Patents

Literature

109 results about "Iodine vapor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iodine Vapor n Of Iodine At Dictionary.com. a nonmetallic halogen element occurring at ordinary temperatures as a grayish-black crystalline solid that sublimes to a dense violet vapor when heated: used in medicine as an antiseptic. Definition Of Iodine By Merriam-Webster.

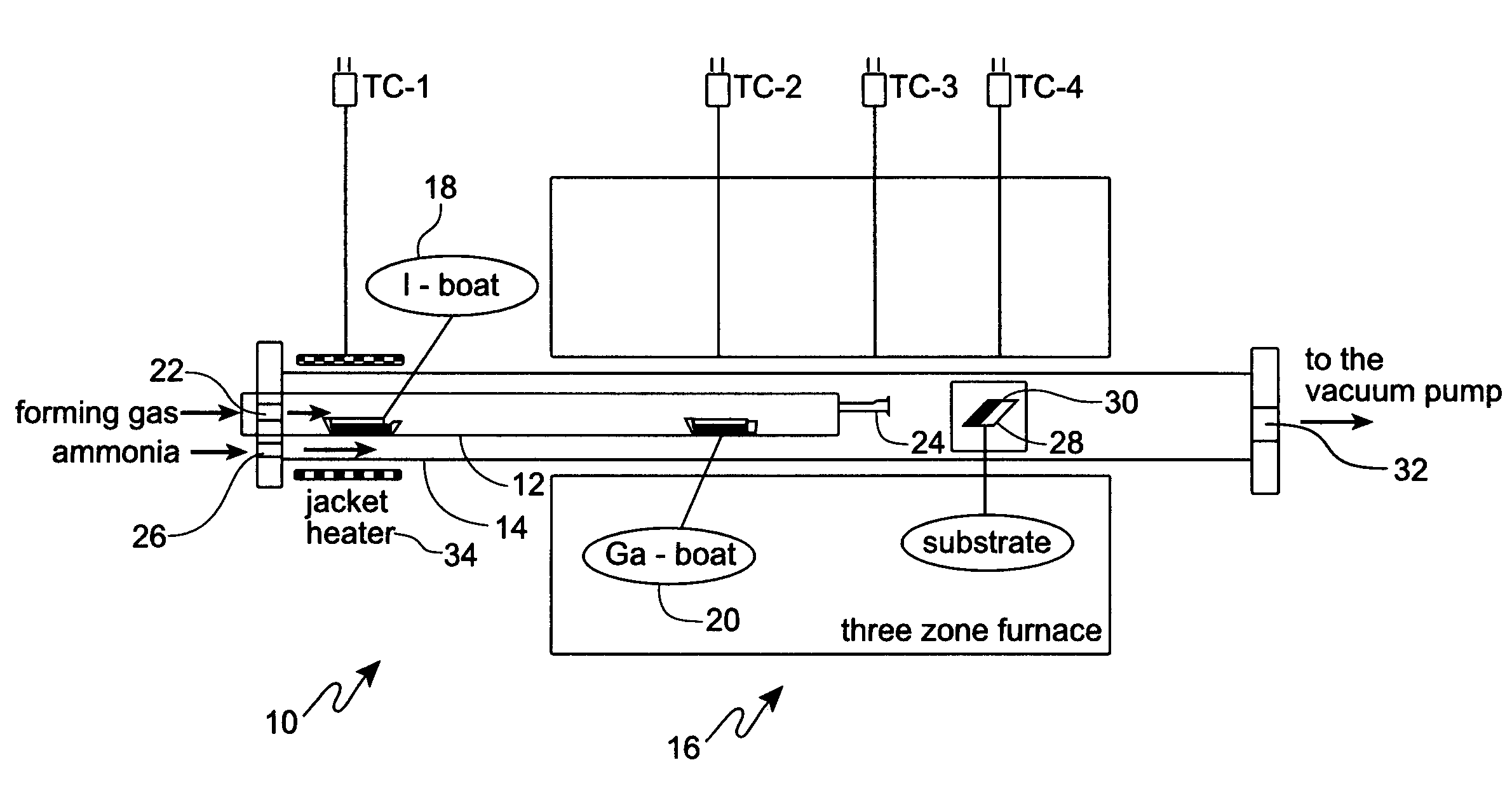

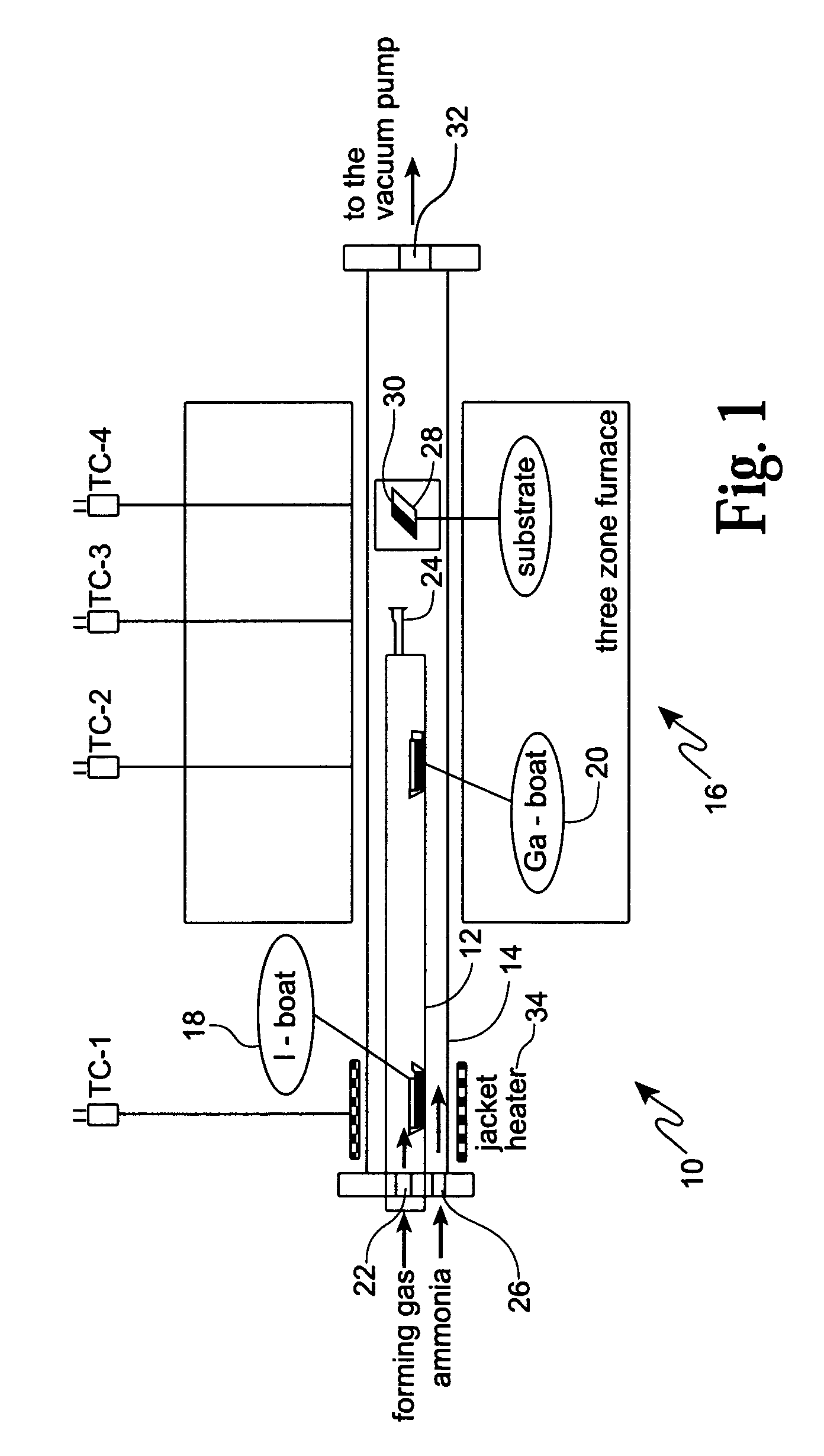

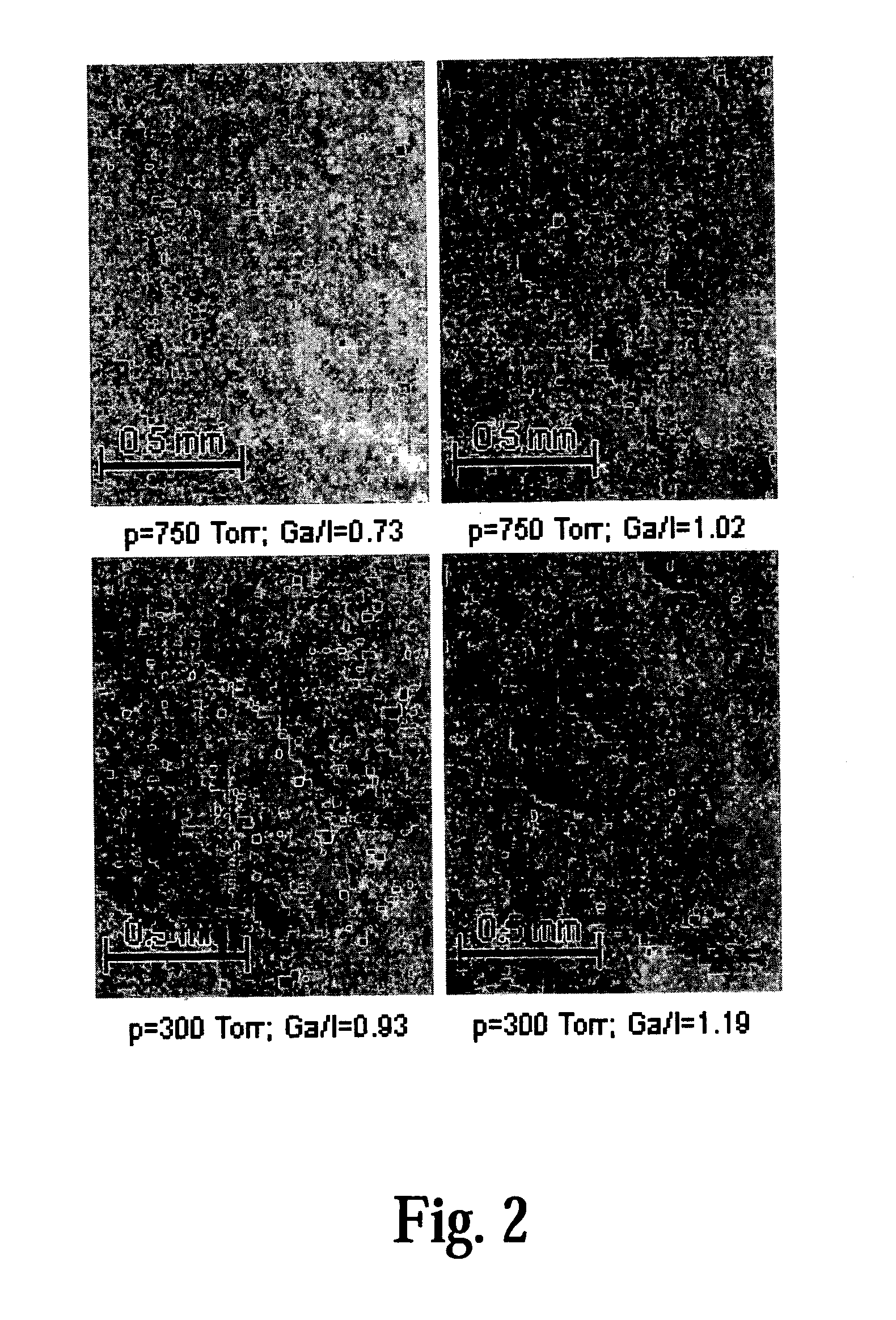

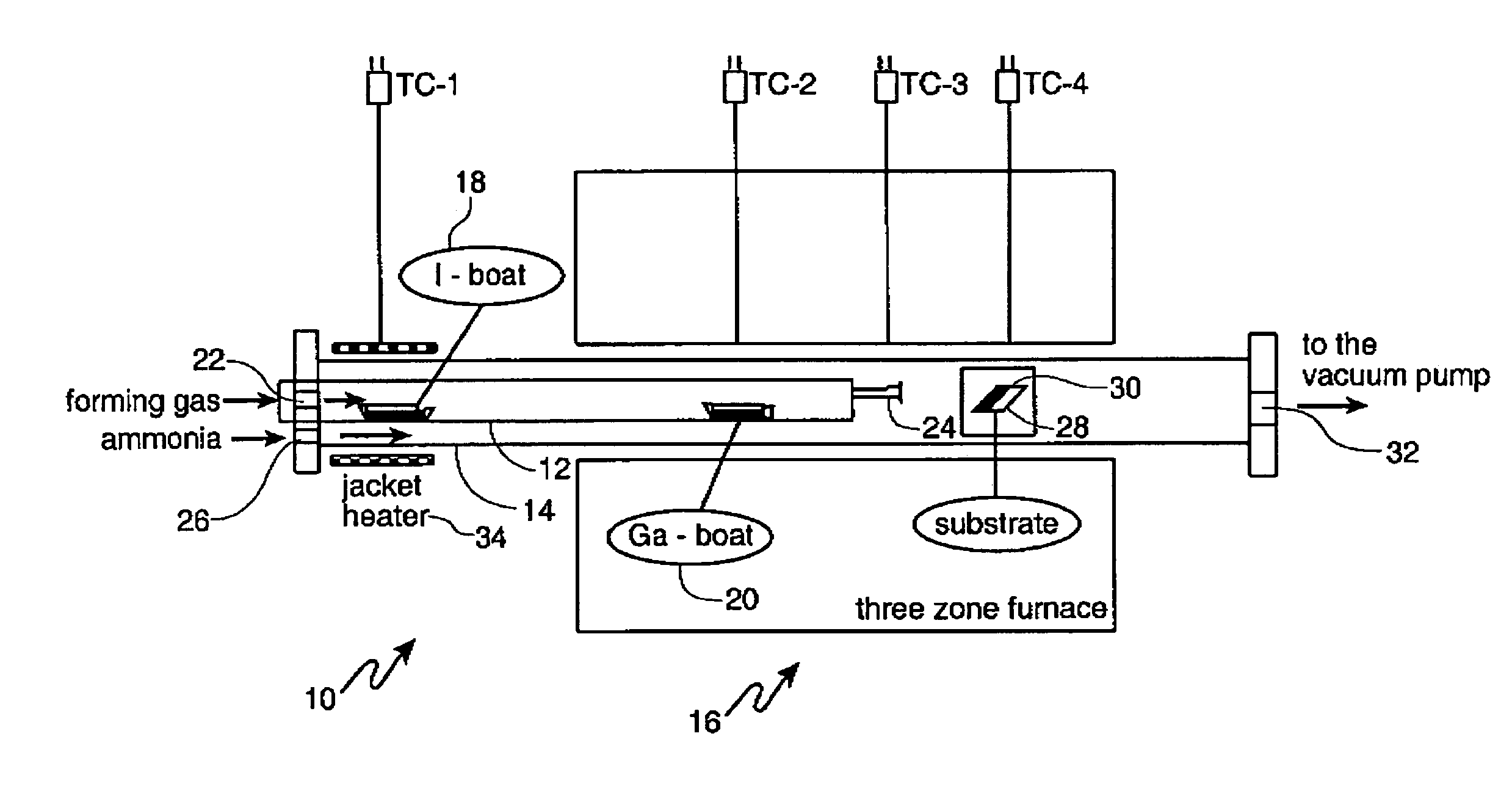

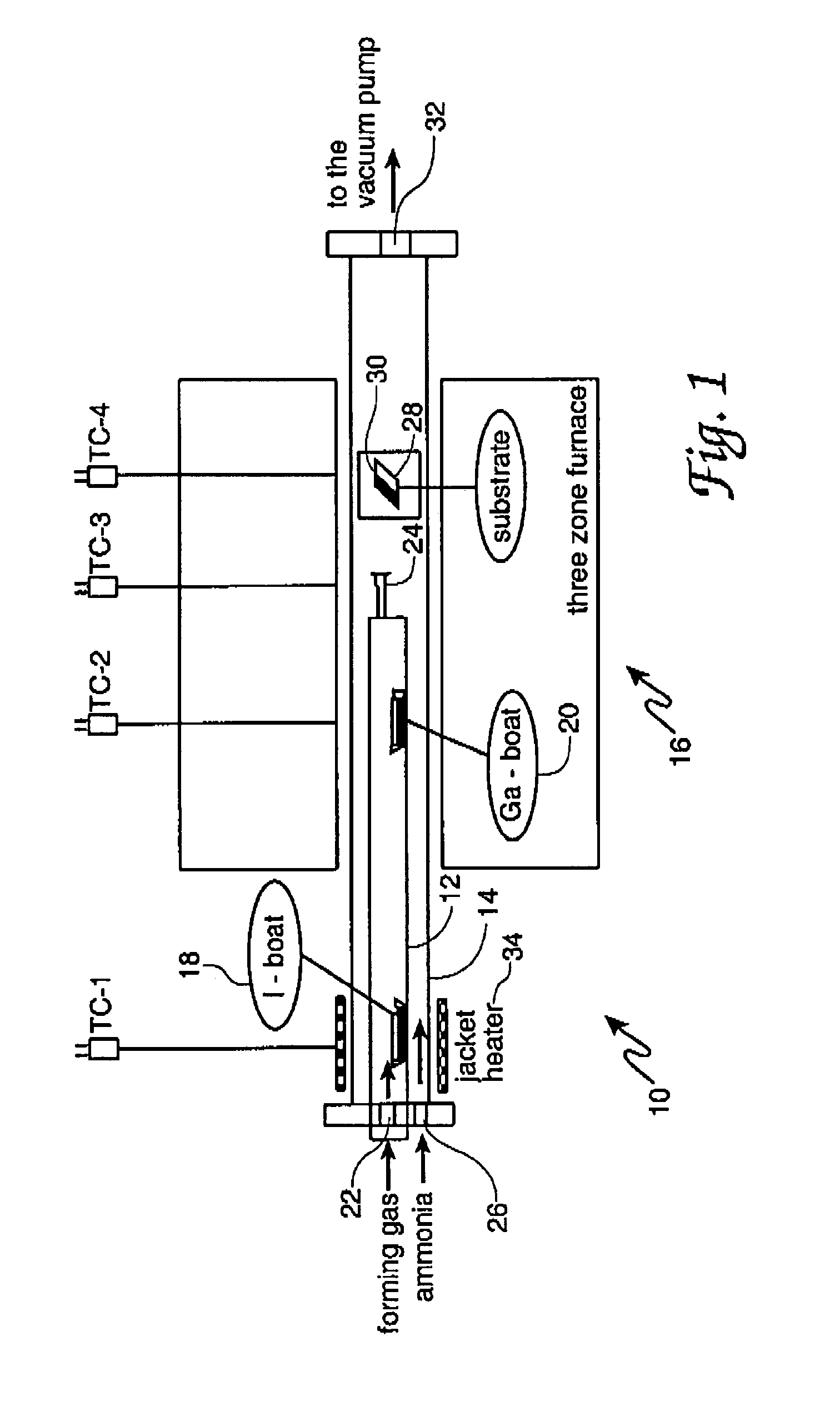

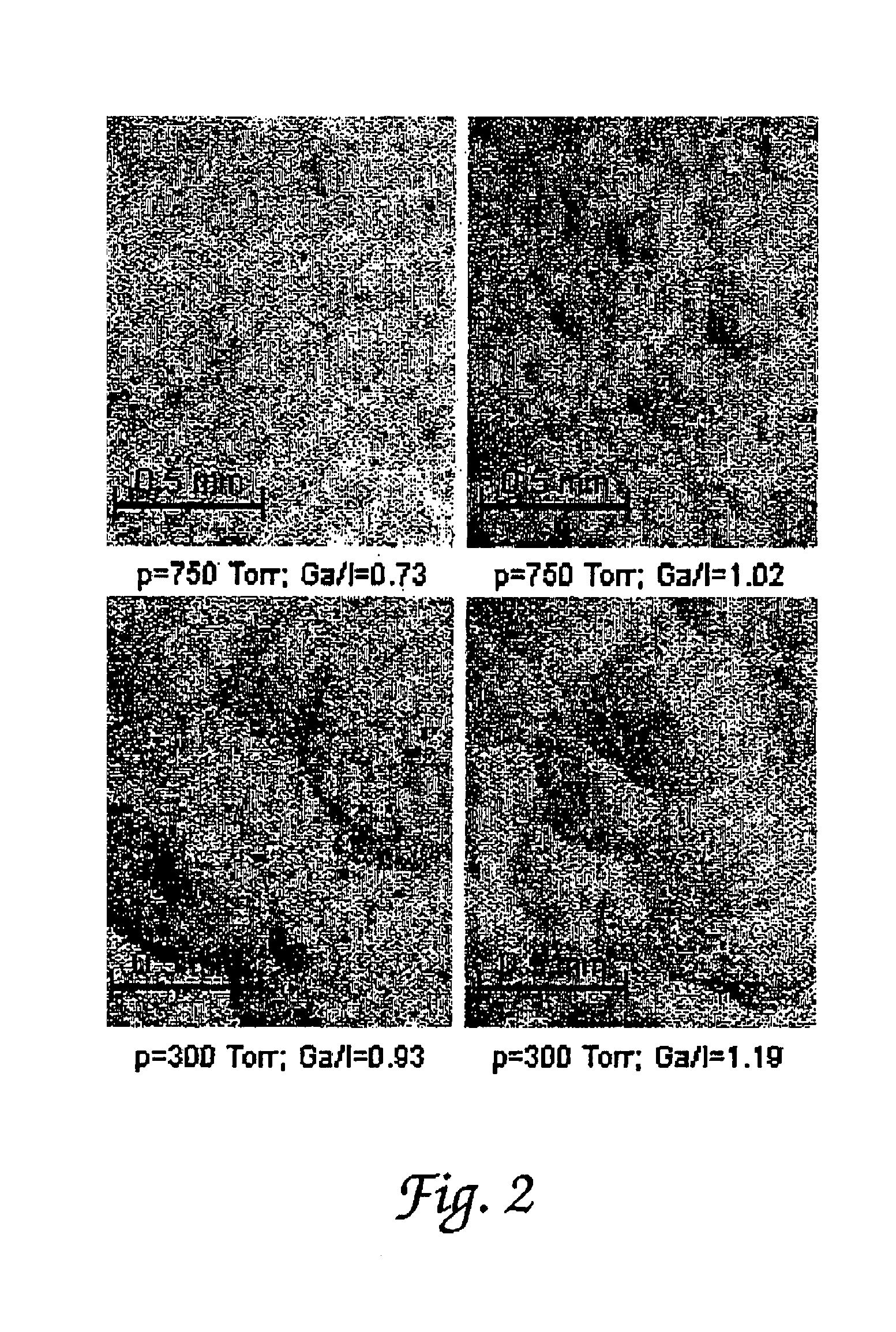

Forming improved metal nitrides

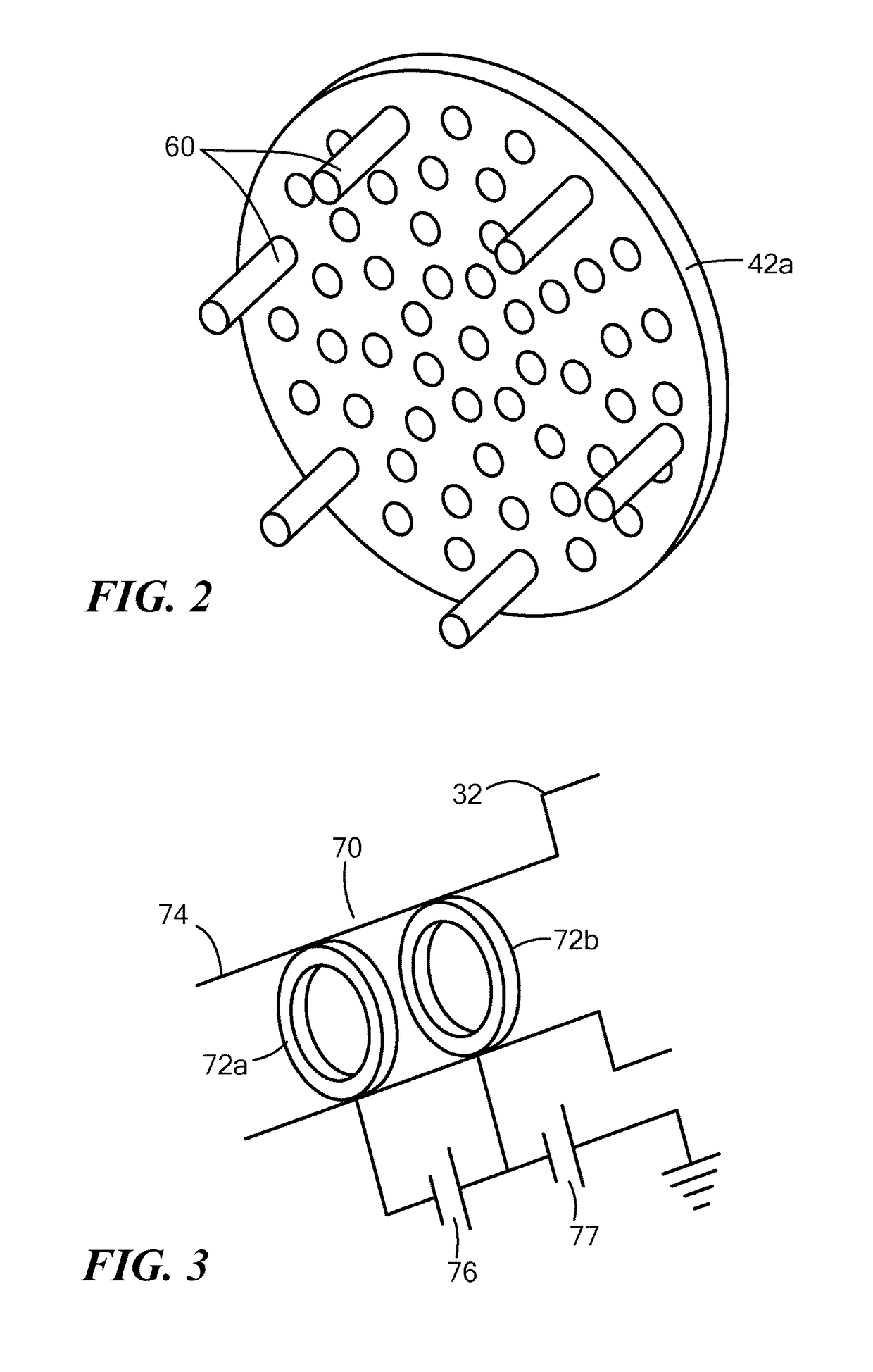

InactiveUS6969426B1Unity of formCellsPolycrystalline material growthMicrowaveSemiconductor materials

Method and apparatus are provided for forming metal nitride (MN), wherein M is contacted with iodine vapor or hydrogen iodide (HI) vapor to form metal iodide (MI) and then contacting MI with ammonia to form the MN in a process of reduced or no toxicity. Such method is conducted in a reactor that is maintained at a pressure below one atmosphere for enhanced uniformity of gas flow and of MN product. The MN is then deposited on a substrate, on one or more seeds or it can self-nucleate on the walls of a growth chamber, to form high purity and uniform metal nitride material. The inventive MN material finds use in semiconductor materials, in nitride electronic devices, various color emitters, high power microwave sources and numerous other electronic applications.

