Pretreatment system and method for printing and dyeing of home textile fabric

A technology for fabrics and home textiles, applied in the field of pre-treatment systems for printing and dyeing of home textile fabrics, can solve problems affecting the processing, and achieve the effects of easy gas entry, better incineration quality, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

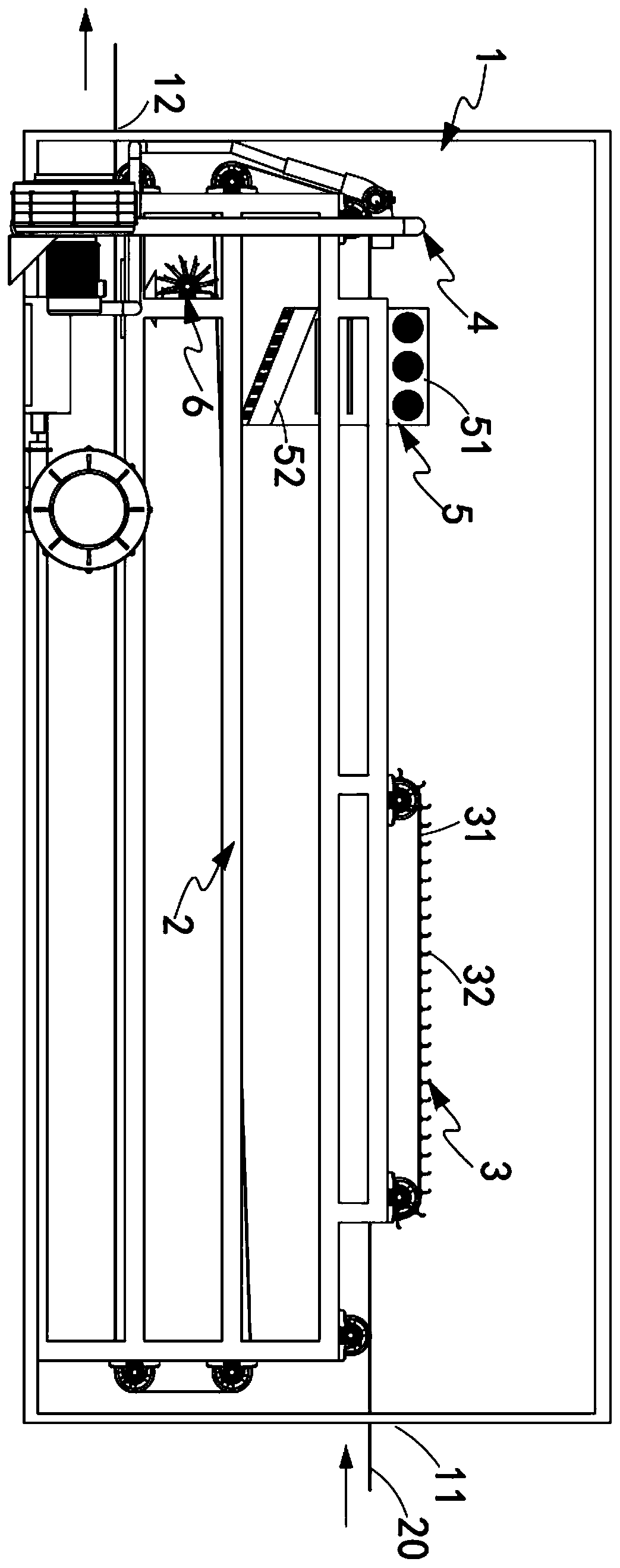

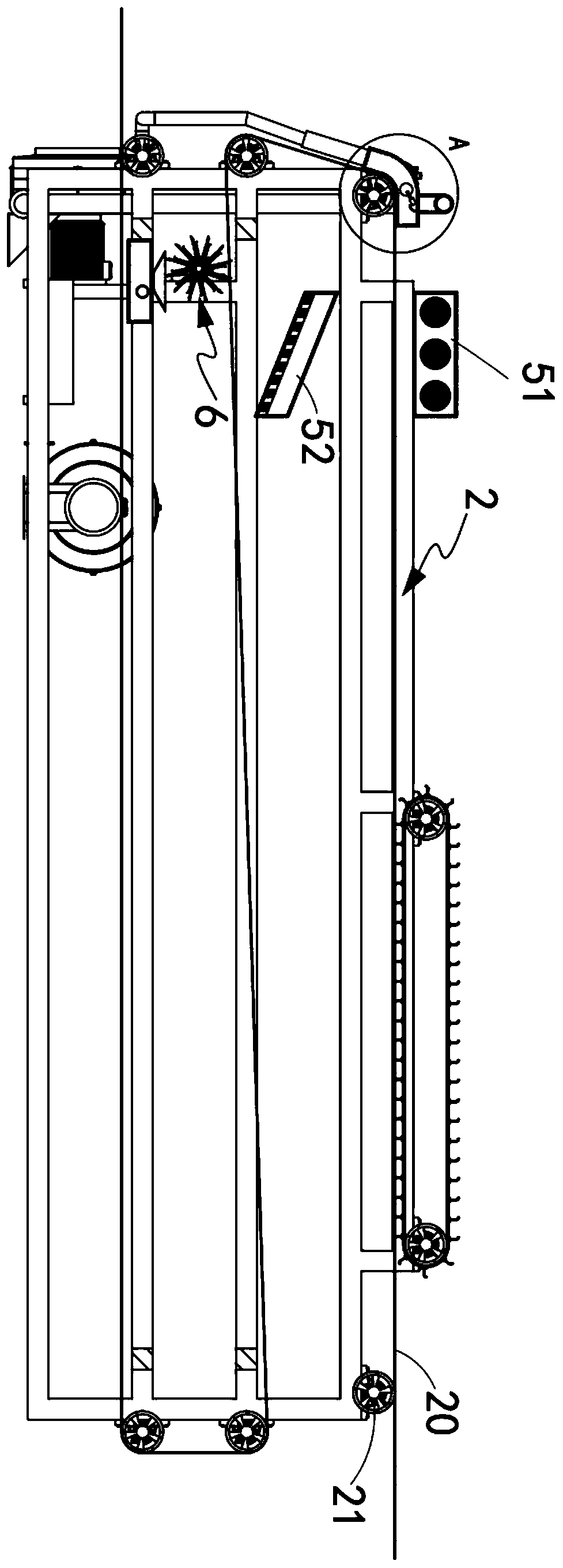

[0084] Such as figure 1 and figure 2 As shown, a pre-treatment system for printing and dyeing of home textile fabrics, including:

[0085] A box body 1, the box body 1 is respectively provided with a material inlet 11 and a material outlet 12;

[0086] Frame 2, described frame 2 is arranged in described box body 1, and it is frame-shaped setting, and is distributed with some rotatable delivery rollers 21 that are set on it, and home textile fabric 20 is wound and conveyed on this delivery roller 21;

[0087] Carding mechanism 3, described carding mechanism 3 is arranged on described frame 2, and it is positioned at described feeding port 11, and it combs described home textile fabric 20 just to the textile fiber of carding mechanism 3 side;

