Patents

Literature

30 results about "Mercury nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mercury(II) nitrate is a toxic colorless or white soluble crystalline mercury(II) salt of nitric acid. It was also used to treat fur to make felt in a process called 'carroting'. The phrase 'mad as a hatter' is associated with psychological illness brought on by excessive exposure to mercury(II) nitrate.

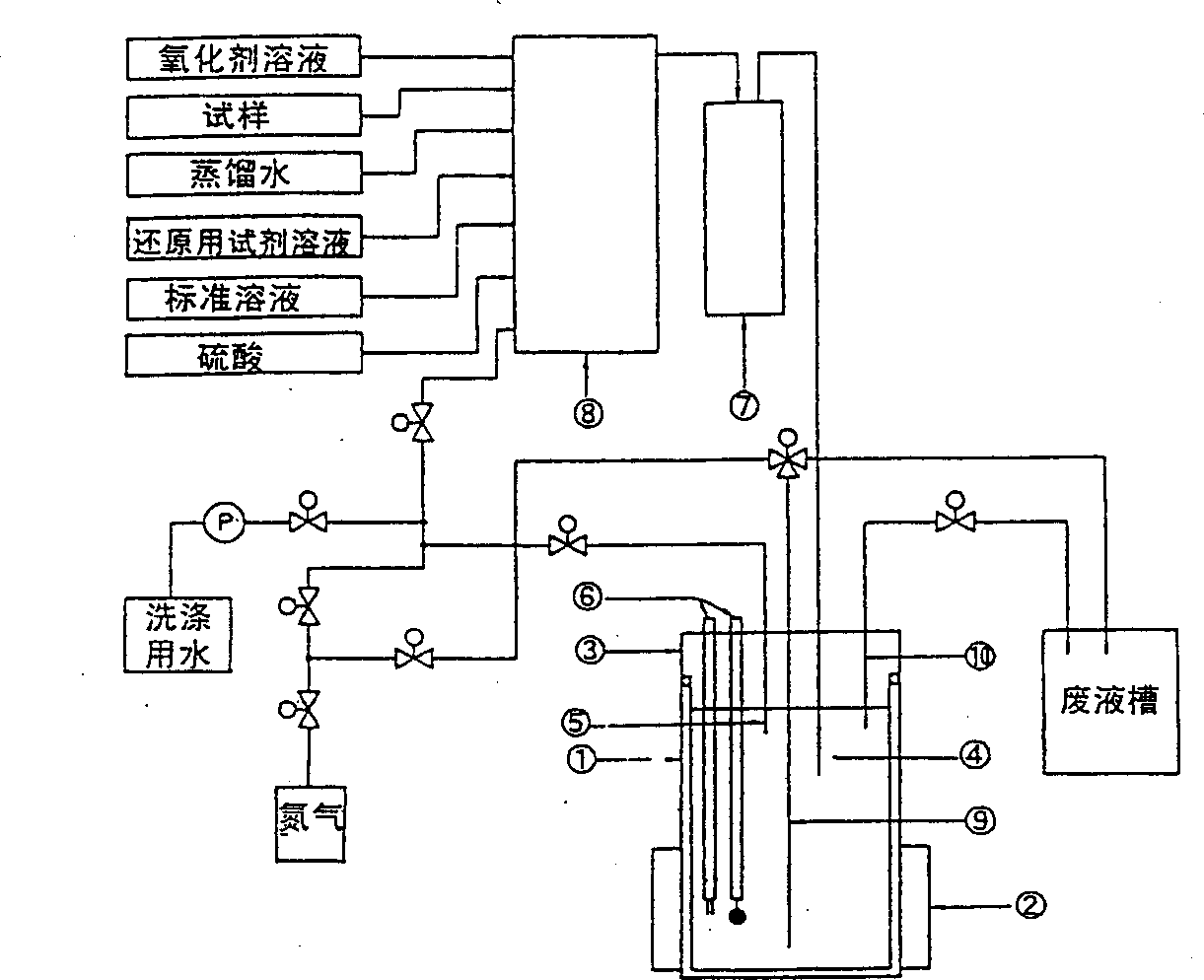

Method for measuring chemical oxygen requirement and its apparatus

InactiveCN1374520AGood reproducibilityWater/sewage treatmentTesting waterChemical oxygen demandChloride

PURPOSE: To provide an apparatus for measuring chemical oxygen demand and a method therefor which generate no measurement errors by halide ions simpler and easy to process without using mercury nitrate, silver nitrate, and the like. CONSTITUTION: According to the method for measuring chemical oxygen demand and the apparatus for carrying out the measurement method, a fixed amount of a sample whose chemical oxygen demand is to be measured is collected. A predetermined amount of sulfuric acid is added to the sample, which is heated under an inert ambience to remove dissolved chloride ions present in the sample as a hydrogen chloride. Then, a fixed amount of an oxidation reagent for oxidizing the sample is added and heated, whereby a substance to be oxidized in the sample is oxidized. The residual oxidation reagent is coulometric titrated by a reagent solution for reduction. An amount of the residual excessive oxidation reagent is measured. An amount of the oxidation reagent consumed for oxidizing the substance to be oxidized of the sample is measured from the fixed amount of the oxidation reagent added beforehand. The chemical oxygen demand is calculated from the volume of the sample, and the measured value of the oxidation reagent consumed for oxidizing the substance to be oxidized in the sample.

Owner:IIJIMA ELECTRONICS CORP

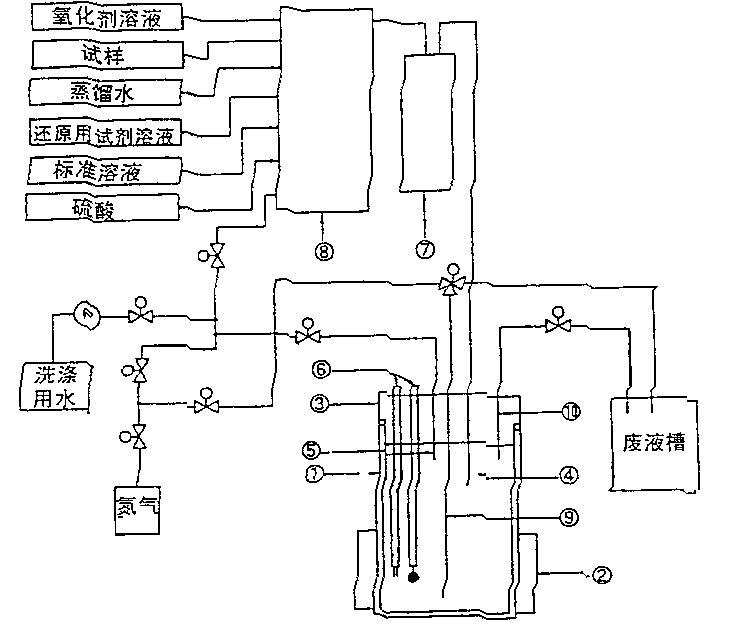

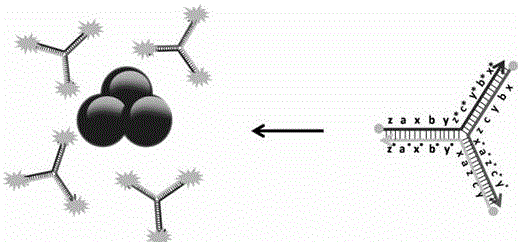

Colorimetric and fluorescent double-signal biosensor for detecting Hg<2+>, and detection method of biosensor

ActiveCN106370638ACheap manufacturingHigh detection sensitivityColor/spectral properties measurementsFluorescence/phosphorescenceUltrapure waterCitrate sodium

The invention discloses a colorimetric and fluorescent double-signal biosensor for detecting Hg<2+>, and a detection method of the biosensor. The colorimetric and fluorescent double-signal biosensor comprises molecular hairpin probes (H1, H2 and H3), auxiliary deoxyribonucleic acid (DNA) and gold nanoparticles. The molecular hairpin probes are fluorescein (FAM)-labeled molecular hairpins. The AuNPs is synthesized by using a method of reducing chloroauric acid by means of sodium citrate. The detection method comprises the steps of dissolving 0.01g of the chloroauric acid in 100mL of ultrapure water, and boiling by reflux heating; adding 2.5mL of a 1wt% sodium citrate solution under the condition of rapidly stirring, carrying out a reaction for 30min, and then cooling to the room temperature to prepare the AuNPs; mixing mercury nitrate with H1, H2 and H3 (30-300 nmol / L) and a Tris-HCl buffer solution of the auxiliary DNA (20-500 nmol / L), carrying out a reaction for 1-5h at the room temperature, then adding the AuNPs, and carrying out a reaction for 5min; detecting respectively by using an ultraviolet-visible spectrophotometer and a fluorimeter. The double-signal biosensor based on the AuNPs and a catalytic hairpin assembly non-enzyme amplification technology is cheap in preparation and high in detection sensitivity, and overcomes the defect of narrow applicability of a single detection mode.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