Owner:AIR FORCE US SEC THE

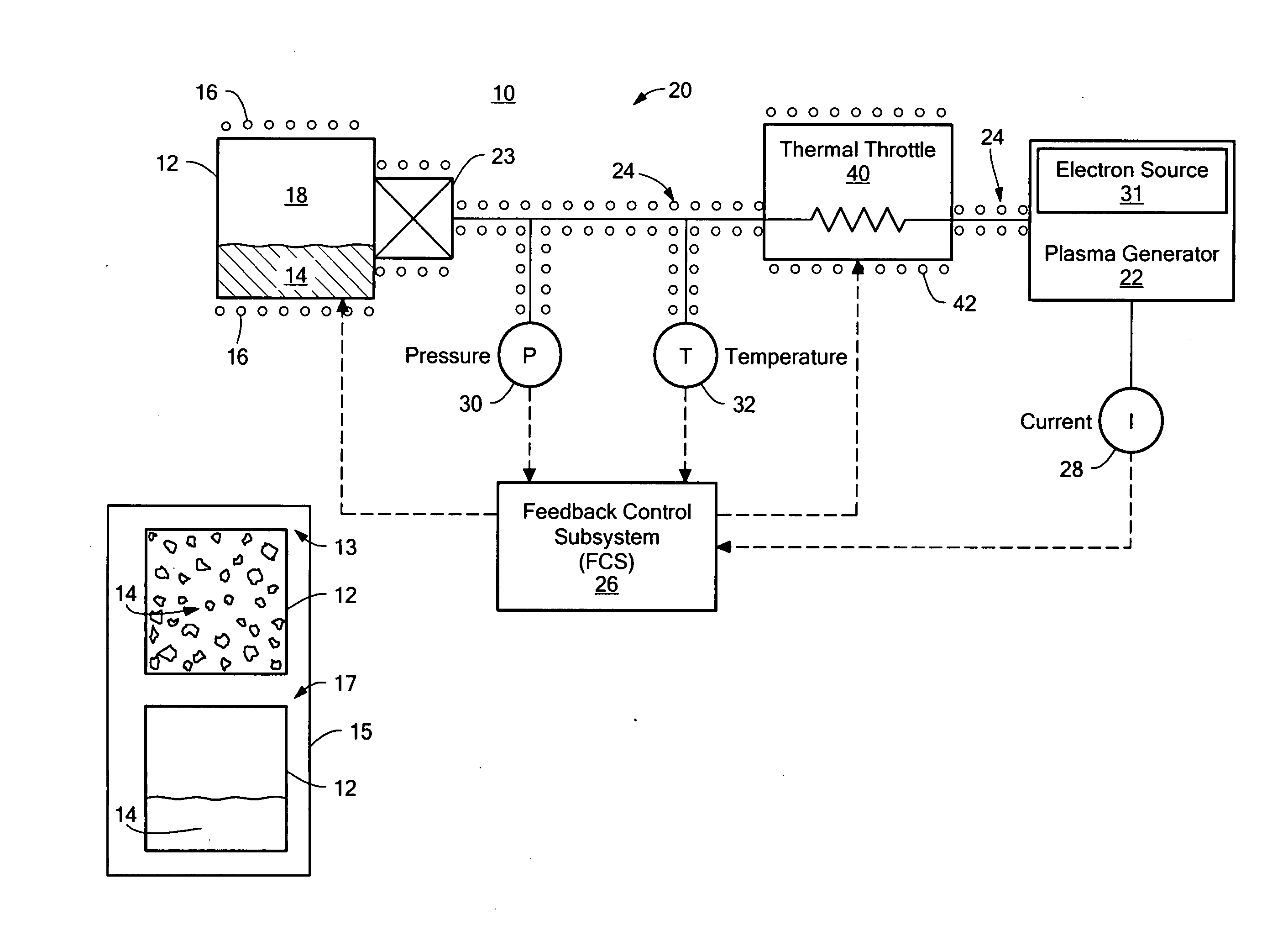

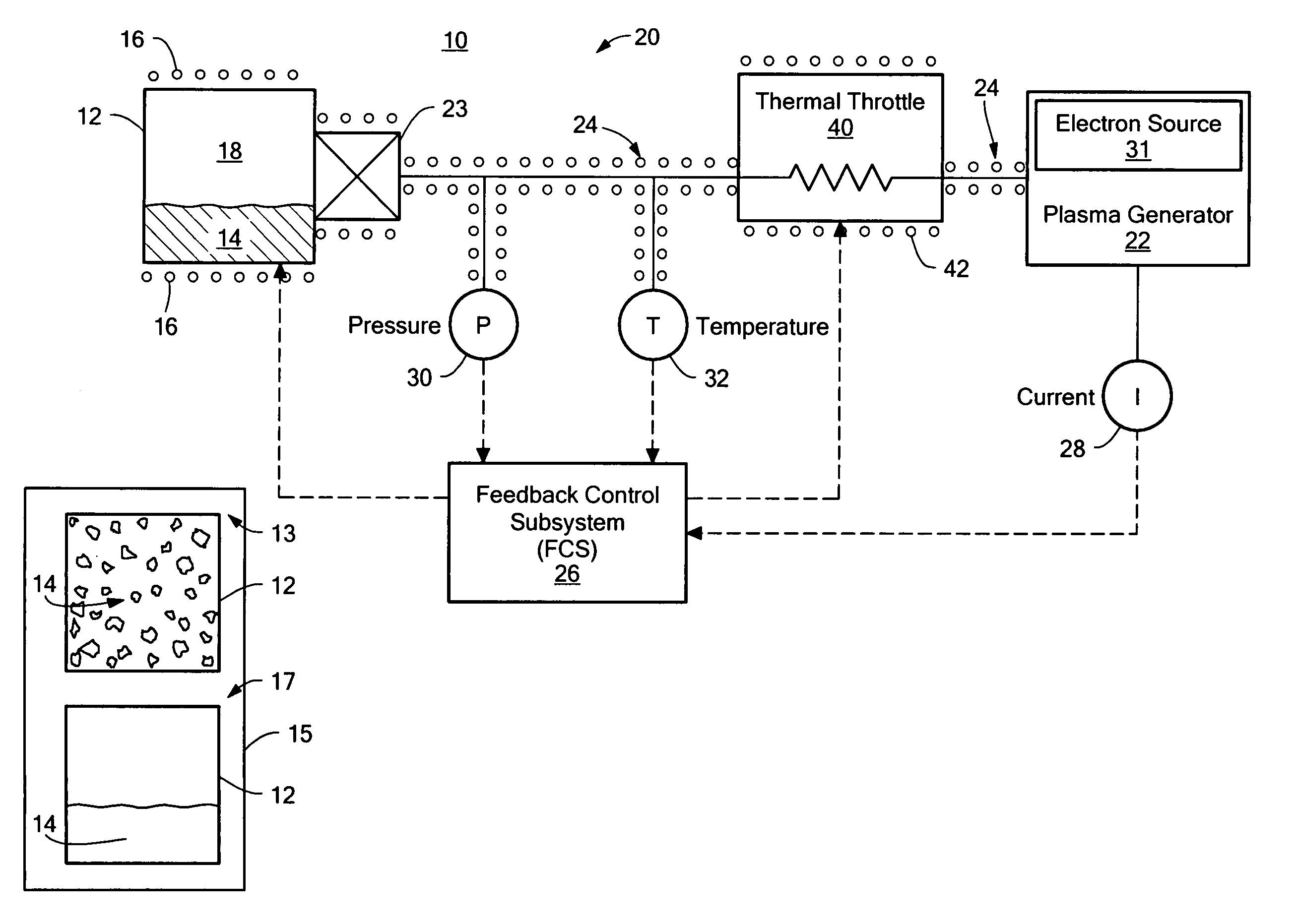

Iodine Fueled Plasma Generator System

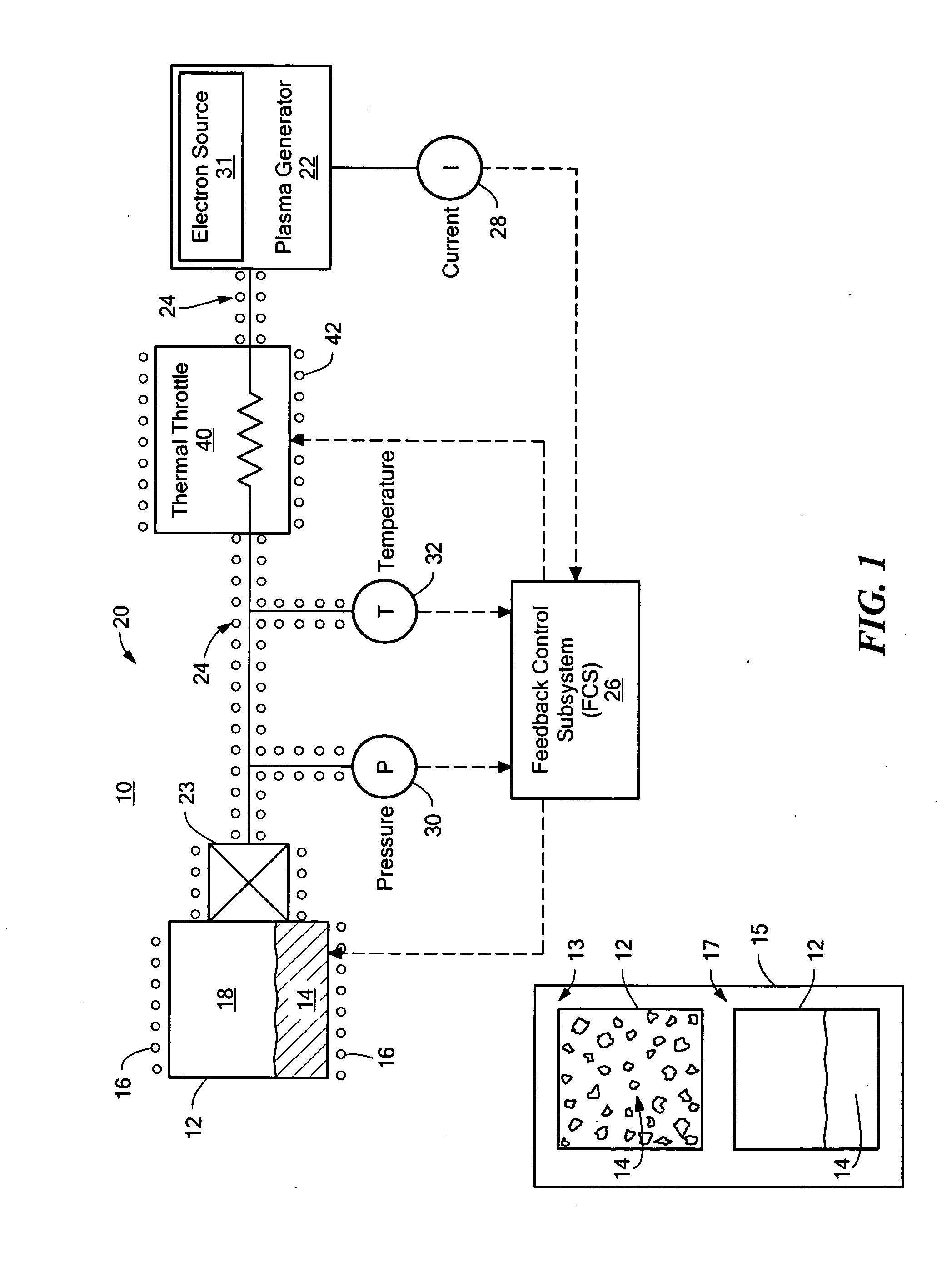

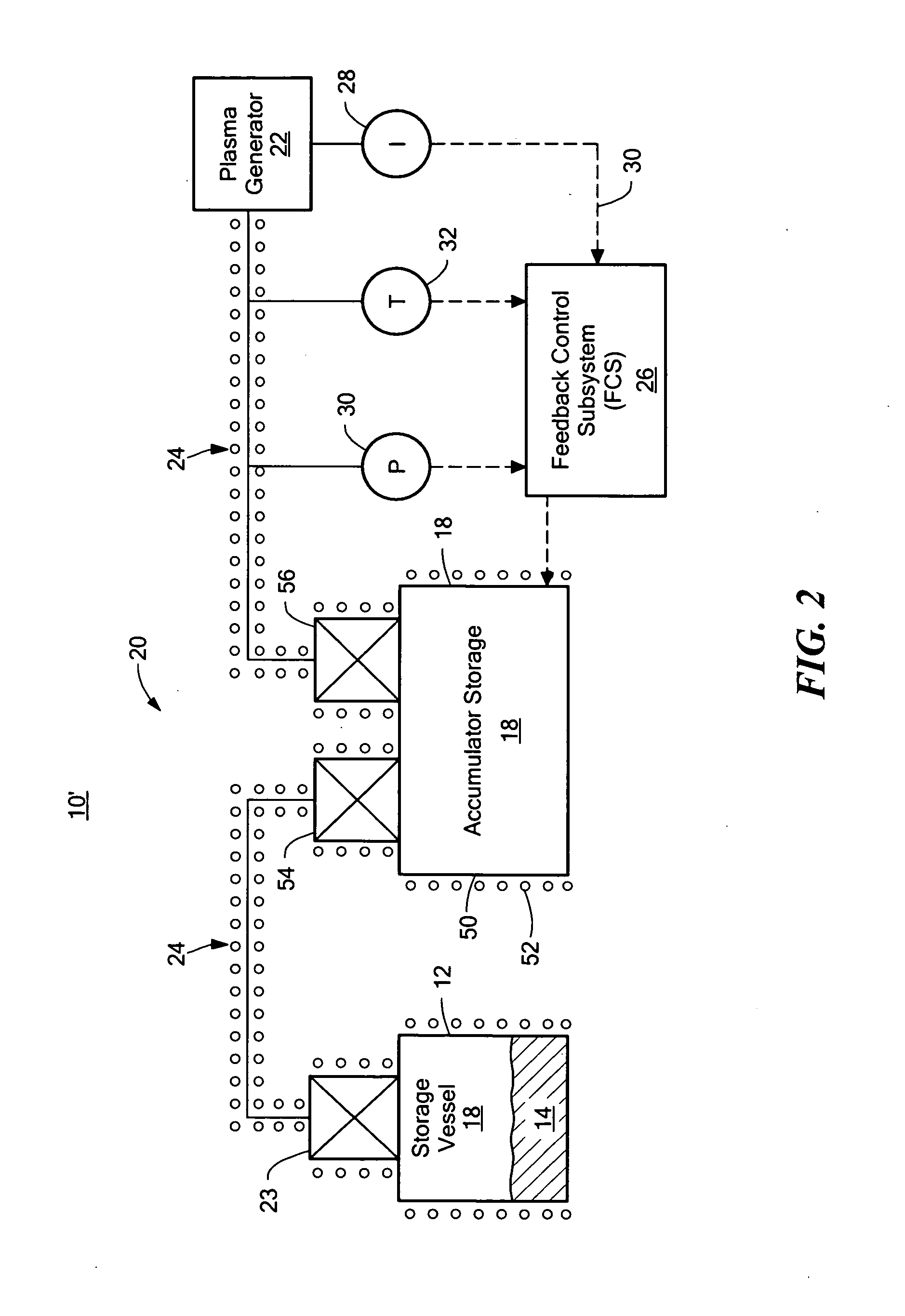

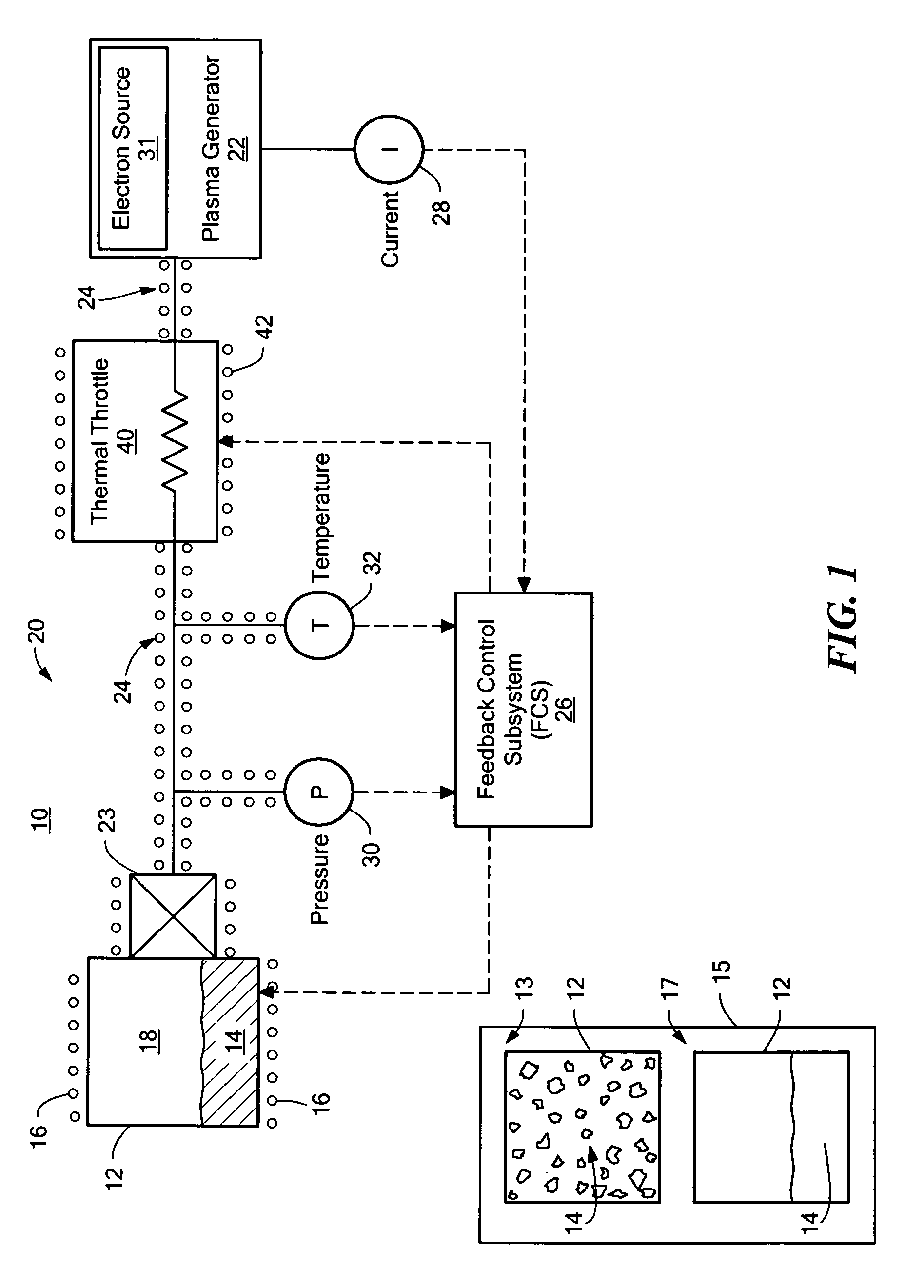

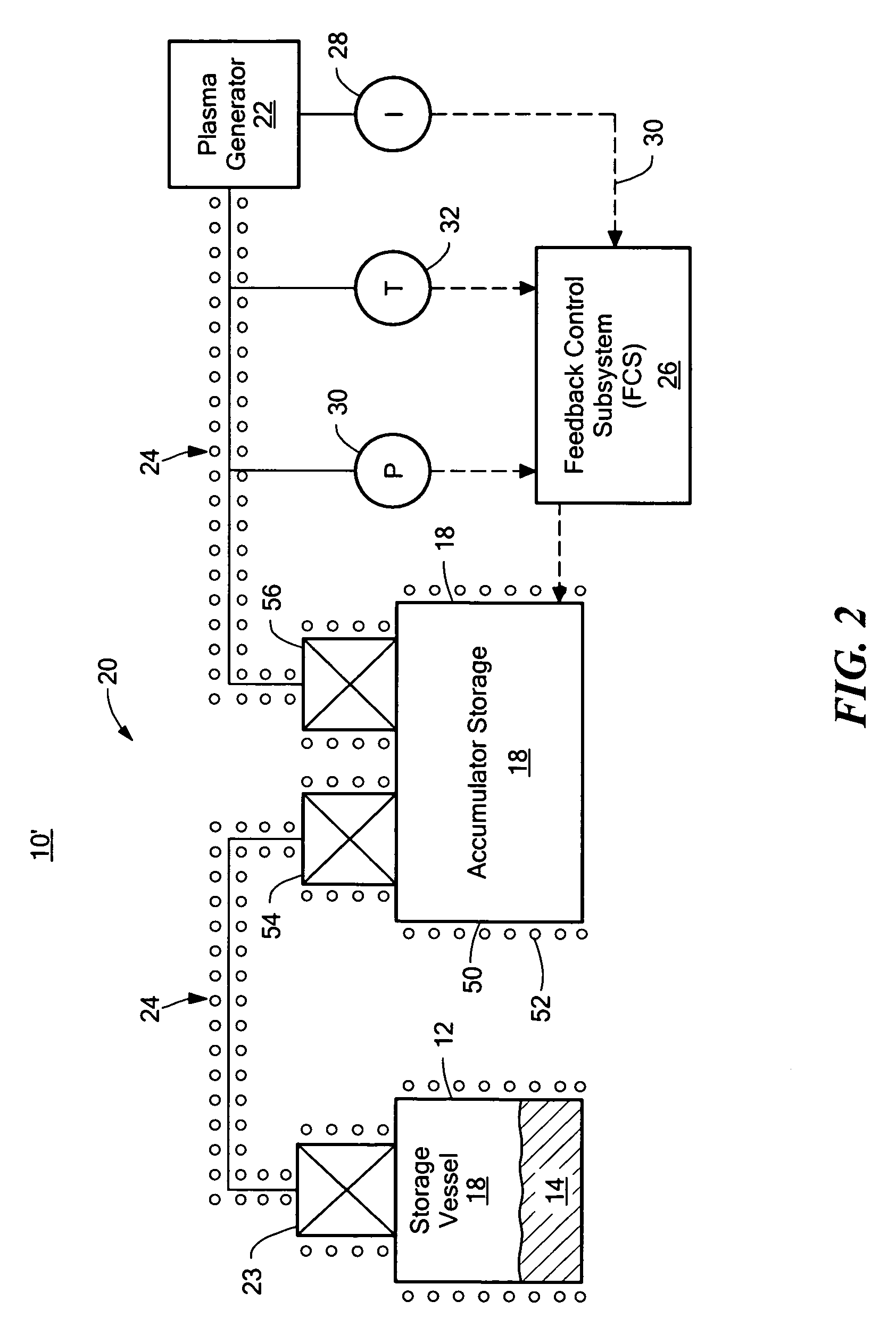

An iodine fueled plasma generator system includes a plasma generator. At least one storage vessel is configured to store condensed phase iodine therein. A heating device proximate to the storage vessel is configured to create iodine vapor from the condensed phase iodine. A propellant management subsystem is configured to deliver the iodine vapor to the plasma generator. A feedback control subsystem is responsive to one or more of plasma generator discharge current, the pressure of the iodine vapor, and / or the temperature of the iodine vapor configured to regulate the flow rate of the iodine vapor to the plasma generator.

