Mixer

A mixer and mixing tank technology, applied in mixers, mixing methods, fluid mixers, etc., can solve the problems of mixing and small radiation area, and achieve the effects of rapid mixing, increased radiation area, and increased injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

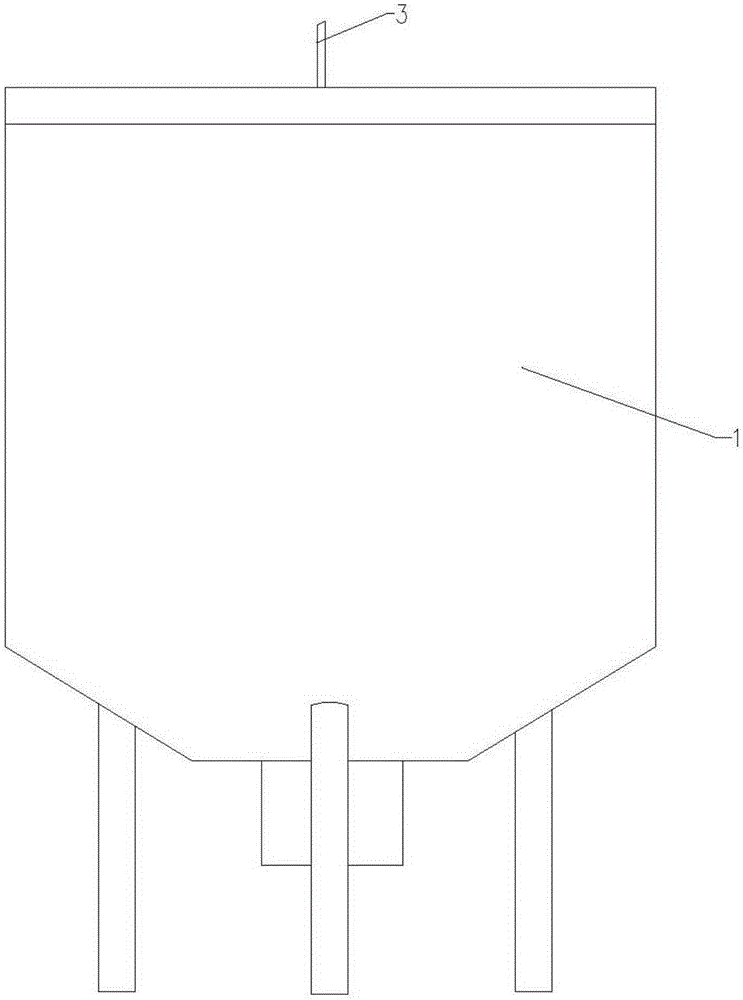

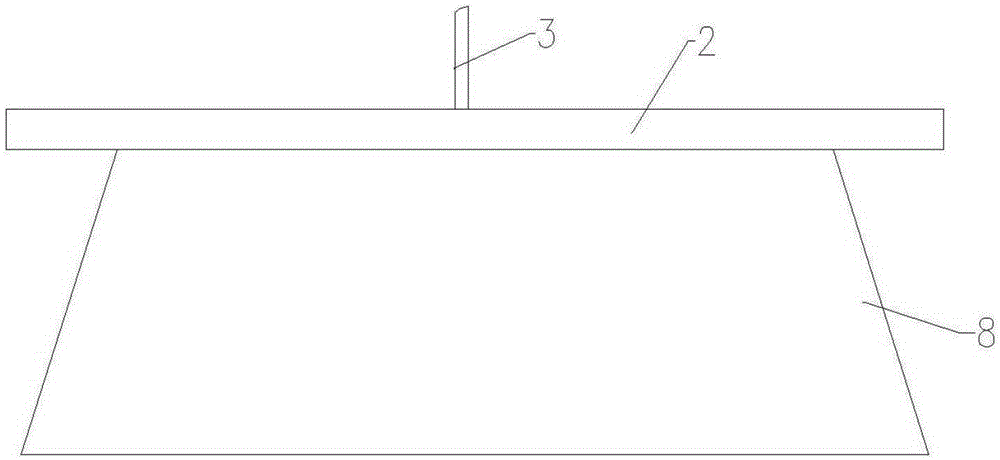

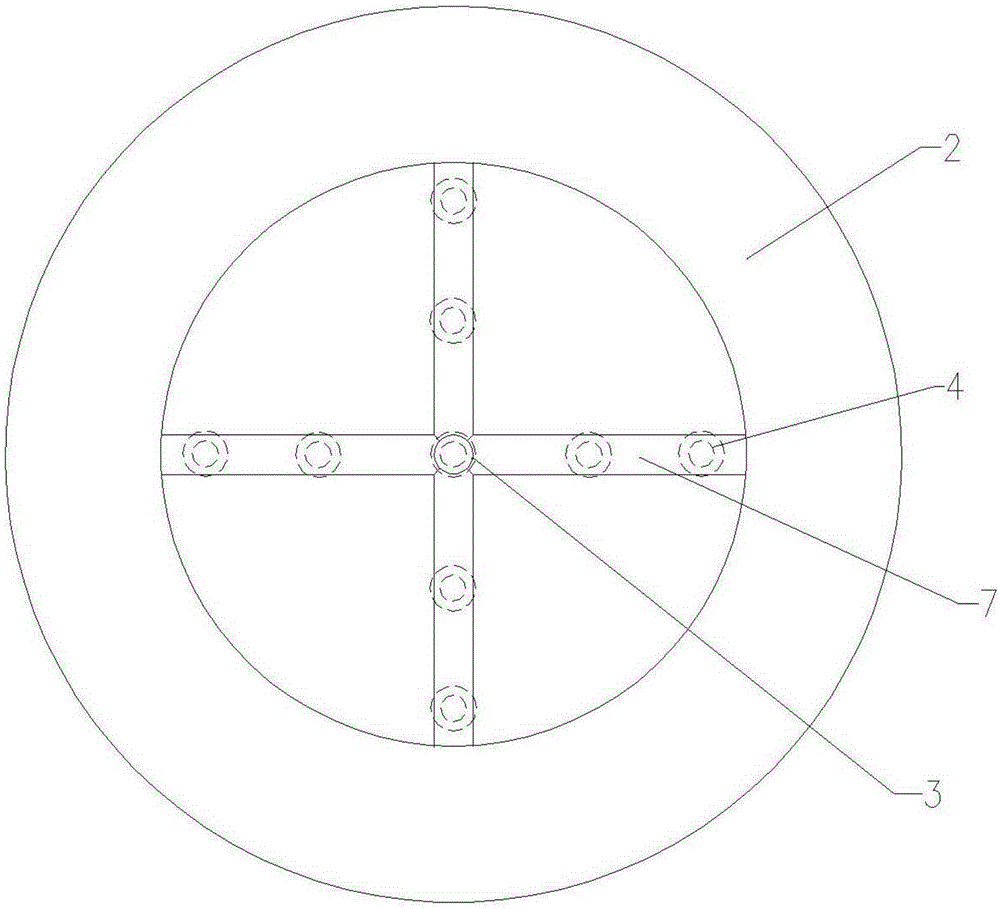

[0015] As shown in the figure, the mixing mixer of the present invention includes a mixing tank 1. What is different from the prior art is that the top of the mixing tank 1 is provided with a top cover 2, and the middle part of the top cover 2 is equipped with a liquid-free The main pipe 3 connected to the water ethanol storage tank. The main pipe 3 is equipped with a pressure nozzle 4 with a mist outlet facing down and protruding into the mixing barrel 1 .

[0016] The top cover 2 is provided with a plurality of installation grooves 5 extending radially along the top cover 2 and evenly distributed in the circumferential direction, and the branch pipes 6 communicating with the main pipe 3 are installed in the installation grooves 5 . The branch pipes 6 are also equidistantly installed with a plurality of pressure nozzles 4 with the mist outlets facing down a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com