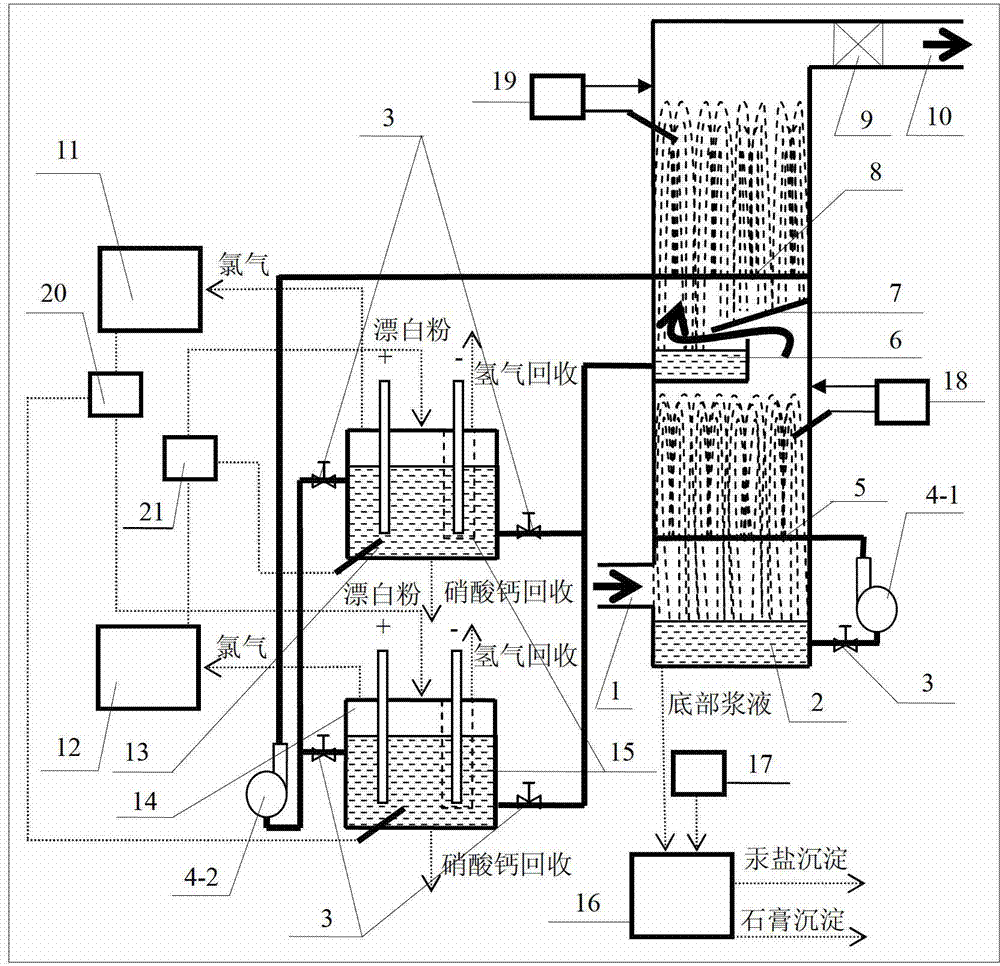

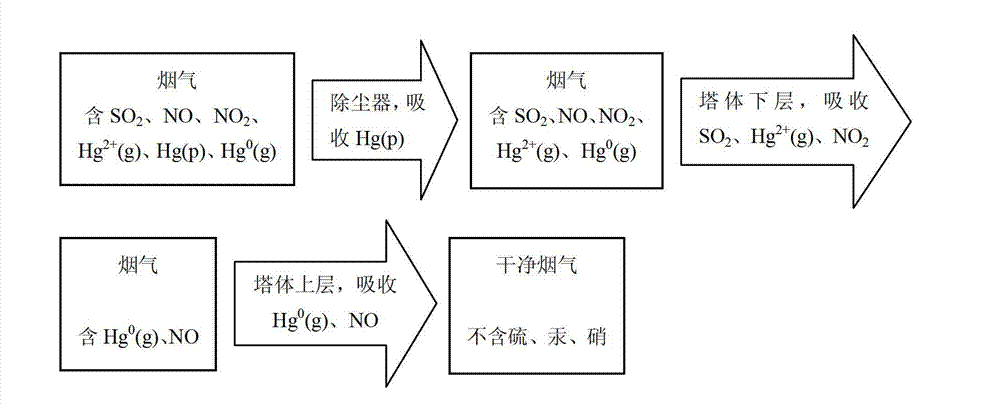

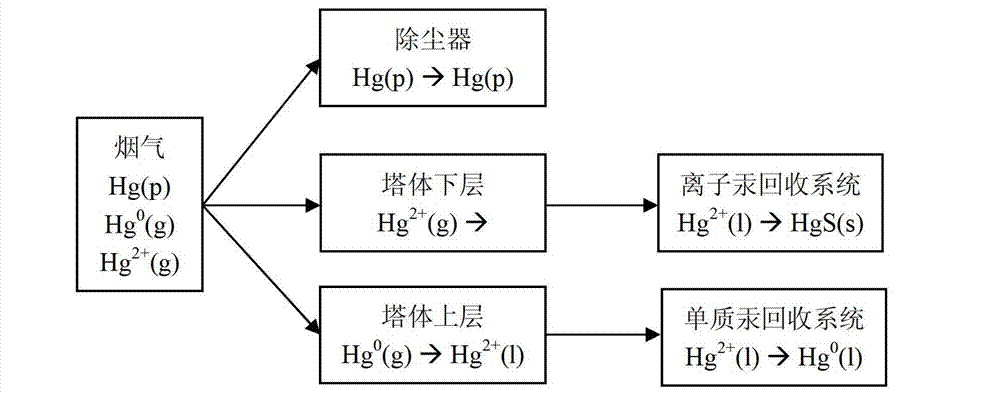

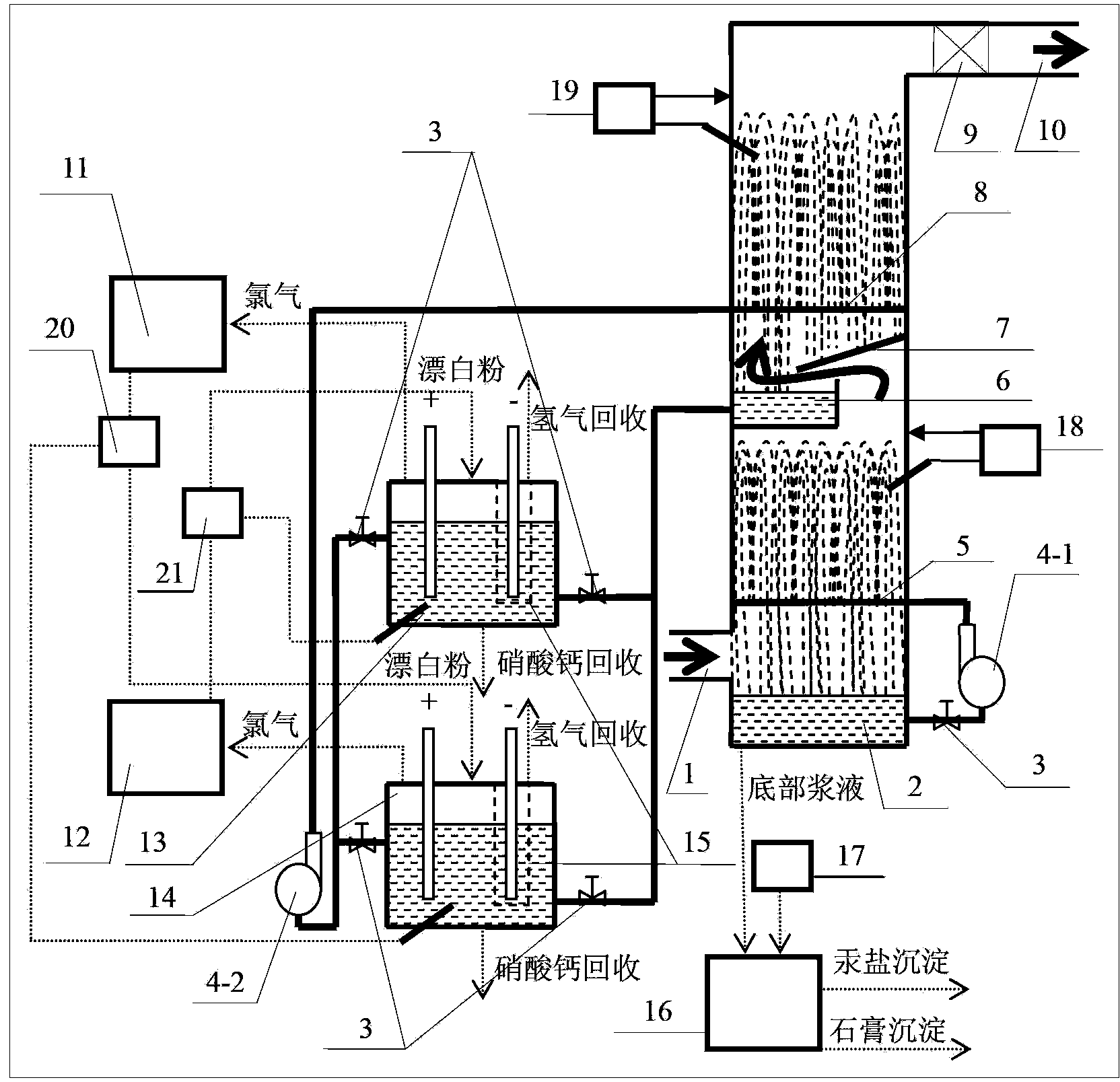

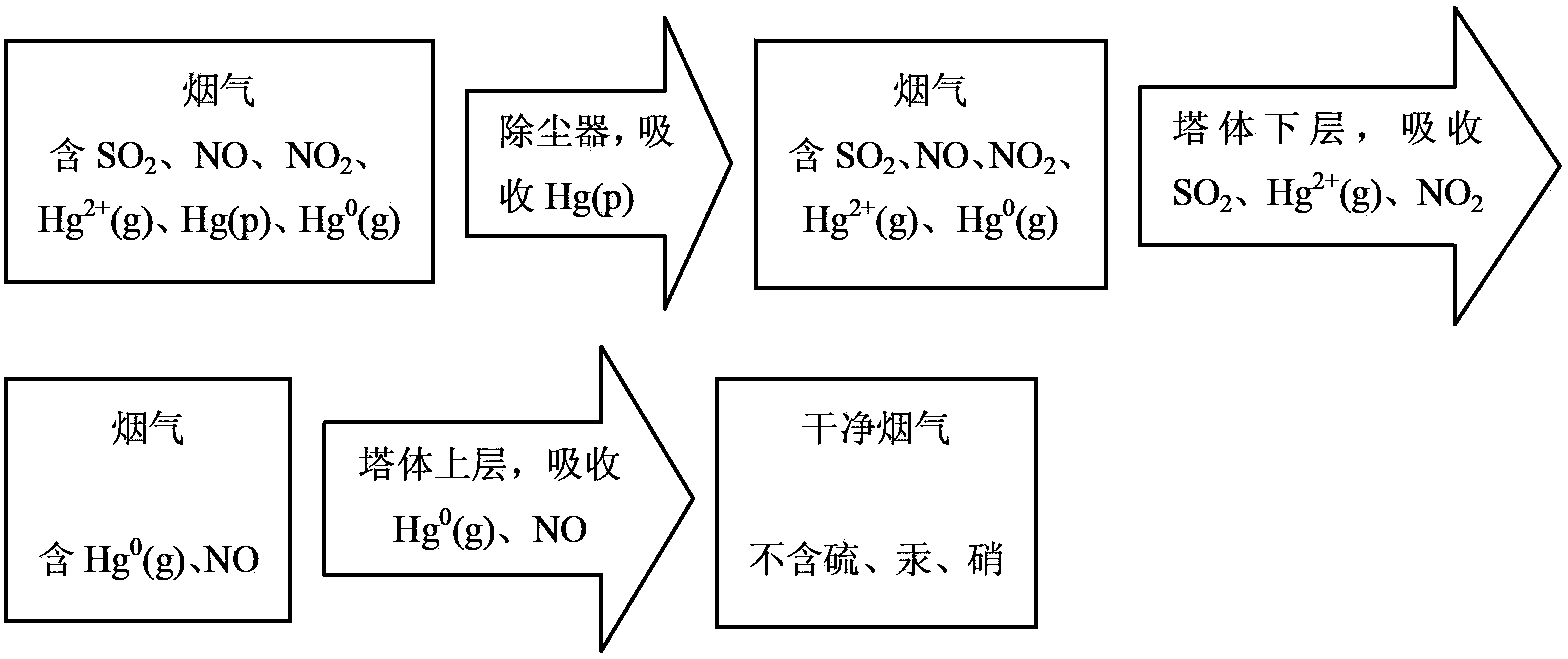

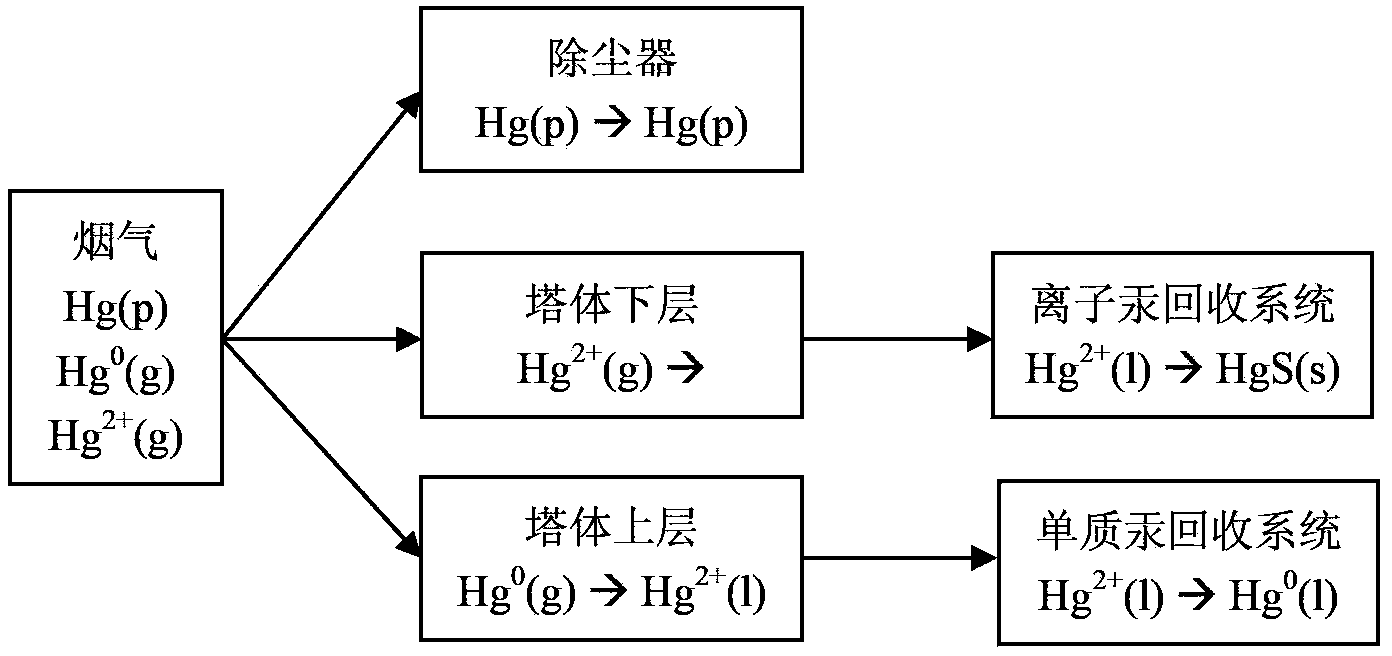

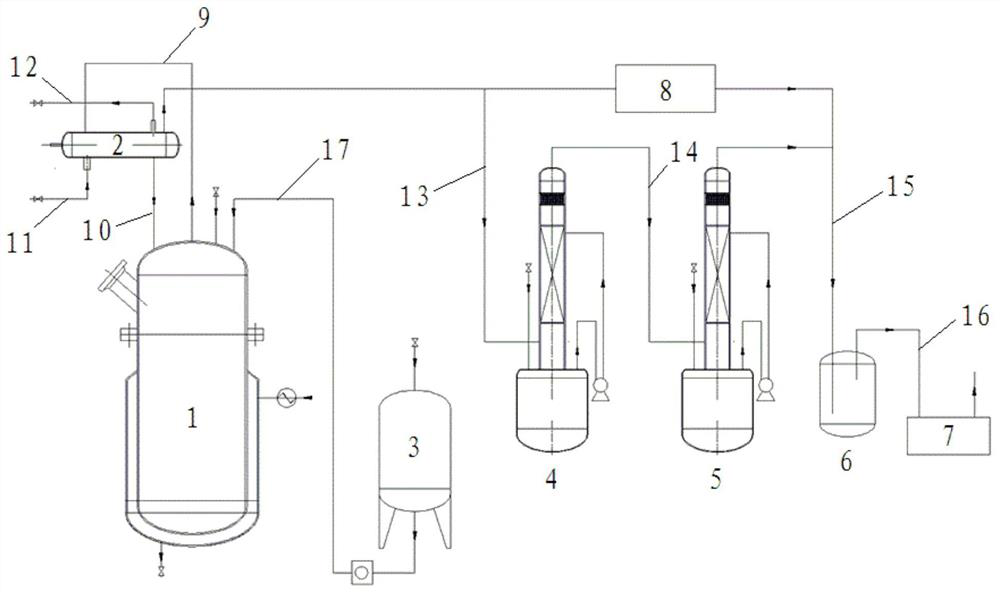

Combined removal device and method for sulphur, mercury and nitrate in smoke

ActiveCN102824843ALow investment costReduce land costCombination devicesProcess efficiency improvementOperational costsOxidizing agent

Disclosed are combined removal device and method for sulphur, mercury and nitrate in smoke. The device comprises a sulphur removal system, a combined mercury-nitrate removal system, a mercury ion recovery system, an elementary mercury recovery system, and an oxidant regeneration system. The sulphur removal system is disposed on the lower portion of a column. The combined mercury-nitrate removal system is disposed on the upper portion of the column. The mercury ion recovery system is connected with the bottom of the sulphur removal system. The elementary mercury recovery system is connected with the combined mercury-nitrate removal system. The oxidant regeneration system is connected with the elementary mercury recovery system. The removal method includes smoke purification, mercury atom recovery and chlorine atom recycling. The removal device and method have the advantages that the structure is simple, integrity is high, operational cost is low, materials are recycled, and byproducts can be recycled.

Owner:XI AN JIAOTONG UNIV

Method for removing chloride ion in sewage

InactiveCN103011465AReduce dosageLow running costWater contaminantsMultistage water/sewage treatmentSuspended particlesParticulates

The invention discloses a method for processing wastewater containing chloride ions. The method comprises the following steps of carrying out flocculation precipitation treatment on chlorine wastewater by polymeric ferrous sulfate, adding 1-5ppt of mercury nitrate reagent to the chlorine wastewater in which suspended particles are removed, adjusting pH value to 9.5-11.5, fully stirring for 10-30 minutes to completely react, then adding excessive sodium sulfate and sodium oxalate to 500-1000mg / L of wastewater, continuing to leach for 30-50 minutes at normal pressure, and precipitating the residual trace mercury ion in the wastewater; finally enabling the wastewater to flow through an absorption tower with a biomass filter material to carry out adsorption treatment, wherein the effluent is the wastewater in which the chloride ions are completely removed, and the biomass filter material is particles of 80-100 meshes which are prepared from straw and sawdust in the manners of baking, crushing and pelletizing after anaerobic fermentation. The method has the characteristics that the method is simple in technologic process, low in operating expense, free of sludge, high in chloride ion removal rate, and the like.

Owner:CHANGZHOU UNIV

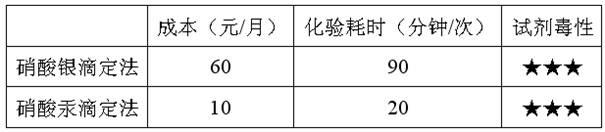

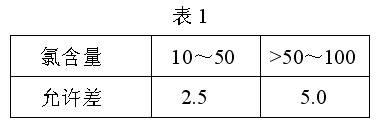

Method for detecting content of chloride ions in emulsion

InactiveCN102419358AEasy to operateShort timeAnalysis using chemical indicatorsChemical analysis using titrationEmulsionChloride

The invention discloses a method for detecting the content of chloride ions in an emulsion, comprising the following steps of: taking an emulsion, adding anhydrous ethanol into the emulsion; adjusting pH of the emulsion to 2.5-3.0 by nitric acid, adding dropwisely diphenylacarbazone as a indicator into the emulsion, carrying out titration by using a mercury nitrate aqueous solution until it becomes stable light claret as a terminal point; and calculating the content of chloride ions C mercury nitrate*V mercury nitrate *M chlorine / V emulsion after titration. With the adoption of the mercury nitrate titration method to replace an original silver nitrate titration method, the method provided by the invention can be used to determine chlorine content in a stable emulsion and a semi-stable emulsion for cold rolling. In comparison with an original method, the method provided by the invention has advantages of simple operation, little time consumption, shortened detection time, little operation error and low cost, and is more beneficial for application.

