Large-scale injection machine

An injection molding machine and large-scale technology, applied in the field of solid rubber injection molding machines, can solve the problems of low production efficiency and unstable product quality of flat vulcanizers, and achieve the effects of good compactness, uniform density and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

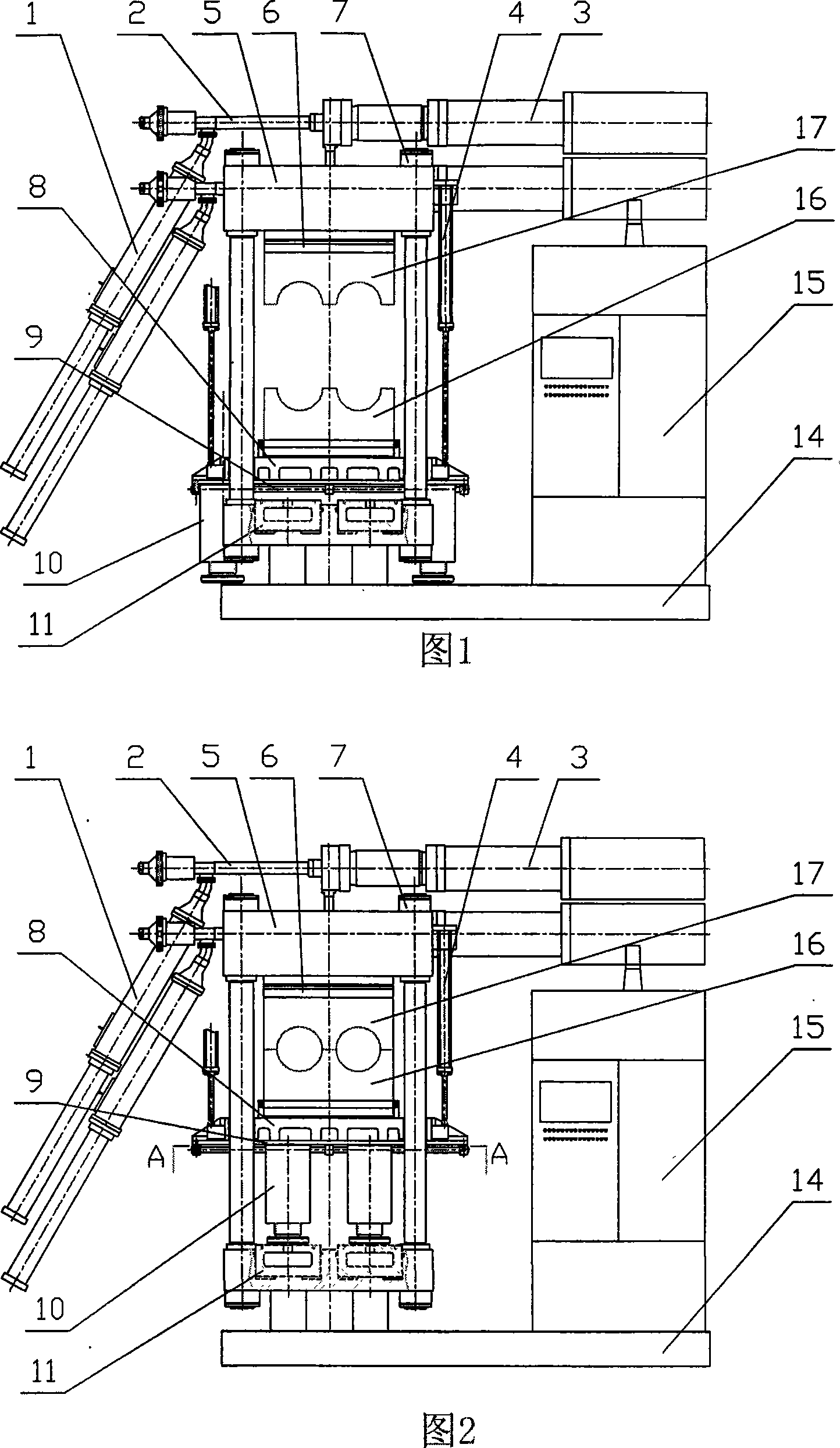

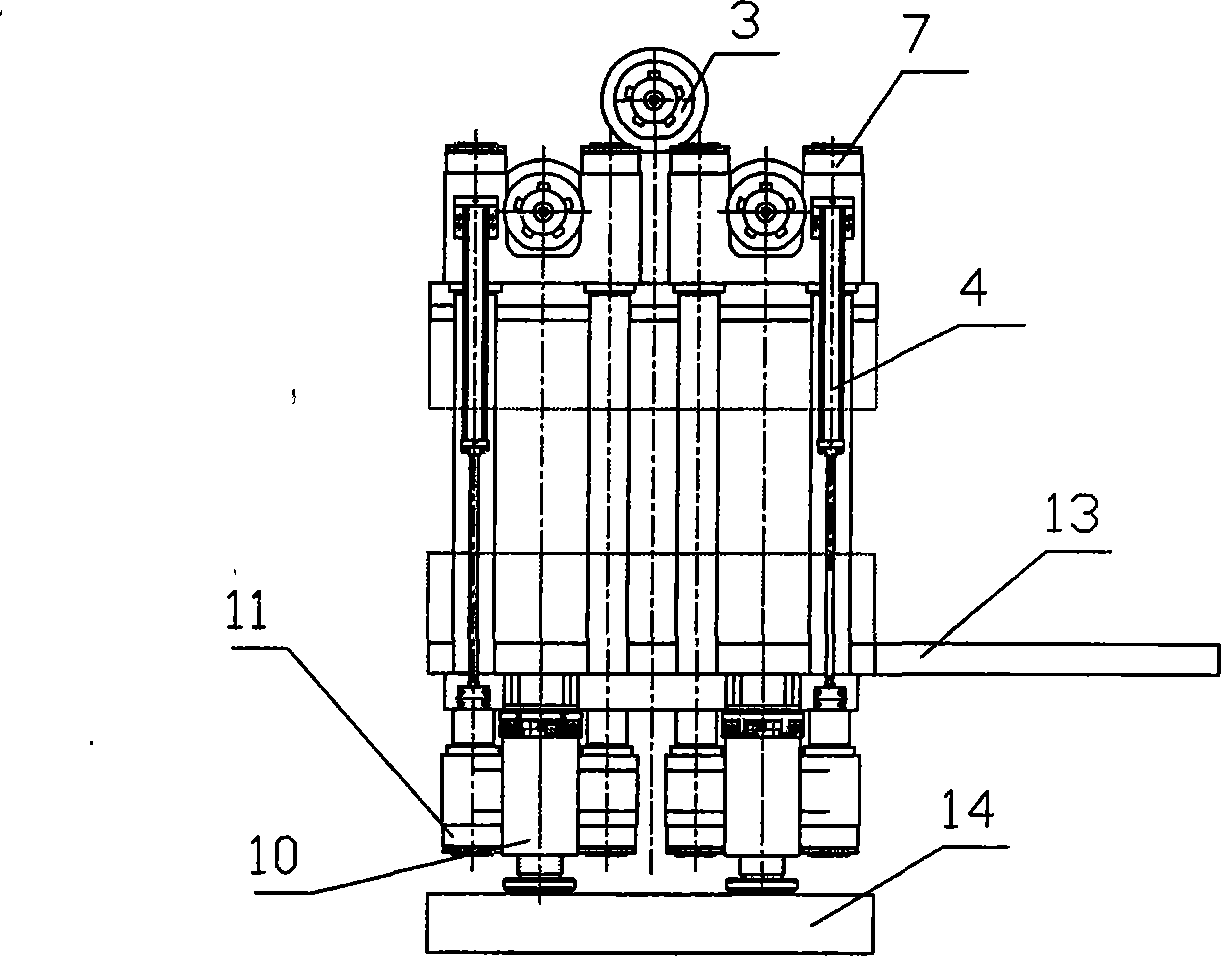

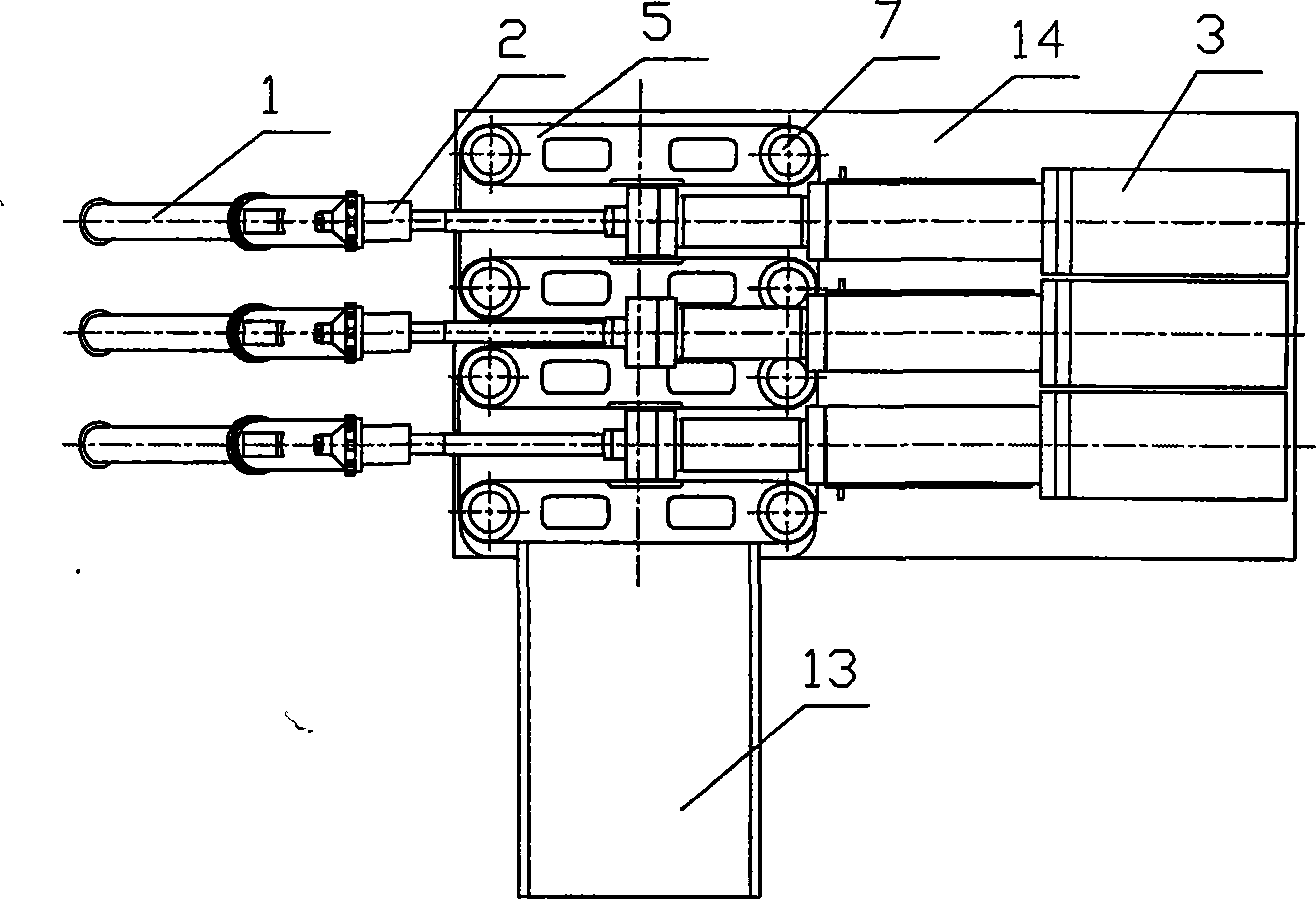

[0024] As shown in the attached figure: a large injection molding machine, which includes three feeding devices 1, three plasticizing devices 2, three injection devices 3, four clamping cylinders 4, two upper templates 5, and cold runners 6. Eight Corinthian pillars 7. Moving template 8. Four pad guide rails 9. Four moving pads 10. Four clamping cylinders 11. Four pad cylinders 12. Mold moving device 13. Base 14. Control System 15 , lower die 16 and upper die 17 .

[0025] The control system 15 is installed on the base 14, and the three injection devices 3 are placed on the upper part of the control system 15 and the upper template 5. The three injection devices 3 are arranged in the shape of a letter along the length direction of the mold, and each injection device is equipped with a plasticizing device. 2 and a feeding device 1.

[0026] The four clamping oil cylinders 11 of the mold clamping part are arranged in a square shape, and the two mold clamping cylinders 11 have a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com