Owner:BUSEK

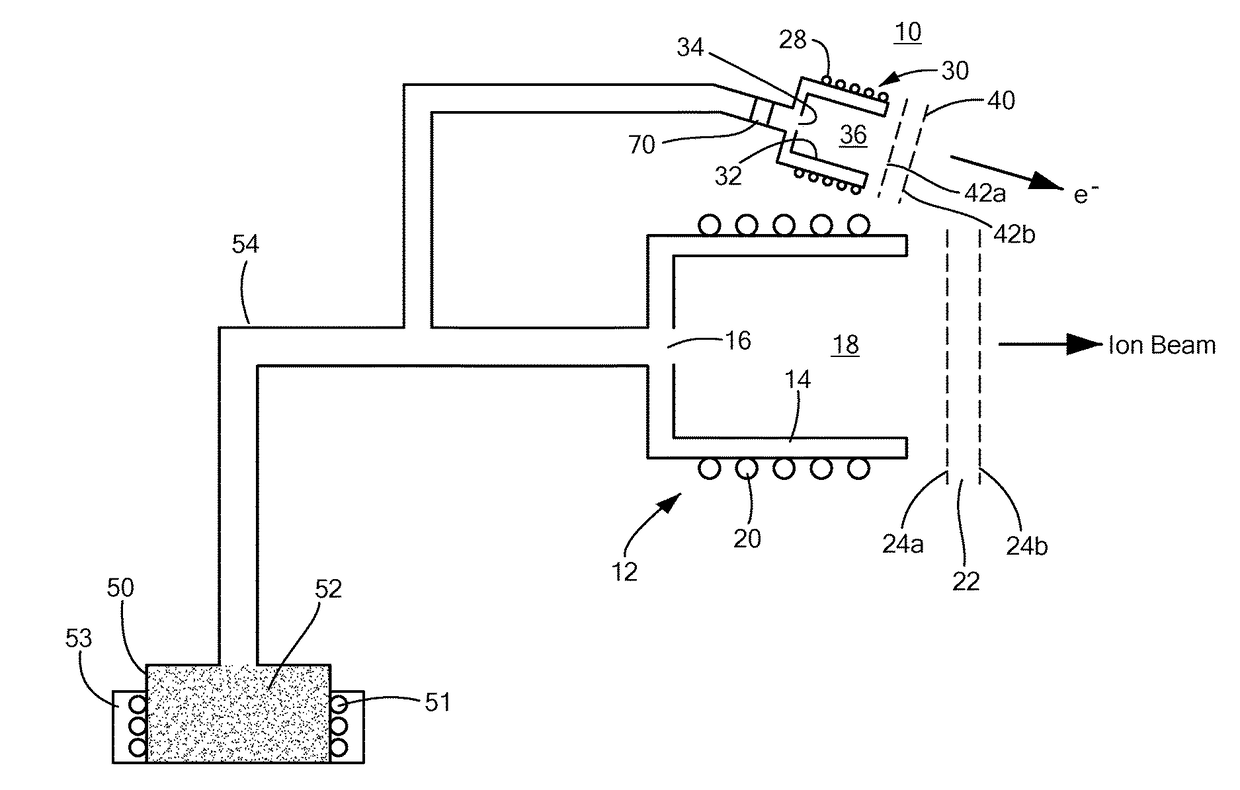

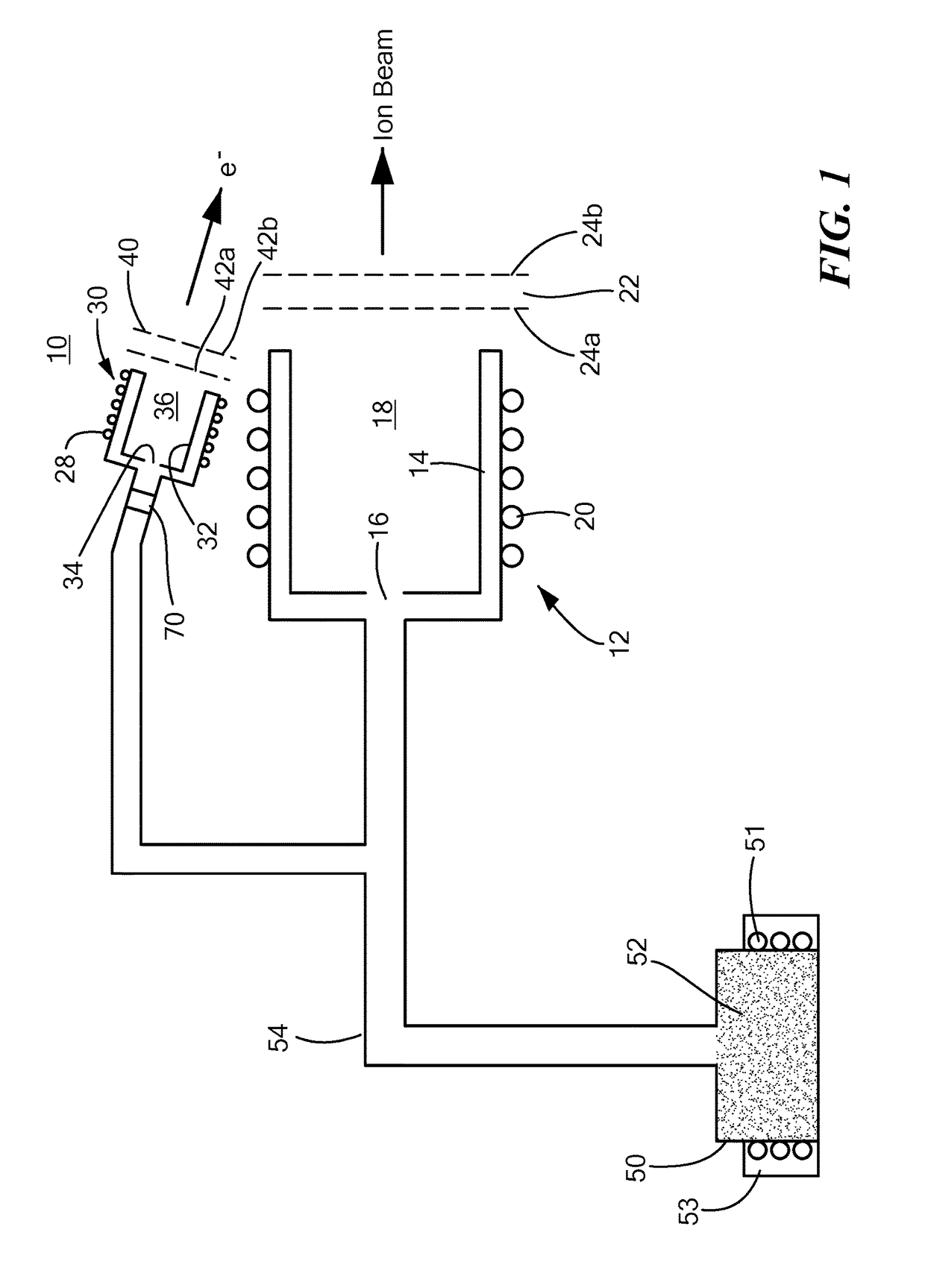

Iodine propellant RF ion thruster with RF cathode

InactiveUS20180023550A1Increase productionIncrease surface areaMachines/enginesIon beam tubesIon beamEngineering

A thrust producing system includes an RF ion thruster with a discharge chamber having a gas inlet and an outlet, and a coil about the discharge chamber. The system further includes an RF cathode proximate the discharge chamber outlet of the RF ion thruster for ion beam neutralization. The RF cathode includes a discharge chamber having a gas inlet and an outlet and a coil about the discharge chamber. A tank for containing iodine in solid form and a heater associated with said tank to produce iodine vapor. A feed subsystem fluidly couples the tank with the RF ion thruster discharge chamber gas inlet and with the RF cathode discharge chamber gas inlet.

Owner:BUSEK

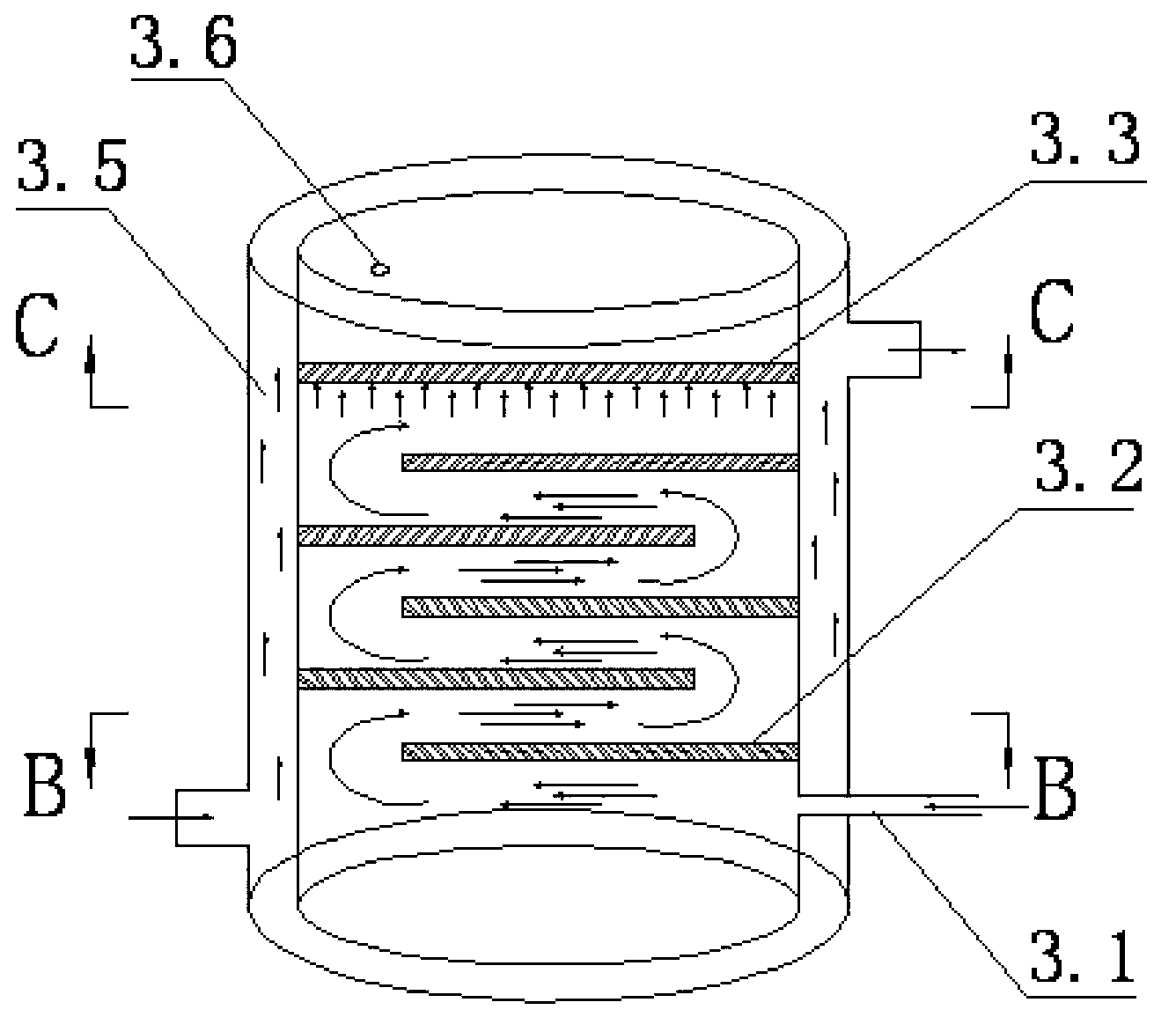

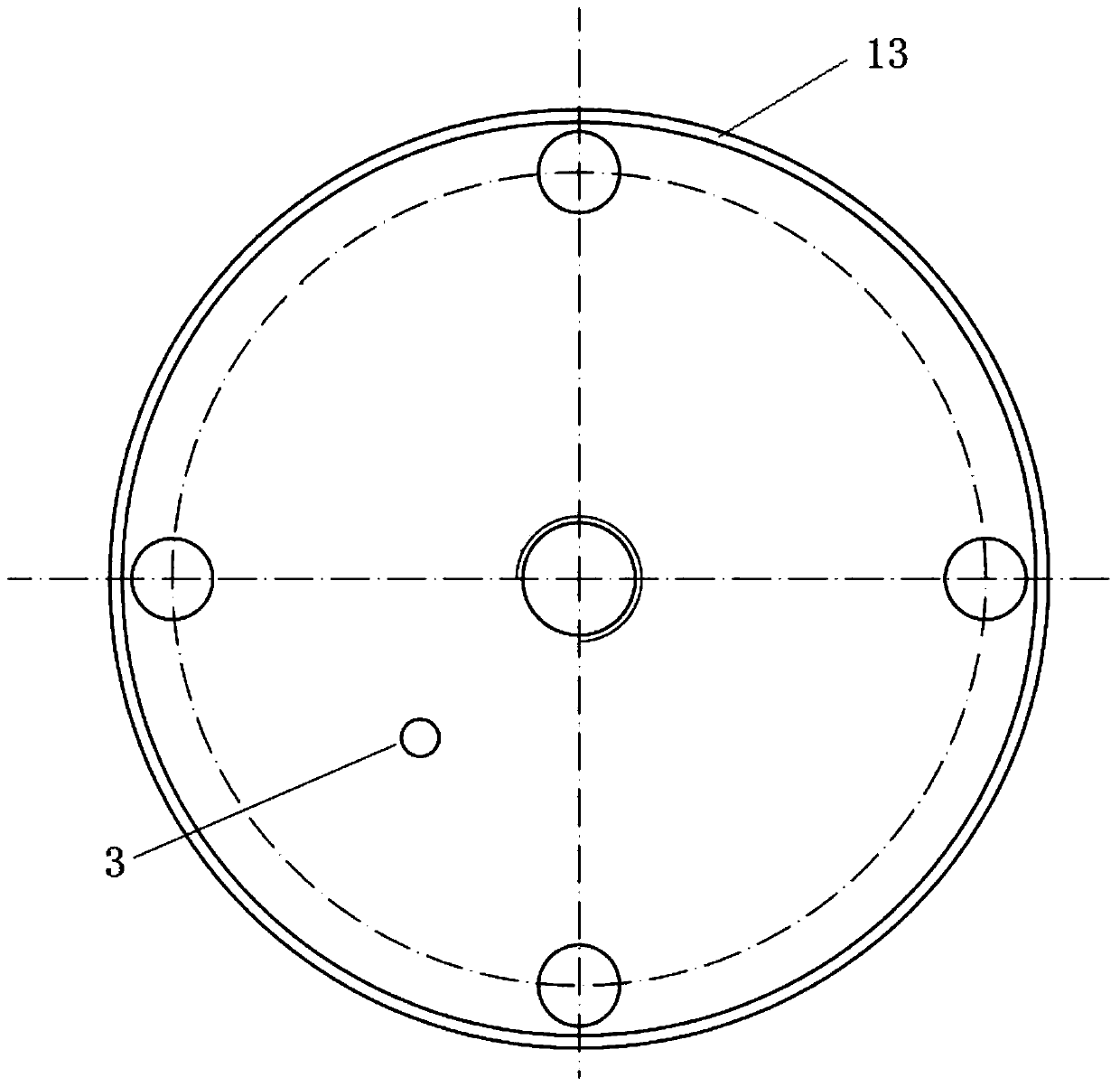

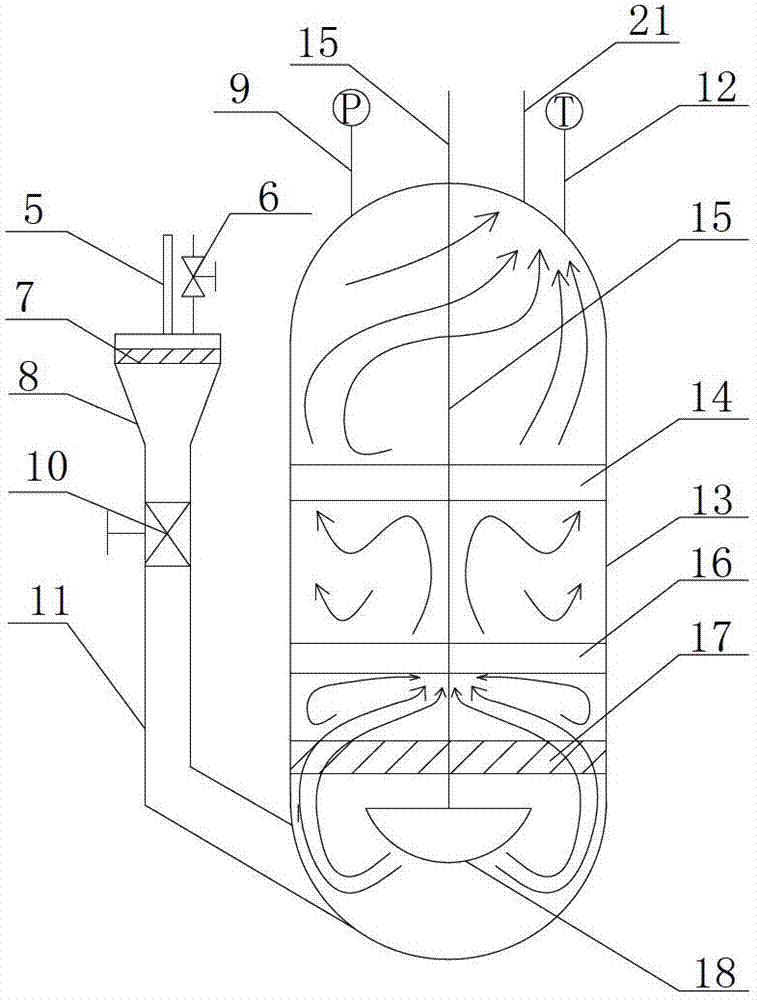

Iodine vapor sampling apparatus under high temperature and high humidity environment

InactiveCN103257059AMeet the needs of iodine concentration measurementPrevent SuckbackWithdrawing sample devicesHigh humidityProcess engineering

The present invention provides an iodine vapor sampling apparatus under a high temperature and high humidity environment. The apparatus comprises a pipeline sampling system, a gas washing system, a condensation system and a bypass system, wherein the pipeline sampling system comprises a break valve, a pressure reduction valve and a connection pipeline, the gas washing system comprises multiple stage absorption bottles and a KI absorption solution filled in the absorption bottle, the condensation system comprises a condensation water tank connected with the final stage absorption bottle, a drying agent box positioned on the rear of the condensation water tank, and a first flow meter connected on the rear of the drying agent box, and the bypass system comprises a first three-way valve, a second three-way valve, a second flow meter, a bypass absorption bottle and an absorption liquid in the bypass absorption bottle. The apparatus has characteristics of simple structure and easy operation, and can be particularly used for measurement of other substances having a suitable absorption liquid under a high temperature and high humidity environment.

Owner:三亚哈尔滨工程大学南海创新发展基地

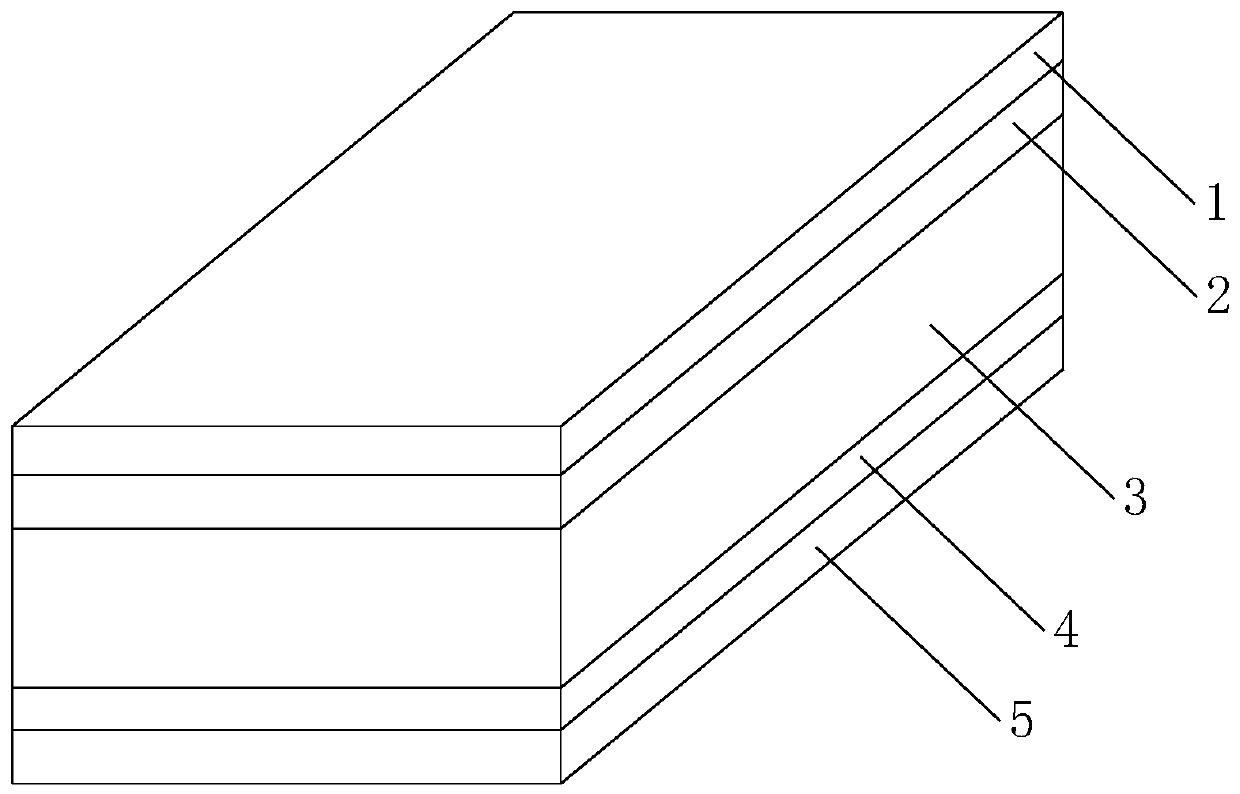

Anti-icing coating and anti-icing material, and preparation methods thereof

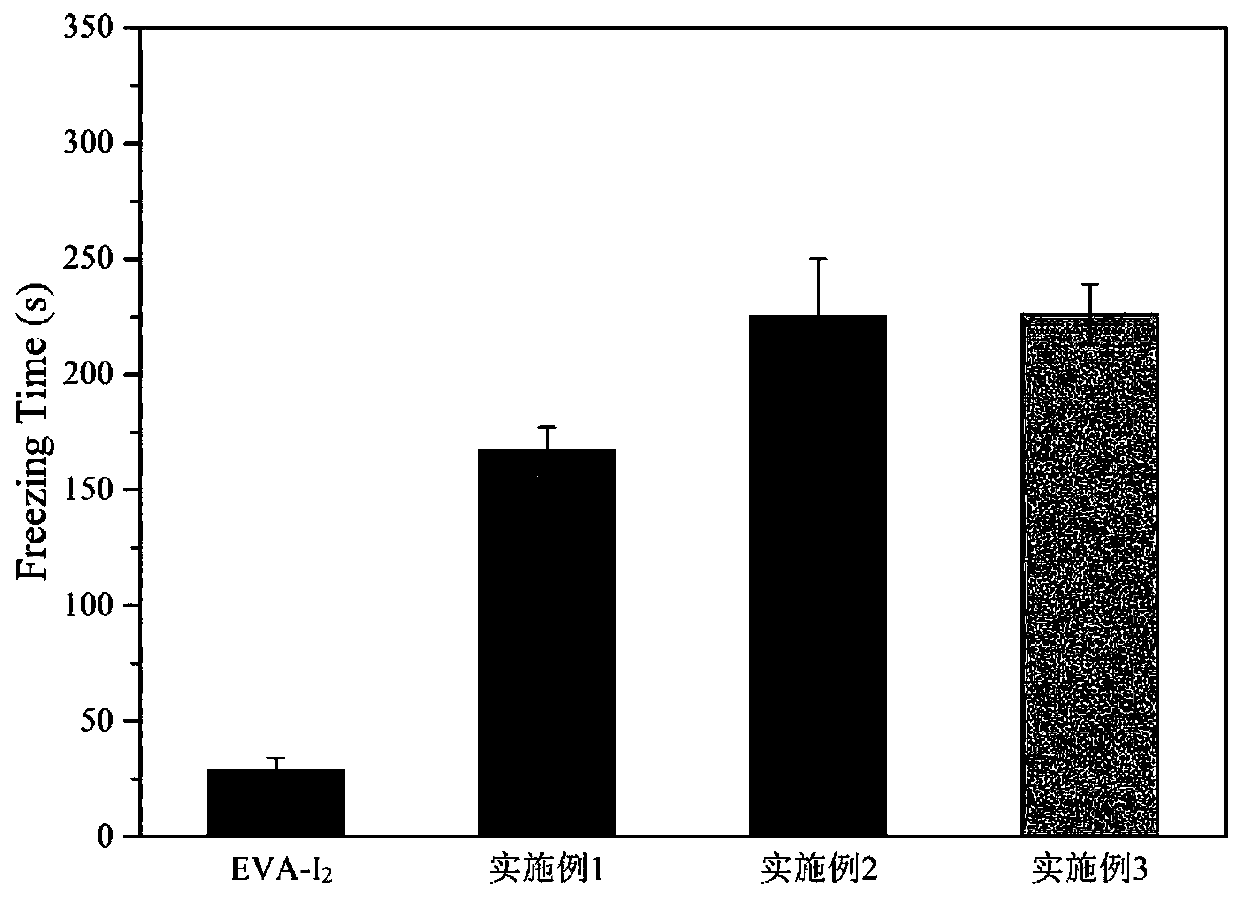

ActiveCN110804395ASimple processLow costOther chemical processesCoatingsMolten stateSurface engineering

The invention belongs to the technical field of material surface engineering, and relates to an anti-icing coating and an anti-icing material, and preparation methods thereof. The preparation method of the anti-icing material comprises the following steps: putting a base material into iodine steam, carrying out adsorption treatment, then spraying the anti-icing coating on the base material subjected to adsorption treatment, and drying to obtain the anti-icing material. The photothermal effect of iodine is introduced into the field of icing prevention for the first time, the base material treated by the iodine steam has excellent photothermal characteristics, and the temperature can be rapidly increased and heat is rapidly emitted under the irradiation of near-infrared light (700-1100 nm),so that an ice layer on the surface is gradually molten, and an ice-water mixture in a semi-molten state can easily slide off from the surface due to the water repellency characteristic of a rough structure of the surface, active photothermal deicing and passive icing prevention are combined, and the anti-icing efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

