Fuel injection control system of flexible fuel engine

A control system and flexible fuel technology, applied in the direction of fuel injection control, engine control, machine/engine, etc., can solve the problem of inability to take into account intake port injection and in-cylinder direct injection, complex control strategies, inability to flexibly select different fuels, etc. problem, achieve simple and effective lean burn and stratified burn, realize lean burn and stratified burn, and improve fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

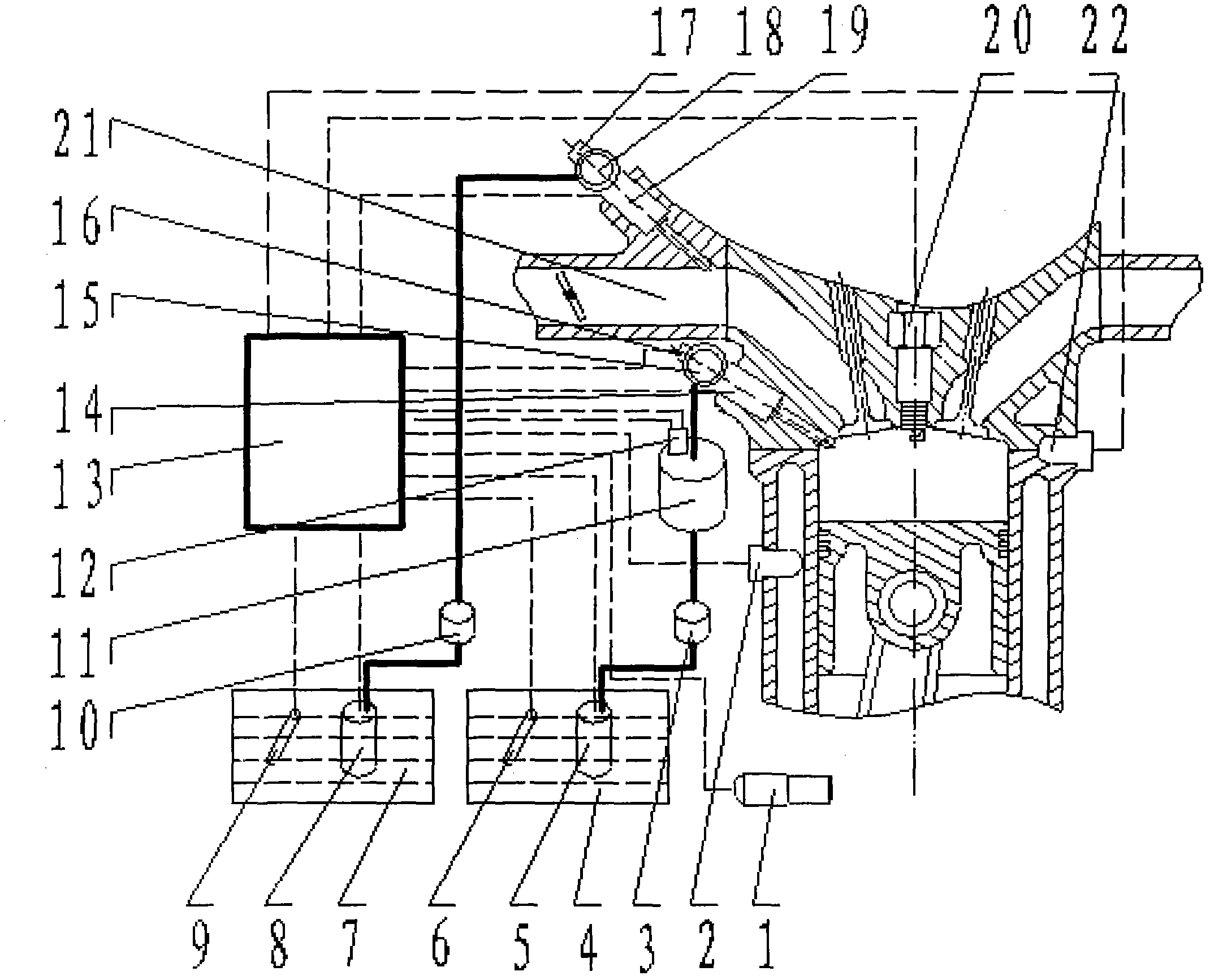

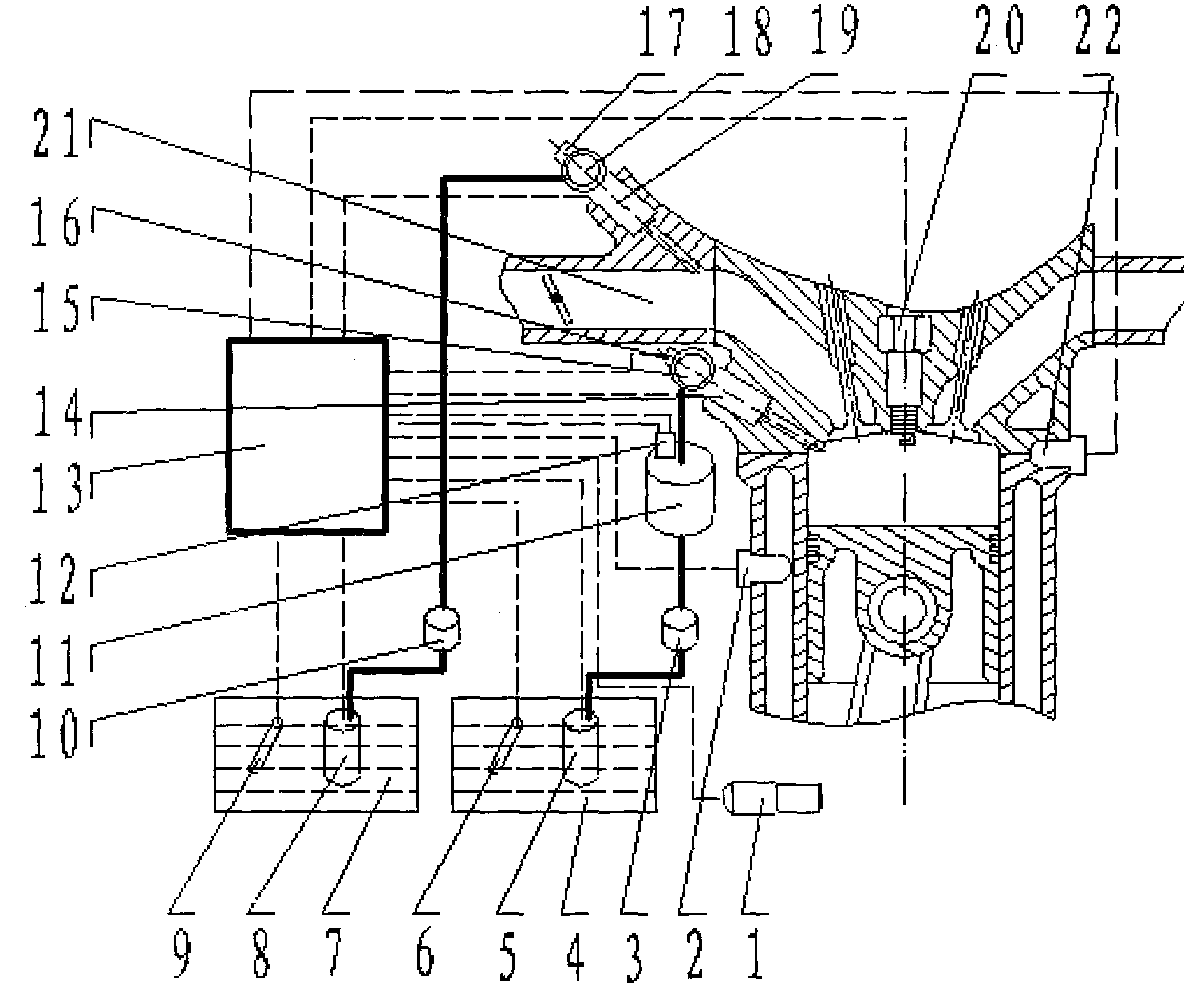

[0037] In conjunction with the accompanying drawings, the present invention will be further described through the embodiments.

[0038] Accompanying drawing shows the schematic diagram of the fuel injection control system of the flexible fuel engine that the present invention announces, comprises intake duct (21), engine temperature sensor (2), crankshaft position sensor (1), electronic control unit (13), knocking Sensor (22), spark plug (20) and fuel tank I (7), low-pressure fuel pump I (8), liquid level sensor I (9), fuel filter I (10), low-pressure fuel pressure regulating valve I (17), The intake port injection (PI) system composed of PI rail I (18) and PI injector I (19) also includes oil tank II (4), low-pressure oil pump II (5), liquid level sensor II (6), Fuel filter II(3), in-cylinder direct injection high-pressure fuel pump II(11), high-pressure oil circuit electronically controlled pressure regulator II(12), DI fuel rail II(15), DI fuel rail pressure sensor II(16) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com