Liquid ejection head, liquid ejection apparatus and inkjet printing apparatus

A liquid ejection head, liquid technology, applied in the direction of printing, inking devices, etc., can solve the problems of no open suppression, deviation of ejection direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Here, an inkjet head using a piezoelectric actuator is described as an example, but the present invention can also be applied to various types of inkjet heads, such as using electrostatic actuators, heat generating elements (heaters), etc. as ejection energy The inkjet head that produces the element. In addition, the present invention can also be applied to a drop-on-demand type inkjet head or a continuous jet type inkjet head. In particular, the present invention is applicable to an inkjet head based on a method using resonance inkjet, as in an inkjet head using a piezoelectric actuator.

[0077] Composition and classification of technical problems in the prior art

[0078] Before describing the embodiments of the present invention, first, the composition of an inkjet head in the prior art will be described, and related technical problems will be classified.

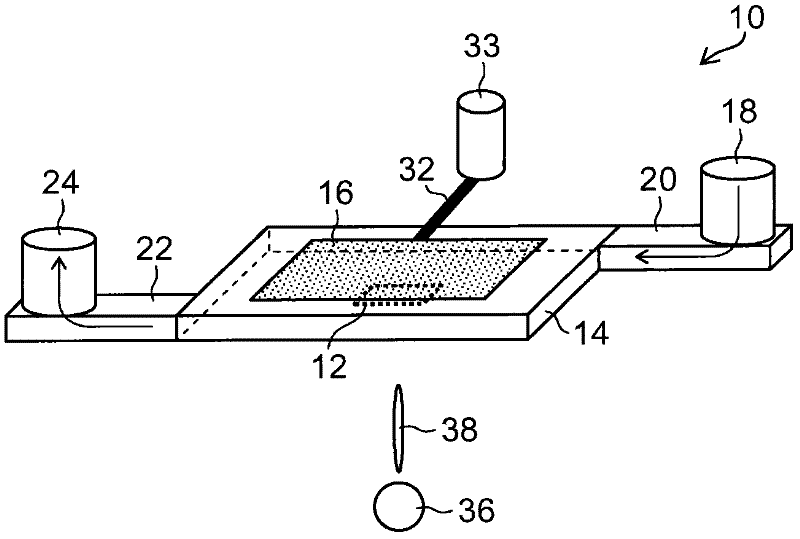

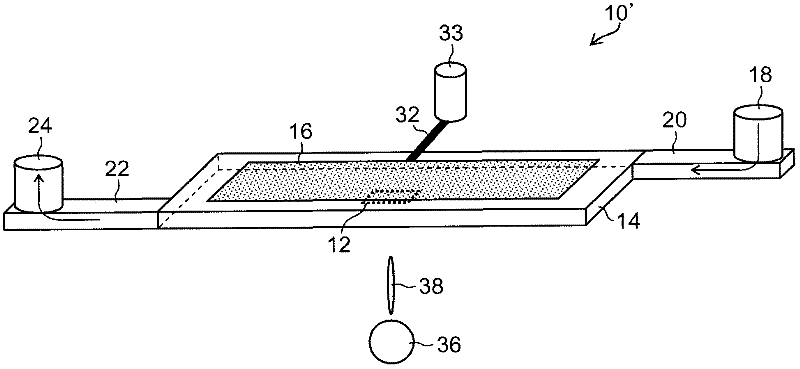

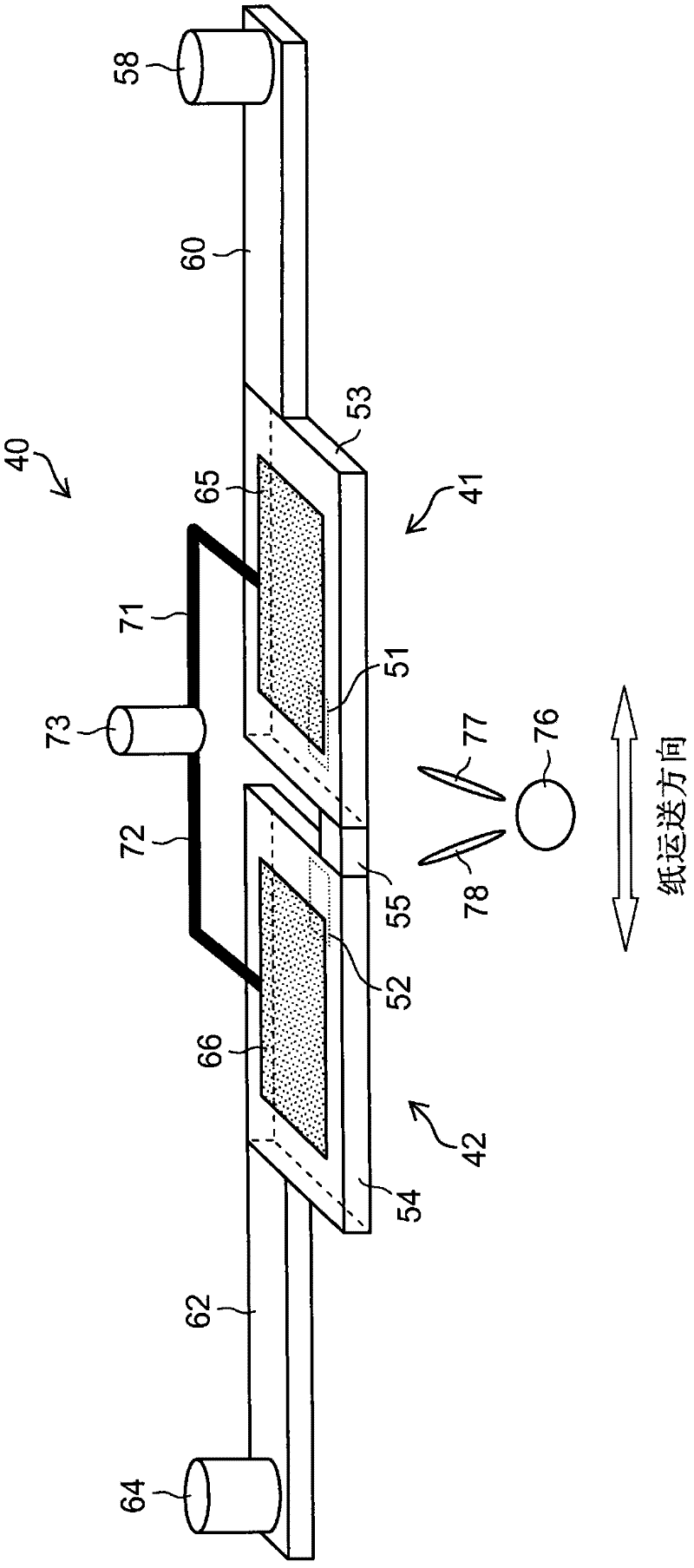

[0079] FIG. 1 is a schematic diagram showing the composition of an inkjet head in the related art using pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com