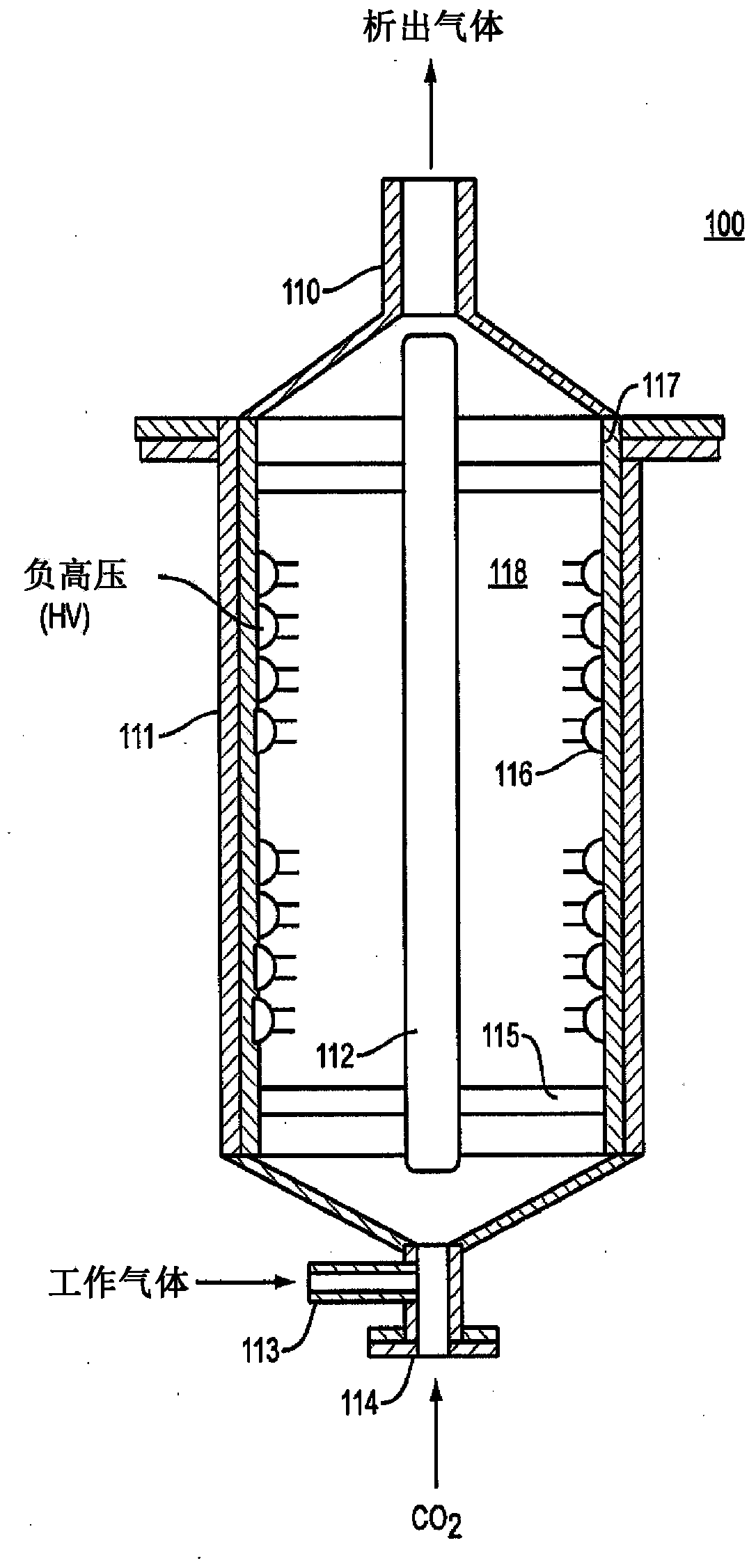

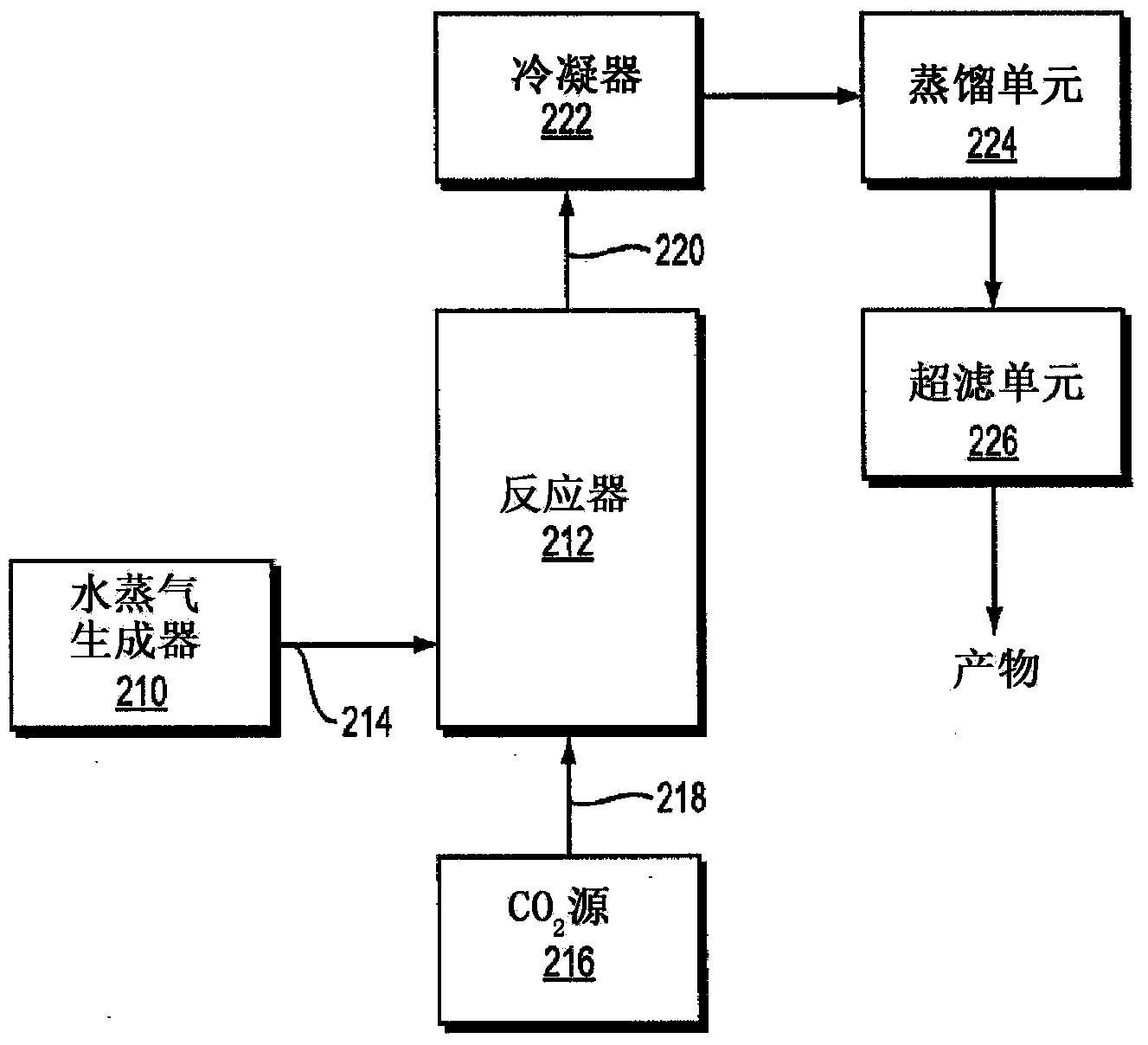

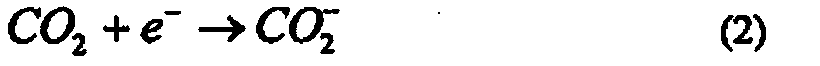

Electronegative-ion-aided method and apparatus for synthesis of ethanol and organic compounds

Provided are electronegative-ion-aided methods and apparatus to achieve reduction of carbon dioxide gas into useful products. In one embodiment, using different methods of discharge, the electronegative gases forms non-equilibrium electronegative ions, so that carbon dioxide reduction occurs for the production of organic compounds. When carbon dioxide is introduced into the container containing at least one electronegative gas, such as water, ammonia, bromine or iodine vapor, it reacts to form organic compounds, such as ethanol, methanol, and oxalic acid in the case of water, urea in the case of ammonia, and tetraiodomethane in the case of iodine.

Owner:HYCHAR HLDG LTD

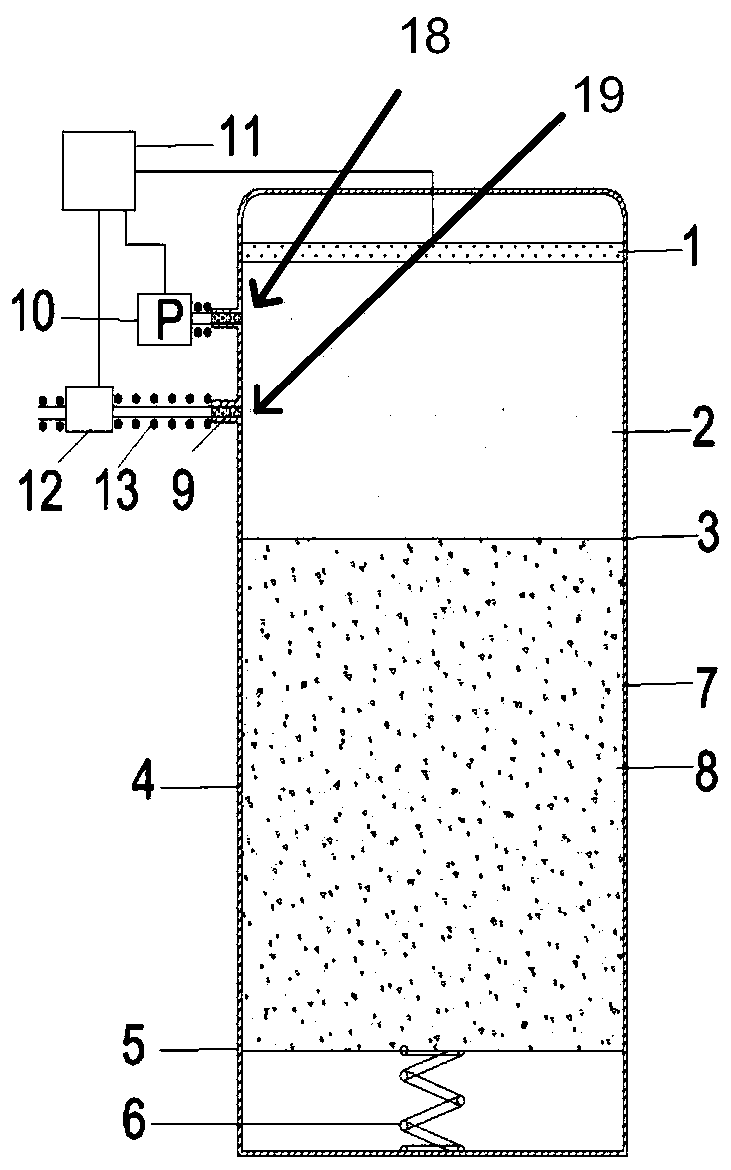

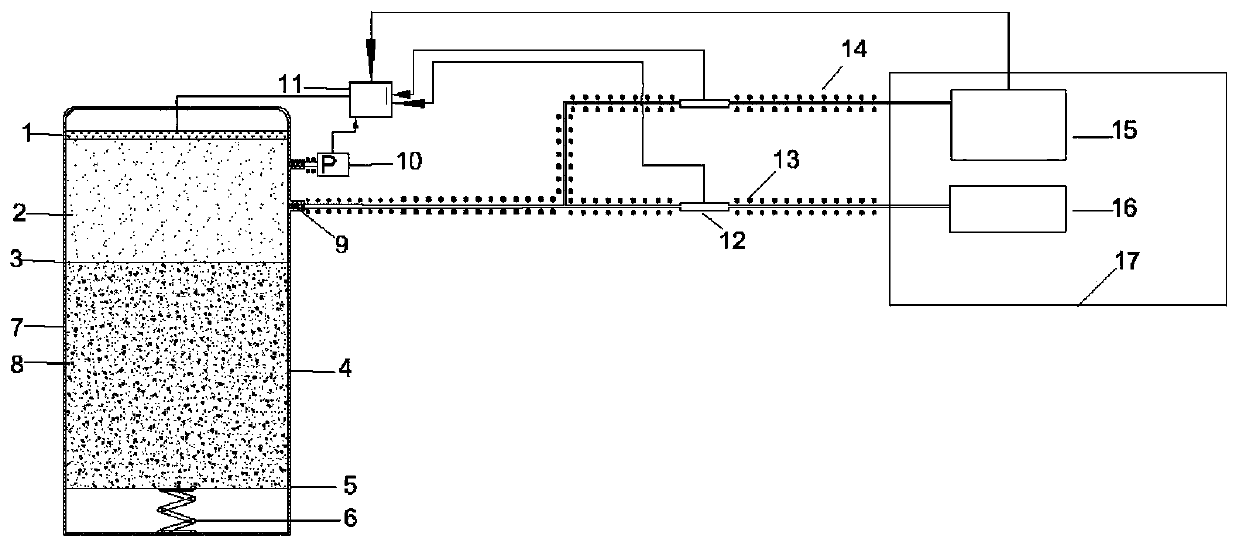

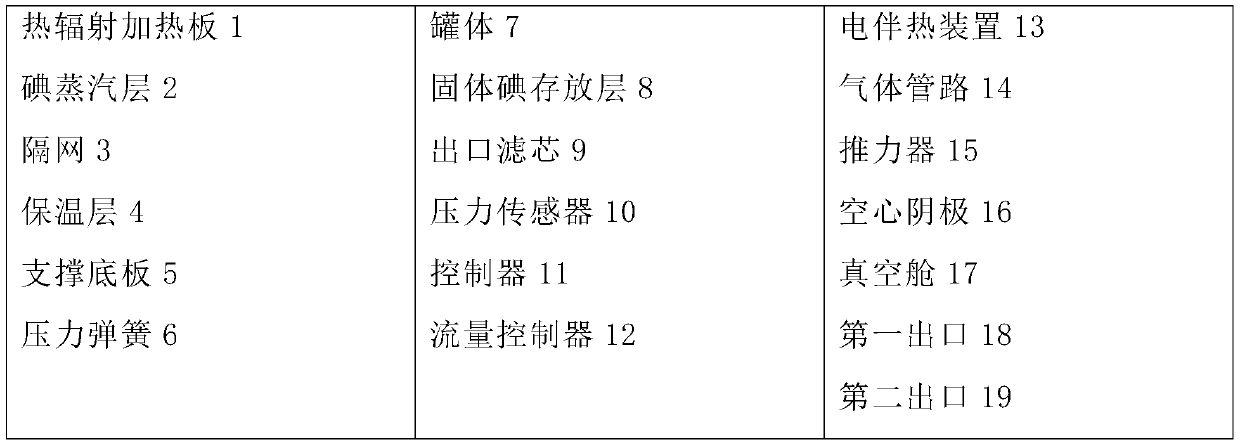

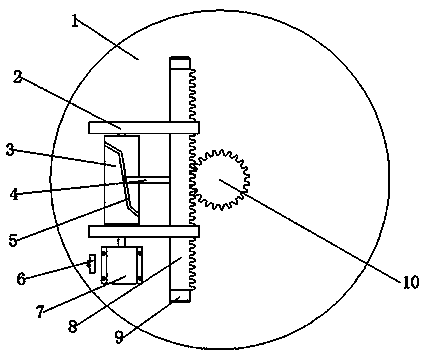

Heat radiation heating storage tank suitable for iodine working medium electric propeller

InactiveCN110374830AReasonable structureEasy to operateMachines/enginesUsing plasmaPropellerEngineering

The invention provides a heat radiation heating storage tank suitable for an iodine working medium electric propeller. The heat radiation heating storage tank comprises a tank body (7), a heat radiation heating plate (1), a pressure sensor (10) and a controller (11), wherein the heat radiation heating plate (1) is arranged inside the tank body (7); the heat radiation heating plate (1) is capable of enabling solid iodine in the tank body (7) to be heated and sublimated into iodine vapor; the pressure sensor (10) is capable of measuring the pressure of the iodine vapor; the controller (11) is capable of controlling the power of the heat radiation heating plate (1); the upper side surface of the tank body (7) is provided with a first outlet (18) and a second outlet (19); the first outlet (18)is positioned below the heat radiation heating plate (1); and the first outlet (18) is capable of being connected to the pressure sensor (10). According to the heat radiation heating storage tank suitable for the iodine working medium electric propeller, the structure is reasonable, the operation is convenient, and the stable output of the iodine in the form of gas and the accurate control of flow can be achieved.

Owner:SHANGHAI JIAO TONG UNIV +1

Forming improved metal nitrides

InactiveUS7276121B1After-treatment apparatusPolycrystalline material growthMicrowaveSemiconductor materials

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

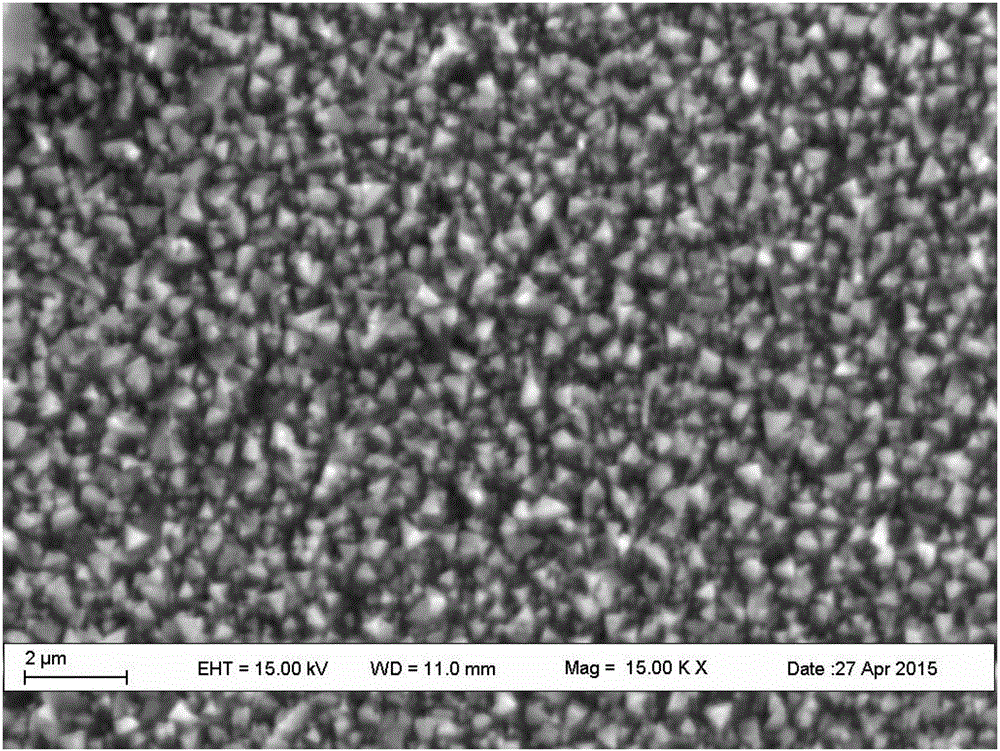

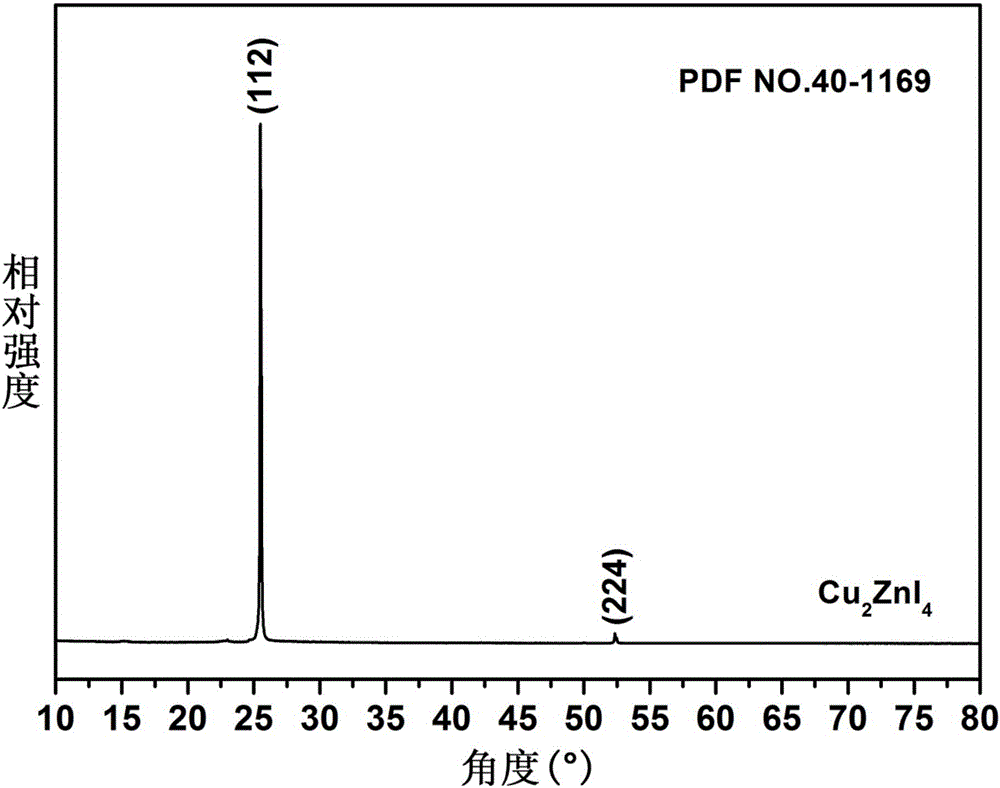

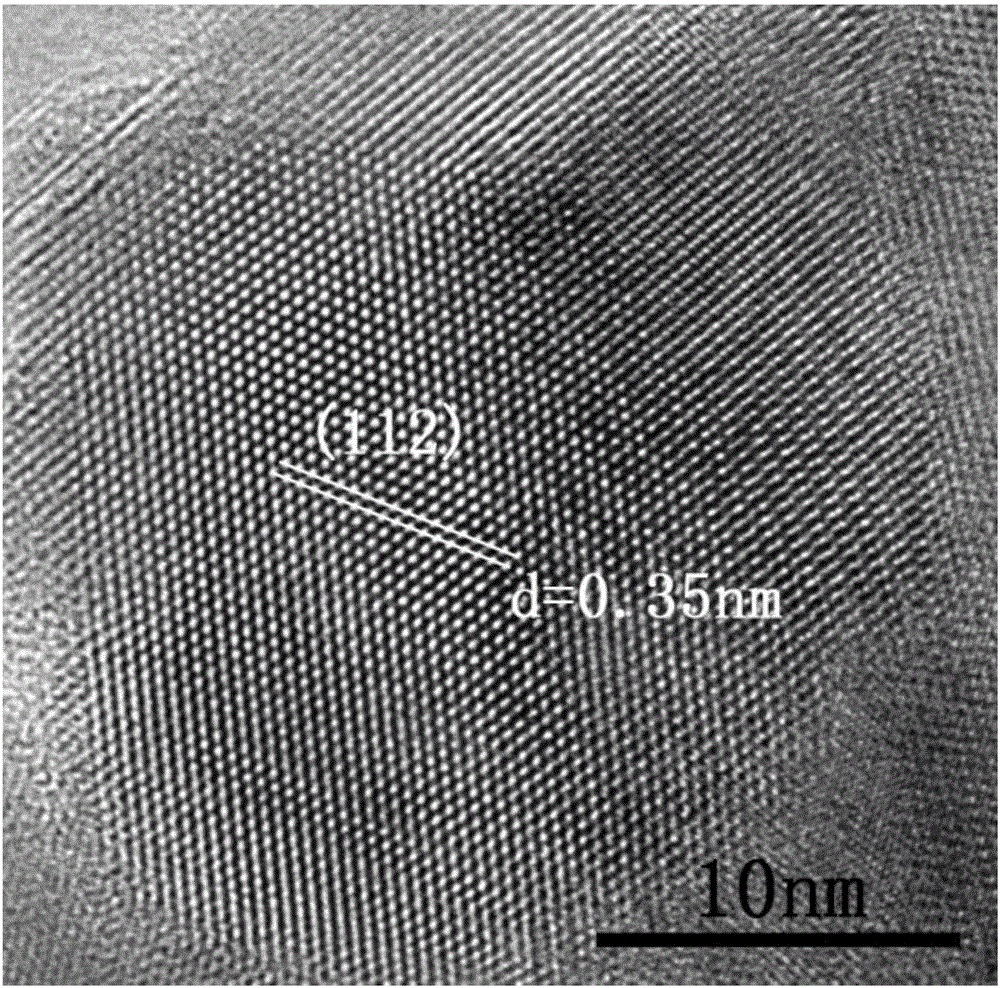

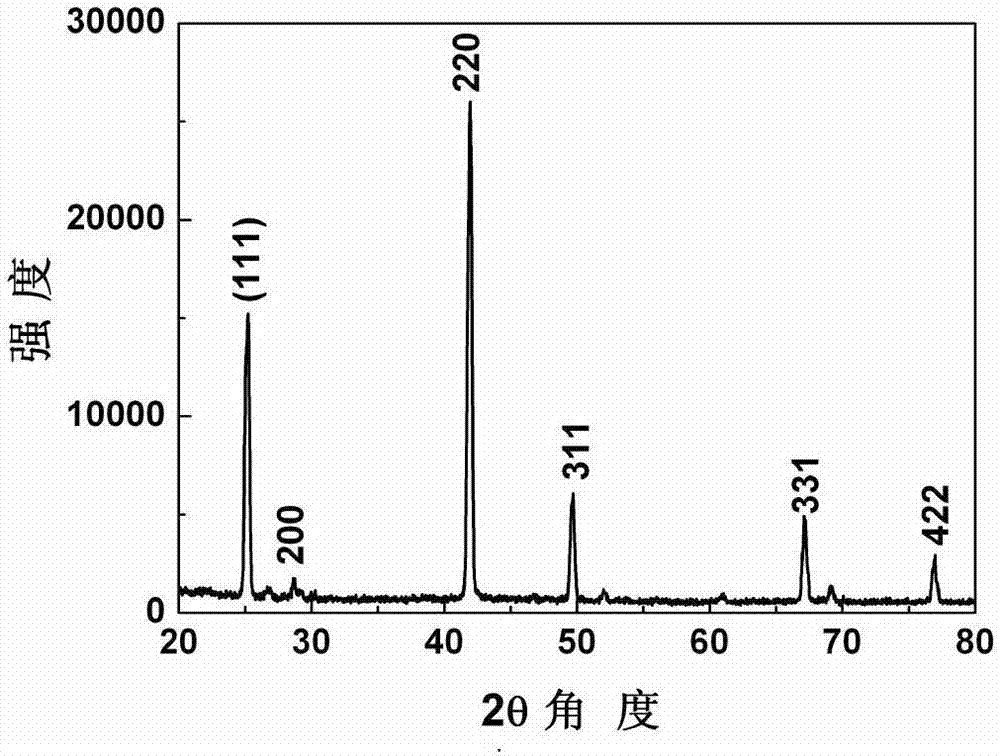

Chemical method for semiconductor film materials of ternary wide bandgap compound of synthesis of copper-zinc iodide

ActiveCN106449367ALow costGood reproducibilitySemiconductor/solid-state device manufacturingZinc alloysFilm material

The invention belongs to chemical technical field, in particular to a chemical method for semiconductor film materials of ternary wide bandgap compound of synthesis of copper-zinc iodide. The method is that putting the copper-zinc alloy film into iodine vapor with a temperature of 45 DEG C to 80 DEG C for co-oxidation reaction of the copper-zinc alloy. The reaction time takes 3 to 8 hours. After reacting for certain time, Cu2ZnI4 films can be produced in situ on the surface of substrate, and that is the semiconductor film materials of the synthesis of the copper-zinc iodide. The preparation method does not require organic solvents to participate in the reaction or reaction medium. The crystal is crystallized well. The product can be used directly without complicated processing. The method has the advantages of simple operation, rapid reaction, better environmental protection, low energy consumption, low cost and good reproducibility. In addition, a film can be directly formed on the substrate surface in the method. The material is more beneficial for the application in photoelectric conversion devices.