Owner:SHANDONG XINMEIDA TECH MATERIAL

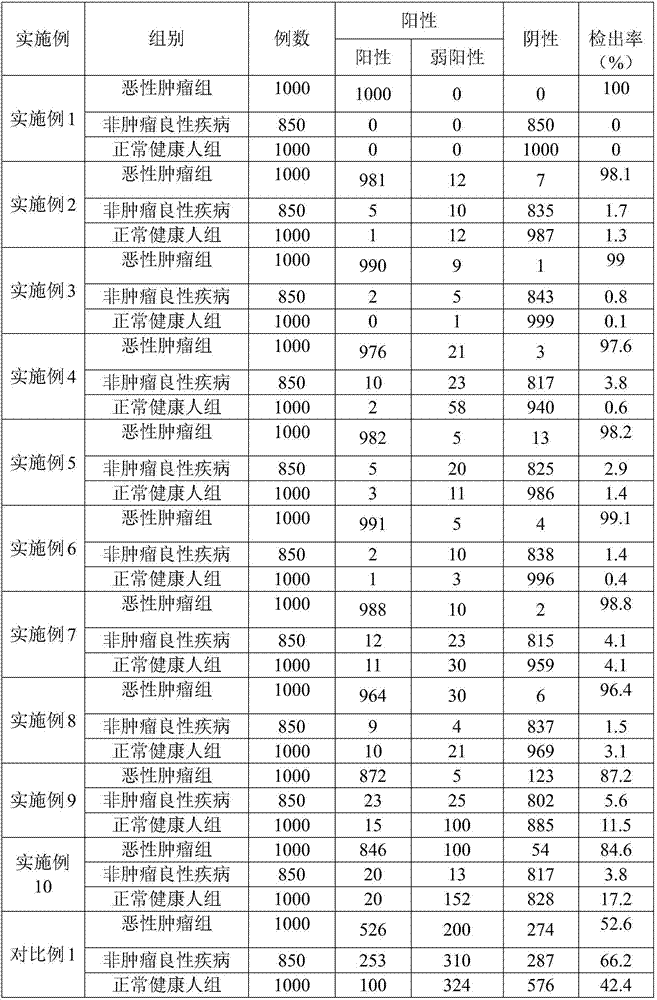

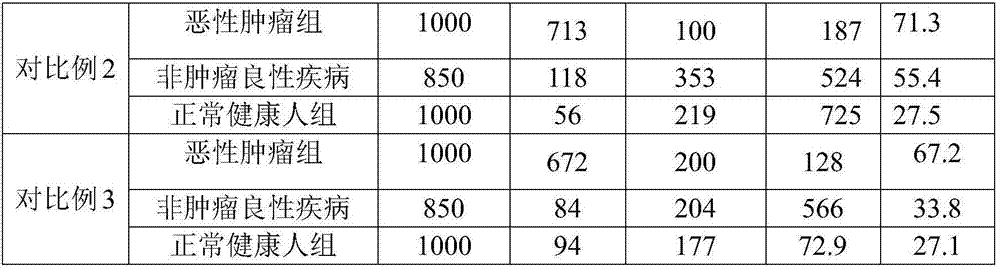

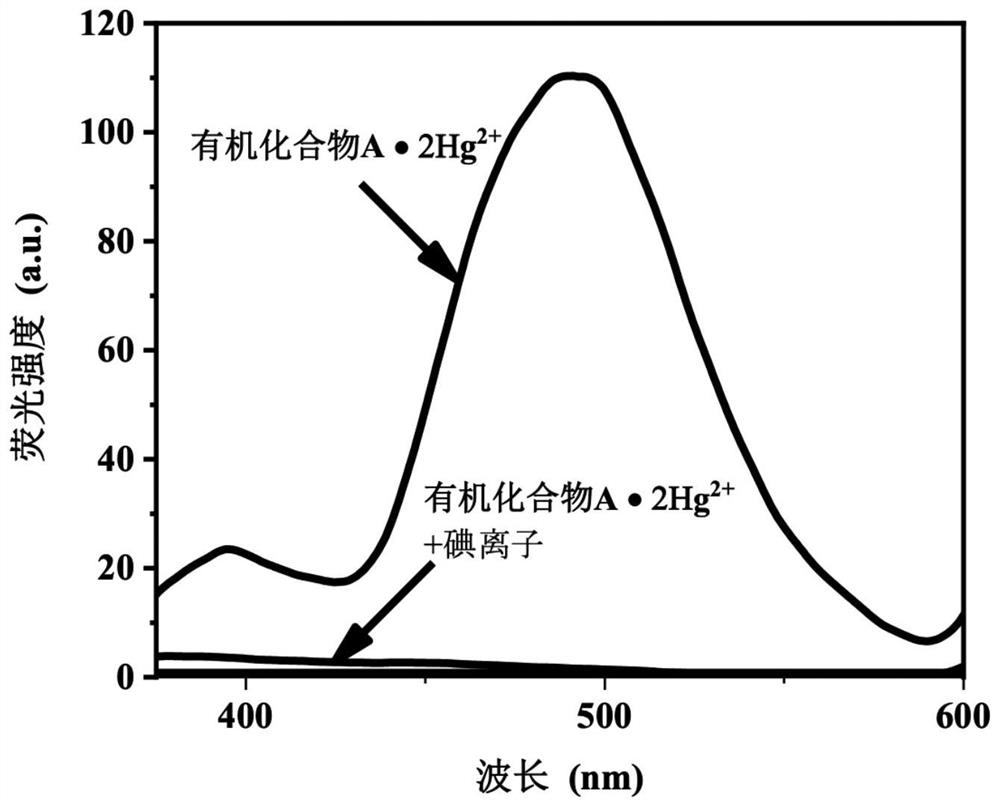

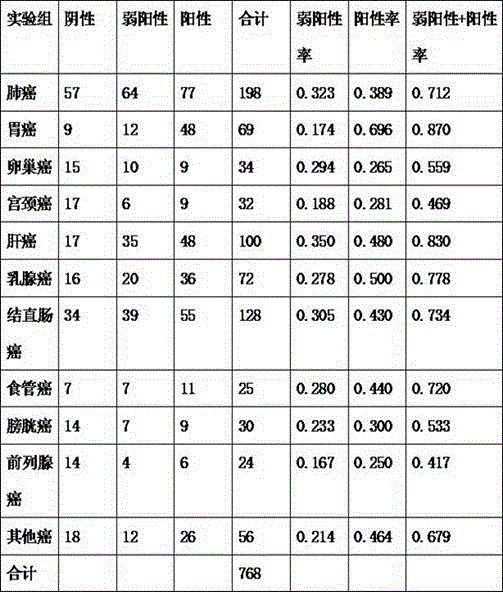

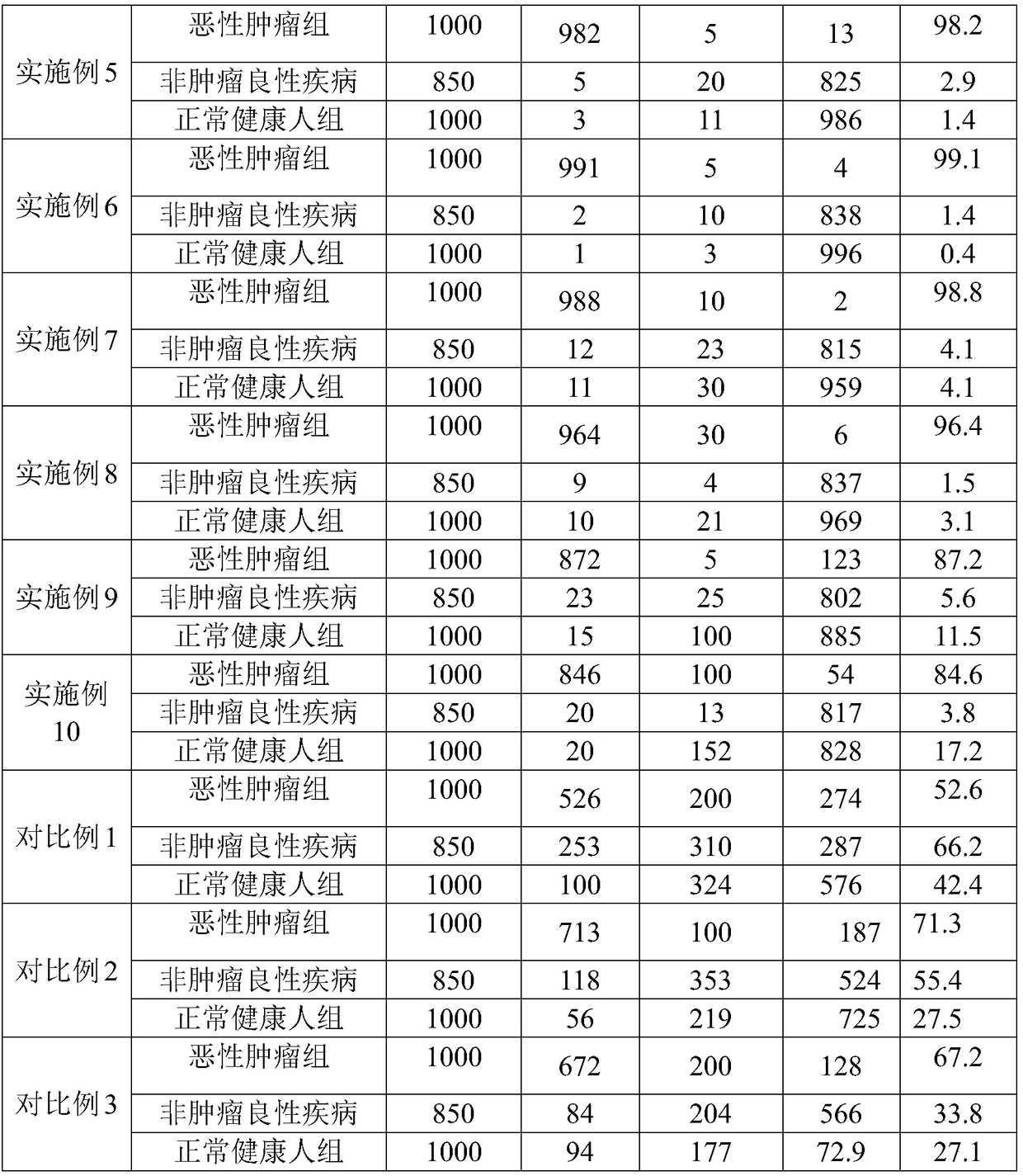

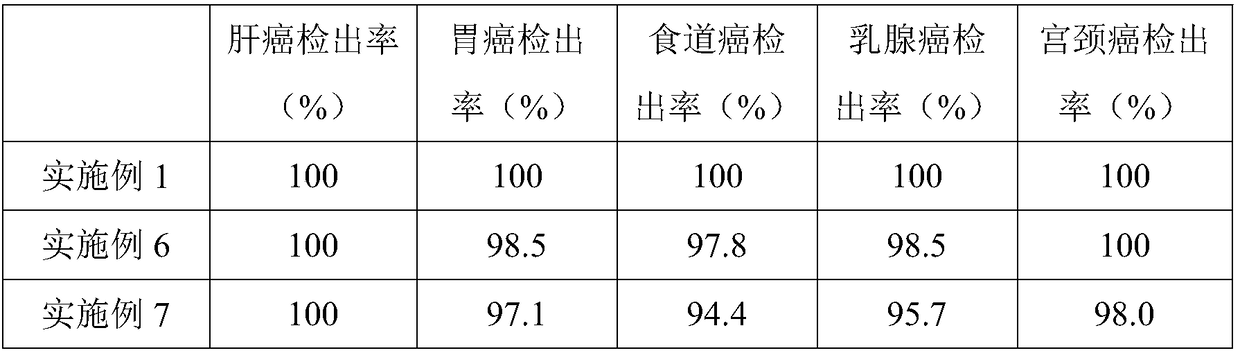

Metabolic screening p-hydroxyl phenylalanine urine detection reagent

InactiveCN107490689ARaw materials are easy to getSave raw materialsDisease diagnosisTreatment effectPhenylalanine

The present invention relates to a metabolic screening p-hydroxyl phenylalanine urine detection reagent, which is formed by mixing a 0.1-0.15 g / ml mercury sulfate aqueous solution, a 0.5-1 g / ml mercury nitrate aqueous solution, a 0.1-0.2 g / ml nickel nitrate aqueous solution and a 1-2 g / ml selenous acid aqueous solution according to a volume ratio of 1:0.6-1.2:0.8-1.5:0.5-1.0. According to the present invention, the detection reagent has characteristics of strong universality, high sensitivity, good specificity and the like in tumor detection, further has advantages of simple detection process, short detection time and easy result judgment, and is particularly suitable for the large-scale population census and the tumor clinical auxiliary diagnosis and treatment effect dynamic examination.

Owner:格朗生物技术(上海)有限公司

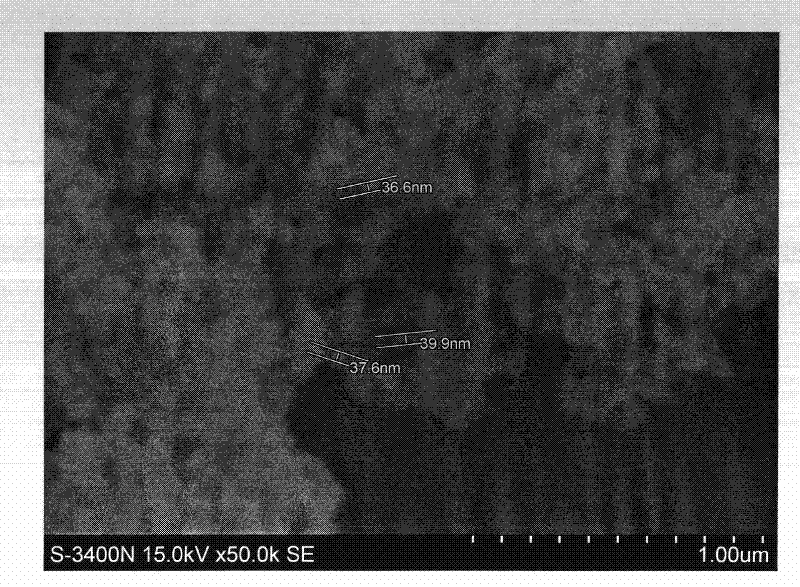

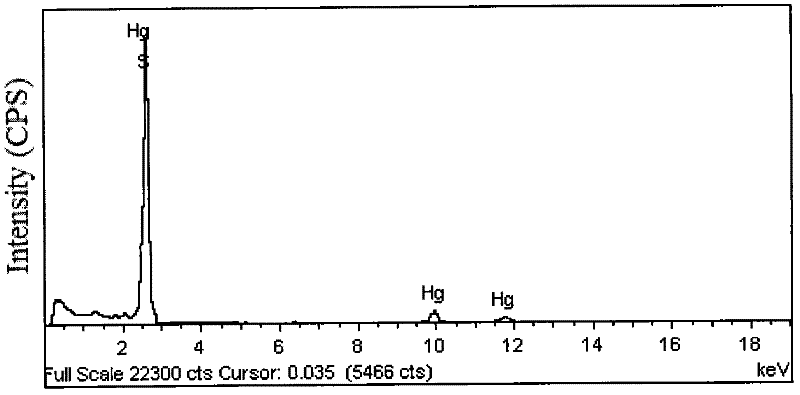

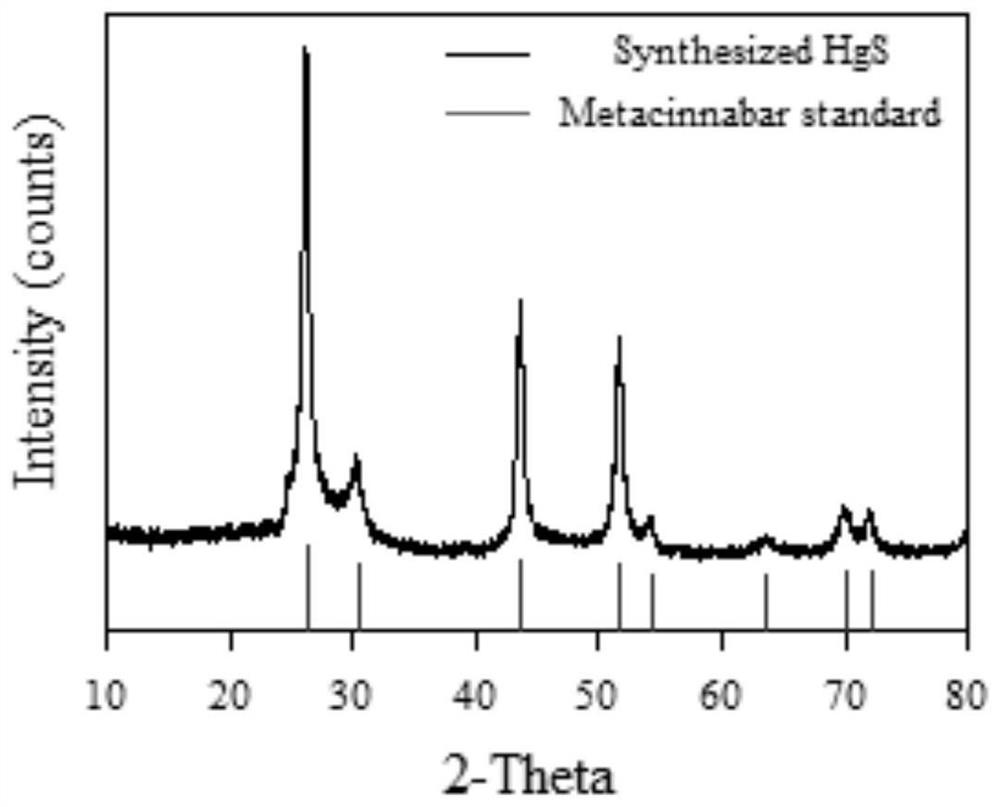

Preparation method for mongolian medicine vermilion nanometer powder

InactiveCN102512444ASmall doseHypnotic effectHeavy metal active ingredientsPowder deliveryMedicineMercury nitrate

