Sprayed film forming method and apparatus

A technology of spray coating and coating gun, which is applied in the field of spray coating forming devices, and can solve the problems of increased materials for spray coating, increased spray coating time, and increased finishing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

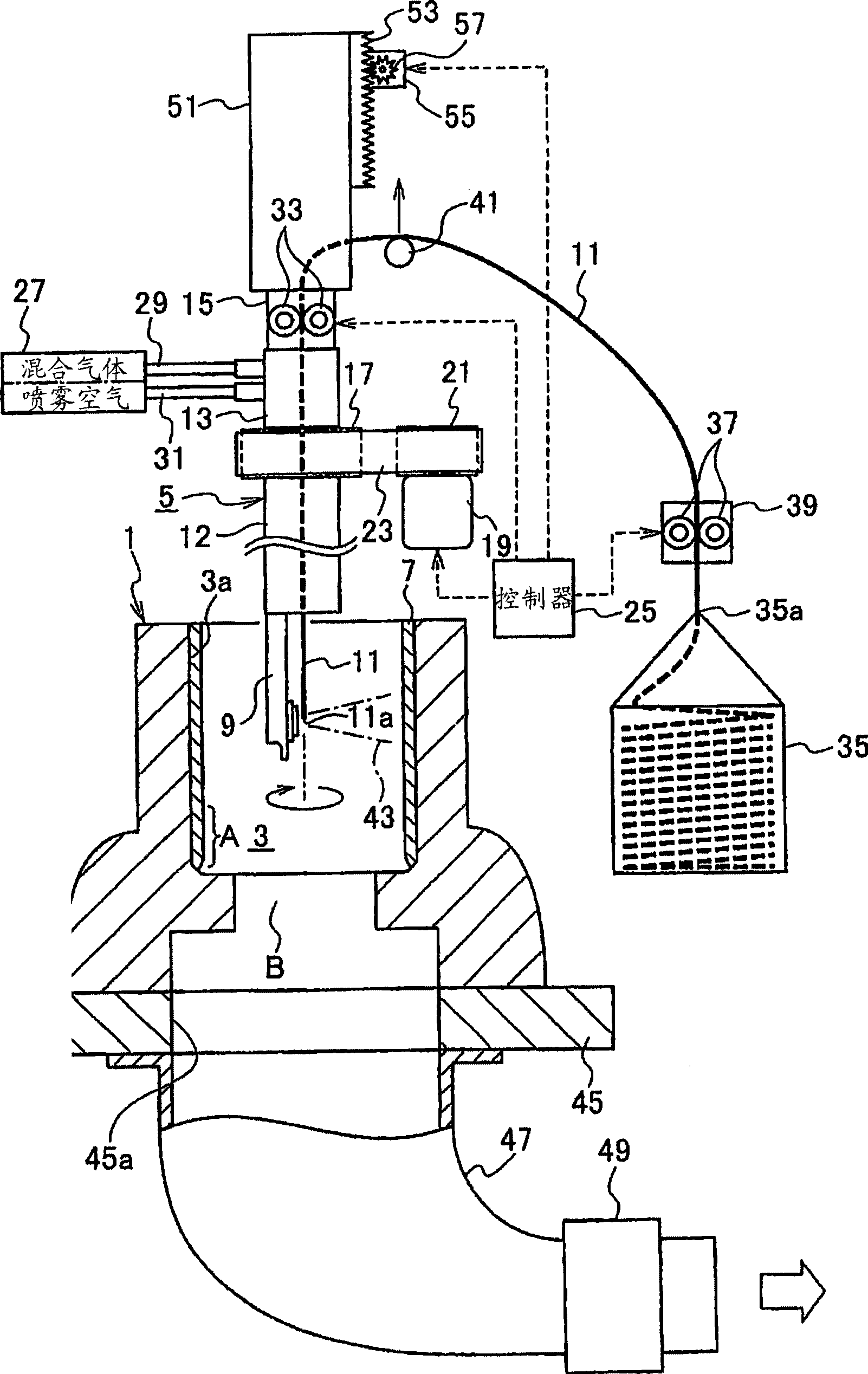

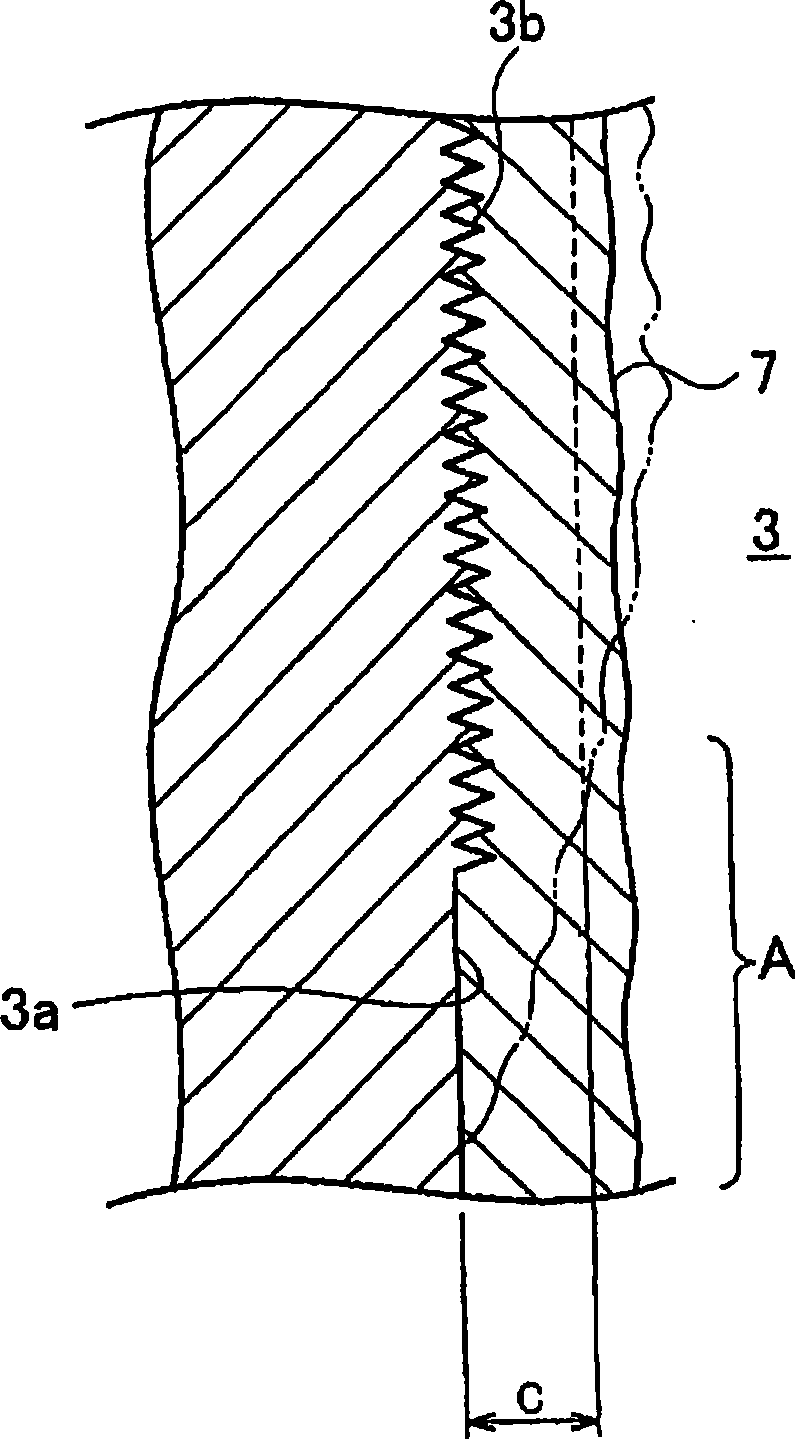

[0016] figure 1 It is a simplified overall configuration diagram showing a thermal sprayed film forming device according to the first embodiment of the present invention. A sprayed coating gun 5 is used to form a sprayed coating on the cylinder inner surface 3a of the cylinder tube 3 in the aluminum alloy cylinder block 1 of the engine. Coating 7. Here, the circular hole is formed by the cylinder 3, and the inner surface of the circular hole is formed by the cylinder inner surface 3a.