Owner:XUCHANG UNIV

Iodine fueled plasma generator system

An iodine fueled plasma generator system includes a plasma generator. At least one storage vessel is configured to store condensed phase iodine therein. A heating device proximate to the storage vessel is configured to create iodine vapor from the condensed phase iodine. A propellant management subsystem is configured to deliver the iodine vapor to the plasma generator. A feedback control subsystem is responsive to one or more of plasma generator discharge current, the pressure of the iodine vapor, and / or the temperature of the iodine vapor configured to regulate the flow rate of the iodine vapor to the plasma generator.

Owner:BUSEK

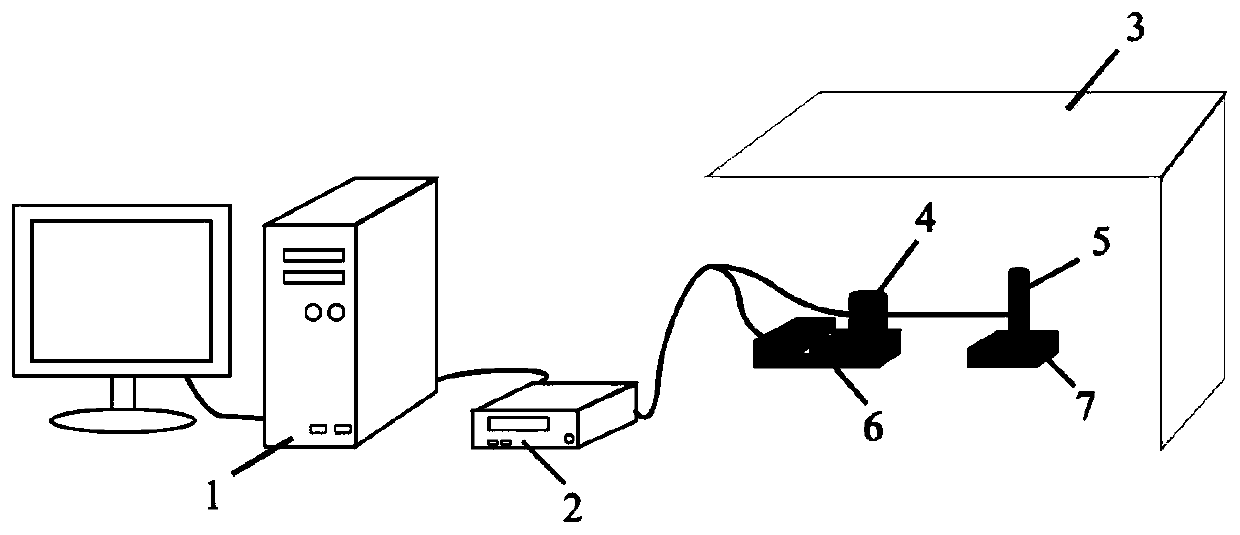

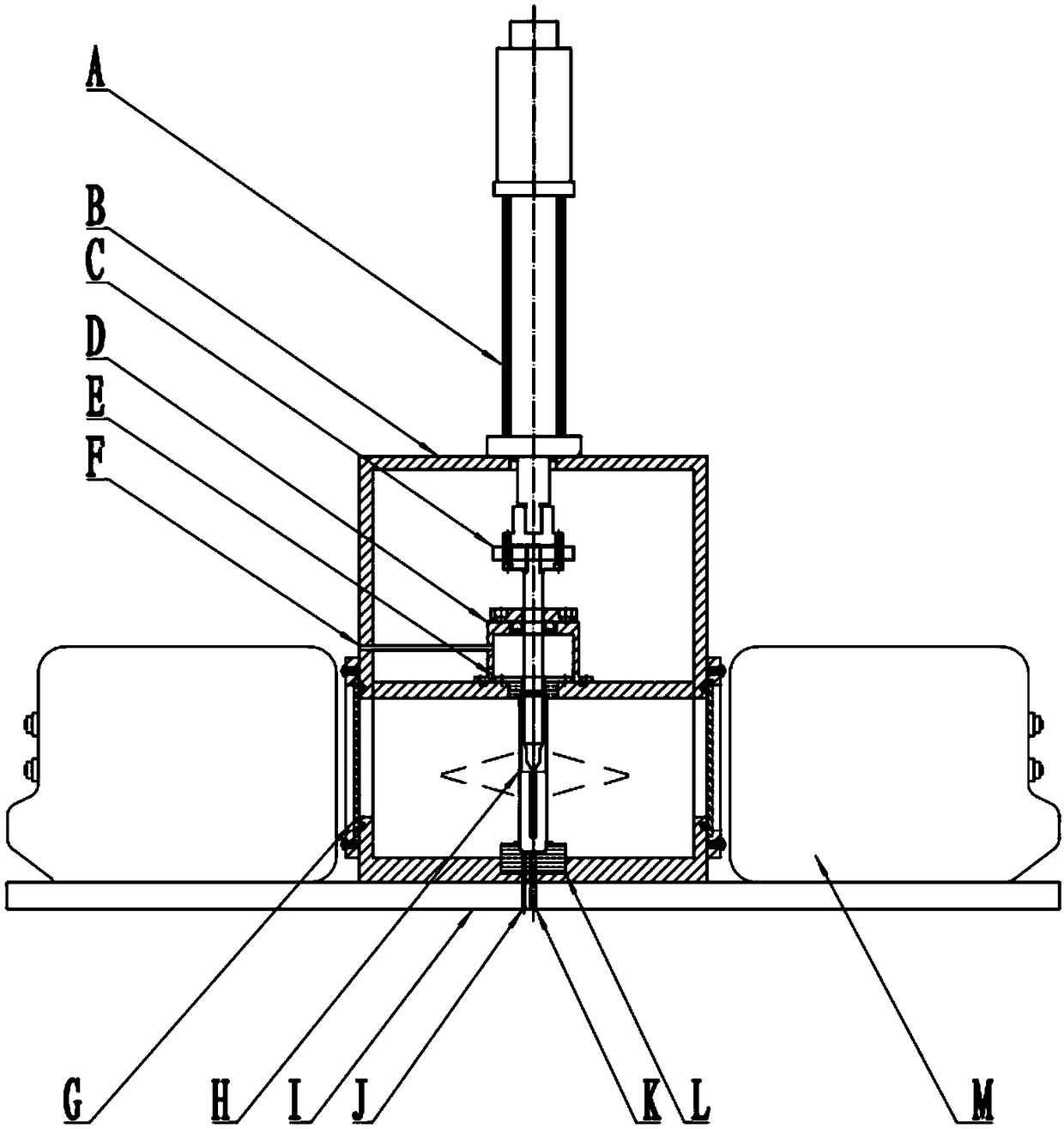

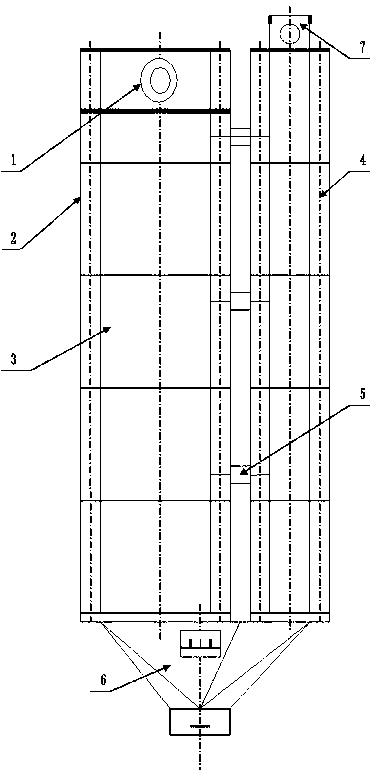

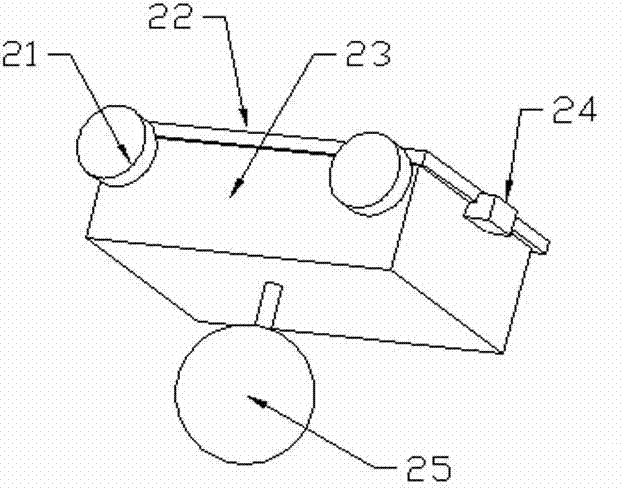

Measuring system for radial deformation of nuclear fuel cladding tube under high temperature iodine vapor environment

The invention discloses a measuring system for radial deformation of a nuclear fuel cladding tube under high temperature iodine vapor environment. The measuring system for the radial deformation of the nuclear fuel cladding tube under the high temperature iodine vapor environment includes a cladding tube, double layer airtight hot chambers for placing the cladding tube, a sealing cover and a sealing base which are arranged at the two ends of the cladding tube, a cylindrical cavity of the upper layer hot chamber, an electronic stretcher extending to the cladding tube, a loading sensor installedon a push rod of the electronic stretcher and a temperature sensor arranged at the bottom of the cladding tube. The measuring system further includes a laser displacement sensor, an air inlet tube and an air outlet tube, and the laser displacement sensor, the air inlet tube and the air outlet tube are arranged outside of visual glass of the two sides of the lower hot chamber. The electronic stretcher is subject to axial compression and radial expansion in the cladding tube, and iodine vapor flow through the cylindrical cavity and the cladding tube. The measuring system for the radial deformation of the nuclear fuel cladding tube under the high temperature iodine vapor environment can reliably and effectively realize the measurement of the radial deformation of the cladding tube under thehigh temperature iodine vapor environment. Steady temperature required by the cladding tube is provided by using the hot chambers. Only iodine vapor environment of inner surface of a cladding is realized by using various sealing technologies. The measurement of the radial deformation of the cladding tube is realized through the laser displacement sensor by using the visual glass of the two sides of the lower layer hot chamber.

Owner:XI AN JIAOTONG UNIV

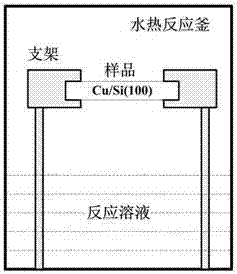

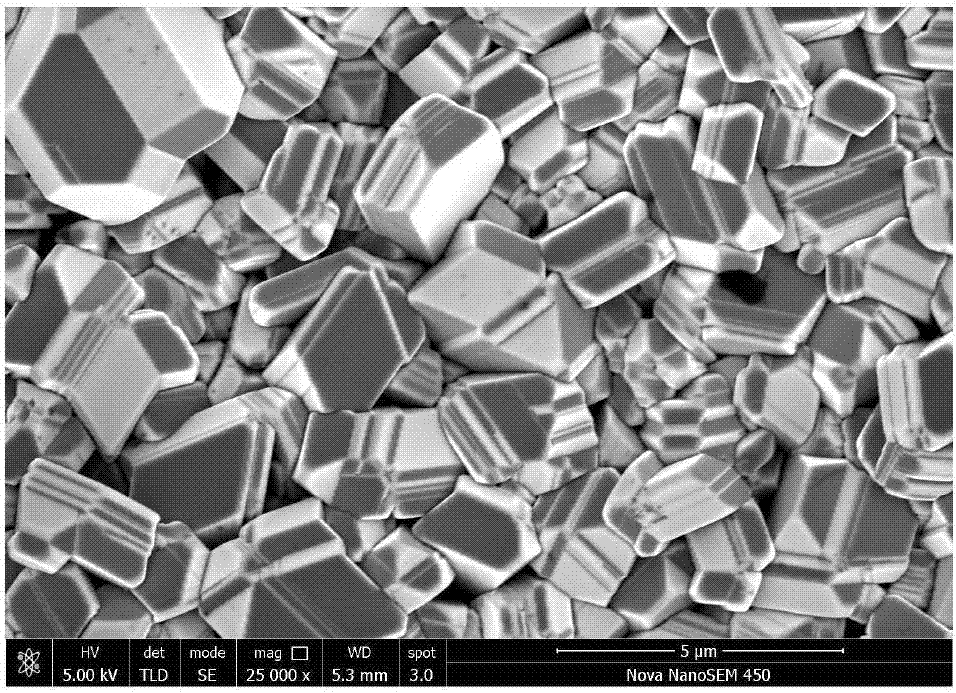

Preparation method of CuI nanostructure

InactiveCN107083532AManufacturing process compatibleImprove crystal qualityVacuum evaporation coatingSputtering coatingEvaporationHigh pressure

The invention relates to a method for preparing a CuI nanostructure, comprising the following steps: cleaning the surface of a single crystal silicon substrate, and putting it into a vacuum growth chamber of an electron beam evaporation device; growing on the surface of a single crystal silicon by electron beam evaporation A layer of copper film; the obtained silicon-based copper film is suspended in the reactor, placed horizontally above the solution, and the precursor solution in the reactor is CuCl 2 , a mixed aqueous solution of polyvinylpyrrolidone and KI; seal the reactor and place it in a blast drying oven for hydrothermal reaction at 120-200°C; after the reaction, take out the sample, wash it, and dry it. For the first time, the present invention uses Cu film and iodine vapor evaporated by hydrothermal synthesis as reaction raw materials to prepare large-area and uniform CuI nanomaterials under low temperature and high pressure conditions, and the preparation process is compatible with the preparation process of optoelectronic devices.

Owner:LUDONG UNIVERSITY

Long-time iodine flow supply device

The invention provides a long-time iodine flow supply device, and relates to the technology of gas supply of a continuous wave oxygen-iodine chemical laser. The main body of the device has two parts: an electric heating iodine vapor storage tank and a combustion chamber for the combustion of two types of gas. The electric heating iodine vapor storage tank enables solid iodine to be heated to a certain temperature and enables the solid iodine to be changed into liquid iodine. Moreover, there is iodine vapor with a certain saturated vapor pressure on the liquid level. The combustion chamber is a closed space which is used for the combustion of carbon monoxide and oxygen, and the generated high-temperature and high-pressure gas enters the iodine vapor storage tank after the temperature adjustment through diluent gas. High-temperature carbon dioxide gas enters the liquid phase of the iodine vapor storage tank and then forms bubbles, thereby enabling heat energy to be transferred to the liquid iodine and enabling the iodine to be vapored into iodine vapor, wherein the bubbles comprise iodine vapor with a certain density. When the bubbles continue to rise in the liquid phase, the phenomenon of mass and heat transfer continues to happen till the balance is reached. The bubbles flow out from the liquid phase, enter a gas phase, pass through a gas supply pipe and then enter a laser main body.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

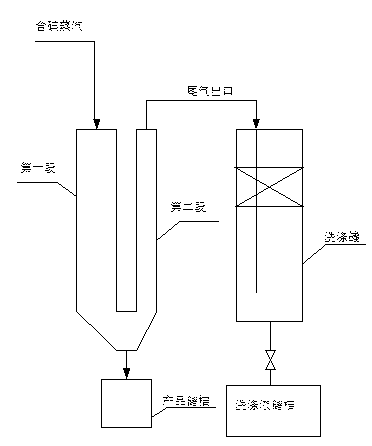

Gas-phase iodine crystallization method

InactiveCN103011083ARealize large-scale industrial productionAvoid heat exchangeIodineSublimationPhysical chemistryIODINE CRYSTALS

The invention discloses a gas-phase iodine crystallization method. A crystallizer adopted by the method is composed of two sections; an iodine vapor inlet is formed in the first section of crystallizer and is a primary iodine crystallization zone; a non-condensable gas outlet is formed in the second section of crystallizer and is a secondary iodine crystallization zone; the iodine vapor enters the first section of crystallizer from the iodine vapor inlet; the outer side is blown by a fan, so that the iodine vapor inside the crystallizer is condensed to become iodine crystal; a little of iodine vapor which is not condensed enters the second section of crystallizer from a cone base, and then is condensed again; and the non-condensable gas is discharged into the behind washer or atmosphere from the non-condensable gas outlet. By adopting the method disclosed by the invention, large-scale industrial production of iodine sublimation or desublimation can be achieved; a single set of device can condense 30Kg of iodine per hour; the highest condensation number can be up to 50Kg; a film is adopted as a cooling heat-exchange medium of iodine; the problems of heat exchange of iodine vapor and an iodine crystal blocking system are solved, and solid foundation is provided for refined purification of iodine by adopting a sublimation method to achieve industrial production.

Owner:WENGFU (GRP) CO LTD

Preparation method of porous nanometer silicon dioxide/MCM (Multi Chip Module)-22 molecular sieve catalyst

ActiveCN103263946AHigh selectivityReduce in quantityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveIsomerization

The invention relates to a preparation method of a porous nanometer silicon dioxide / MCM (Multi Chip Module)-22 molecular sieve catalyst, which belongs to the technical field of shape selective catalysis. The preparation method comprises the following steps of: firstly, dispersing MCM-22 molecular sieves in alcohol, adding purified nanometer attapulgite to a hydrophilic organic solvent; and then, slowly adding the purified nanometer attapulgite to alcohol dispersion liquid of the MCM-22 molecular sieves to prepare attapulgite / MCM-22 molecular sieves; and finally, placing the prepared attapulgite / MCM-22 molecular sieves in iodine vapor to prepare the porous nanometer silica / MCM-22 molecular sieve catalyst. According to the preparation method of the porous nanometer silicon dioxide / MCM-22 molecular sieve catalyst disclosed by the invention, the attapulgite / MCM-22 molecular sieves are placed in the iodine vapor for achieving a doping effect, so that the attapulgite can be converted into porous nanometer silica, the number of acid active sites on the outer surfaces of the MCM-22 molecular sieves is reduced, isomerization reaction of the paraxylene on the outer surfaces of the molecular sieves is effectively lowered, and the selectivity of the paraxylene is further improved.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

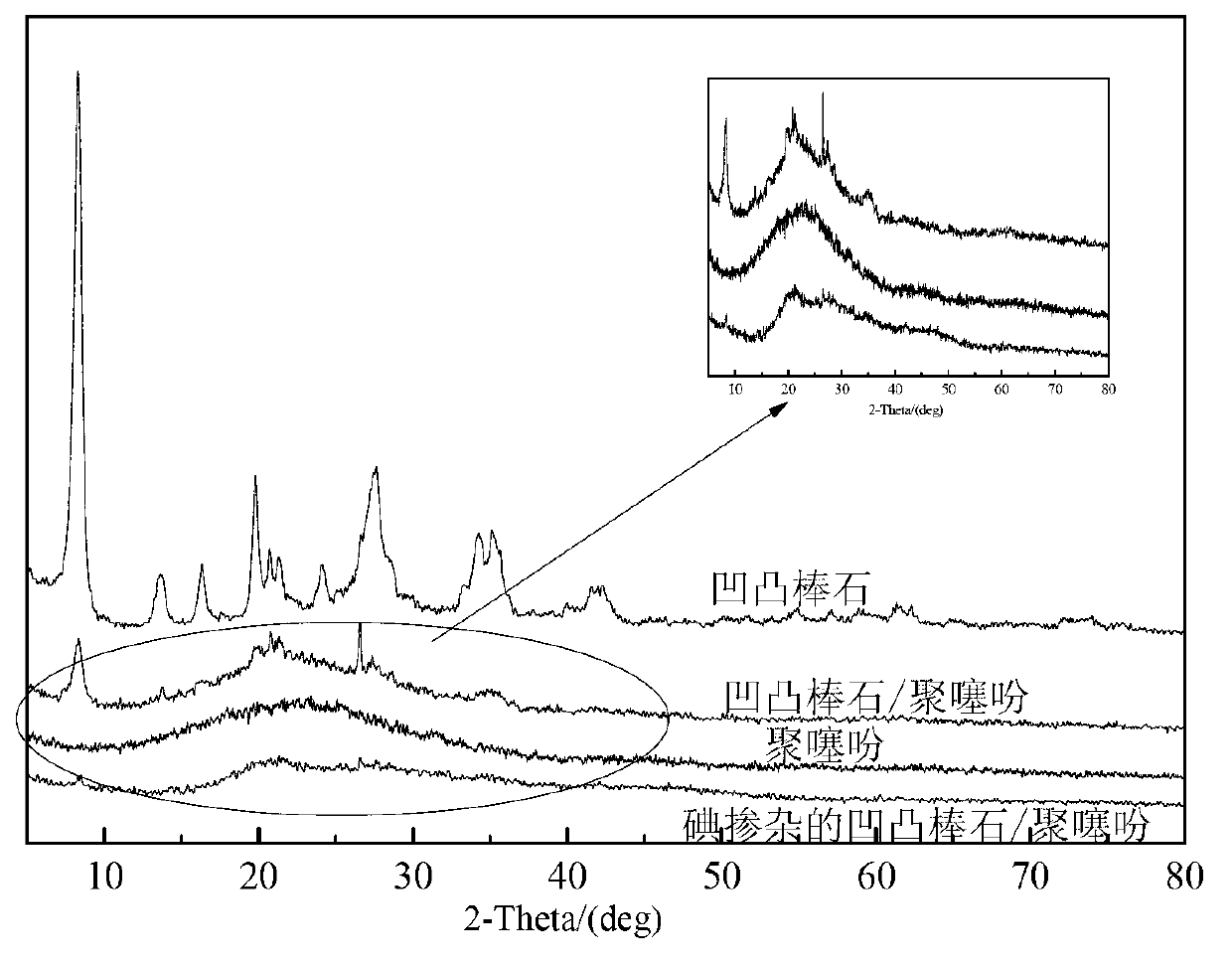

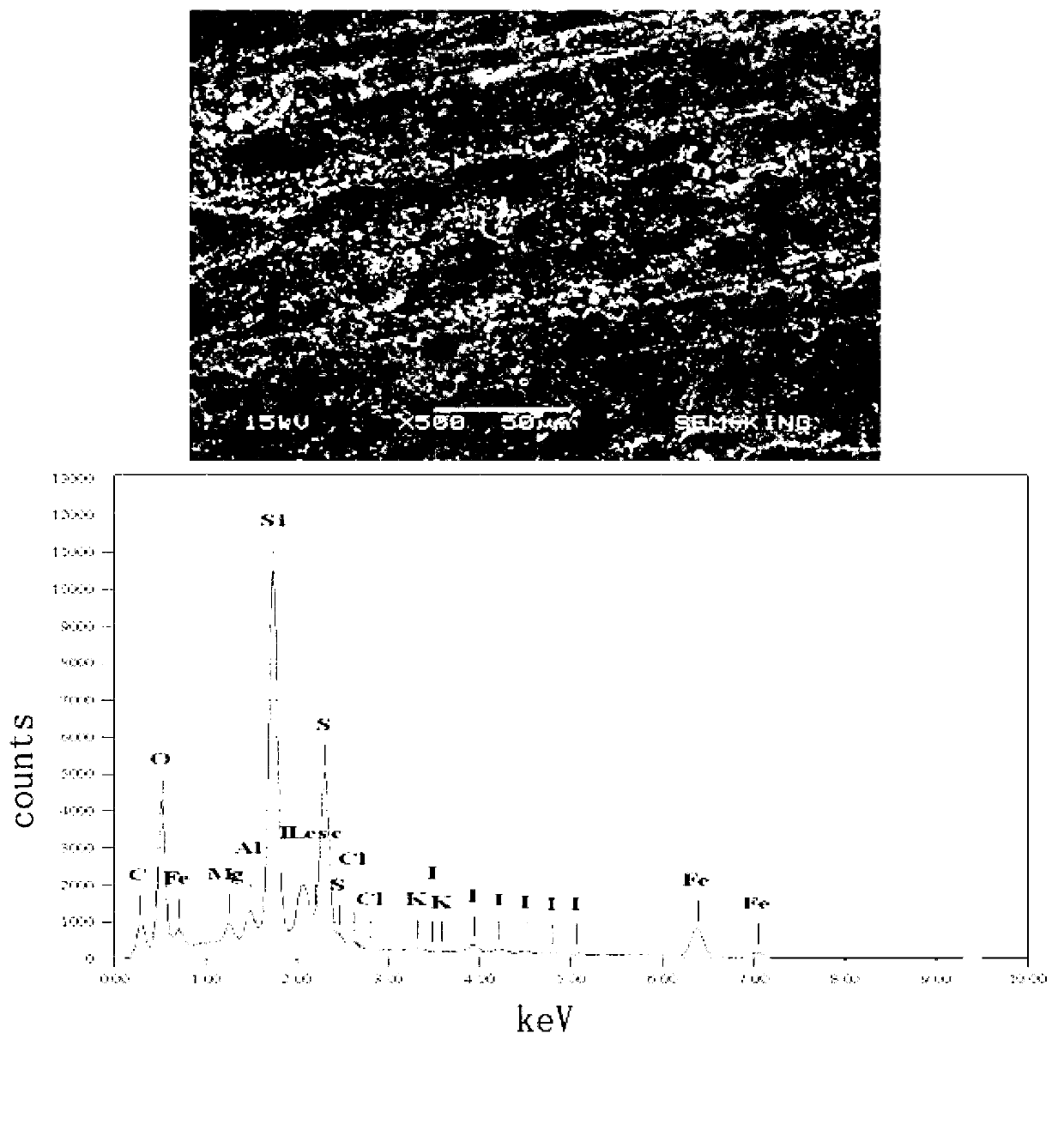

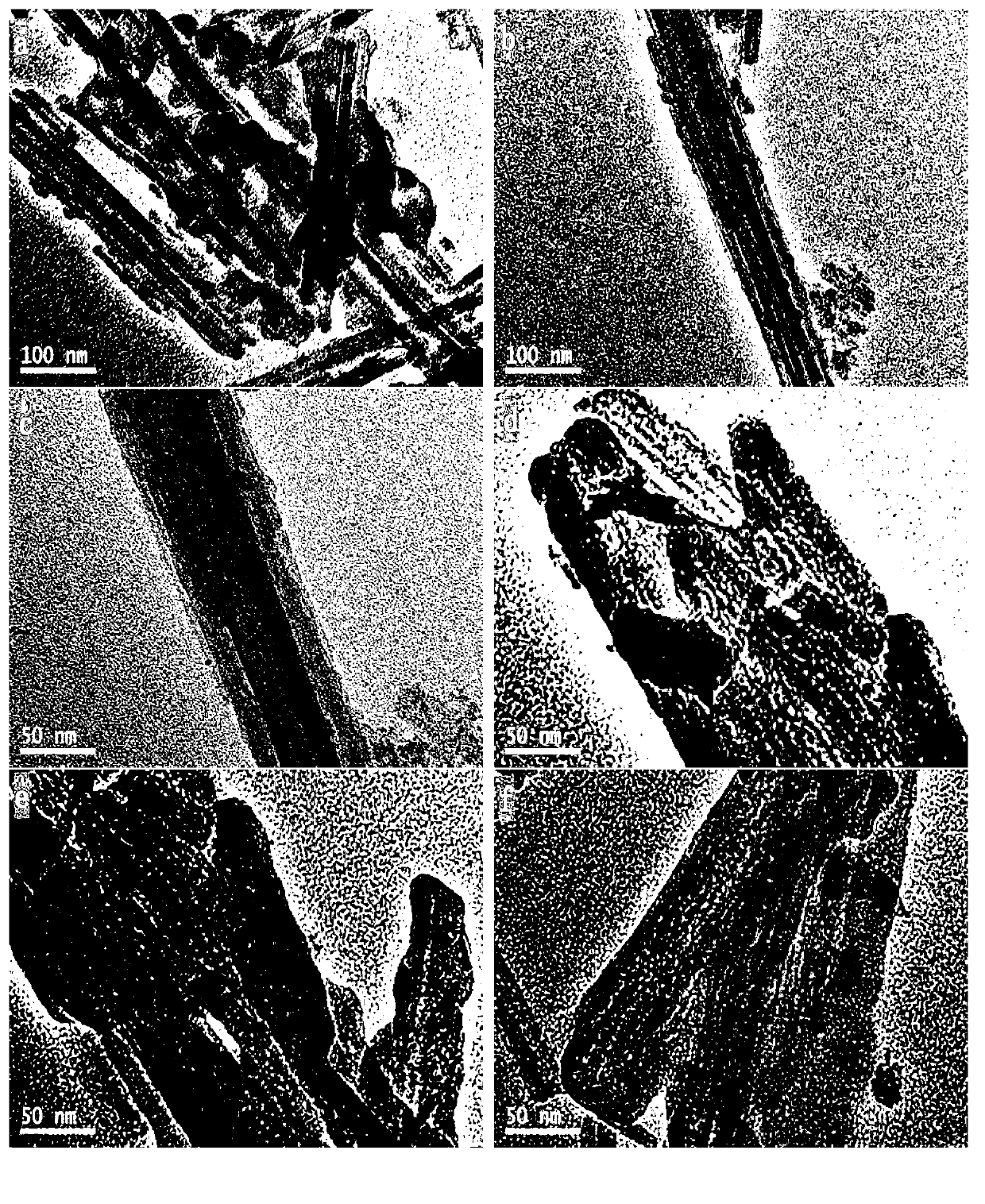

Polythiophene nanometer conductive composite material and preparation method thereof

The invention provides a polythiophene nanometer conductive composite material and a preparation method of the polythiophene nanometer conductive composite material based on the advantages of attapulgite of special crystal structure, physico-chemical property and low price, solving the shortcoming in the prior art that the polythiophene-inorganic nanometer composite material is high in cost. The polythiophene nanometer conductive composite material is an iodine-doped porous rod shaped silica / polythiophene amorphous conductive composite material. The preparation method of the polythiophene nanometer conductive composite material comprises the following steps in sequence: dissolving a thiophene monomer into an organic solvent I; adding purified nano attapulgite and an oxidant to an organic solvent II; dropping the mixture to the thiophene solution in an one-by-one way so as to prepare the thiophene / polythiophene nano composite material; and placing the prepared thiophene / polythiophene nano composite material into the iodine vapor to prepare into the porous rod shaped silica / polythiophene amorphous conductive composite material.