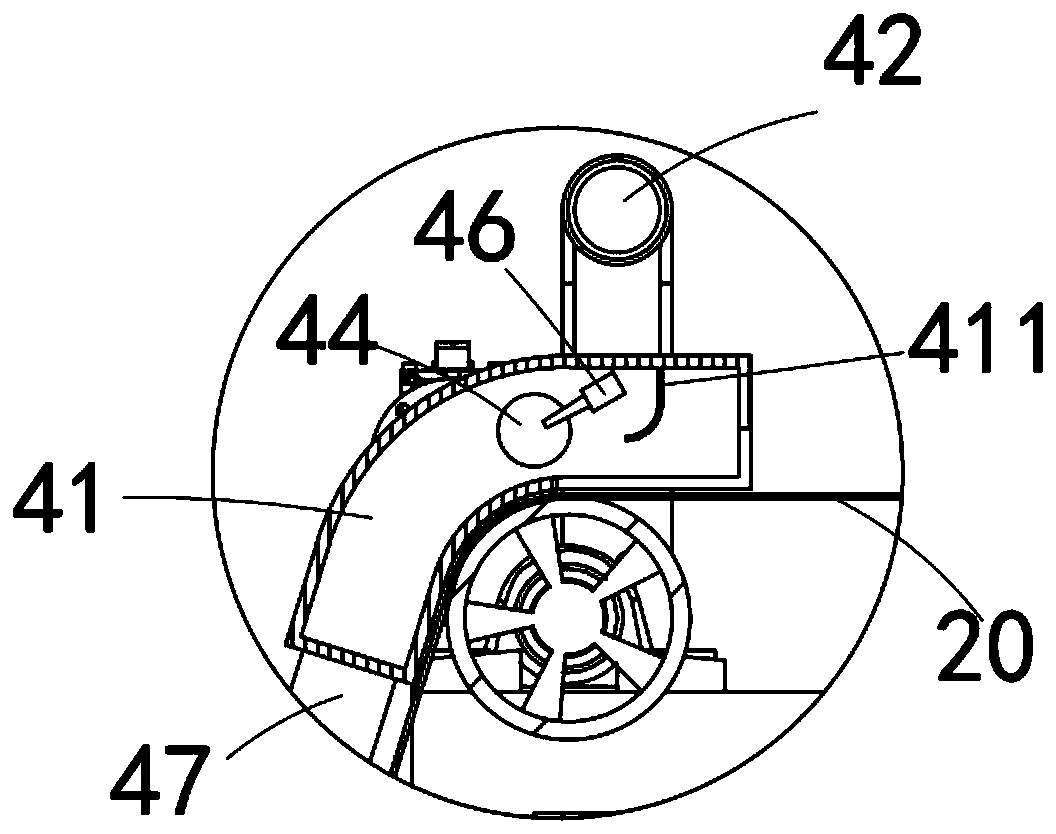

[0088] Singeing mechanism 4, said singeing mechanism 4 is arranged on the rear side of said carding mechanism 3 along the conveying direction of said home textile fabric 20, and it is located at the reversing position of said home text...

Embodiment approach

[0092] Such as figure 1 As shown, as a preferred embodiment, the combing mechanism 3 includes:

[0093] Brush hair belt 31, described brush hair belt 31 turns and arranges, and it moves oppositely to the part of described home textile fabric 20 and this home textile fabric 20; And

[0094] The brush needles 32 are evenly distributed on the bristle belt 31 , and the brush needles 32 are arranged in a hook shape, and their needle ends move toward the home textile fabric 20 along with the bristle belt 31 .

[0095] It should be noted that, in order to ensure that the attachment direction of each textile fiber on the home textile fabric 20 remains consistent before the home textile fabric 20 is singed, the brush needle 32 is lifted by the reverse rotation of the brush belt 31 and the home textile fabric 20. The randomly arranged fibers on the home textile fabric 20 make the fibers all face one direction through the carding of the brush needles 32 .

[0096]In addition, in the pr...

Embodiment 2

[0135] With reference to Example 1, a pretreatment method for printing and dyeing of home textile fabrics in Example 2 of the present invention is described.

[0136] Such as Figure 19 Shown, a kind of home textile fabric printing and dyeing processing method, comprises the following steps:

[0137] Step 1, input, the home textile fabric 20 is horizontally conveyed and installed under the carding mechanism 3 on the top of the frame 2 through the conveying roller 21;

[0138] Step 2, carding, the conveying direction of the home textile fabric 20 below the carding mechanism 3 is opposite to the running direction of the carding mechanism 3, and the brush needles 32 on the carding mechanism 3 card the textile fibers on the home textile fabric 20;

[0139] Step 3, standing wool, the home textile fabric 20 after carding is horizontally transported to the negative pressure exhaust assembly 51 located at the rear side of the conveying mechanism 3 through the conveying roller 21, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com