Machine needle cooling mechanism of sewing machine, sewing machine and air suction and exhaust mechanism

A cooling mechanism, sewing machine technology, applied in the direction of sewing machine components, sewing equipment, lubricating/cooling devices, etc., can solve the problems of increased injection volume, air introduction into the needle bar assembly, and inability to fully compress the air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

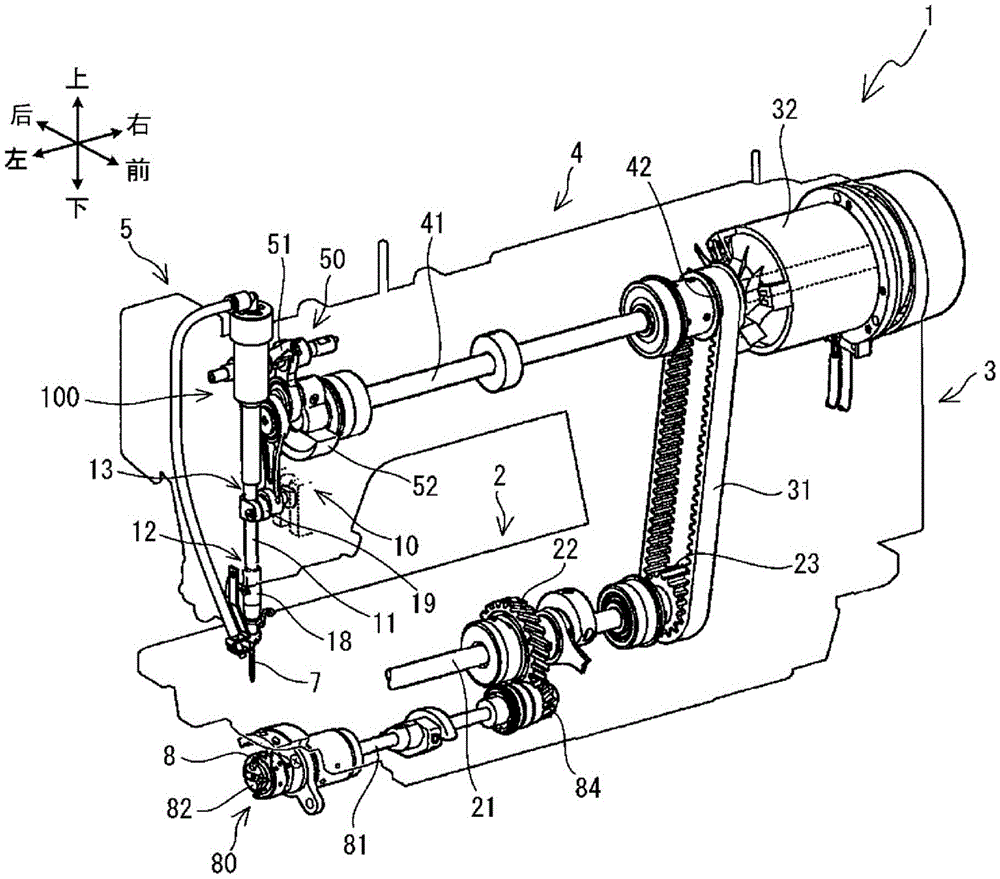

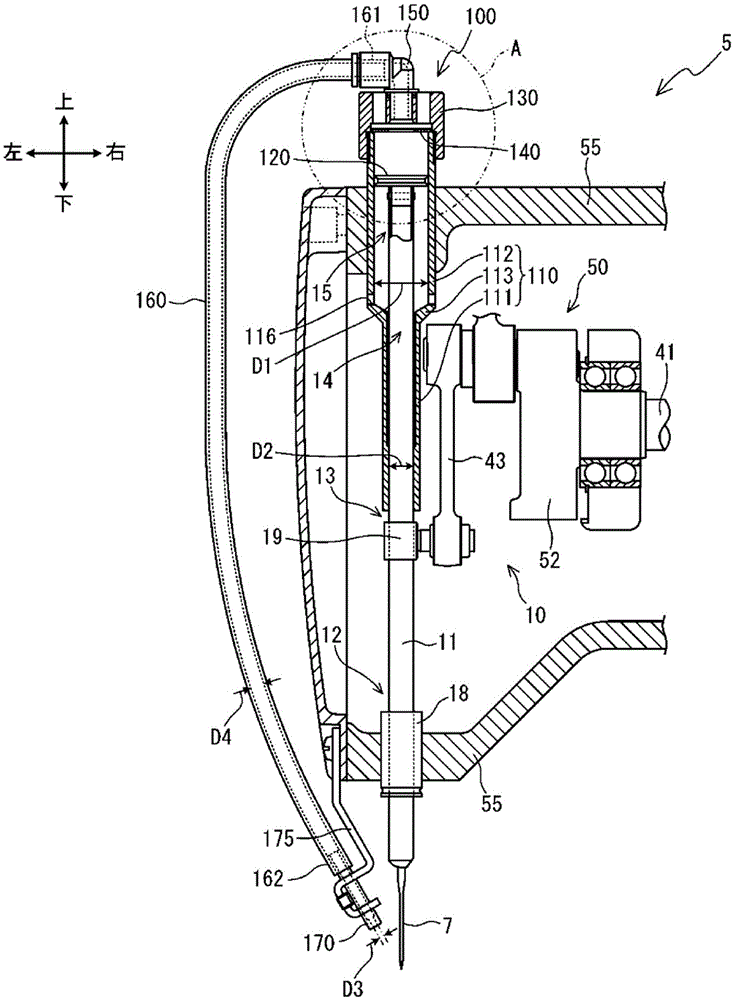

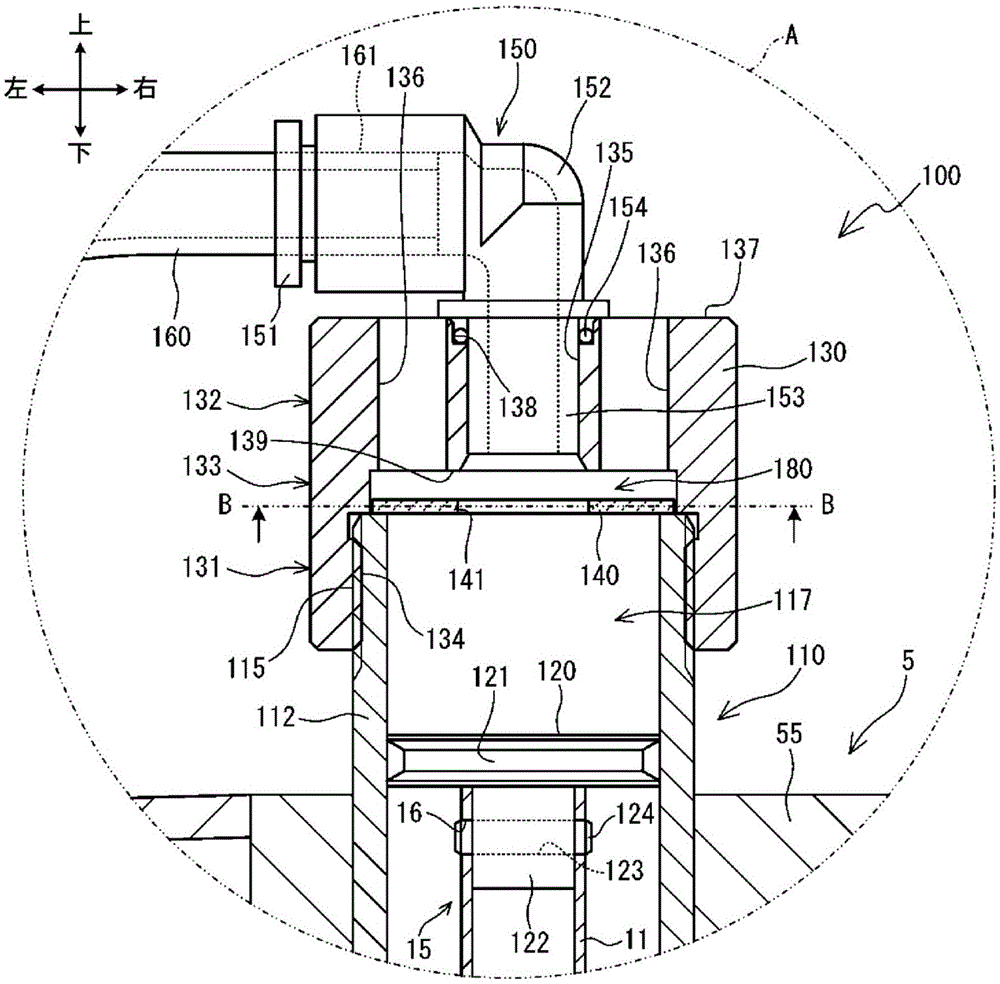

[0024] A schematic structure of a sewing machine 1 having a needle cooling mechanism will be described with reference to the drawings. In the following description, up and down, left and right, and front and back indicated by arrows in the figure are used. Such as figure 1 As shown, the sewing machine 1 includes a base portion 2 , a pillar portion 3 , an arm portion 4 and a top end portion 5 . The base portion 2 extends in the left-right direction, and has a lower shaft 21, a shuttle mechanism 80, and the like inside. The pillar part 3 extends upward from the right end side of the machine base part 2, and has a timing belt 31, a sewing machine motor 32, and the like inside. The arm part 4 extends leftward from the upper side of the pillar part 3 . The arm portion 4 faces the upper surface of the base portion 2 and has a spindle 41 and the like inside. The sewing machine motor 32 rotates the main shaft 41 clockwise when viewed from the left side. The arm part 4 has a tip p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com