Owner:CHANGZHOU UNIV

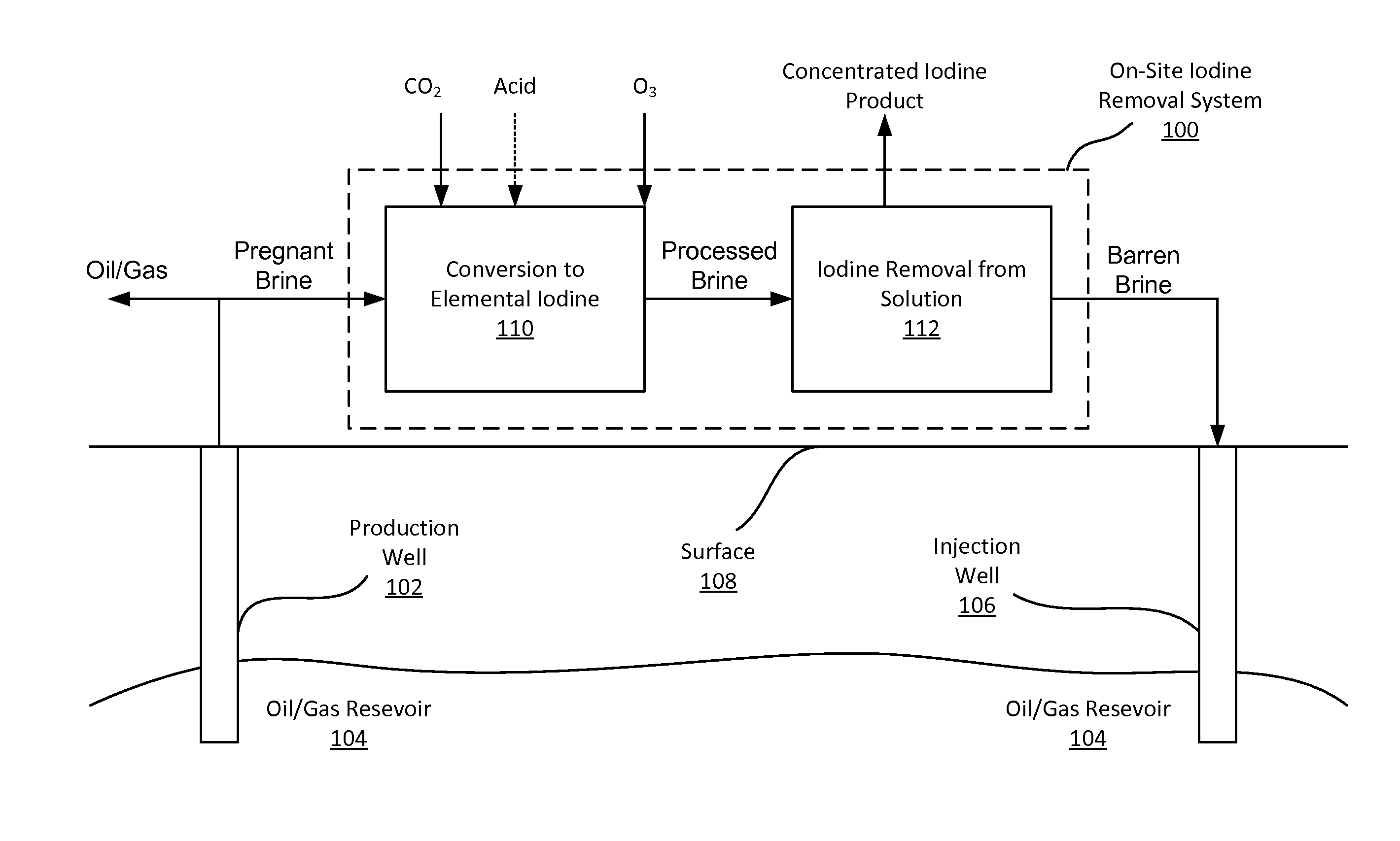

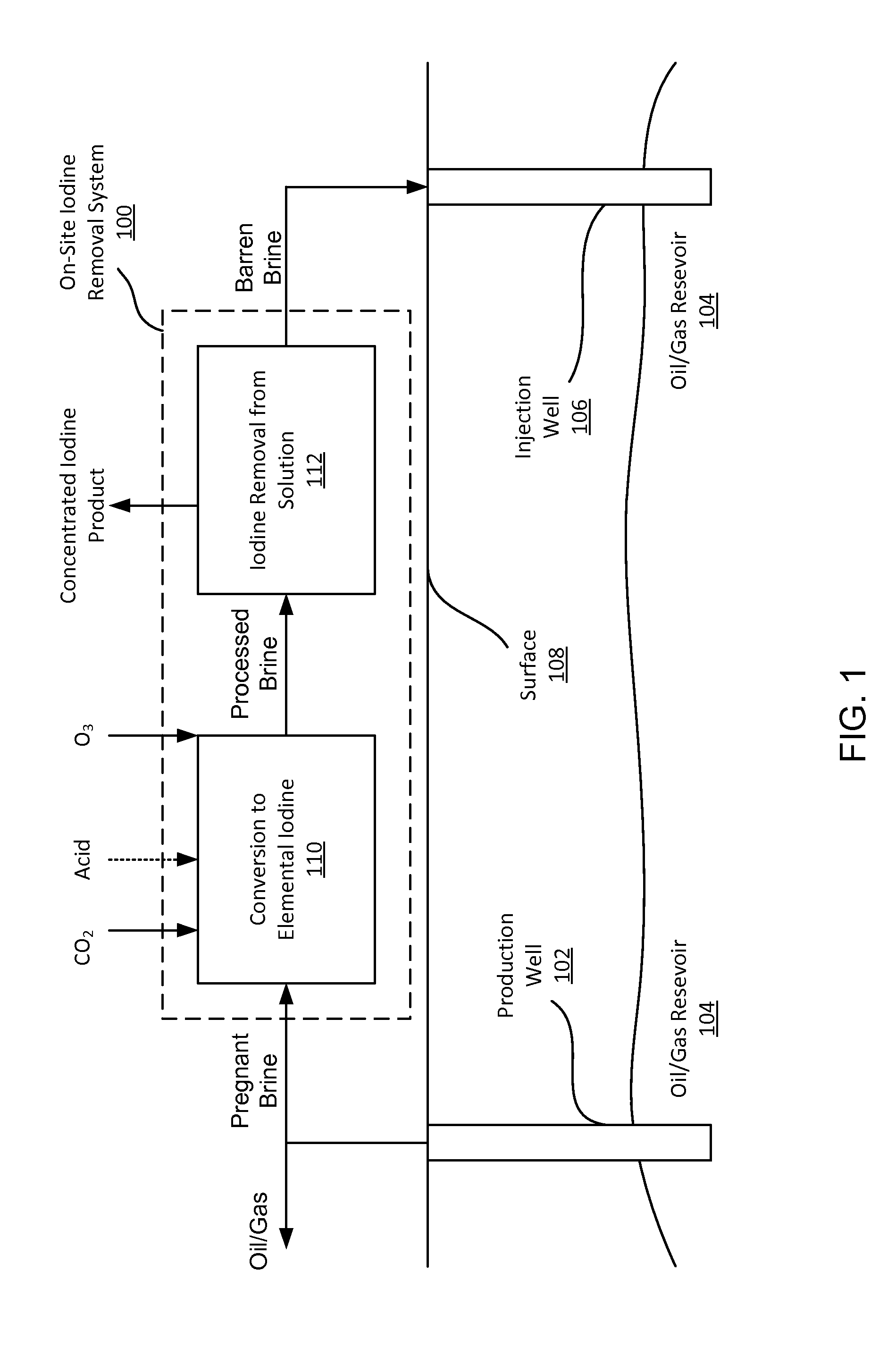

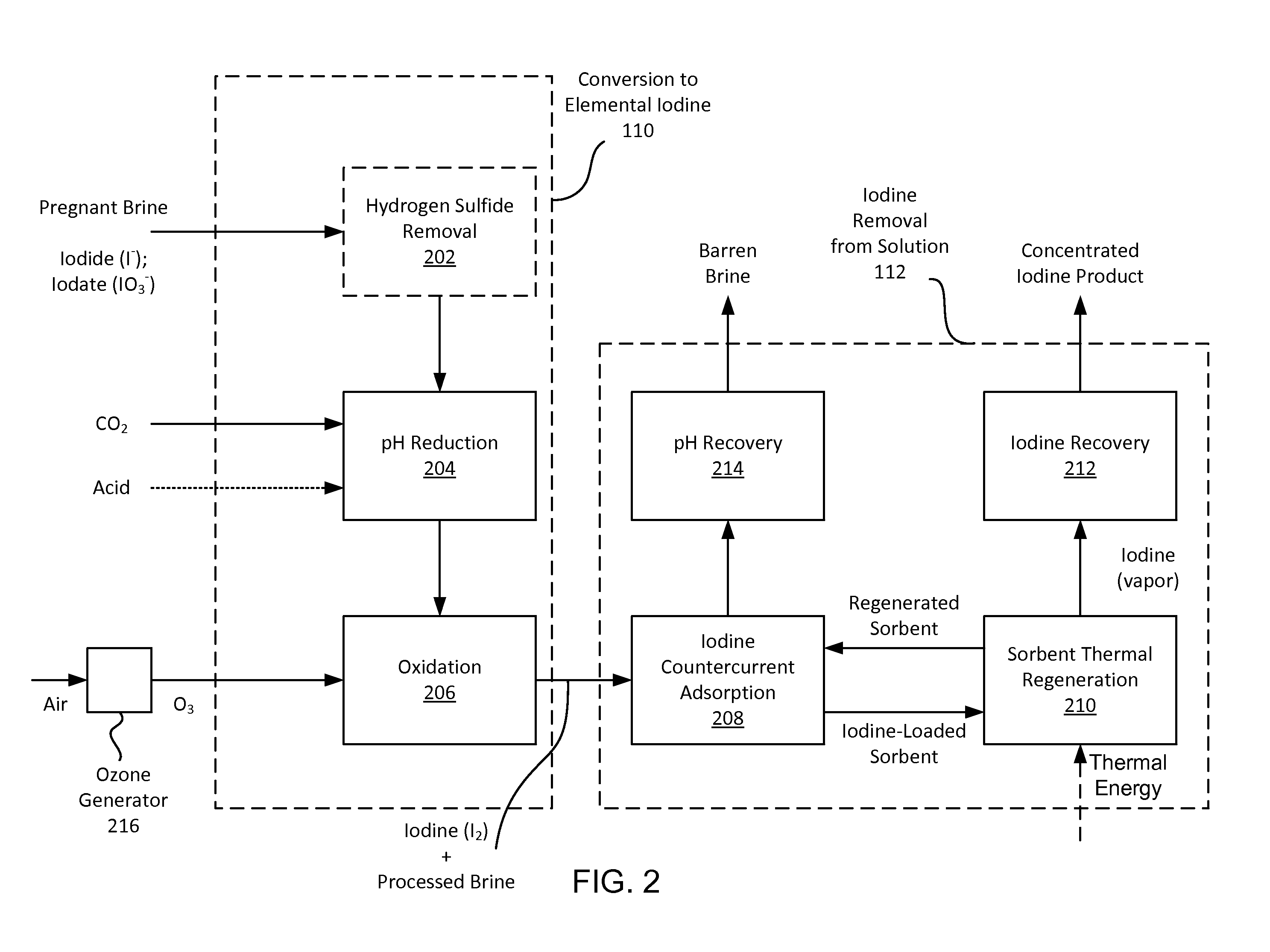

Systems, methods, and apparatus for iodine removal from high volume dilute brine

This disclosure describes systems, methods, and apparatus for recovery and purification of iodine from strong brine solutions having low concentrations of iodine. This can involve acidifying and oxidizing the strong brine solution to produce a solution of processed brine and elemental iodine. This solution can then be passed through a countercurrent sorber causing the elemental iodine to adsorb onto a solid sorbent such as GAC. The iodine-loaded sorbent is separated and regenerated, for instance via heating, producing regenerated sorbent and iodine vapor. The vapor can be condensed thus leaving solid elemental iodine.

Owner:DRAKE WATER TECH

Segmented tightness testing method

Owner:ZHEJIANG OCEAN UNIV

Porous silica/ZSM-5 molecule sieve catalyst preparation method

ActiveCN103272632AHigh selectivityReduce in quantityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationIsomerizationOrganic solvent

The present invention relates to a porous silica / ZSM-5 molecule sieve catalyst preparation method, and belongs to the technical field of shape selecting catalysis. The preparation method comprises: dispersing a ZSM-5 molecule sieve in ethanol, adding purified nanometer attapulgite to a hydrophilic organic solvent, slowly adding the obtained mixed solution to the ZSM-5 molecule sieve ethanol dispersion to prepare an attapulgite / ZSM-5 molecule sieve, and placing the prepared attapulgite / ZSM-5 molecule sieve in iodine vapor to prepare the porous silica / ZSM-5 molecule sieve catalyst. According to the present invention, the attapulgite / ZSM-5 molecule sieve is placed in the iodine vapor so as to provide a doping effect, such that the attapulgite can be converted into porous silica, the number of acid active sites on the outer surface of the ZSM-5 molecule sieve is reduced, isomerization reactions of p-xylene on the outer surface of the molecule sieve is effectively reduced, and selectivity on p-xylene is further increased.

Owner:广州光义化工科技发展有限公司

Maintenance-facilitating box-type substation

ActiveCN110535052AReduce the temperatureSubstation/switching arrangement cooling/ventilationDistribution substationsTransformerEngineering

The invention discloses a maintenance-facilitating box-type substation, relates to the technical field of power transmission and transformation, and mainly aims at cooling the substation box body andpreventing the substation box body from directly contacting water. The main technical scheme is as follows: the maintenance-facilitating box-type substation comprises a box body and an air flow circulation part. A transformer is arranged in the box body. The box body is provided with a box wall, and the box wall is provided with a hollow chamber for filling iodine powder. The air flow circulationpart comprises a separating mechanism, a heat dissipating element and a collector. The separating mechanism is provided with a first inlet, a first outlet and a second outlet. The collector is provided with a second inlet and a third outlet. The first inlet is connected with the hollow chamber and used for guiding the iodine powder and the air to the separating mechanism. The separating mechanismis used for separating iodine vapor and the iodine powder. The first outlet is connected with the hollow chamber and used for guiding solid iodine back to the hollow chamber. One end of the heat dissipating element is connected with the second outlet, and the other end is connected with the second inlet. The third outlet is connected with the hollow chamber.

Owner:YONGSHENG CONSTR GRP

Analytical pure potassium iodide preparation method using waste liquid containing iodine

InactiveCN106517252AFix security issuesSimple and fast operationAlkali metal iodidesSludgeImpurity ions

The invention discloses an analytical pure potassium iodide preparation method using waste liquid containing iodine. The method comprises the steps of at first reducing all inorganic iodine of different forms in waste liquid containing iodine into iodide ions, using hydrogenperoxide as oxidant, under 80 DEG C oxidizing the iodide ions directly into iodine elements, subliming and overflowing, making sure that the iodine elements do not get oxidized further, breaking iodine clock reaction, after KOH absorbing iodine vapor, generating IO3<->, using hydrazine for reduction, making sure that no other impurity ions are introduced into potassium iodide solution, at last acquiring the analytical pure potassium iodide. The method is applicable for the treatment of waste liquid containing iodine of any forms and concentrations. The method has the advantages of being environment-friendly and economical, being simple and convenient to operate, low in cost, high in recyclability, and causing no secondary contamination during the whole process. The method can be used for the direct preparation of analytical pure potassium iodide, thus avoiding the safety problems of iodine storage and iodine vapor.

Owner:WUXI YISHUIYUAN RESOURCE RECYCLING TECH CO LTD

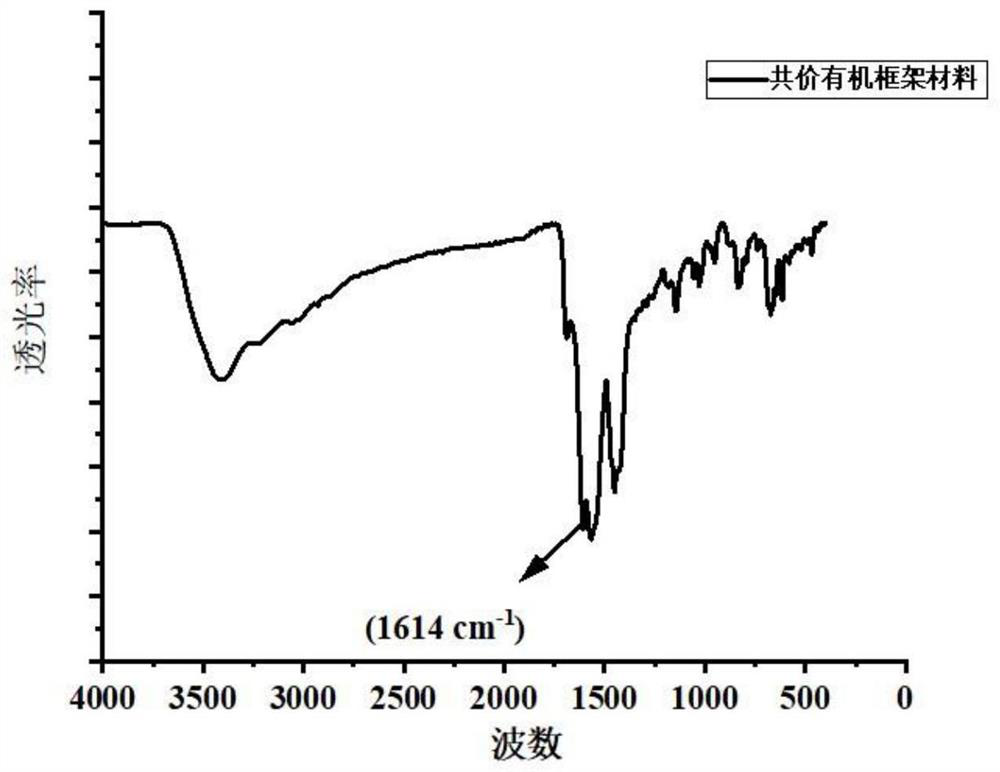

Covalent organic framework material as well as preparation method and application thereof

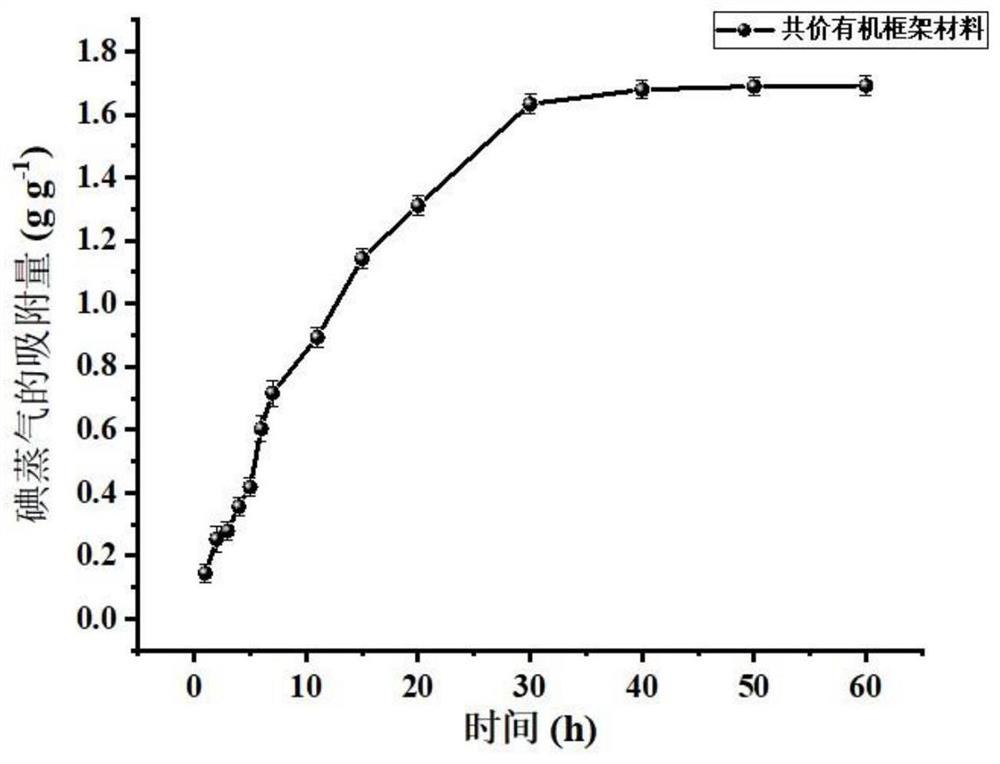

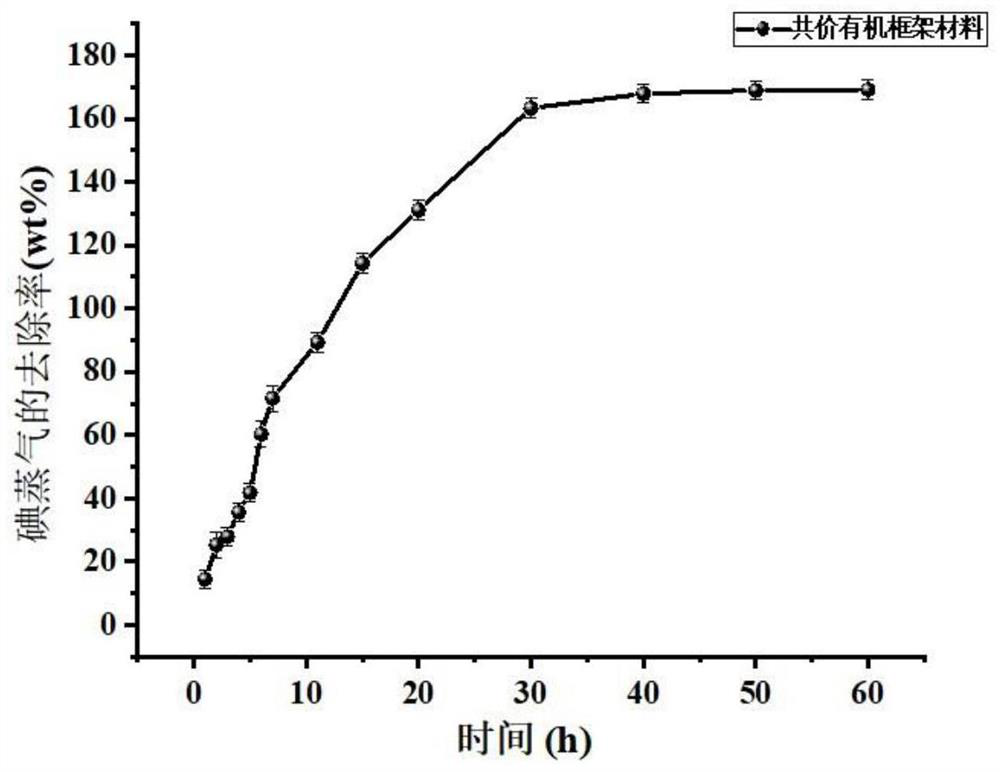

PendingCN113501921AImprove adsorption capacityRegular structureOther chemical processesIodineAdsorption equilibriumOrganosolv

The invention discloses a covalent organic framework material as well as a preparation method and application thereof, and relates to a covalent organic framework material as well as a preparation method and application thereof. The technical problem that an existing covalent organic framework material is only suitable for iodine vapor adsorption and long in iodine adsorption equilibrium time is solved. The structural unit of the covalent organic framework material is shown in the specification. The covalent organic framework material is obtained by reacting 2-(4-aminophenyl)-1H-phenanthrene [9, 10-d] imidazole-6, 9-diamine with isophthalaldehyde, and the covalent organic framework material is used for adsorbing iodine vapor or iodine in an organic solvent III. The maximum adsorption capacity for iodine vapor can reach 1.69 g.g <-1 >, adsorption equilibrium is achieved in 30 hours, and the removal rate of the iodine vapor is 169 wt%. The adsorption capacity for iodine in a 100 mg / L cyclohexane-iodine solution is 127.80 mg.g <-1 >. The material can be recycled for more than four times. The material can be used in the field of iodine removal.