[0017] exist figure 1 In the spraying gun 5, there is a spraying nozzle part 9 on the tip side corresponding to the lower end side, and a metal wire 11 as a material for spraying made of an iron-based metal is drawn from the figure 1 The upper end of the spray gun 5 is inserted into the spray gun 5 and supplied to the spray nozzle part 9 .

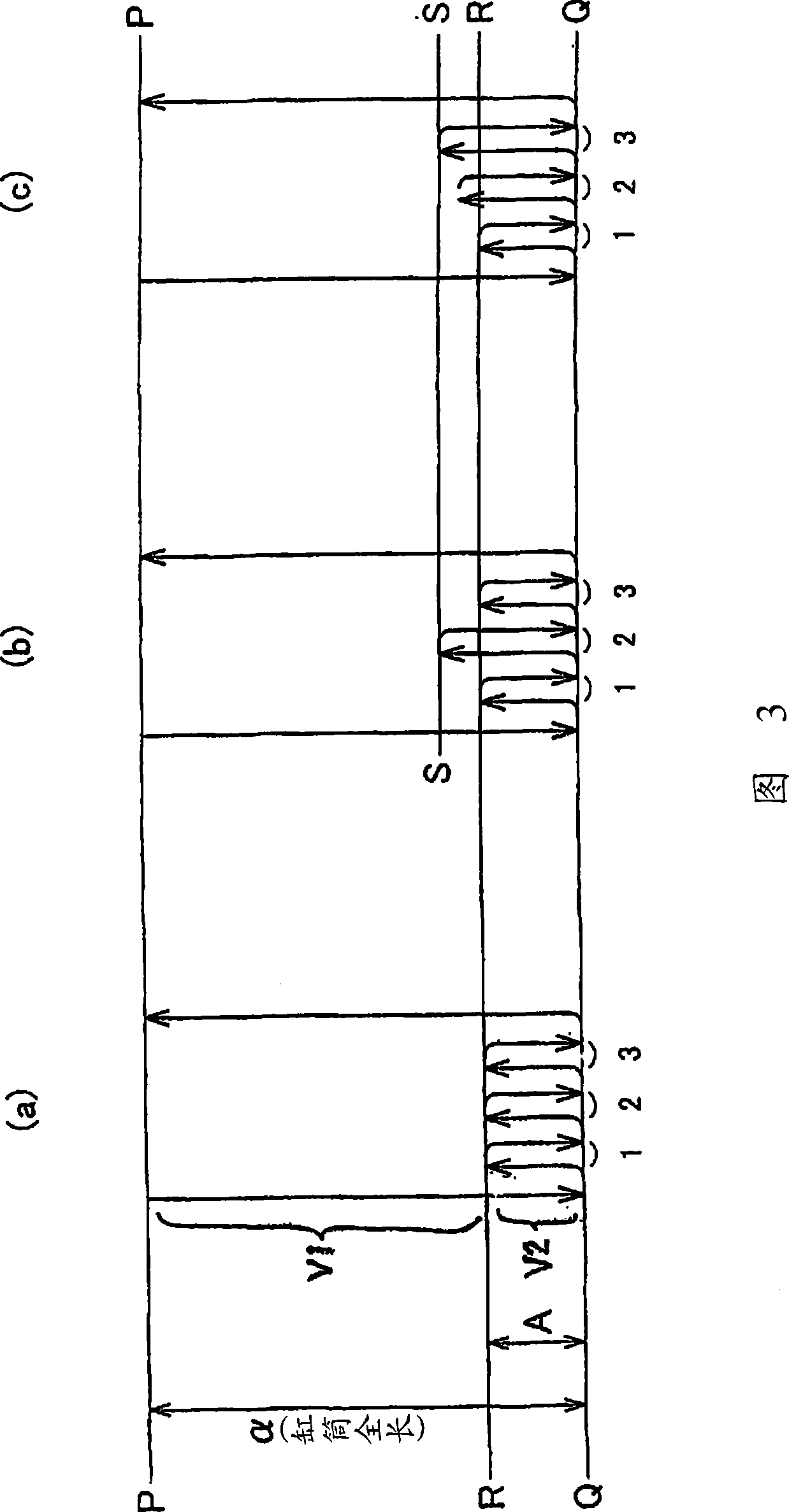

[0018] The thermal spray gun 5 has a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com