The invention discloses a preparation method for mongolian medicine vermilion nanometer powder. The method is as follows: mercury nitrate and thioacetamide are used as raw materials for preparation of nanometer mercuric sulfide by using a wet process; a solution with a certain concentration is prepared from the raw materials; the raw materials are rapidly mixed under magnetic stirring, and the solution is uniformly heated until the solution boils so as to prepare nanometer mercuric sulfide powder. According to the invention, environmental pollution in traditional preparation processes for mongolian medicine vermilion is reduced, the process of preparation is more controllable, components are more specific, and quality of different batches of the nanometer powder is stable.

Owner:INNER MONGOLIA MEDICAL COLLEGE

Human urine detection reagent for monohydroxyphenyl metabolites

The invention provides a human urine detection reagent for monohydroxyphenyl metabolites. The human urine detection reagent for the monohydroxyphenyl metabolites comprises mercury sulfate solution, mercury nitrate solution, nickel sulfate solution, silicotungstic acid solution, trichloroacetic acid solution and mercury ion (i) mesoporous silica. The concentration of the mercury sulfate solution is 0.7-3 mol / L; the concentration of the mercury nitrate solution is 0.1-0.6 mol / L; the concentration of the nickel sulfate solution is 0.01-0.05 mol / L; the concentration of the silicotungstic acid solution is 1.0-4.0 mmol / L; the concentration of the trichloroacetic acid solution is 0.6-5.0 mmol / L; the mass fraction of the mercury ion (i) mesoporous silica is 3-10%.

Owner:浙江道家医疗科技有限公司

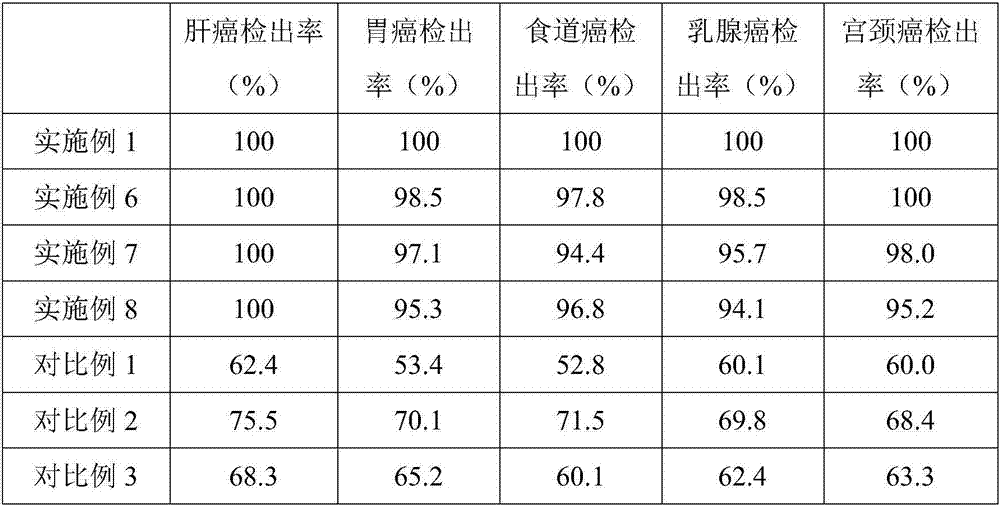

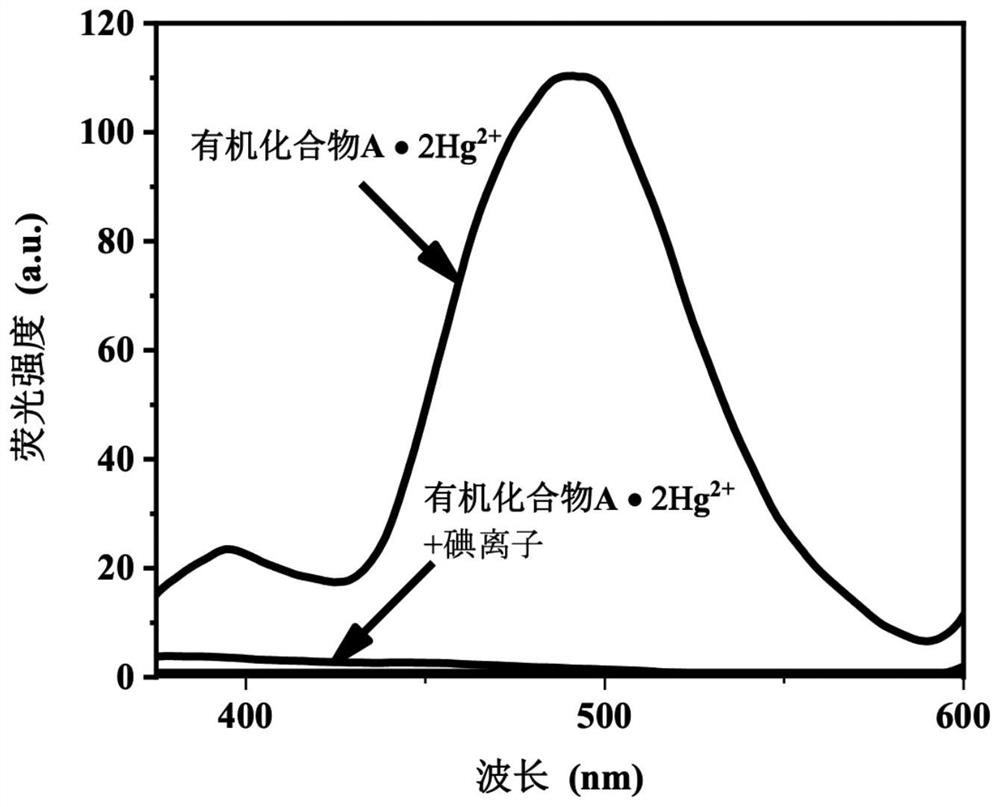

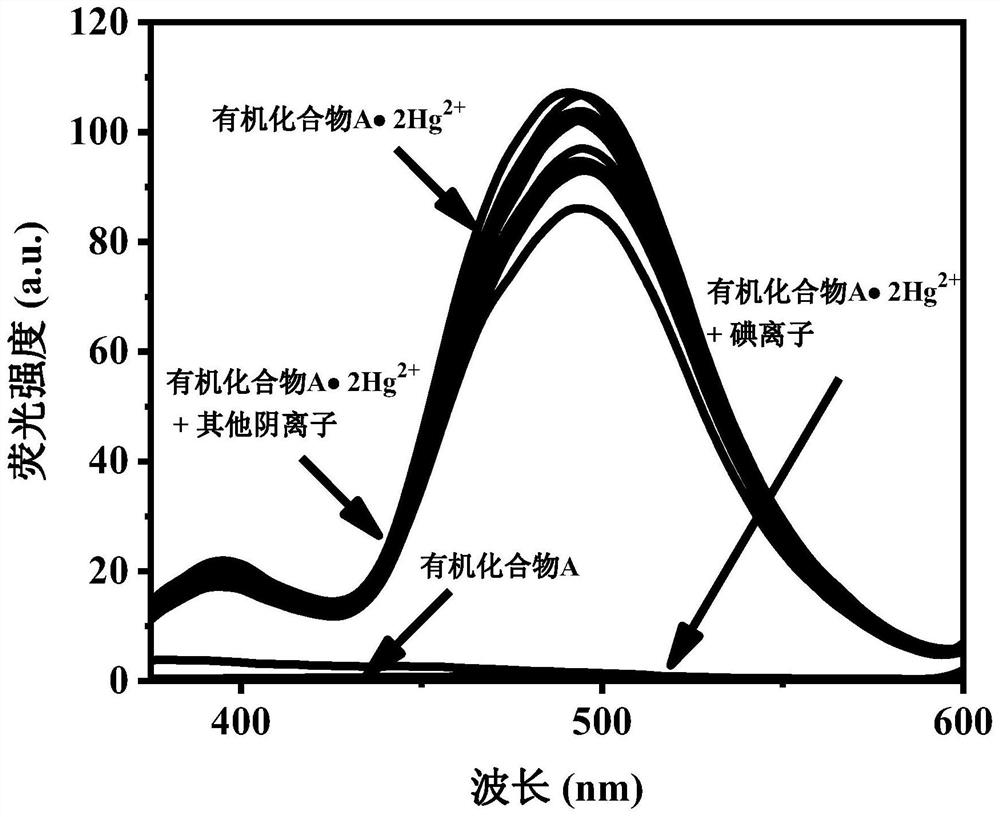

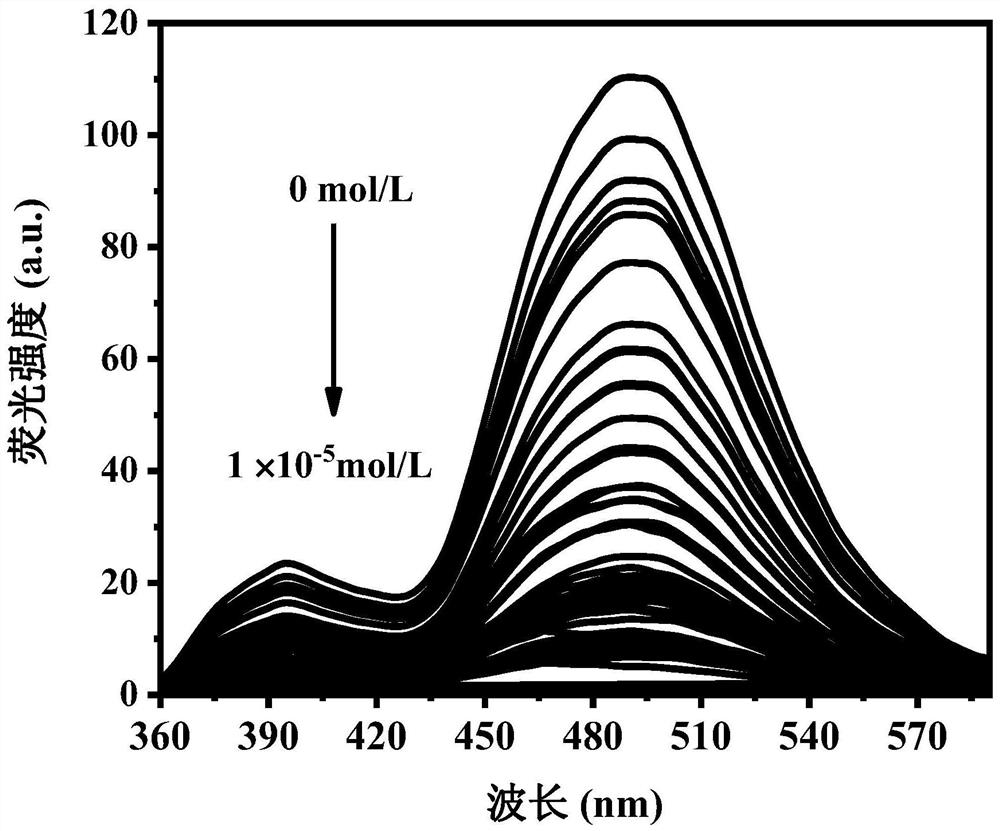

Molecular platform for detecting iodine in different forms by spectrometry and colorimetry as well as preparation method and application thereof