Owner:QIQIHAR UNIVERSITY

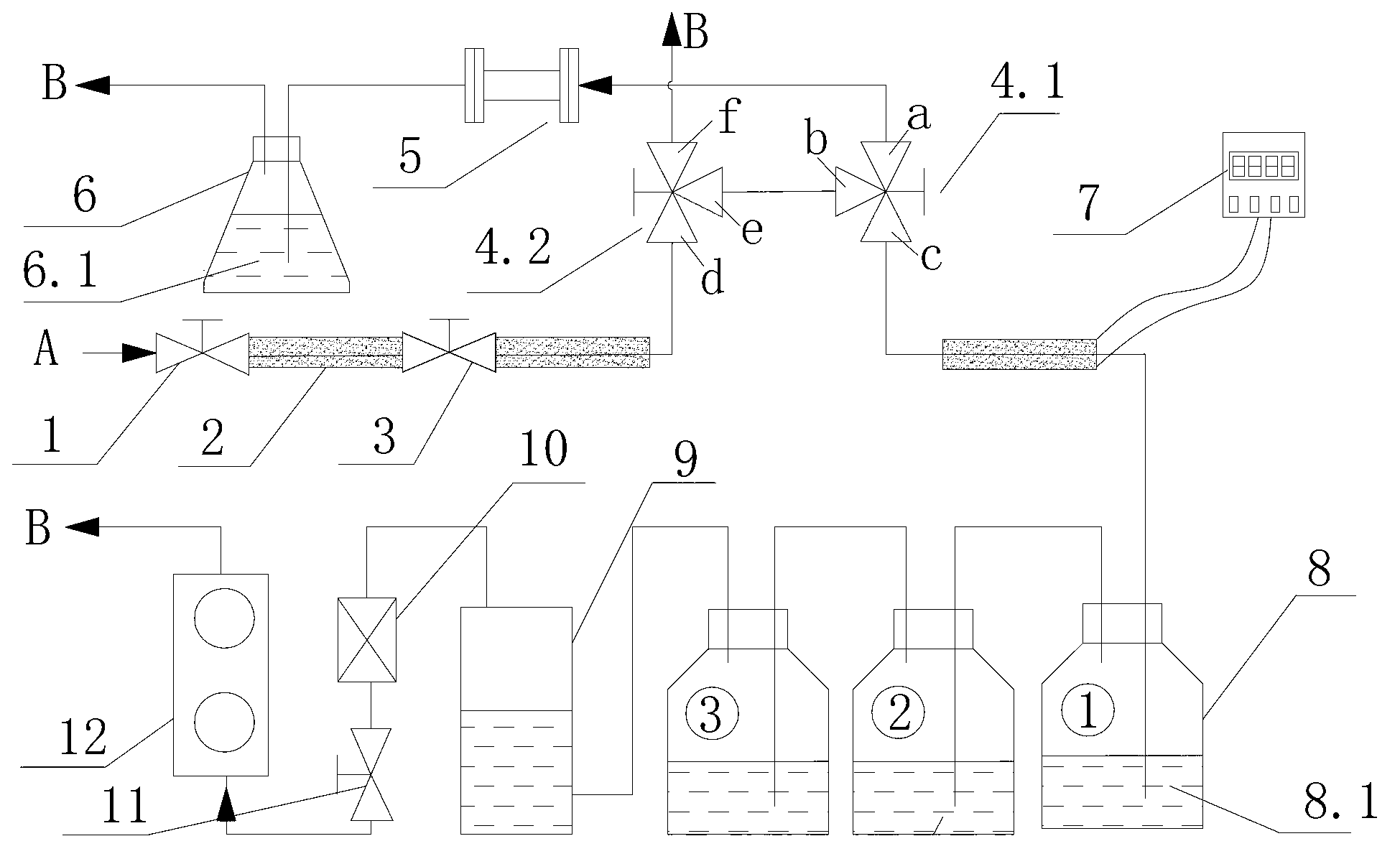

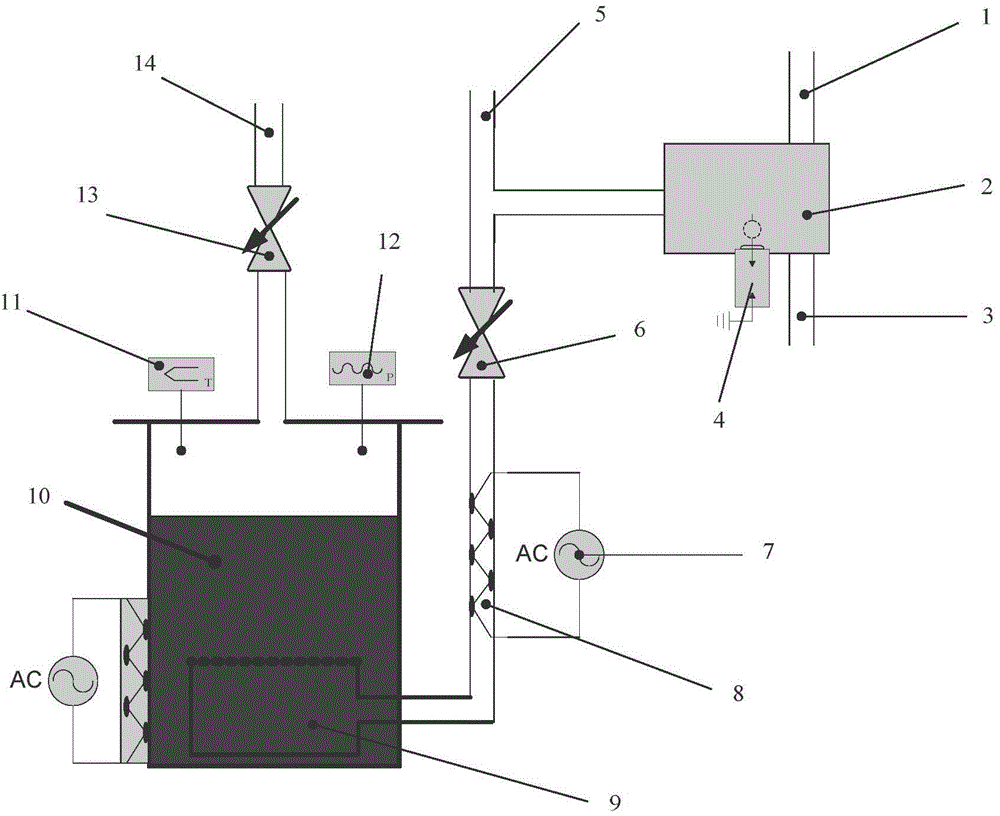

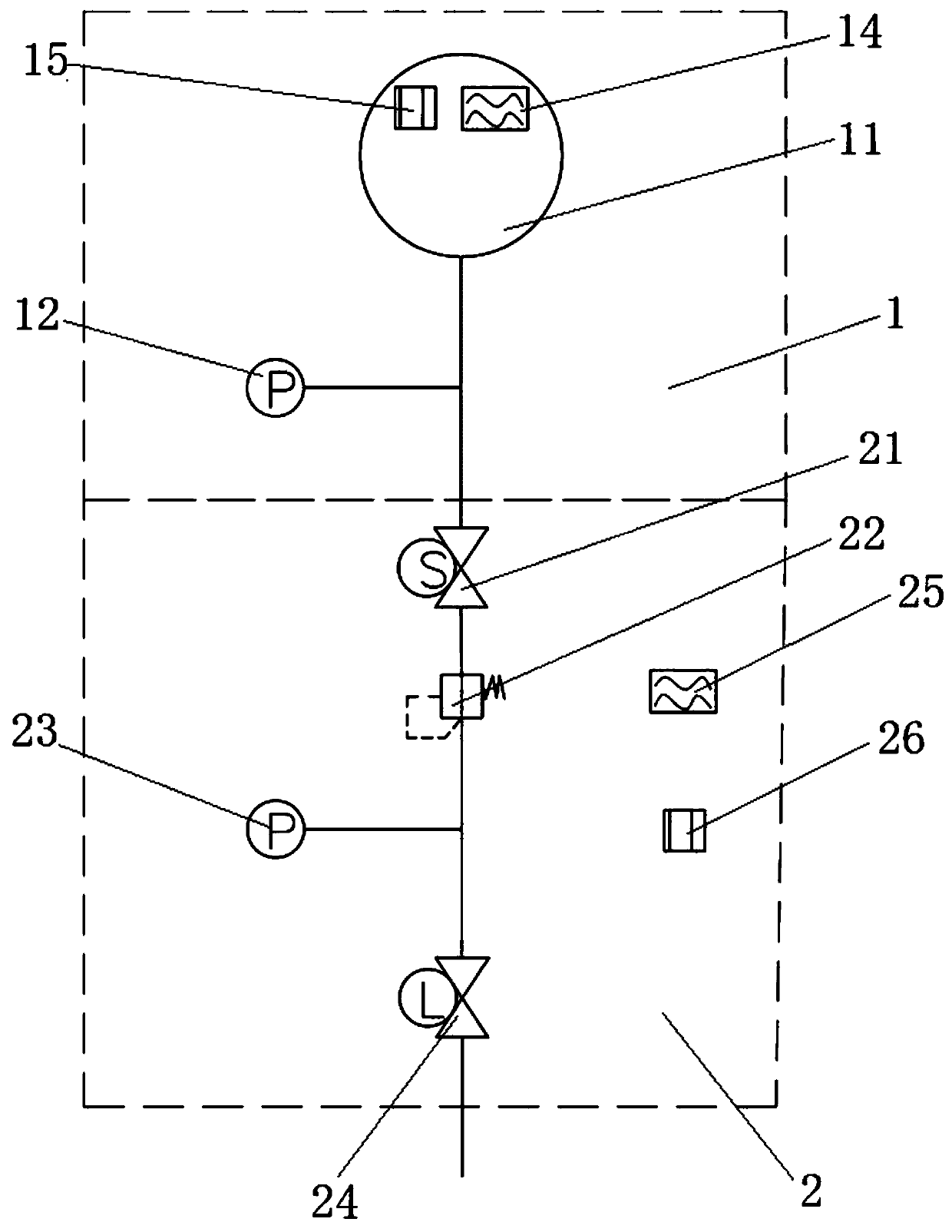

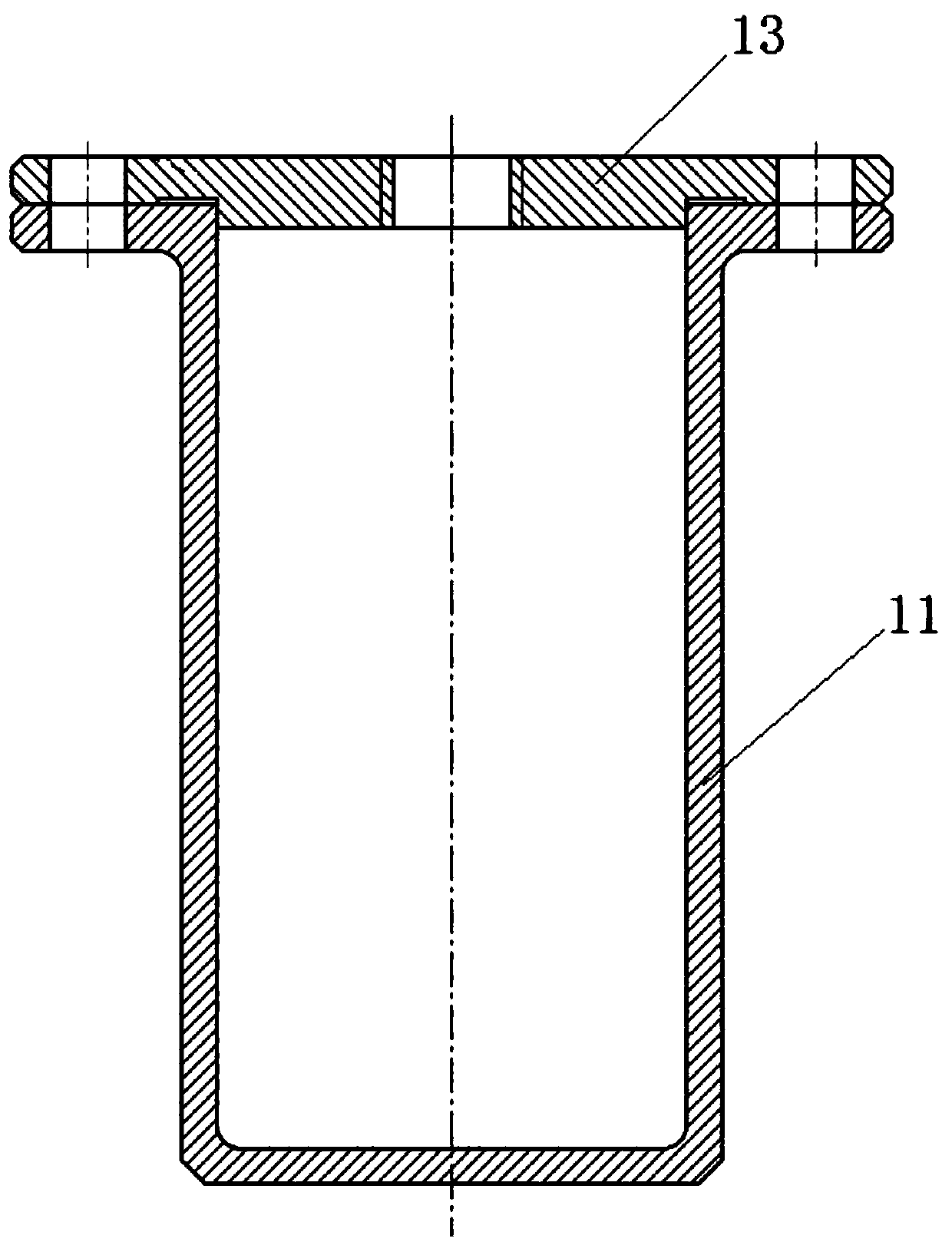

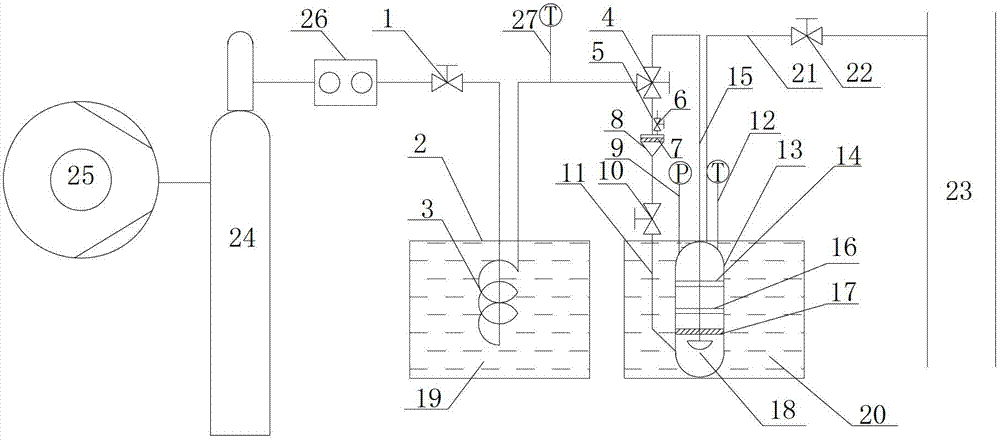

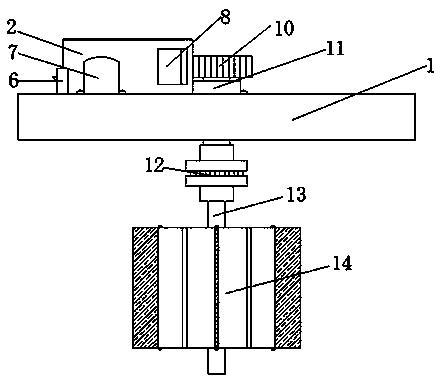

Iodine medium ground gas supply device for Hall thruster and using method

ActiveCN111140450ALower ionization energyLow priceMeasurement devicesMachines/enginesControl cellEngineering

The invention relates to the technical field of aerospace Hall electric propulsion, in particular to an iodine medium ground gas supply device for a Hall thruster and a using method. The iodine mediumground gas supply device includes an iodine vapor generating unit and an iodine vapor flow control unit, wherein the iodine vapor generating unit includes a solid iodine storage tank and a first pressure sensor. The iodine vapor flow control unit includes a shut-off valve, a pressure relief valve, a second pressure sensor and a flow control valve. The iodine medium ground gas supply device for the Hall thruster adopts an iodine medium propellant to achieve good thrust parameter performance, and the thruster is more efficient. An iodine medium is heated and sublimated into iodine vapor for transportation, the condensation of the iodine vapor in the transportation process is prevented, the flow rate of the iodine vapor can be controlled in real time, and it is ensured that the iodine vaporcan be stably and accurately transported to the Hall thruster.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

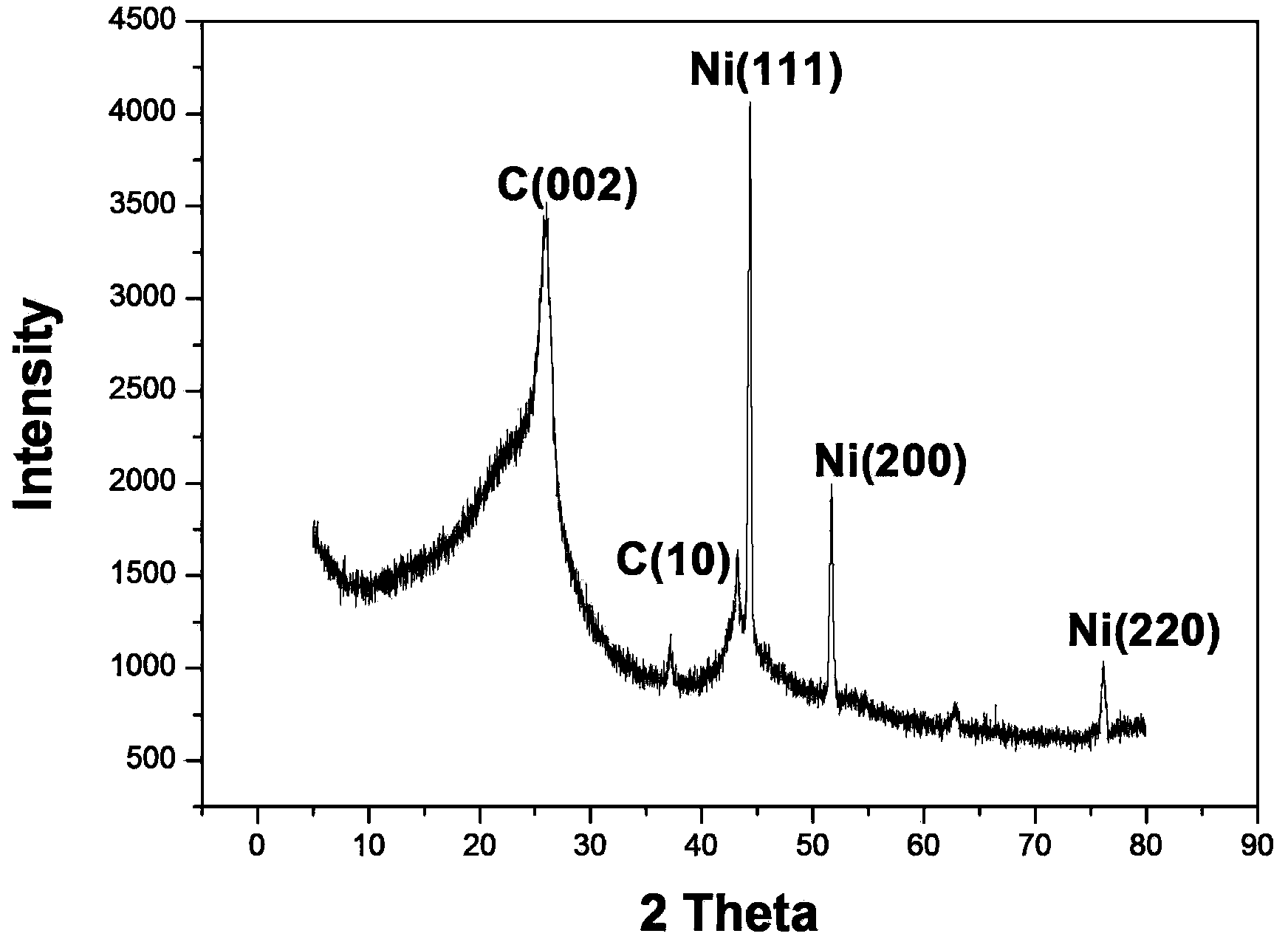

Preparation method for PVC-based carbon nanofiber

ActiveCN103409852ALarge specific surface areaEasy to recycleFilament/thread formingFibre chemical featuresFiberCarbon nanofiber

The invention related to a preparation method for carbon nanofiber. The preparation method is characterized in that: PVC and a catalyst precursor are mixed firstly by using an organic solvent, stirred at 40-50 DEG C to prepare a uniform electrostatic spinning solution; a PVC-based carbon nanofiber precursor is prepared from the spinning solution through an electrostatic spinning device; the PVC-based carbon nanofiber precursor is dried in a drying case, and the dried PVC-based carbon nanofiber precursor is subjected to iodine vapor treatment or alkaline liquor treatment to remove hydrogen chloride, and then the PVC-based carbon nanofiber precursor is put into a muffle furnace to perform preoxidation in an air environment and is forged into the PVC-based carbon nanofiber in a tube furnace under a condition of piping in inert gas continuously. By utilization of the method, resource reuse of the PVC can be achieved with simple equipment and easy operation, and large-scale preparation can be achieved. The PVC-based carbon nanofiber has a large specific surface area. The PVC-based carbon nanofiber is prone to recycle and can be reutilized. The PVC-based carbon nanofiber is suitable for applications in the fields of hydrogen storage, fuel cells, lithium ion batteries, and the like.

