Seamless small tubular fabric setting machine and setting method thereof

A technology of cylindrical fabric and setting machine, which is applied in the direction of fabric surface trimming, setting/stretching loop fabric, fabric finishing guide/expander, etc., can solve the problem of low automation level, large area of setting machine and poor setting effect. and other problems to prevent sagging and improve the effect of styling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

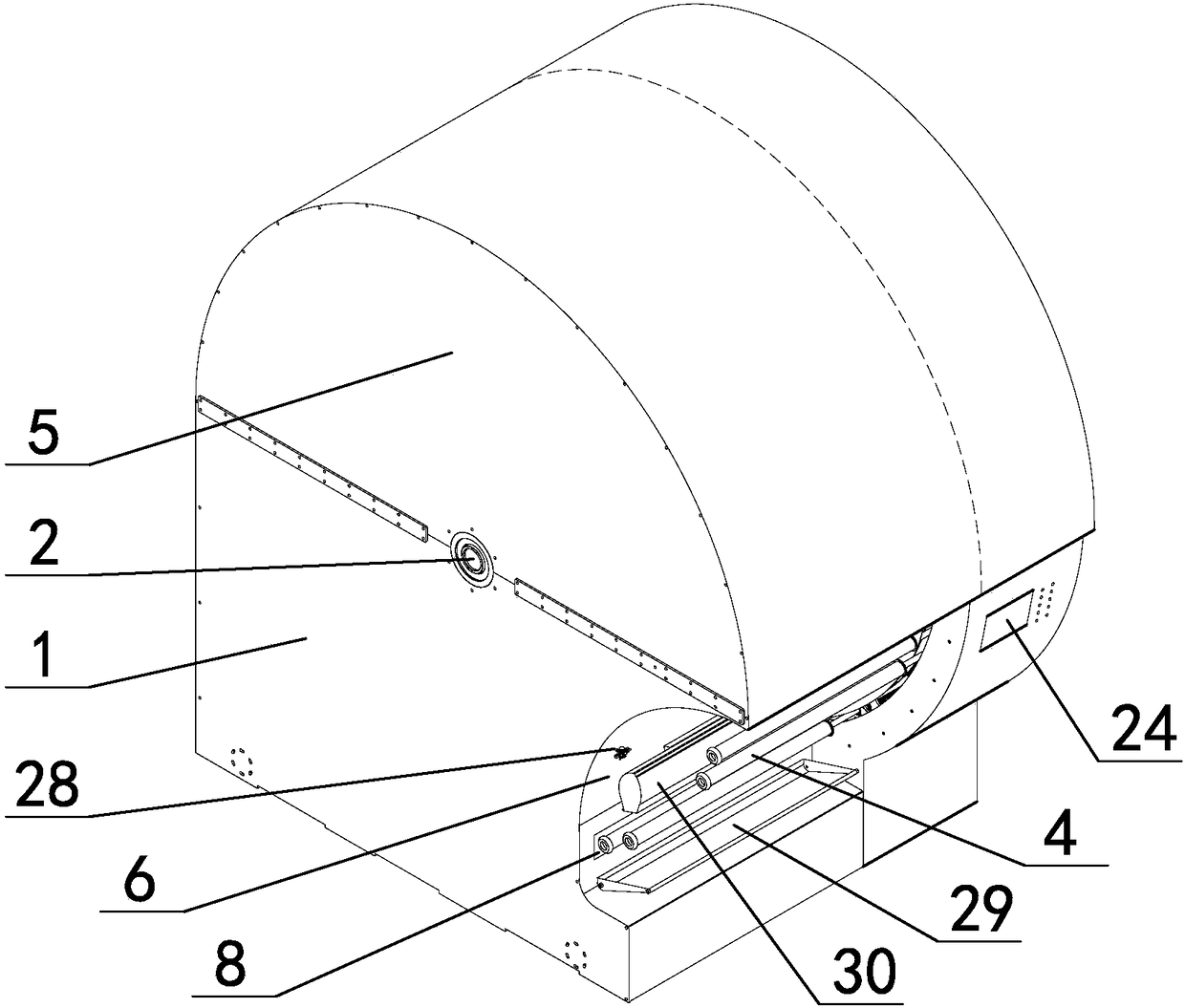

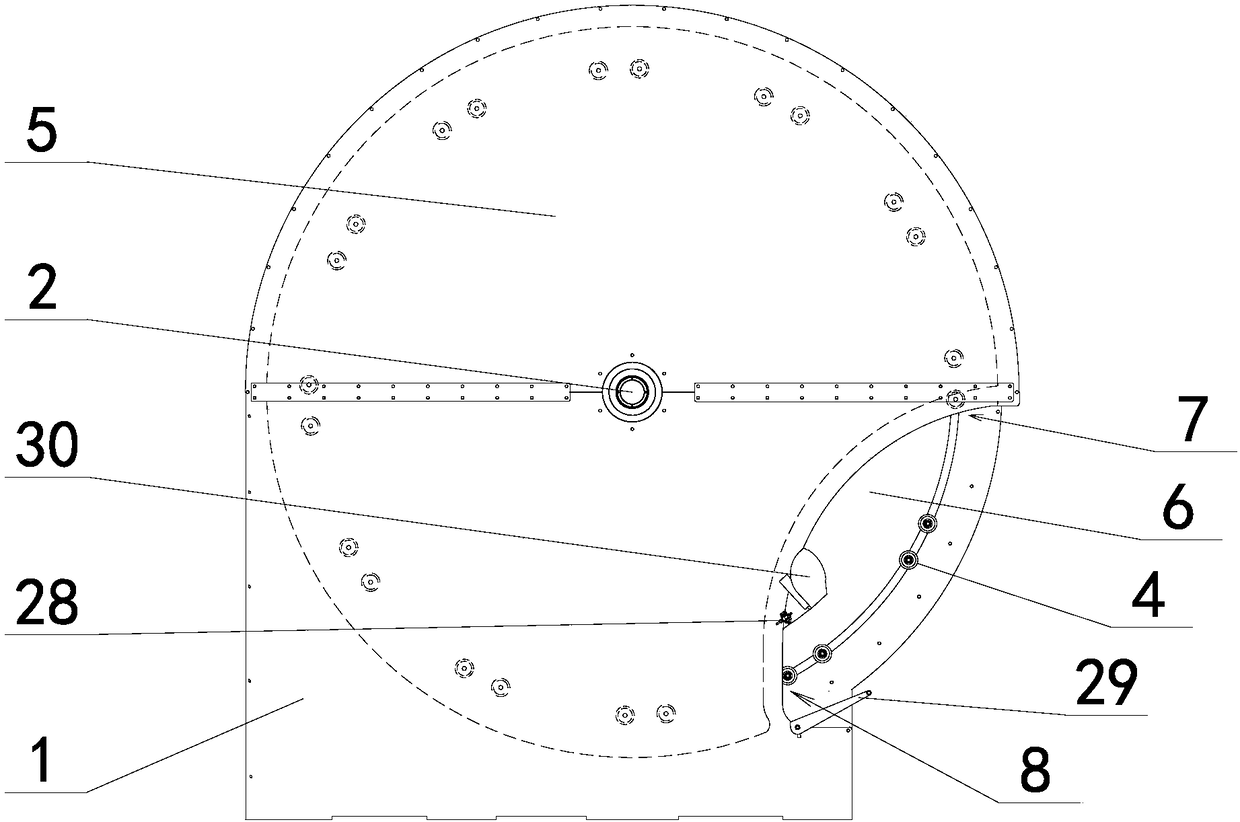

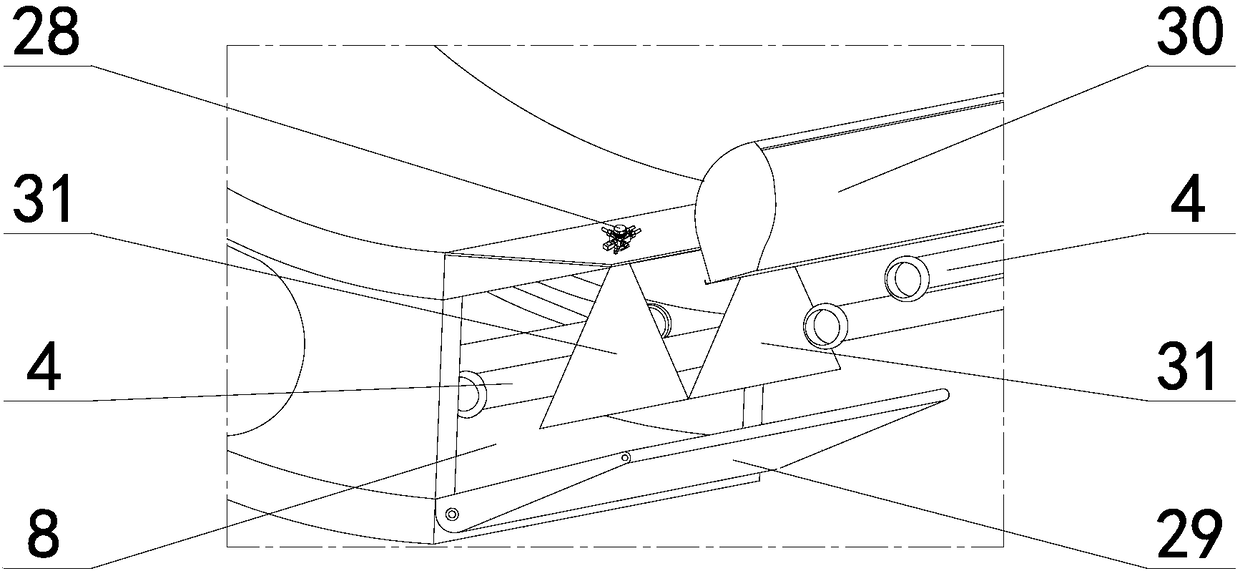

[0040] in such as Figure 4 Figure 5 In the shown embodiment 1, a seamless small cylindrical fabric sizing machine includes a frame 1, a controller 24 and a sizing cavity 5 arranged on the frame, and the frame is provided with a horizontally arranged rotating shaft 2 , the rotating shaft is driven by the main motor (not shown in the figure) arranged on the frame, and the rotating shaft is provided with a turntable 3 perpendicular to the rotating shaft, and the turntable includes a coaxial and parallel left turntable 17 and a right turntable 18 (See Image 6 Figure 8 ), there is a fixed rod 19 connecting the left and right turntables between the left turntable and the right turntable, and the left side of the left turntable and the right side of the right turntable are provided with a shaping cavity and 10 and the turntable surface Vertical sizing frame 4, the left and right turntables and the sizing frames on the left and right turntables are all symmetrical structures, a...

Embodiment 2

[0045] in such as figure 1 figure 2 In the shown embodiment 2, a kind of seamless small cylindrical fabric setting machine comprises a frame 1, a controller 24 and a shaping cavity 5 arranged on the frame, and the frame is provided with a horizontally arranged rotating shaft. Turntable, the left side of the turntable is set close to the molding cavity ( figure 1 It shows the position of the shaping cavity on the left and the position of the turntable on the right side of the shaping cavity), along the circumference of the turntable, there are 12 shaping frames 4 perpendicular to the surface of the turntable (see figure 2 , figure 2 The number of calibrating racks is shown), the calibrating rack includes fixed rollers and movable rollers parallel to each other, the fixed rollers are arranged on the turntable through bearings and connected with the fixed roller rotation motor, and the movable rollers are slidably arranged on the turntable through sliding seats It is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com