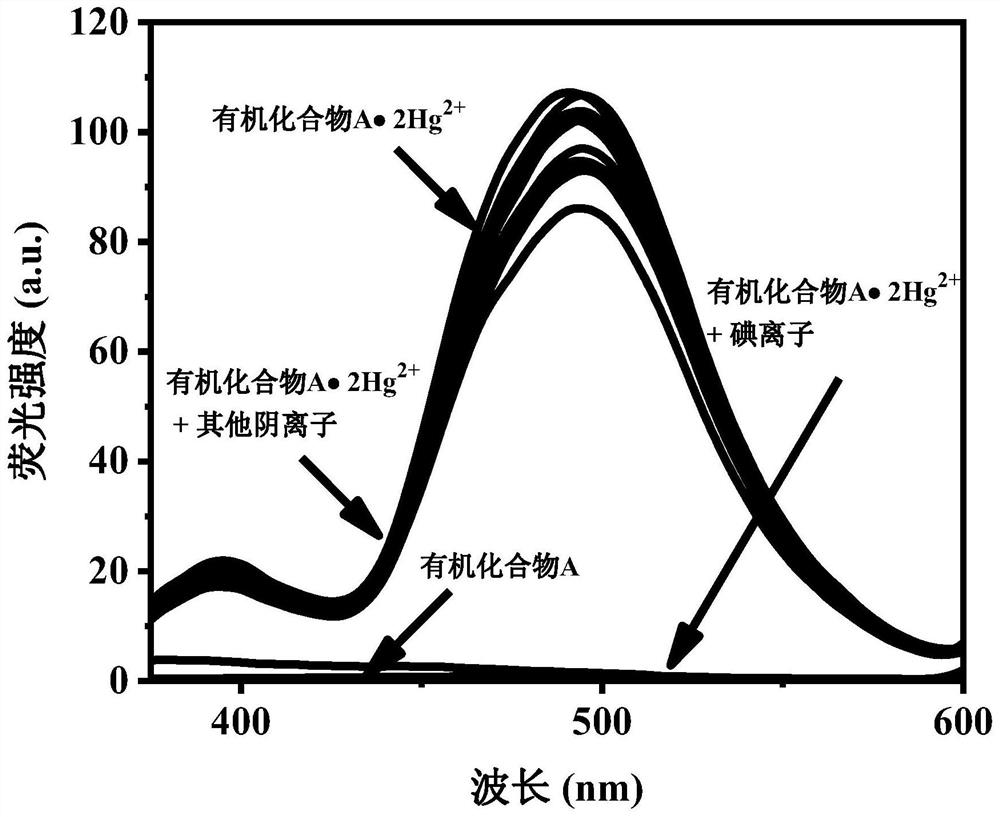

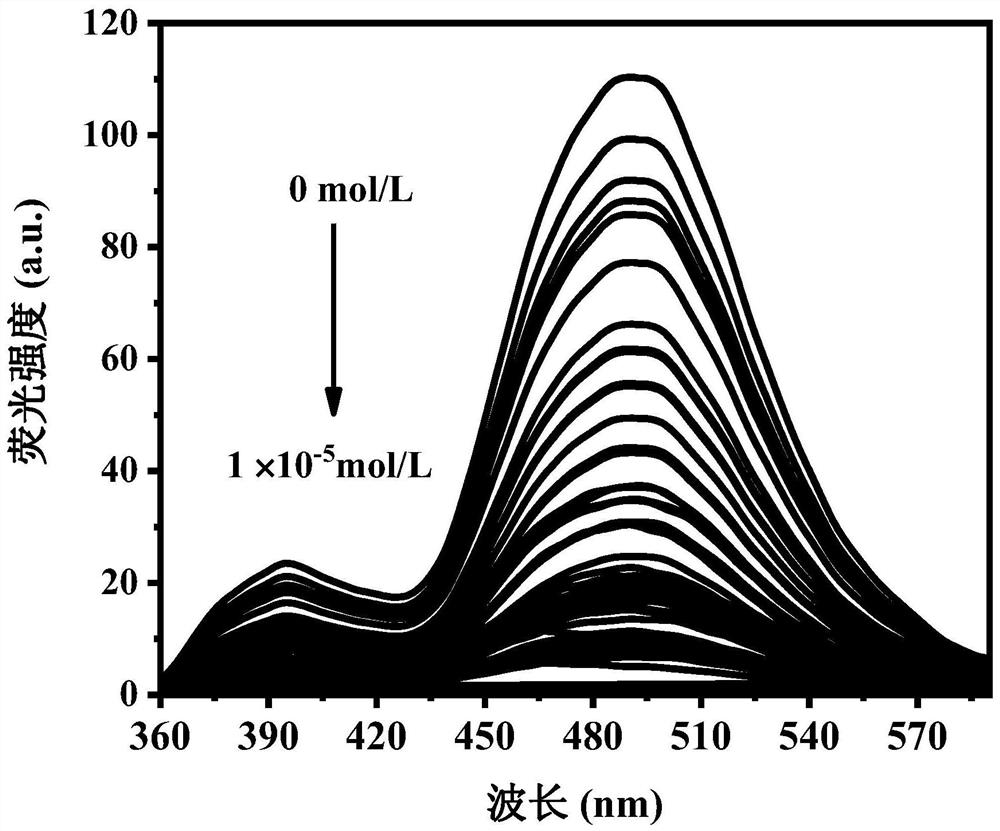

ActiveCN111795960AEasy to makeStable structureOrganic chemistryFluorescence/phosphorescenceStructural formulaOrganic compound

The invention discloses a molecular platform for detecting iodine in different forms by spectrometry and colorimetry as well as a preparation method and application thereof, and relates to a molecularplatform for detecting iodine as well as a preparation method and a detection method thereof. The invention aims to solve the technical problems that the existing iodine detection materials are few in variety, only one form of iodine can be detected, the detection mechanism is single, the detection limit is high, and the detection can be easily interfered by the external environment. The structural formula of the molecular platform is described in the specification. The preparation method of the molecular platform comprises the following steps of: reacting 2-(3-amino-6-hydroxyphenyl) phenanthroimidazole with terephthalaldehyde to obtain an organic compound A, and reacting the organic compound A with mercury nitrate to obtain the molecular platform. The molecular platform can be used for qualitative or quantitative detection of iodide ions, iodine elementary substances or / and iodine vapor in different media. The molecular platform is convenient to use and quick in response, and can beapplied to the field of iodine ion, iodine elementary substance and iodine vapor detection.

Owner:QIQIHAR UNIVERSITY

Combined removal device and method for sulphur, mercury and nitrate in smoke

ActiveCN102824843BLow investment costReduce dosageCombination devicesProcess efficiency improvementOperational costsOxidizing agent

Disclosed are combined removal device and method for sulphur, mercury and nitrate in smoke. The device comprises a sulphur removal system, a combined mercury-nitrate removal system, a mercury ion recovery system, an elementary mercury recovery system, and an oxidant regeneration system. The sulphur removal system is disposed on the lower portion of a column. The combined mercury-nitrate removal system is disposed on the upper portion of the column. The mercury ion recovery system is connected with the bottom of the sulphur removal system. The elementary mercury recovery system is connected with the combined mercury-nitrate removal system. The oxidant regeneration system is connected with the elementary mercury recovery system. The removal method includes smoke purification, mercury atom recovery and chlorine atom recycling. The removal device and method have the advantages that the structure is simple, integrity is high, operational cost is low, materials are recycled, and byproducts can be recycled.

Owner:XI AN JIAOTONG UNIV

Method for detecting content of impurities in titanium sponge

PendingCN108226373ASimple detectabilitySimple stepsChemical analysis using titrationAnalysis by thermal excitationEthylene diamineFiltration

The invention provides a method for detecting the content of impurities in titanium sponge. The method comprises the following steps: 1) weighing titanium sponge, and recording the initial mass of thetitanium sponge; 2) wiping the titanium sponge for removing TiCl4, weighing the wiped titanium sponge, and recording the mass; 3) adding ethanol and a catalyst, performing heating to the preset temperature, and measuring the quantity of the generated gas; 4) adding an acid indicator, and performing titration with acid till the end point of titration; 5) performing filtration for removing insoluble substances, and equally dividing the solution into three parts; 6) adding a metal indicator to the first part of the solution, and performing titration with EDTA (Ethylene Diamine Tetraacetic Acid)till the end point of titration; 7) adding mercury nitrate to the second part of the solution, and performing titration; 8) measuring the content of all Ti elements in the third part of the solution;and 9) calculating the content of all impurities according to the consumption of related substances. The method provided by the invention has the advantages that the needed detection equipment is simple, detection steps are simple, and the content of all substances can be obtained by measuring the content of Mg, Cl and Ti.

Owner:SHENWU TECH GRP CO LTD

Kit for qualitatively detecting tyrosine metabolites in human urine

InactiveCN104880458AEasy to operateInstant resultsMaterial analysis by observing effect on chemical indicatorTreatment effectMetabolite

The invention discloses a kit for qualitatively detecting tyrosine metabolites in human urine. The kit is formed by mixing the following reagents: 0.2-0.5g / mL of mercuric chloride solution, 0.5-1.0g / mL of mercuric nitrate solution, and 0.05-0.1g / mL of ferric nitrate solution, the volume ratio of the mercuric chloride solution to the mercuric nitrate solution to the ferric nitrate solution is 1 to (0.5-2) to (0.5-1.5). The kit disclosed by the invention has the features that the operation method is simple; a special apparatus is not needed; the urine of a patient is adopted for detection, so that the detection is noninvasive, and easy to implement; the result can be instantly obtained; the detection expense is lower than that of the similar method; the kit is suitable for large-scale population screening and therapeutic effect monitoring of cancerous person, and further suitable for the primary hospital.

Owner:SUZHOU RELING BIOTECH CO LTD

Preparation method of wide-spectrum tumor urinalysis reagent

InactiveCN106093033AMaterial analysis by observing effect on chemical indicatorHydroxy compoundMetal mercury

The invention discloses a preparation method of a wide-spectrum tumor urinalysis reagent. The preparation method comprises solution A preparation: making 1 part by weight of metal mercury and 2.1-2.5 parts by weight of nitric acid with a concentration of 1.42g / ml react to produce a mixed solution and measuring a volume Va of the mixed solution, solution B preparation: weighing analytically pure nickel nitrate, dissolving the nickel nitrate in distilled water and adding distilled water into the solution until a concentration of the nickel nitrate solution is in a range of 0.10-0.15g / ml, and mixing: uniformly mixing the solution A and solution B according to a ratio of Va: Vb of 1: 1.5-1.8 to obtain the wide-spectrum tumor urinalysis reagent. The wide-spectrum tumor urinalysis reagent mainly contains mercury nitrate, mercury nitrite, nickel nitrate, nitric acid and a small amount of nitrous acid. The detected object is a phenolic hydroxyl group-containing amino acid derivative in urine. The wide-spectrum tumor urinalysis reagent obtained by the preparation method has high detection accuracy, a low false positive rate and good use safety.

Owner:江西格朗生物技术有限公司

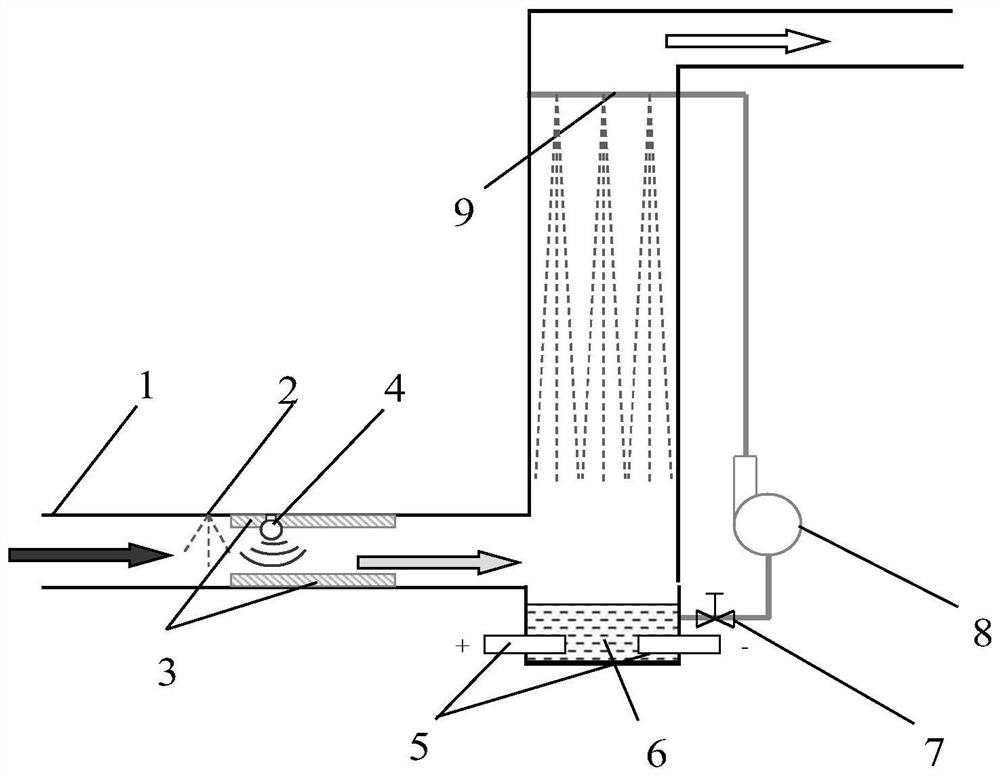

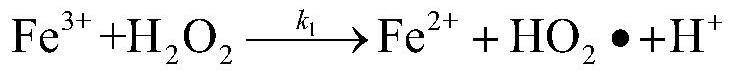

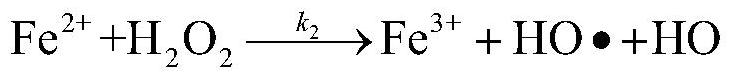

Photoelectric synergistic catalytic oxidation and wet absorption mercury nitrate integrated removal system and method

PendingCN113648812AEnable recyclingRegulate operating energy consumptionGas treatmentDispersed particle separationAtomizer nozzleCatalytic oxidation

The invention discloses a photoelectric synergistic catalytic oxidation and wet absorption mercury nitrate integrated removal system and method. The system can simultaneously remove elemental mercury and nitrogen oxide in coal-fired flue gas, and two devices are used for respectively carrying out photoelectric synergistic catalytic oxidation elemental mercury and wet absorption and removal of mercury and nitrogen elements. Atomizing nozzles are arranged in a flue gas pipeline, a hydrogen peroxide solution containing ferrous sulfate hexahydrate is sprayed, elemental mercury is efficiently converted into water-soluble divalent mercury under the action of an electrode plate electric field and an ultraviolet lamp, then the flue gas enters a subsequent wet-process denitrification device. The mercury and nitrogen elements in the flue gas can be absorbed and removed at the same time. The system can be modified on the basis of the existing wet denitrification process, is simple in process flow, low in investment cost and high in removal efficiency, and has relatively high economic value and practical production significance.

Owner:XI AN JIAOTONG UNIV

Color-changing coating for copper

InactiveCN103665967ALow discoloration temperatureHigh precisionThermosensitive paintsCupric nitrateEuropium(III) oxide

A color-changing coating for copper comprises the components in parts by mass as follows: 100 parts of potassium iodide, 15-30 parts of nitric acid, 15-20 parts of cupper nitrate, 15-25 parts of strontium nitrate, 25-45 parts of aluminum nitrate, 10-25 parts of mercury nitrate, 10-20 parts of silver nitrate, 5-10 parts of europium oxide, 10-20 parts of dysprosium oxide, 10-15 parts of ammonium carbonate, 5-10 parts of ammonium bicarbonate, 15-25 parts of sulfur dioxide and 10-20 parts of water. The color-changing coating turns red from orange at the temperature of 35 DEG C, turns orange yellow from red at the temperature of 40 DEG C, turns orange red from orange yellow at the temperature of 45 DEG C and turns brown from orange red at the temperature of 50 DEG C.

Owner:JIANGSU PAQINI COPPER IND

Method for analyzing chlorine content in rubber

InactiveCN111044665AReduce stepsReduce generationComponent separationAlcoholEnvironmental engineering

The invention discloses a method for analyzing chlorine content in rubber. According to the key technology, an oxygenated combustion device is adopted, and standard operation of analysts is achieved;an ion chromatograph is used for an analysis technology, so that operation steps in a sample analysis process are reduced, and operation is simpler and more convenient and is easy to master; analysiserrors are reduced, the amount of used reagents is small, generated waste liquid is little, a large amount of ethyl alcohol is not used, no characteristic pollutant is generated, particularly, a mercury-containing reagent, namely mercury nitrate, is not used, and it is not required to collect the mercury-containing reagent or treat the mercury-containing reagent by qualified departments. And the difference between two results of parallel determination is not greater than 5% of the average value of the two results, so that the existing technical problems are solved, and the requirement of analyzing and testing the chlorine content in rubber is completely met.

