Method for separating and preparing ricinine

A technology of ricinine and castor, which is applied in the field of separation and preparation of ricinine, can solve the problems of low purity of ricinine, troublesome crystallization process, small preparation amount, etc., and achieve strong separation ability, short separation time, advanced The effect of large sample volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 100 g of castor bean kernels, add 500 ml of petroleum ether and diethyl ether solution with a volume ratio of 2:1, extract with magnetic stirring at room temperature for 1 h, and filter with suction to obtain castor meal. Repeat the above steps 2 times, and the castor meal (filter cake) is air-dried.

[0028] Weigh 20 g of the filter cake, extract it with 200 ml of 95% (volume percent) ethanol aqueous solution for 3 h, concentrate the extract in vacuo at 45° C. to 20 ml, and freeze-dry in vacuo to obtain a crude extract of ricinine.

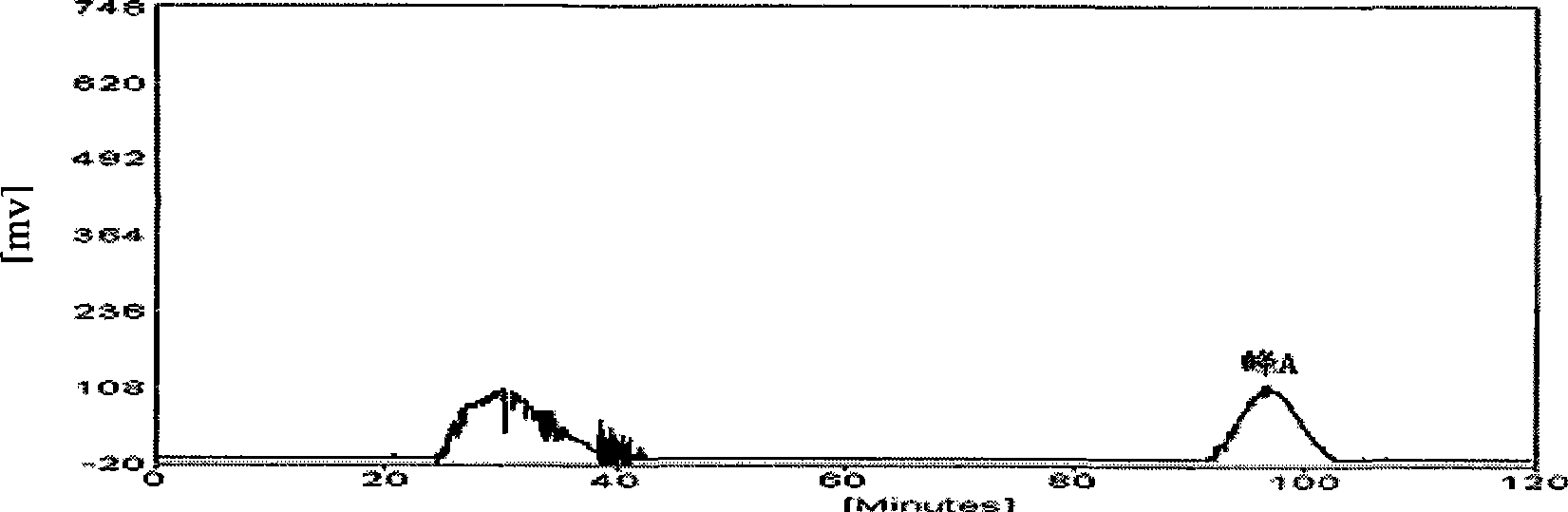

[0029] Using chloroform / methanol / water with a volume ratio of 2:1:1 as a two-phase solvent system, after mixing them thoroughly, let stand to separate the phases, and ultrasonically degas the two phases for 30 minutes respectively. Take the upper phase as the stationary phase and the lower phase as the mobile phase. Pump the stationary phase into a 325ml high-speed countercurrent chromatography separation column at a flow rate of 6m...

Embodiment 2

[0034] Weigh 100 g of castor bean kernels, add 800 ml of petroleum ether and diethyl ether solution with a volume ratio of 2:1, extract with magnetic stirring at room temperature for 2 h, and filter with suction. Repeat the above steps 3 times to air dry the filter cake.

[0035] Weigh 20g of filter cake, Soxhlet extraction with 160ml of 95% (volume percent) ethanol aqueous solution for 5h, the extract is concentrated in vacuo at 45°C to 15ml, and vacuum freeze-dried to obtain a crude extract of ricinine.

[0036] Use trichloromethane / methanol / water with a volume ratio of 5:4:2 as the two-phase solvent system, mix them thoroughly, and then let stand to separate the phases, and degas the two phases by ultrasonic wave for 30 minutes respectively. Take the upper phase as the stationary phase and the lower phase as the mobile phase. Pump the stationary phase into a 325ml high-speed countercurrent chromatography separation column at a flow rate of 6ml / min, start the high-speed cou...

Embodiment 3

[0038] The operation steps are the same as in Example 2, except that the mobile phase flow rate of high-speed countercurrent chromatography is 6ml / min, the volume ratio of the two-phase solvent system (chloroform / methanol / water) is 2:2:1, and the separation column speed is 500rpm, the volume The ratio of 2:1 petroleum ether and diethyl ether solution was 400ml, and 20g of the filter cake was extracted with 120ml of 95% (volume percent) ethanol aqueous solution for 5 hours by Soxhlet extraction. The yield of ricinine was 73%, and the purity was detected by HPLC according to the conditions of Example 1, reaching more than 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com