Owner:FUJIAN NORMAL UNIV

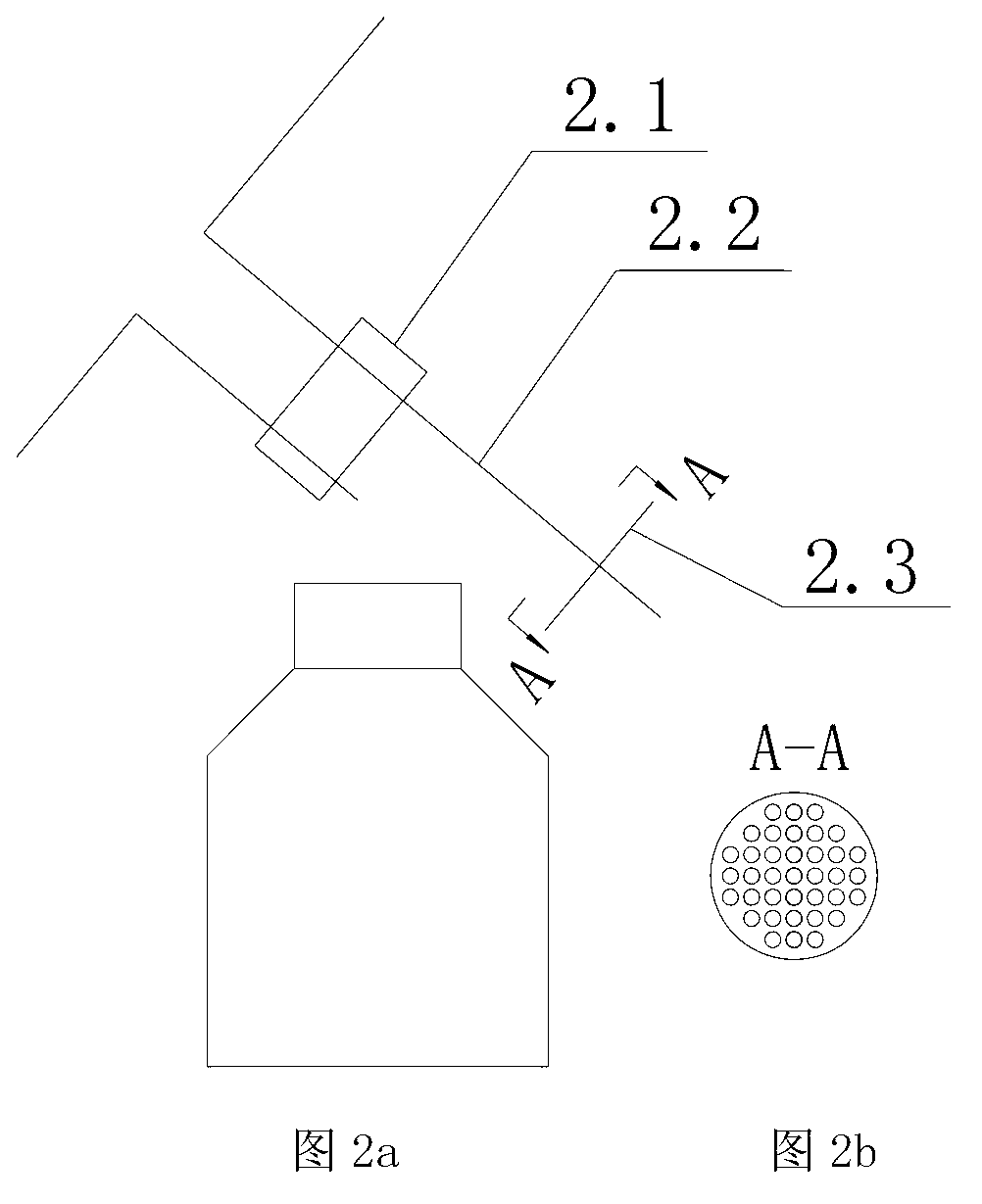

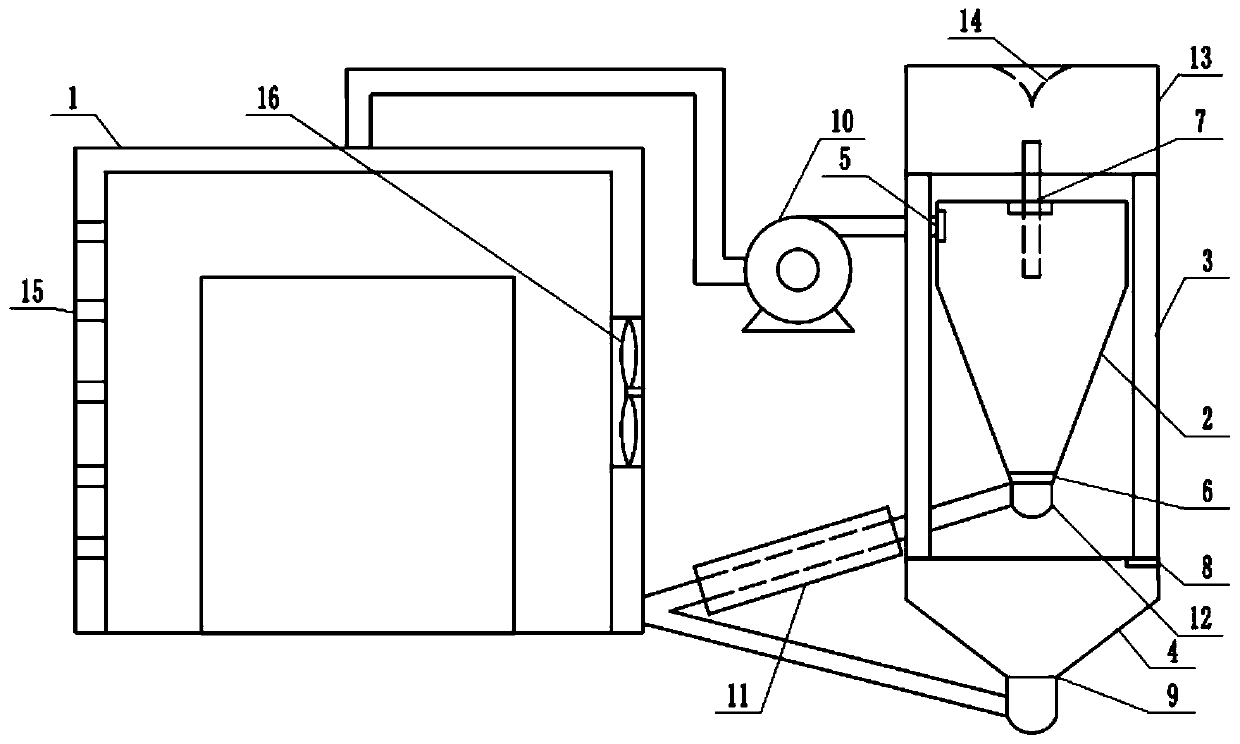

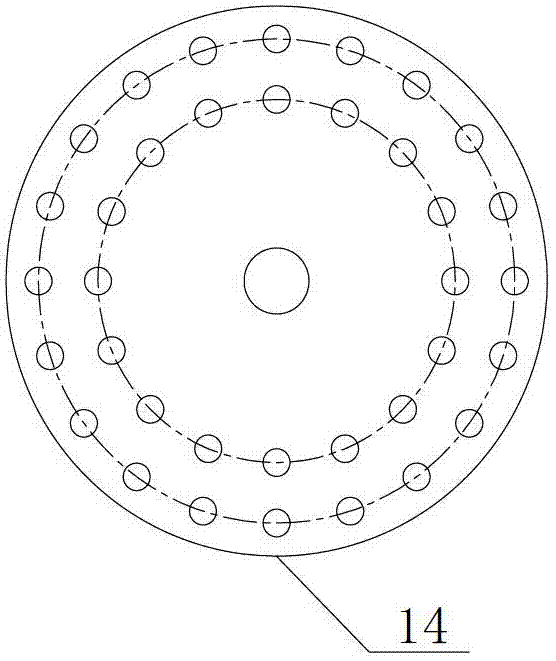

Iodine vapor distributing device with on-line iodine function

ActiveCN103111211AMeet the continuous operation requirements of different working conditionsContinuous and stable supplyFlow mixersNuclear energy generationWater bathsChemical industry

The invention provides an iodine vapor distributing device with an on-line iodine feeding function. The iodine vapor distributing device comprises an iodine vapor generating system, a carrier gas preheating system, an online iodine feeding system, pipelines and valves, wherein the pipelines and the valves are used for connecting all the systems; the carrier gas preheating system comprises an air compressor, a gas storage cylinder, a spiral pipe and a first water bath; the iodine vapor generating system comprises an iodine pool, an upper gas distributing plate, a carrier gas pipe, a lower gas distributing plate, a carrier gas diffusion nozzle and a second water bath; and the online iodine feeding system comprises a feeding hopper, a spherical valve and a feeding pipe. The iodine vapor distributing device provided by the invention is economic and reliable, can meet requirements on continuous operation under different working conditions, can be applied to performance tests of a safety housing filtering and discharging system, and is also suitable for other fields such as chemical industry needing continuous iodine feeding for a long time.

Owner:CHINA NUCLEAR POWER ENG CO LTD

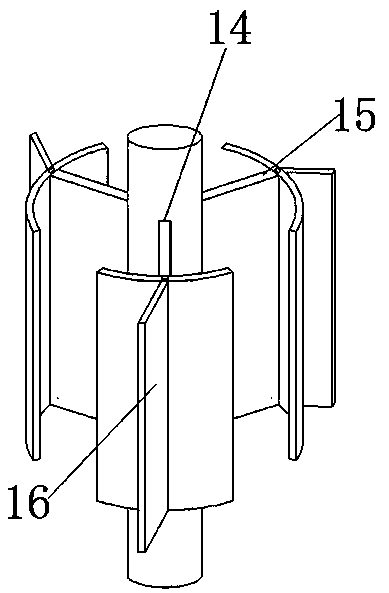

Industrial crude iodine recovery stirring device

The invention discloses an industrial crude iodine recovery stirring device, which comprises a sealing cover, wherein a gear shaft is arranged at the central position of the top of the sealing cover;a rack is arranged on the left side of the gear shaft; a moving rod is arranged at the left end of the rack; a cylindrical cam is arranged at the left end of the moving rod; and a supporting frame isarranged above the cylindrical cam, and the supporting frame is further arranged below the cylindrical cam. A braking device of the crude iodine recovery stirring device drives the rack to move back and forth by a cylindrical cam mechanism, the rack drives a stirring rod to rotate in the positive and negative directions, the stirring speed is small, the solution can be fully heated, the heating ismore uniform, and the rotation in the positive and negative directions can cause the solution to generate larger water fluctuation and more vapor dense, so that the iodine vapor still maintains a higher temperature during the transfer process, blocking plates on stirring fan blades can further generate larger water fluctuation, and the swinging plate can enlarge the stirring range.

Owner:天津市艾碘科技股份有限公司

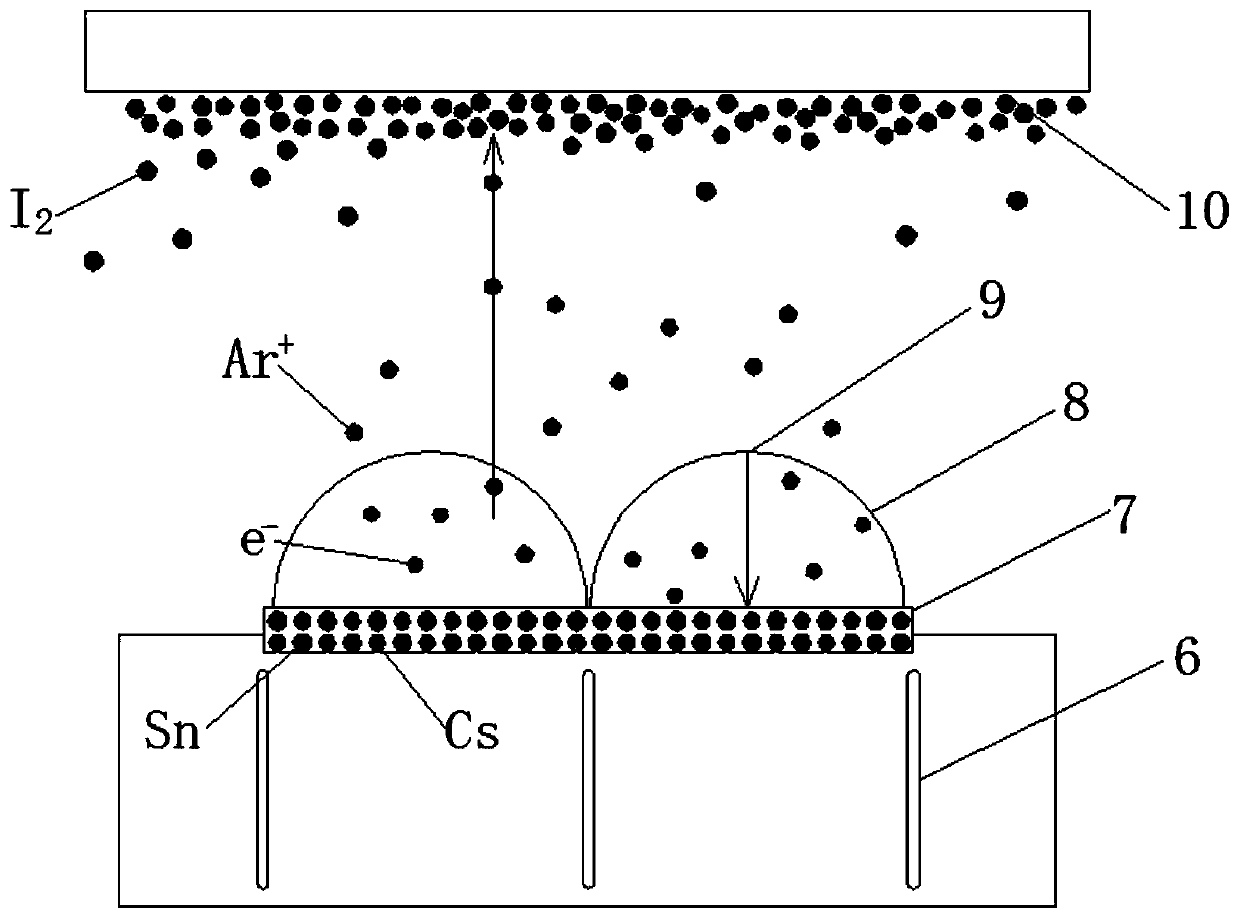

Magnetron sputtering method for preparing all-inorganic perovskite solar cell

ActiveCN110246926AGuaranteed smoothnessGood surface morphologyFinal product manufactureVacuum evaporation coatingAlloyHole transport layer

The invention relates to a magnetron sputtering method for preparing an all-inorganic perovskite solar cell. The method comprises a step of preprocessing a substrate, a step of forming an electron transport layer on the surface of the preprocessed substrate by magnetron sputtering and then continuing to adopting a caesium-tin alloy target for magnetron sputtering equipment to react to obtain an all-inorganic perovskite material, a step of forming a solar cell hole transport layer on a perovskite material layer by magnetron sputtering, and a step of drying and completing the deposition of a cathode metal electrode to obtain the all-inorganic perovskite solar cell. The method has the advantages that the ozone cleaning and the magnetron sputtering argon ion cleaning are combined, and the surface finish degree of the material is further ensured. The magnetron sputtering method is employed by a perovskite absorption layer, iodine vapor is introduced to be in full contact with metal ions such as caesium and tin, the good surface morphology is formed, and a perovskite film with large crystal grains and without pores is formed.

Owner:UNIV OF SCI & TECH LIAONING

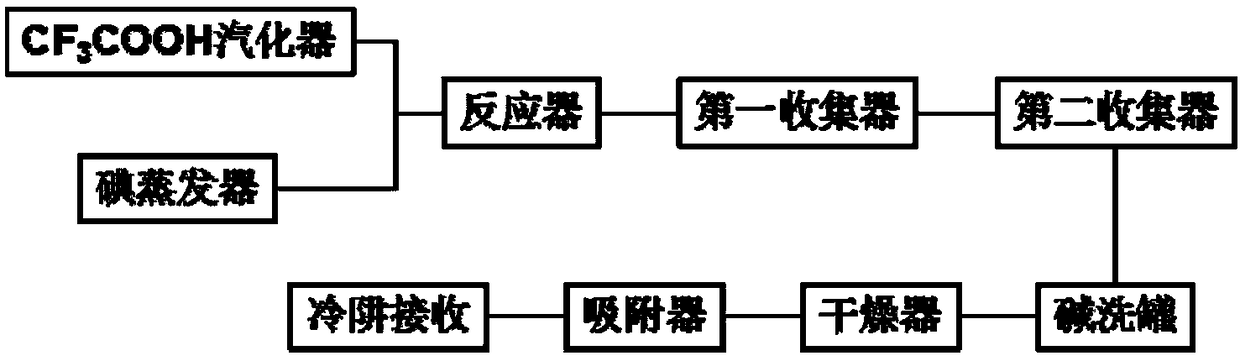

Method for efficiently synthesizing trifluoromethyl iodide

ActiveCN108246277AIncrease profitHigh yieldHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsReaction rateIodide

The invention discloses a method for efficiently synthesizing trifluoromethyl iodide. The method comprises the following steps: reacting CF3COOOH vapor with iodine vapor under the action of a catalystto generate the trifluoromethyl iodide, wherein the catalyst is a catalyst which selects activated carbon or graphene as a carrier and is loaded with 1 to 10 weight percent of KNO3 and 2 to 7 weightpercent of RbNO3; then effectively removing impurities and moisture in CF3I by a NaOH solution, silica gel and a molecular sieve in sequence, thus efficiently collecting high-purity CF3I products. Themethod has the advantages of fast reaction rate, good selectivity, high yield, high reactant utilization and energy conservation; the method is expected to realize industrialized production and meetscurrent market demands.

Owner:DALIAN KELIDE OPTOELECTRONICS MATERIALS CO LTD

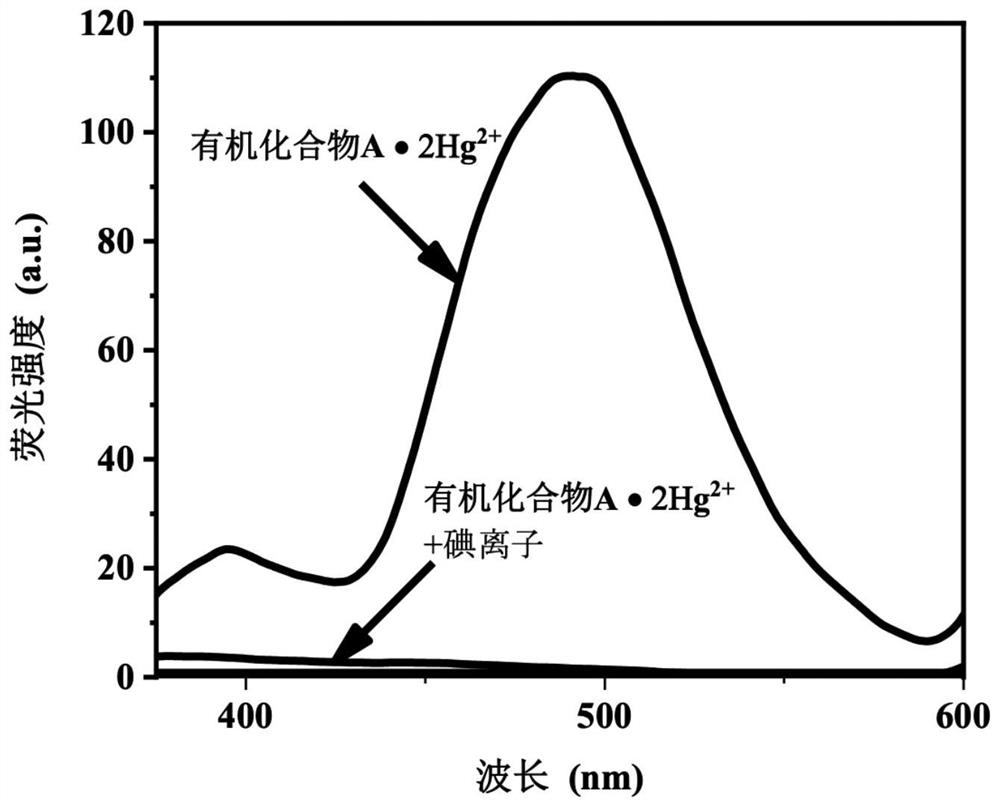

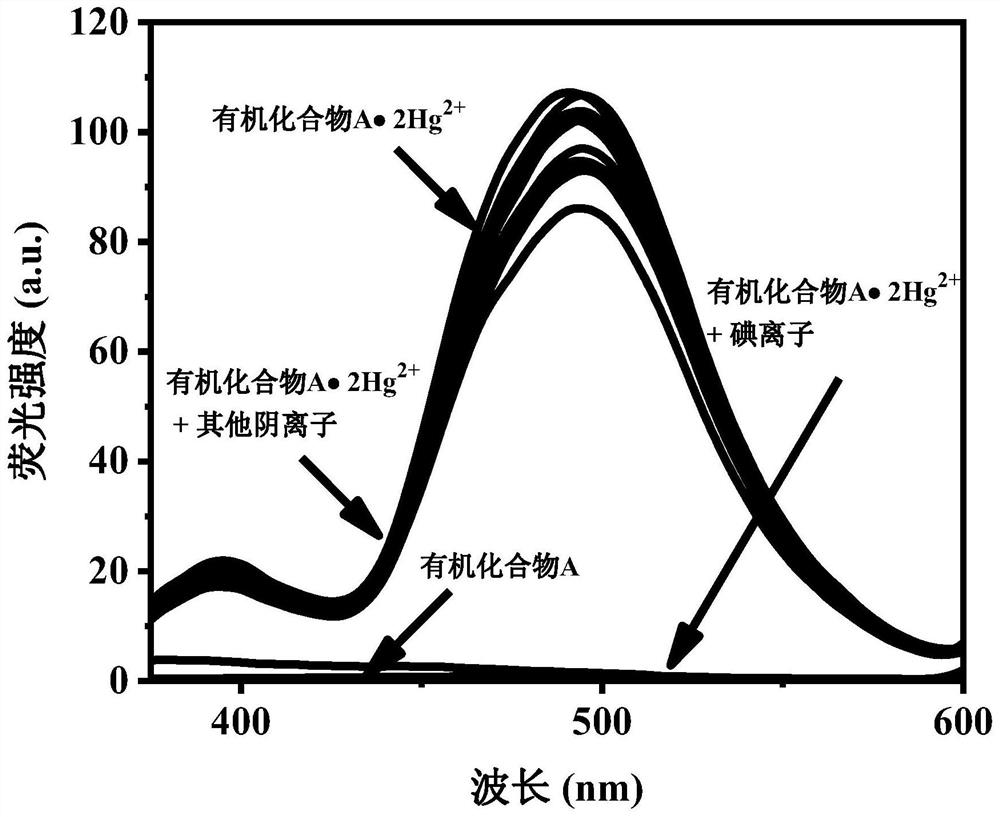

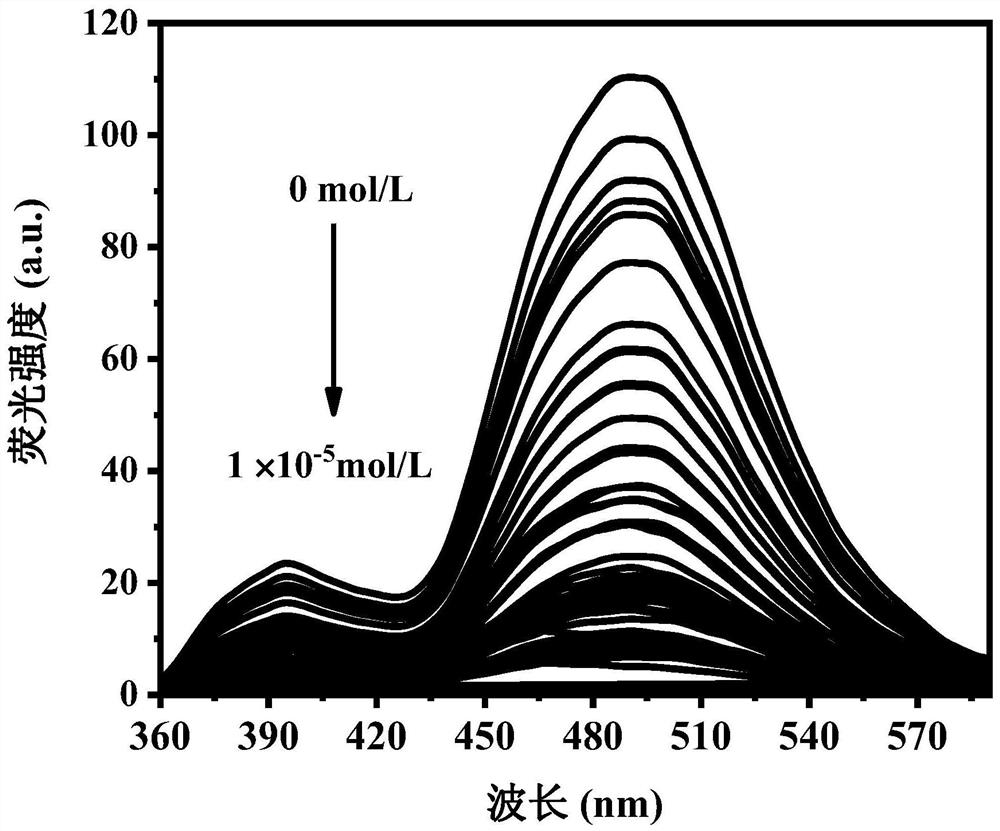

Molecular platform for detecting iodine in different forms by spectrometry and colorimetry as well as preparation method and application thereof

ActiveCN111795960AEasy to makeStable structureOrganic chemistryFluorescence/phosphorescenceStructural formulaOrganic compound

The invention discloses a molecular platform for detecting iodine in different forms by spectrometry and colorimetry as well as a preparation method and application thereof, and relates to a molecularplatform for detecting iodine as well as a preparation method and a detection method thereof. The invention aims to solve the technical problems that the existing iodine detection materials are few in variety, only one form of iodine can be detected, the detection mechanism is single, the detection limit is high, and the detection can be easily interfered by the external environment. The structural formula of the molecular platform is described in the specification. The preparation method of the molecular platform comprises the following steps of: reacting 2-(3-amino-6-hydroxyphenyl) phenanthroimidazole with terephthalaldehyde to obtain an organic compound A, and reacting the organic compound A with mercury nitrate to obtain the molecular platform. The molecular platform can be used for qualitative or quantitative detection of iodide ions, iodine elementary substances or / and iodine vapor in different media. The molecular platform is convenient to use and quick in response, and can beapplied to the field of iodine ion, iodine elementary substance and iodine vapor detection.

Owner:QIQIHAR UNIVERSITY

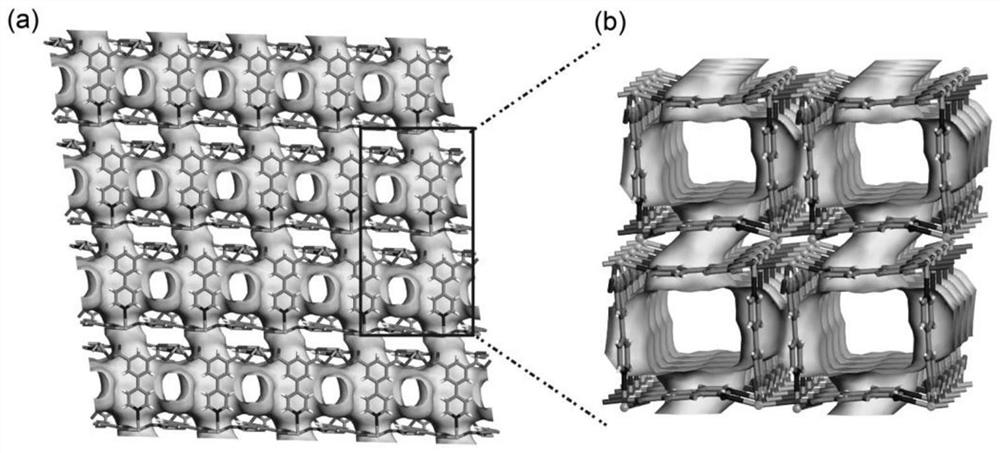

MOF (Metal Organic Framework) porous adsorption material as well as preparation method and application thereof

PendingCN114405482AImprove applicabilityGuaranteed application effectOther chemical processesAlkali metal oxides/hydroxidesAlkaneMetal-organic framework

The invention belongs to the technical field of complex application, and discloses an MOF (Metal Organic Framework) porous adsorption material, a preparation method thereof and application of the MOF porous adsorption material in the aspects of efficiently adsorbing iodine vapor and capturing iodine molecules in an iodine aqueous solution. The MOF iodine adsorption material is prepared through solvothermal reaction of lead ions and 5-(4-pyridine) isophthalic acid (pi), the chemical formula is [Pb2 (pia) 2 (DMA)]. DMA, the compound is of a column-chain structure, Pb < 2 + > ions and ligand carboxylic acid groups form a defective double-cube alkane [Pb4O6]-based metal carboxyl chain, and the defect double-cube alkane [Pb4O6]-based metal carboxyl chain is used for adsorbing iodine. Adjacent chains are expanded into a three-dimensional porous network structure with a square window one-dimensional nano pore channel through pia ligands which are arranged in parallel. The MOF can be used for efficiently capturing iodine vapor and iodine molecules in an aqueous solution after being replaced with a low-boiling-point solvent and subjected to heating, vacuumizing and activating treatment, and the material keeps high structural stability in the iodine adsorption process.

Owner:SHAANXI UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com