Owner:GANSU YINGUANG CHEM IND GRP CO LTD

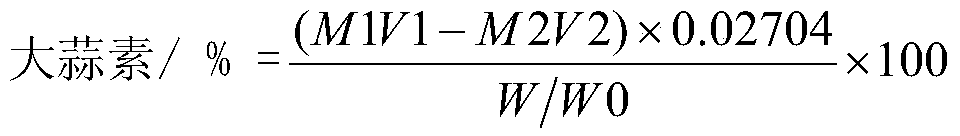

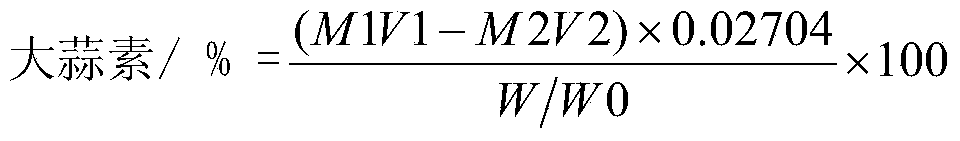

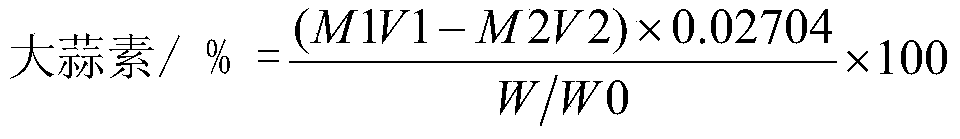

Method for detecting garlicin by mercury nitrate precipitation method

InactiveCN105510171AEasy to operateLess time consumingWeighing by removing componentTrichloroacetic acidTime-Consuming

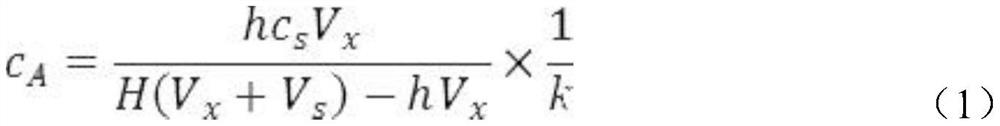

The invention relates to a method for detecting garlicin by a mercury nitrate precipitation method. the method of the invention comprises the following steps: (1) removing impurities such as protein from a garlic extracting solution by the use of trichloroacetic acid, centrifuging and fetching a supernatant; (2) carrying out a reaction between the supernatant and excessive mercury nitrate to generate a milk white precipitate; and (3) using ammonium ferric sulfate as an indicator, carrying out titration on the rest mercury nitrate solution by the use of a KSCN solution, and calculating content of garlicin by the formula (I). The detection method of garlicin can be adopted to directly detect content of garlicin, is simple to operate, and is less time-consuming.

Owner:张瑞节

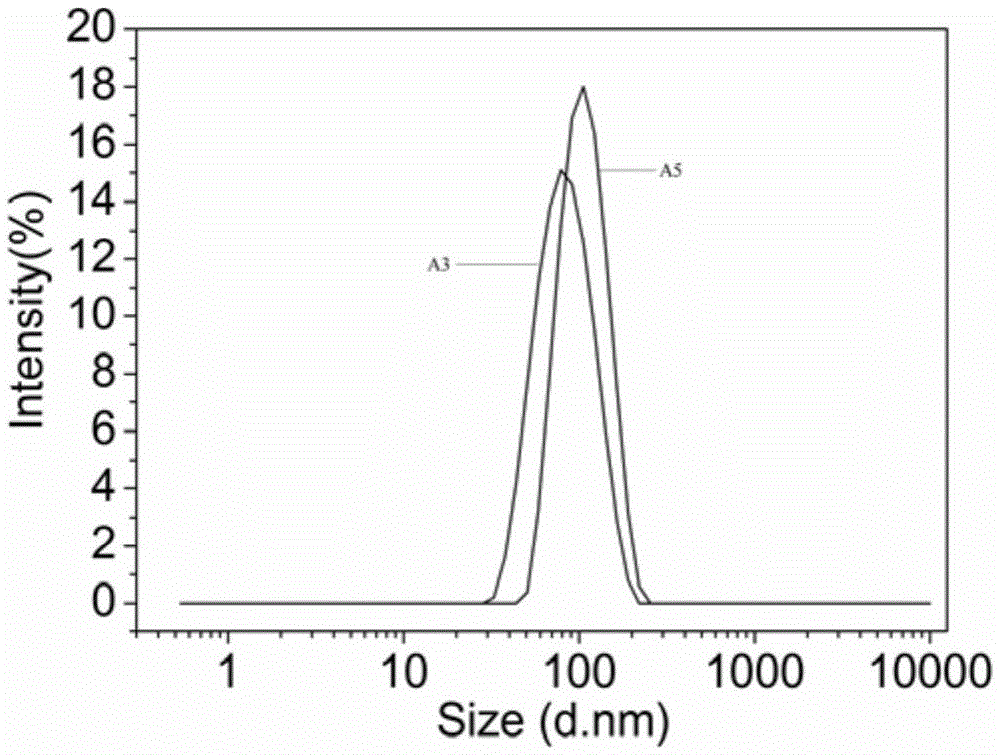

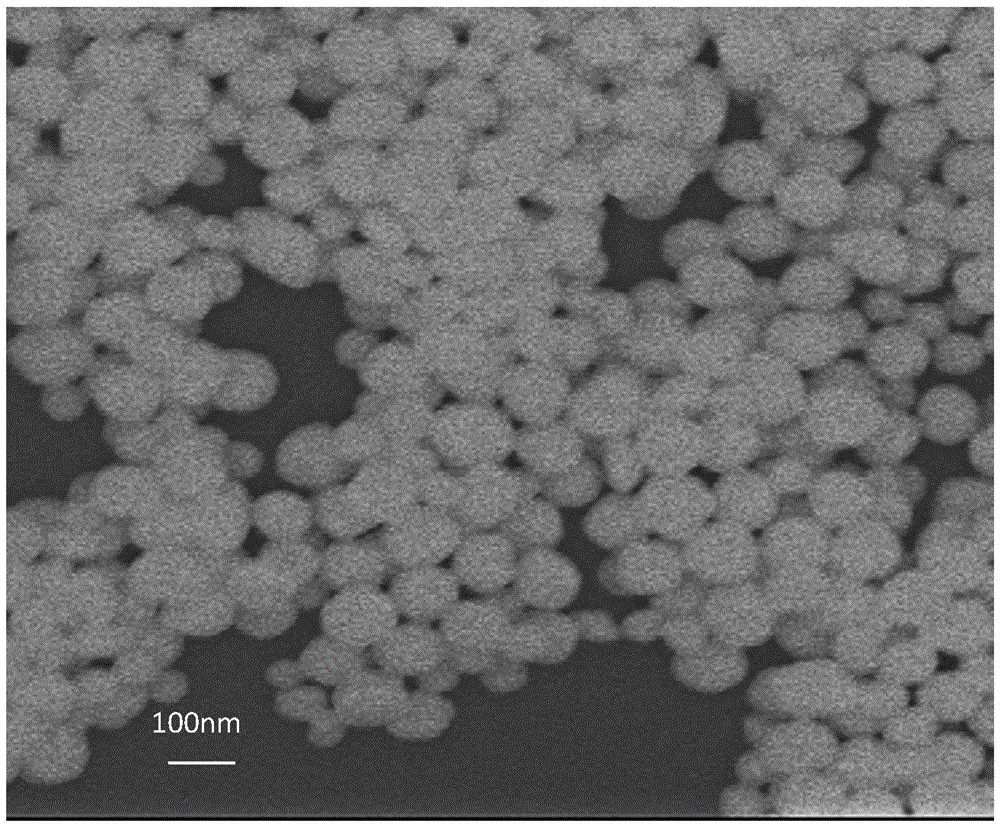

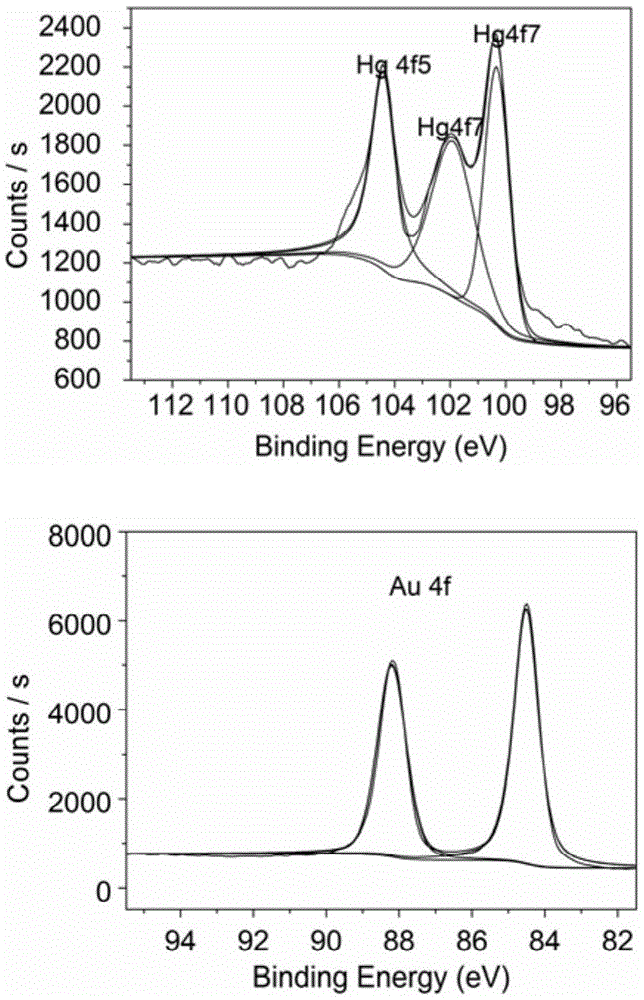

Preparation method of gold mercury amalgam nano particle with high catalytic activity and application thereof

The invention discloses a preparation method of a gold mercury amalgam nano particle with a high catalytic activity and an application thereof. The preparation of the gold mercury amalgam nano particle comprises the following steps: taking sodium citrate as a reducing agent, and synthesizing a gold nano particle by reducing chloroauric acid step by step; physically loading the gold nano particle to a surface of a glassy carbon electrode surface, then taking the glassy carbon electrode as a working electrode, placing the glassy carbon electrode into a mercury nitrate solution, obtaining a glassy carbon electrode of the surface modified gold mercury amalgam nano particle through a cyclic voltammetry, and performing an ultrasonic treatment, then the gold mercury amalgam nano particle can be obtained. The preparation method is simple, low in cost and simple and convenient in operation; the prepared gold mercury amalgam nano particle shows an obvious electrocatalytic activity for oxygen reduction, and has a better stability and a potential application value in fuel cells, environmental catalysis and other aspects.

Owner:CENT SOUTH UNIV

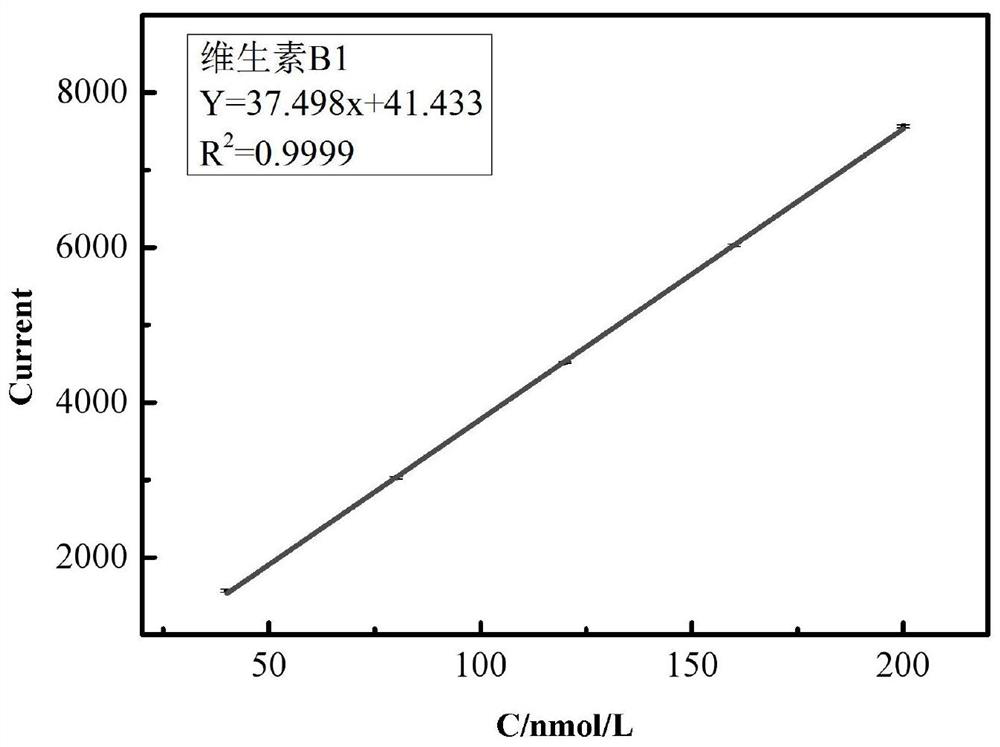

Preparation method of modified electrode for detecting vitamin B1 and detection method thereof

InactiveCN112557470AAccurate measurementHigh sensitivityMaterial electrochemical variablesInfrared lampCopper electrode

The invention belongs to the technical field of vitamin detection methods, and particularly relates to a preparation method of a modified electrode for detecting vitamin B1. The method comprises the following steps: selecting a glassy carbon electrode or a copper electrode as a matrix electrode, and polishing and cleaning the surface of the matrix electrode for later use; and dropwise coating or electroplating a modification solution on the surface of the matrix electrode, and drying by using an infrared lamp to obtain the modified electrode, wherein the modification solution is composed of one or more of hydrochloric acid, nitric acid, acetic acid, bismuth nitrate, mercury nitrate, silver nitrate, potassium chloride, sodium chloride, cadmium nitrate, lead nitrate and amino black 10B, andthe concentration of each component ranges from 0.0001 mol / L to 1 mol / L. The method overcomes the defects in the prior art, has the advantages of high sensitivity, good reproducibility, convenience and quickness in operation and the like, and accurately measures the content of vitamin B1 in a blood sample.

Owner:合肥天一生物技术研究所有限责任公司

A molecular platform for spectroscopic and colorimetric detection of different forms of iodine and its preparation method and application

ActiveCN111795960BEasy to makeStable structureOrganic chemistryFluorescence/phosphorescenceStructural formulaOrganic compound

A molecular platform for detecting different forms of iodine by spectrometry and colorimetry, as well as a preparation method and application thereof, relate to a molecular platform for detecting iodine and a preparation and detection method thereof. It is to solve the technical problems that the existing iodine detection materials have few types, can only detect one form of iodine, a single detection mechanism, a high detection limit, and is easily disturbed by the external environment. The structural formula of the molecular platform of the present invention is: preparation method : After reacting with 2-(3-amino-6-hydroxyphenyl) phenanthroimidazole and terephthalaldehyde, organic compound A is obtained, and organic compound A is reacted with mercury nitrate to obtain molecular platform. The molecular platform can be used for qualitative or quantitative detection of iodide ion, elemental iodine or / and iodine vapor in different media. The utility model has the advantages of convenient use and rapid response, and can be used in the detection field of iodide ion, elemental iodine and iodine vapor.

