Printed fabric hair brushing and sucking machine

A brushing and fabric technology, applied in the field of textile fabrics, can solve the problems of poor surface smoothness, low work efficiency, and poor processing effect of gray cloth, and achieve the effects of high work efficiency, simple and reasonable structure, and improved surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

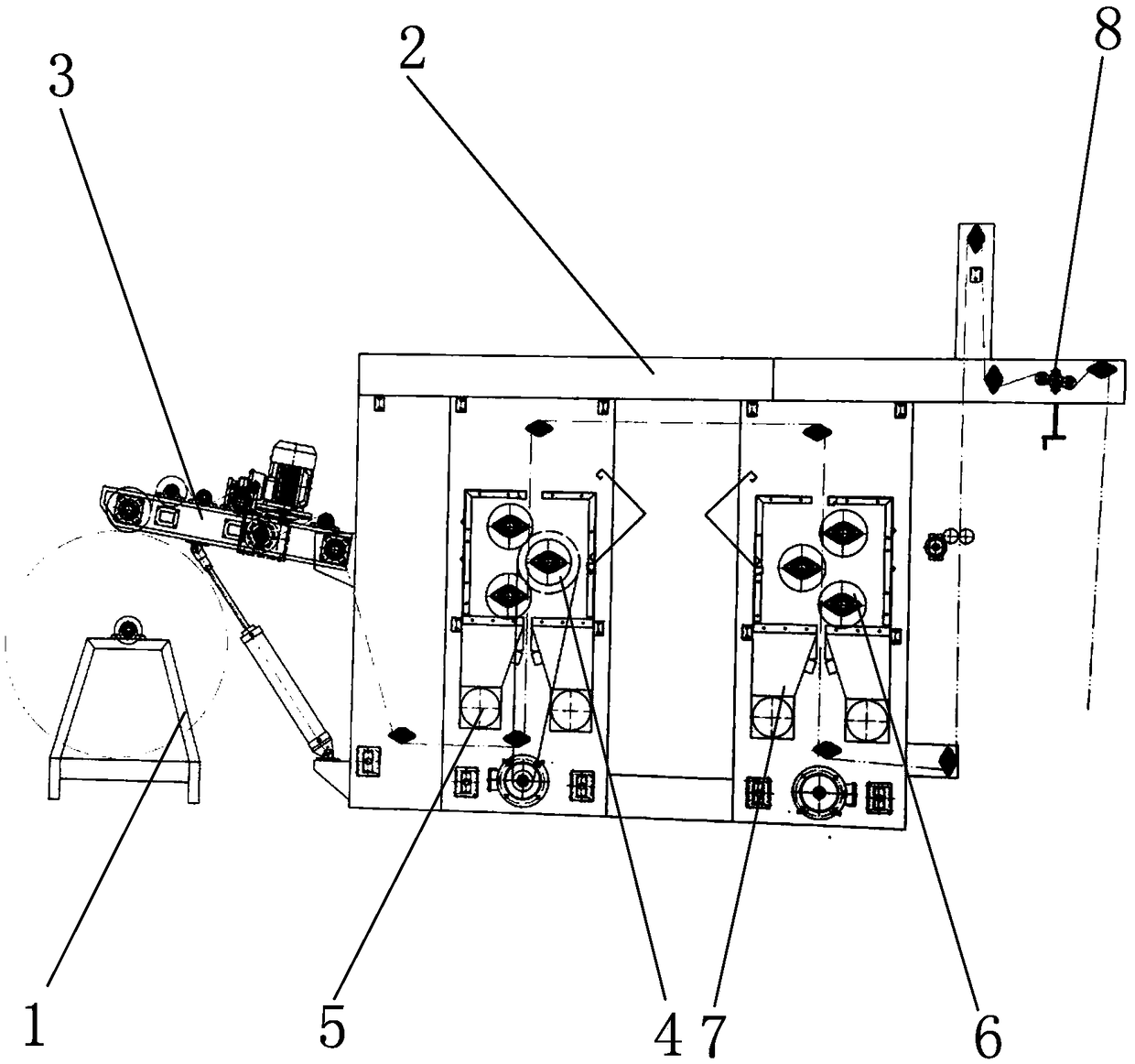

[0023] combine figure 1 , the invention discloses a printing fabric brushing hair suction machine, comprising a gray cloth support seat 1, a body 2, a movable swing arm 3 installed on the body 2, a sanding mechanism and a brushing mechanism. The gray cloth support seat 1 is used to support and place the gray cloth coil, and the gray cloth support seat 1 is positioned at one side of the machine body 2, and a support roller is horizontally installed on the gray cloth support seat 1 . The gray cloth coil is sleeved on the supporting roller. The supporting roller is erected on the gray cloth support seat 1 and rotates relative to the gray cloth support seat 1 .

[0024] The movable swing arm 3 is installed on one end of the body 2 and is hinged with the body 2 . The movable swing arm 3 can swing relative to the body 2 . A driving cylinder is arranged on the body 2, and the driving cylinder is connected with the movable swing arm 3 to drive the movable swing arm 3 to rotate. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com