Fully-automatic setting machine edge cutting and ironing device and control method thereof

A control method and a technology of a setting machine, which are applied in the cutting of textile materials, trimming of fabrics, and trimming of fabric surfaces, etc., can solve the problems that polyester nets cannot be fully automatic trimmed, etc., so as to reduce labor intensity and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

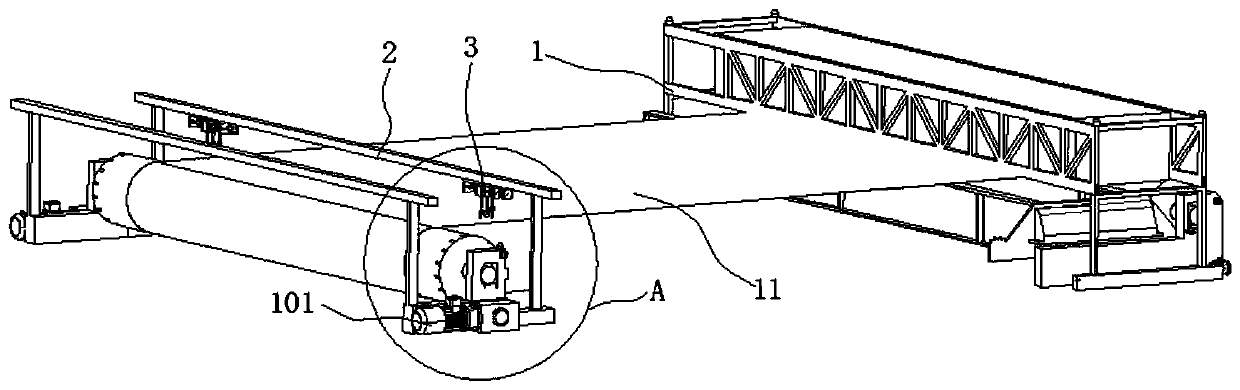

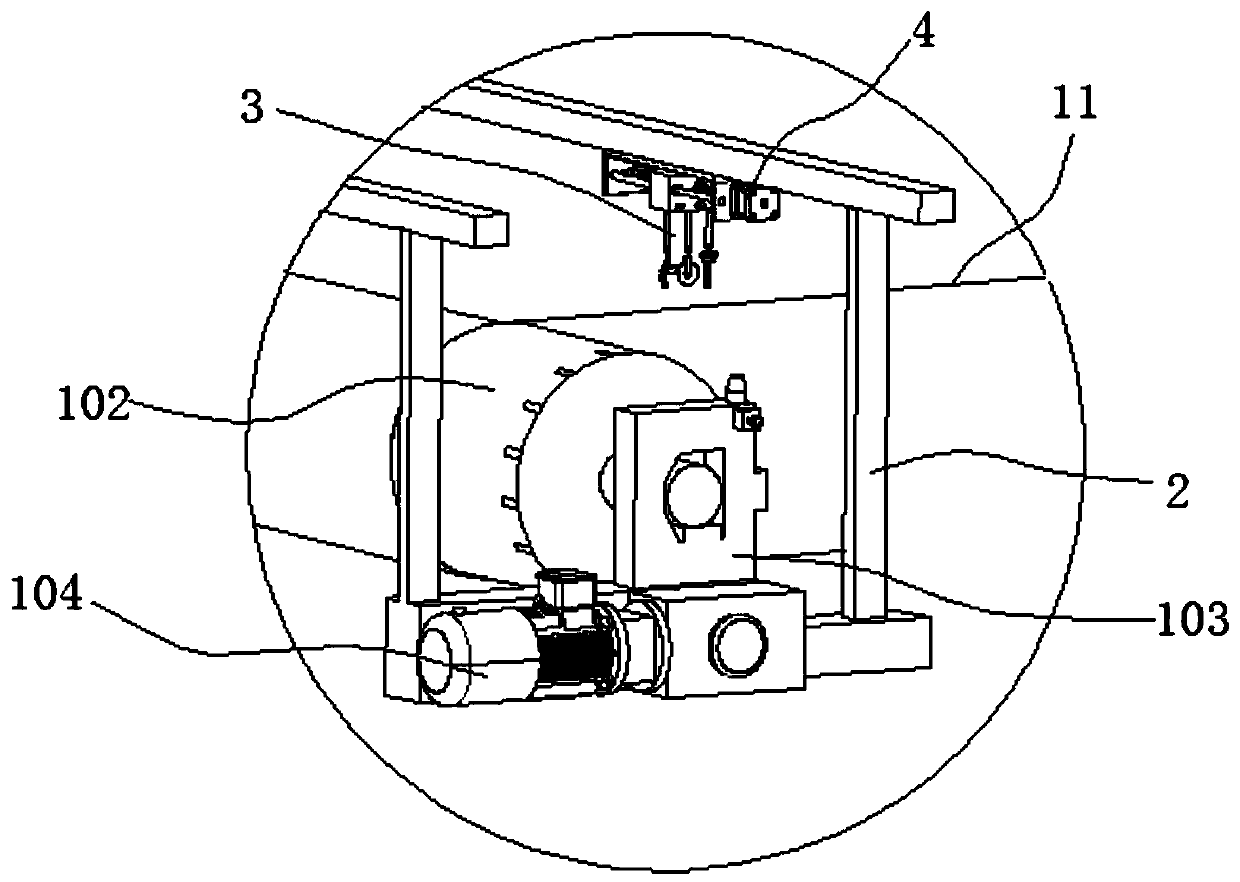

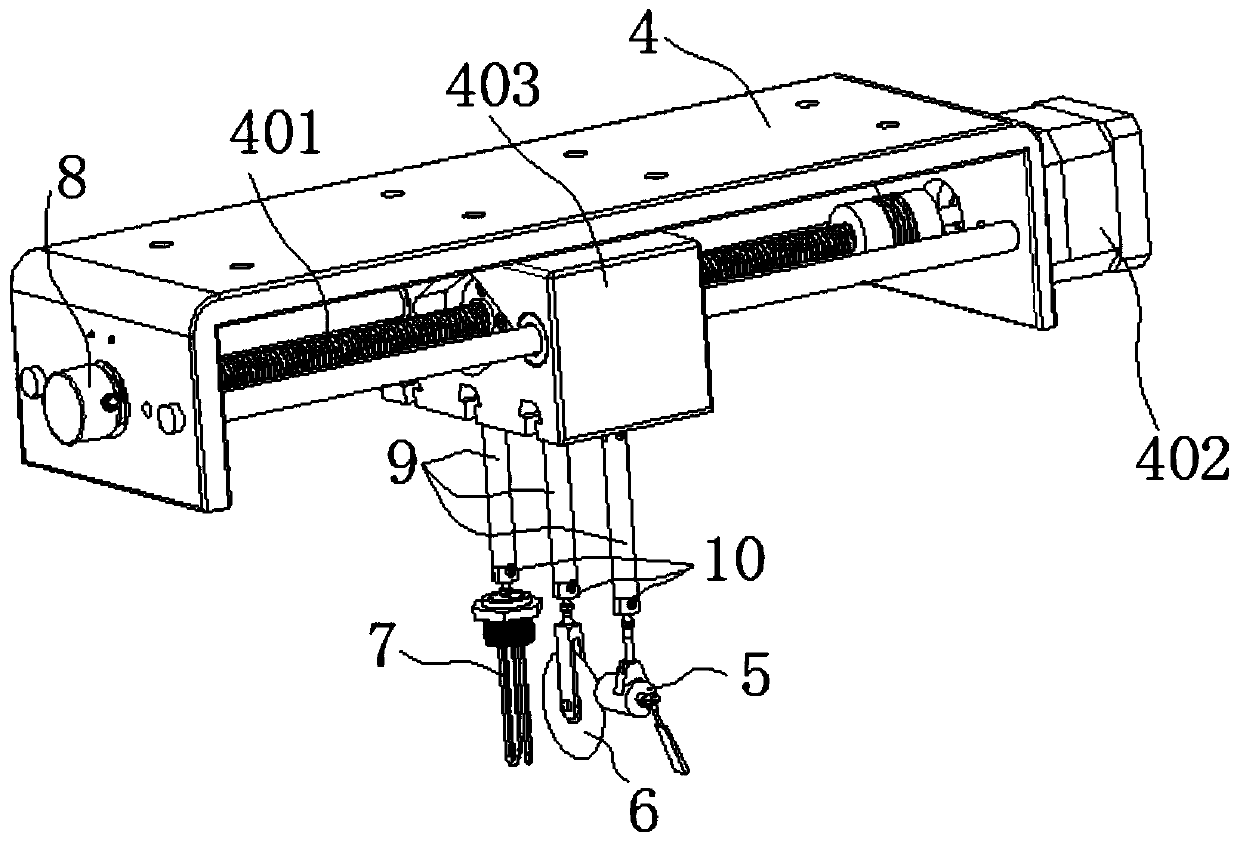

[0030] Such as Figure 1-3 Shown is a full-automatic edge trimming device for a sizing machine, including a bracket 2 installed on the sizing machine 1, and both sides of the bracket 2 are provided with an edge trimming assembly 3 and a driving edge trimming assembly 3 to operate along the bracket 2 The driving assembly 4 of linear motion; The edge trimming assembly 3 includes an edge detector 5 (the model can be SN09-E) for measuring the distance between the edge trimming assembly 3 and the edge of the polyester net 11, a cutter for realizing edge trimming 6 and the heating tube 7 for realizing edge welding.

[0031] Specifically, the drive assembly 4 is a sliding table module (the model of the sliding table module can be FSL30), and the sliding table module includes a sliding table frame, a rotating shaft 401, an optical shaft, a coupling, a motor 402 and a slider 403, The edge trimming assembly 3 is arranged on the slide block 403 of the slide table module. The width of t...

Embodiment 2

[0040] Such as Figure 4 Shown is to provide a kind of control system for the device described in embodiment 1, the control method of this system comprises the following steps:

[0041] Step 1: The lifting device is connected to the starter, the sensor, the stepping motor and the starter are connected to the PLC controller, and the PLC controller is in communication with the upper computer; the lifting device is a cylinder, the starter is a solenoid valve, and the sensor is an edge detector (The model can be SN09-E).

[0042] Step 2: The edge detector detects the test distance between the edge trimming component and the edge of the object to be processed. The upper computer sets the working distance between the edge trimming component and the edge of the polyester net. The upper computer checks the test distance and Comparing the working distance, calculating the distance that the stepper motor needs to drive the edge trimming assembly and converting the distance into the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com