Owner:QIQIHAR UNIVERSITY

Method for preparing cuprous oxide

The invention discloses a method for preparing cuprous oxide and belongs to the technical field of cuprous oxide preparation.The method includes the steps that bottom mud of a metallurgy sewage treatment plant is collected, after the bottom mud is mixed with water and a mercury nitrate solution and centrifuged, supernate containing mercury clostridium is obtained, then a culture solution is prepared from methyl cobalt ammonia, glycine betaine and the like, rocking bed shaking culture is conducted on the culture solution, after standing and filtering are conducted, triphosadenine is added to filtrate and mixed, diethyl ether is added for extraction, formaldehyde is added to extraction liquor, after anaerobic reduction is conducted, the mixture is mixed with copric chloride dihydrate and soaked for a reaction, starch is added for anaerobic fermentation, then aeration is conducted on the mixture, centrifugation is conducted, sediment on the lower layer is taken, and the cuprous oxide is obtained after washing, drying and grinding are conducted.The method has the advantages that the preparation steps are simple, purity of an obtained product is 19.2% or above higher than that of other products, and the particle size is small and uniform; particles are not prone to clustering in the formation process, dispersing performance is high, and the yield is raised by 30-40%.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

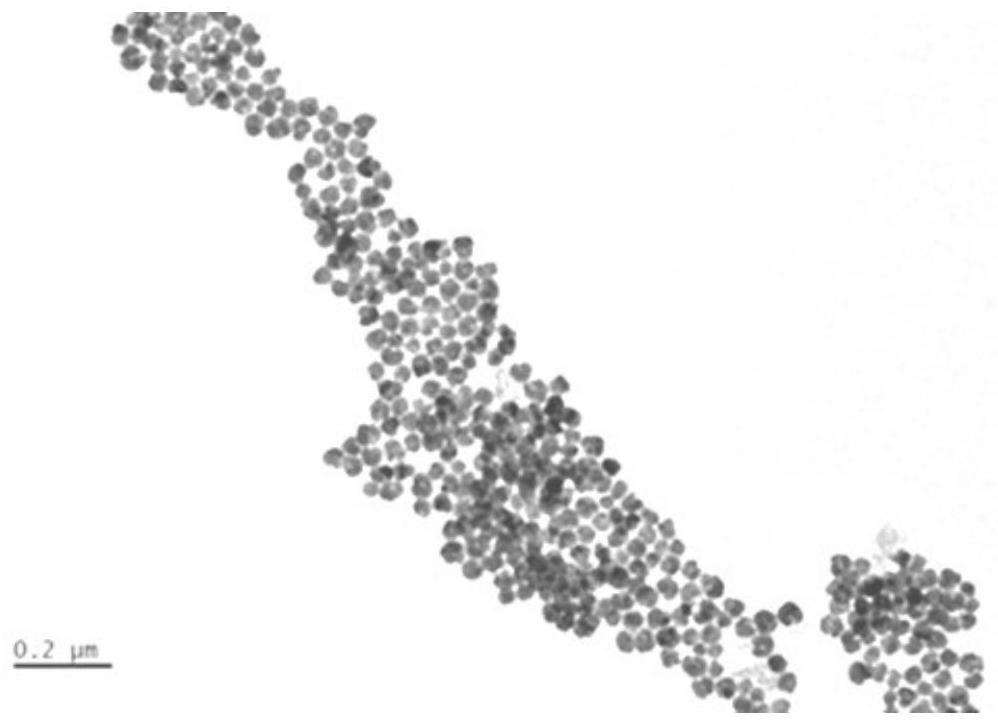

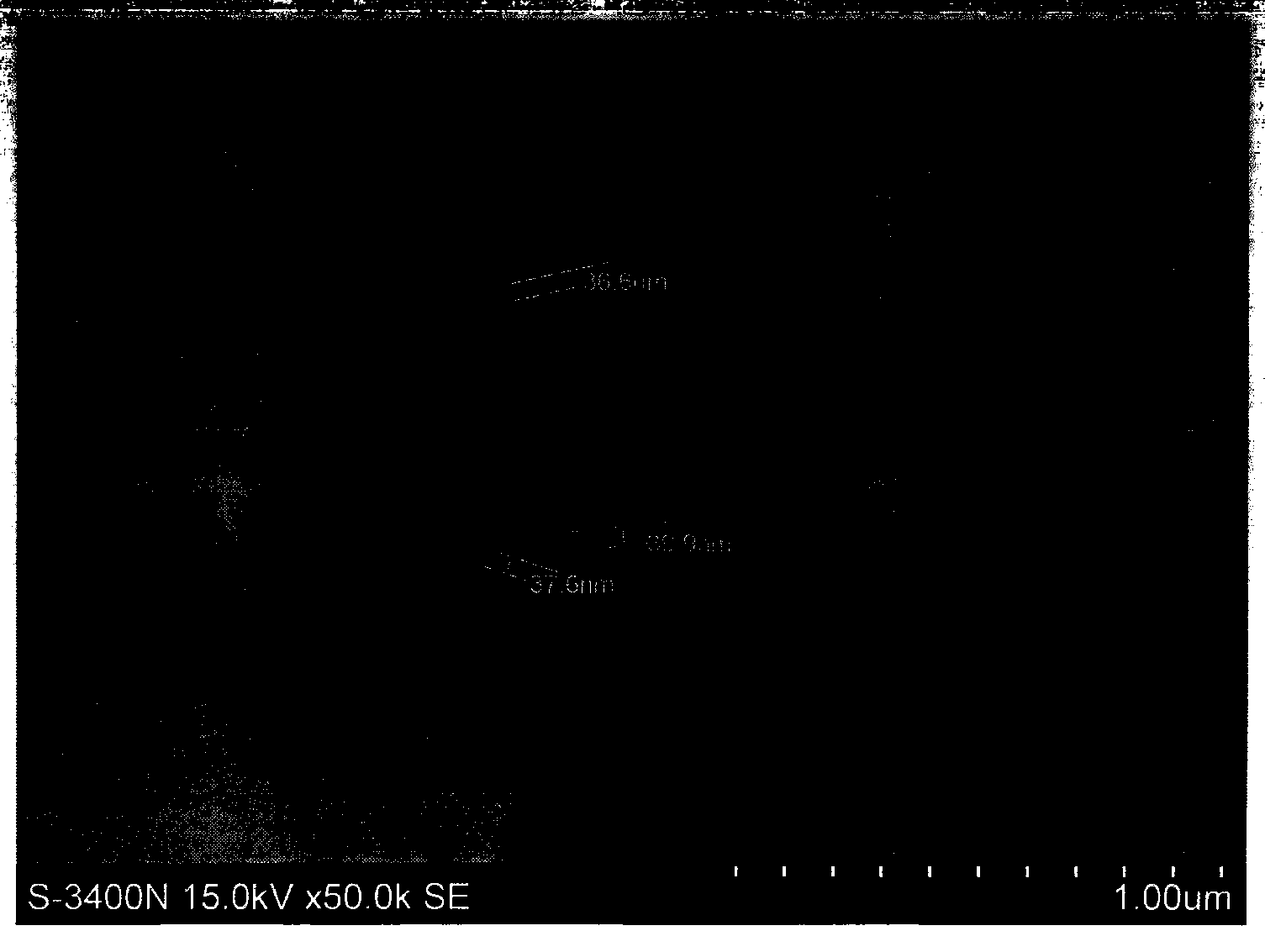

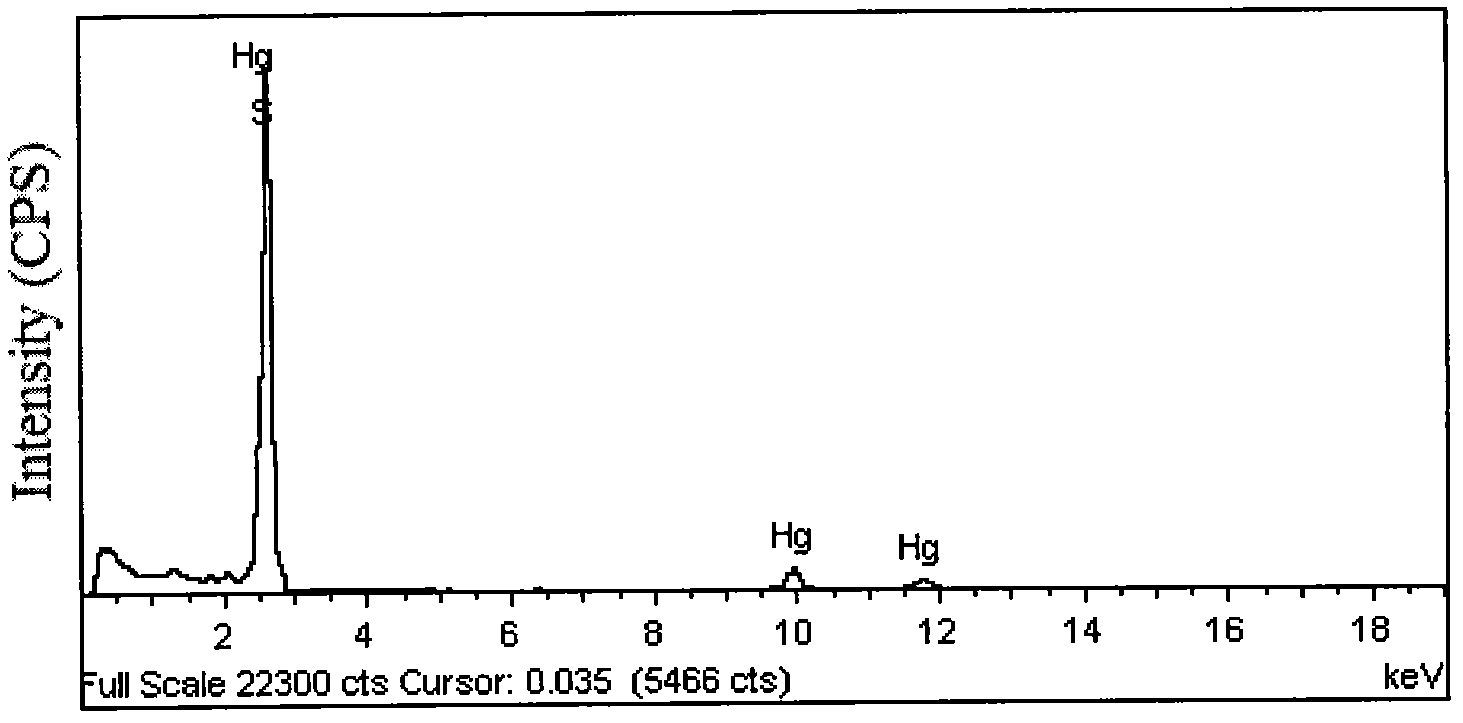

A method for rapidly preparing spherical mercury sulfide nanoparticles

ActiveCN112194172BSingle crystal formGood dispersionNanotechnologyMercury compoundsFreeze-dryingPyrrolidinones

The invention belongs to the field of semiconductor nanomaterial preparation, in particular to a method for rapidly preparing spherical mercury sulfide nanoparticles, aiming at the existing problem of not being able to save energy and time, and synthesizing mercury sulfide nanoparticles with uniform shape and size and good dispersibility. Propose the following scheme, which includes the following steps: S1: Preparation of reaction mixture: at room temperature, add 0.5mmol of mercury nitrate, 0.5mmol of sulfur powder, and 0.15g of polyvinylpyrrolidone to 500g of ethylene glycol to prepare a mixture; S2: Synthesis of mercury sulfide nanoparticles: transfer the mixed solution into an oil bath filled with dimethyl silicone oil, and perform magnetic stirring to make the mixed solution react for 2 hours; S3: Separation of mercury sulfide nanoparticles: transfer the mixed solution from the bath Take it out from the pot, add an equal volume of ultrapure water and centrifuge for 15 minutes, remove the supernatant to retain the precipitate, and wash the precipitate with ultrapure water, and the precipitate will be spherical mercury sulfide nanoparticles after freeze-drying. The solvothermal synthesis system of the present invention can be used to prepare spherical nano-mercuric sulfide; the obtained spherical nano-mercuric sulfide particles have a single crystal form, good dispersibility, uniform shape and high stability; the method and process are simple, time-consuming, and the reaction temperature Low energy consumption, low cost of raw materials, easy to obtain, and conducive to industrial production.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

The preparation method of Mongolian medicine silver bead nanopowder

The invention discloses a preparation method for mongolian medicine vermilion nanometer powder. The method is as follows: mercury nitrate and thioacetamide are used as raw materials for preparation of nanometer mercuric sulfide by using a wet process; a solution with a certain concentration is prepared from the raw materials; the raw materials are rapidly mixed under magnetic stirring, and the solution is uniformly heated until the solution boils so as to prepare nanometer mercuric sulfide powder. According to the invention, environmental pollution in traditional preparation processes for mongolian medicine vermilion is reduced, the process of preparation is more controllable, components are more specific, and quality of different batches of the nanometer powder is stable.

Owner:INNER MONGOLIA MEDICAL COLLEGE

Method for producing silver chloride and bismuth nitrate from mercury-containing waste liquid

The invention discloses a method for producing silver chloride and bismuth nitrate from a mercury-containing waste liquid. The method comprises feeding a waste mercury catalyst into a seal-type distiller, carrying out distillation so that mercuric chloride is directly sublimated to form gas and is cooled to form a liquid, carrying out a reaction process on the mercuric chloride solution and the silver nitrate solution to obtain a silver nitrate precipitate-mercury nitrate mixed solution, carrying out enclosed pumping filtration to obtain silver chloride filter cake, carrying out washing, drying, crushing and packaging to obtain a silver chloride product, further processing the clear mercury nitrate solution, carrying out a reaction process on the mercury nitrate solution and a bismuth hydroxide emulsion to produce a mercuric oxide precipitate-bismuth nitrate mixed solution, filtering the mixed solution to obtain mercuric oxide filter cake, carrying out washing, spin-drying, drying, crushing and packaging to obtain a mercuric oxide product, carrying out distillation on the clear bismuth nitrate solution, carrying out cooling, carrying out crystallization and carrying out packaging to obtain a bismuth nitrate crystal product. The method effectively prevents waste mercury catalyst-caused environmental pollution and produces high economic benefits.

Owner:CHANGDE YUNGANG BIOTECHNOLOGY CO LTD

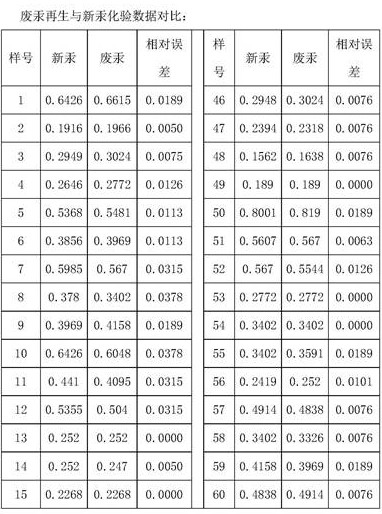

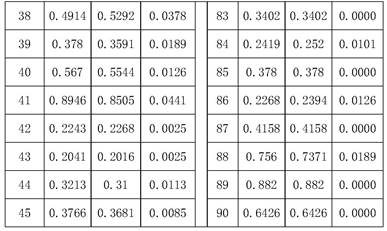

Synergistic waste mercury regeneration technique and soaking precipitation pool thereof

PendingCN113604674ATo regenerateAffirmative recyclingProcess efficiency improvementChemical reactionEnvironmental engineering

The invention discloses a synergistic waste mercury regeneration technique and a soaking precipitation pool thereof, and relates to the technical field of ore excavation. The technique comprises the following steps that original waste mercury is collected, and injected into a particulate filter through a corrugated suction pipe, at the moment, particulate impurities on the surface of the original waste mercury are filtered through the particulate filter, and the particulate impurities are discharged into a particulate collection box through a particulate discharge pipe; residual waste mercury in the particulate filter can be discharged into a precipitation pool body, and at the moment, 2% or more of nitric acid is poured into the precipitation pool body through an immersion pipe, so that the waste mercury is soaked in the nitric acid, and meanwhile, the waste mercury reacts with the nitric acid to generate mercuric nitrate; and after mercury nitrate is generated, the mercury nitrate and metal elements in the original waste mercury are subjected to a replacement reaction, mercury in the mercury nitrate is replaced at the moment, and the waste mercury is regenerated at the moment. According to the technique, through the chemical reaction between nitric acid and waste mercury, recycling of waste mercury is achieved, and cost waste is reduced.

