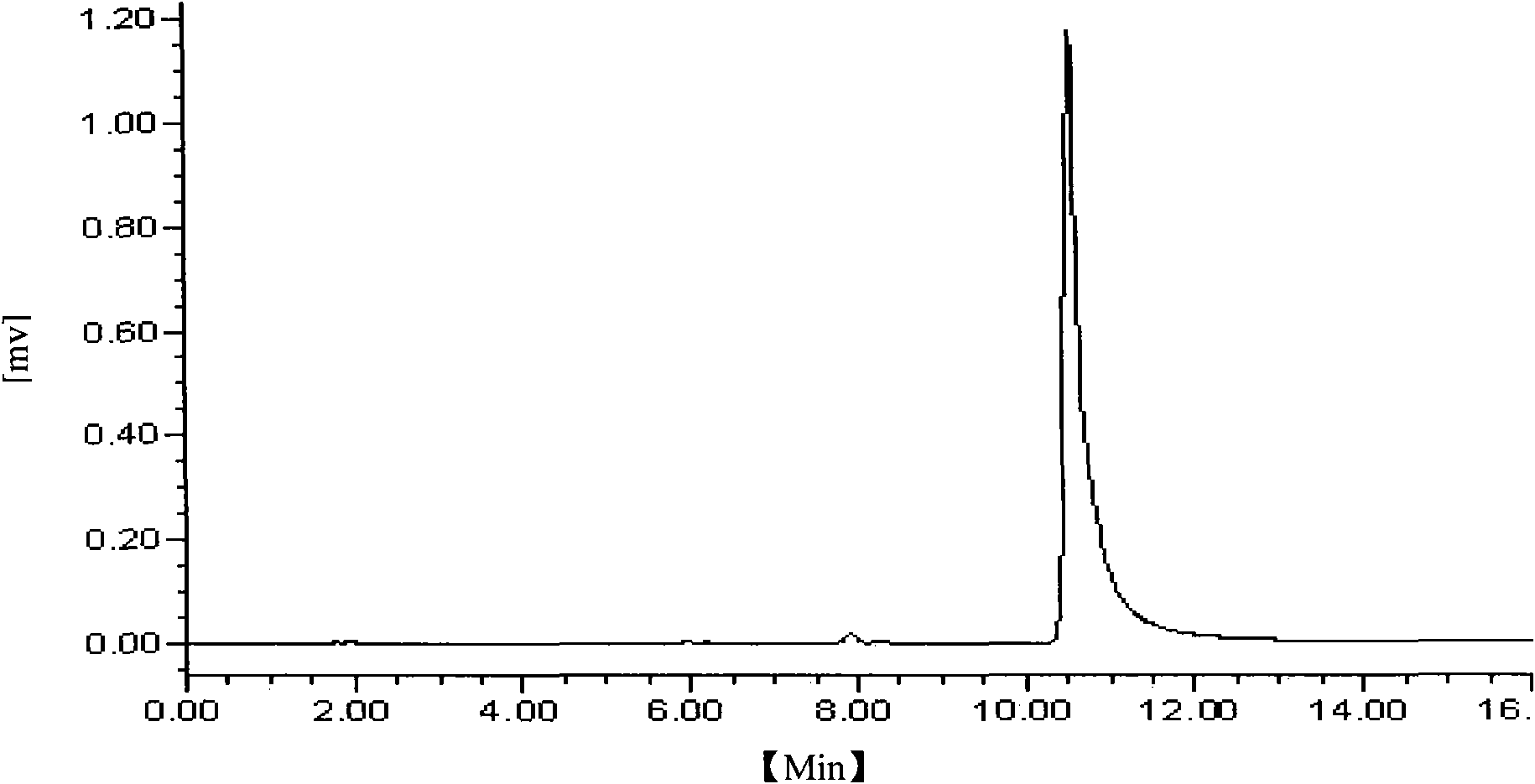

[0020] 2) with the volume ratio being 8: 7: 5: 0.8 the mixed solution that is made up of n-hexane, acetonitrile, ethyl acetate and water is used as two-phase solvent system, adopts high-speed countercurrent chromatograph, the usnic acid that step 1) obtains The crude extract is dissolved in the two-phase solvent system for separation and purification. The specific steps are as follows: after the two-phase solvent system is fully mixed, the phases are separated by standing still, and the two phases are degassed under 100 KHz ultrasoni...

Embodiment 2

[0027] 1) Weigh 100 g of Usnea longissima with a mesh size of 60 mesh after crushing, add 800 ml of petroleum ether with a boiling range of 60-90° C., reflux for extraction for 4 hours, and filter with suction. Repeat the above reflux extraction step 3 times. The combined filtrates were concentrated to 15 ml at 45° C. under vacuum (vacuum degree: 0.01 MPa), and allowed to stand at room temperature overnight to obtain a crude usnic acid extract.

[0028]2) with the volume ratio being 8: 7: 5: 0.8 the mixed solution that is made up of n-hexane, acetonitrile, ethyl acetate and water is used as two-phase solvent system, adopts high-speed countercurrent chromatograph, the usnic acid that step 1) obtains The crude extract is dissolved in the two-phase solvent system for separation and purification. The specific steps are as follows: after the two-phase solvent system is fully mixed, the phases are separated by standing still, and the two phases are degassed under 100 KHz ultrasonic...

Embodiment 3

[0031] Prepare usnic acid according to the same steps as in Example 2, only change the mesh number of Usnea longus in step 1) to 80 mesh, the extraction solvent is ether, consumption 1000mL / time, reflux extraction for 3 hours, extract 2 times , 35 DEG C of vacuum concentrating filtrate to 10ml; In step 2), the amount of usnic acid crude extract is changed to 10 mg, the mobile phase flow rate is changed to 4ml / min, the separation column temperature is 20 DEG C, and the separation column speed is changed to 500rpm.

[0032] According to the same detection conditions as in Example 1, the peak A product was detected by HPLC, and the obtained detection results were the same as in Example 1. The nuclear magnetic detection result of this product is also identical with embodiment 1. From the above NMR and HPLC detection results, it can be seen that the peak A product structure in the HSCCC spectrogram is correct, which is usnic acid with a purity of 99.5% and a yield of 40.08%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com