Owner:云南金鼎锌业有限公司

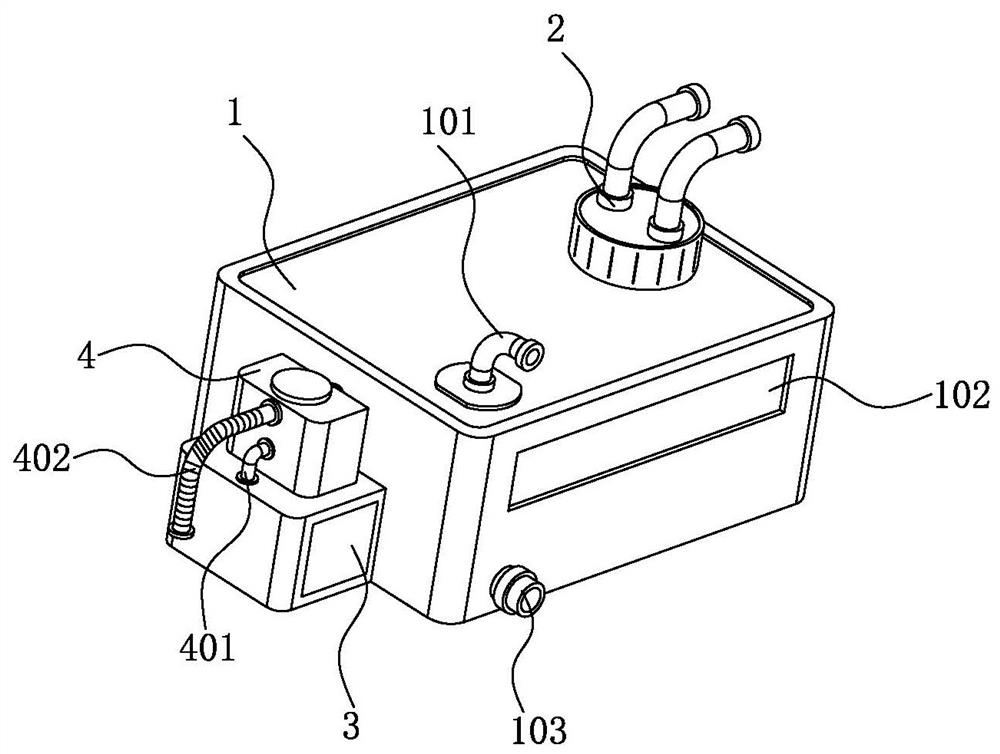

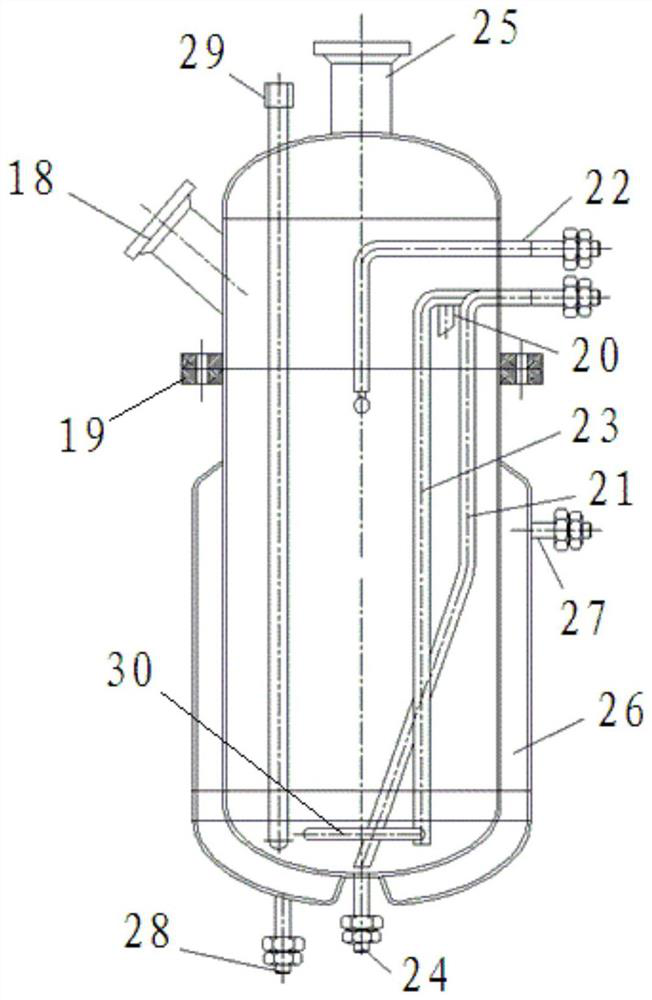

An Aluminum Matrix Mercury Catalytic Technology Dissolving System

ActiveCN111187902BEffective dissolutionControl the speed of the dissolution reactionProcess efficiency improvementFuel reprocessingTemperature control

The invention belongs to the technical field of spent fuel reprocessing, and specifically relates to a system for dissolving aluminum matrices by virtue of mercury catalysis technology. The system isused for dissolving aluminum matrix rings of a neptunium target by virtue of a mercury catalysis dissolution reaction. The system comprises a strong-acid-resistant and high-temperature-resistant dissolving tank (1), wherein the dissolving tank (1) is provided with a feeding chute (18) and used for performing the mercury catalysis dissolution reaction; a temperature control device for adjusting thetemperature of the dissolving tank (1) is arranged on the periphery of the dissolving tank (1); the dissolving tank (1) is also provided with, in a running-through manner, a dripping pipe (22) for adding nitric acid, a charging pipe (20) for adding a mercuric nitrate solution, a bubbling pipe (23) for introducing nitrogen into a dissolving solution in the dissolving tank (1), and a discharging pipe (21) for discharging the dissolving solution in which the aluminum matrix rings are dissolved; and the top of the dissolving tank (1) is also provided with an exhaust outlet (25). The system for dissolving the aluminum matrices by virtue of the mercury catalysis technology can control and recover a large amount of H2 and NOx gases generated in the dissolution reaction, and can control the speedof the dissolution reaction so as to avoid a risk of explosion caused by over high concentration of H2.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A human urine detection reagent for monohydric phenol metabolites

Owner:浙江道家医疗科技有限公司

Mercury-containing waste catalyst recycling method

A mercury-containing waste catalyst recycling method relates to the technical field of ''three wastes'' treatment and utilization of organic industrial waste mercury catalysts. A waste mercury catalyst undergoes the following three steps for preparation of silver chloride and co-production of mercuric oxide and aluminium nitrate: firstly, sending the waste mercury catalyst into a sealed distillerfor distillation to directly sublimate mercuric chloride into a gas, and cooling to obtain liquid mercuric chloride; then carrying out a reaction between the above mercuric chloride solution and a silver nitrate solution to generate silver chloride precipitate and mercury nitrate mixed solution; carrying out closed suction filtration to obtain a filter cake silver chloride, washing and drying, crushing and packaging to obtain a silver chloride product; processing the clarified mercury nitrate solution; carrying out a reaction between the above mercuric nitrate solution and an aluminium hydroxide emulsion to generate mercuric oxide precipitate and aluminium nitrate mixed solution; filtering to obtain a filter cake mercuric oxide, washing, spin-drying, drying, crushing, and packaging to obtain a mercuric oxide product; and distilling the clarified aluminium nitrate solution, cooling, crystallizing and packaging to obtain an aluminium nitrate crystal product. By the method, the pollutionof the waste mercury catalyst to the environment is effectively prevented, and high economic benefit is generated.

Owner:张妮妮

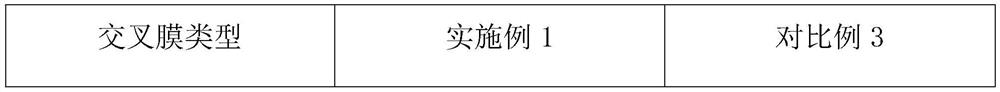

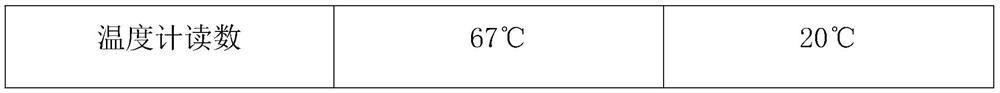

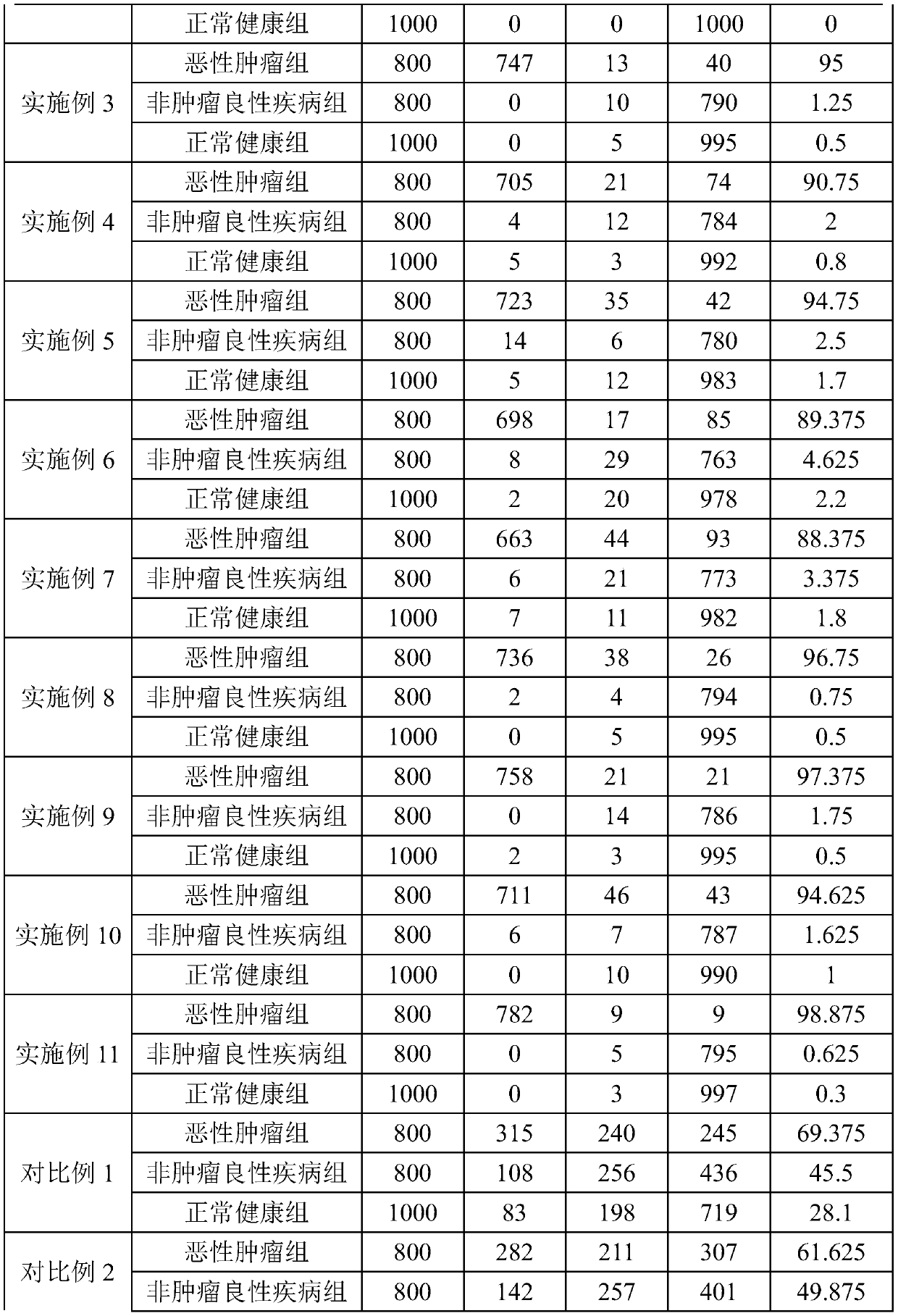

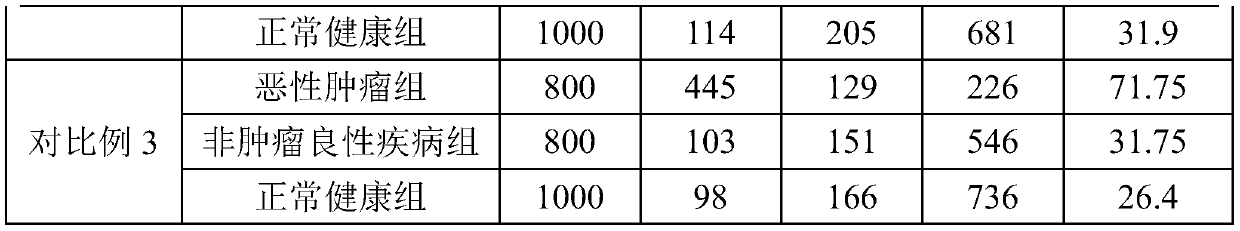

High-performance tensile nano-modified strong cross membrane and preparation method thereof

InactiveCN112708159AGood hygroscopicityHigh densityBuilding insulationsElectrolytic agentMercuric ion

The invention discloses a high-performance tensile nano-modified strong cross membrane and a preparation method thereof. The high-performance tensile nano-modified strong cross membrane comprises zirconium-modified phosphogypsum, a chloroethane cured product, a mercury nitrate solution, a sodium chloride electrolyte, a tackifier, a softener, a coupling agent and rubber. The surface of the zirconium-modified phosphogypsum has a large number of binding sites, so that the adhesion between the cross membrane and a cement base is enhanced, water permeation is prevented, the zirconium-modified phosphogypsum has hygroscopicity, the density is increased after water absorption saturation, permeation of water molecules is prevented, moisture is evaporated after drying, the density is recovered, and the durability is improved. Chloroethane is hydrolyzed to release heat to evaporate moisture and prevent the moisture from damaging the cross membrane, reaction is performed in the reverse direction after moisture evaporation, a large amount of heat is absorbed, heat on a house is taken away, and the inside of the house is cool. When the cross membrane is on fire, mercurous chloride reacts with diluted hydrochloric acid to generate a mercurous chloride film to cover a fire point, mercury ions absorb heat while oxygen is isolated, the temperature is reduced to be lower than the fire point to extinguish fire, and a fire disaster is prevented.

Owner:江苏求实塑业有限公司

Urine 5-hydroxyindoleacetic acid detection reagent and preparation method thereof

InactiveCN110940663AAvoid interferenceHigh sensitivityMaterial analysis by observing effect on chemical indicatorPhosphomolybdic acidO-Phosphoric Acid

The invention discloses a urine 5-hydroxyindoleacetic acid detection reagent. The detection reagent is an aqueous solution containing nitric acid, phosphoric acid, mercury nitrate, mercurous nitrate,zinc nitrate, phosphomolybdic acid and silicotungstic acid, wherein the concentration of the mercury nitrate is 0.12 mol / L to 0.35 mol / L, the concentration of the mercurous nitrate is 0.56 to 1.15 mol / L, the concentration of the zinc nitrate is 0.25 to 1.37 mmol / L, the concentration of the phosphomolybdic acid is 0.63 to 3.10 mmol / L, and the concentration of the silicotungstic acid is 2.19 to 8.20mmol / L. The invention further provides a preparation method of the urine 5-hydroxyindoleacetic acid detection reagent. The urine 5-hydroxyindoleacetic acid detection reagent is prepared by mixing theprepared mercury nitrate solution, mercurous nitrate solution, zinc nitrate solution, phosphomolybdic acid solution and silicotungstic acid solution according to a certain proportion. The urine 5-hydroxyindoleacetic acid detection reagent disclosed by the invention is simple in preparation process, high in detection result accuracy, good in specificity and convenient and rapid in detection process, has universality when being used for cancer detection, and is suitable for large-scale popularization.

Owner:欧迪玛(湖北)生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com