Combined removal device and method for sulphur, mercury and nitrate in smoke

A combined removal and flue gas technology, applied in the field of combined removal of nitrate, mercury, and sulfur in flue gas, can solve the problems of weakening economy, high cost, and failure to recycle mercury elements, so as to reduce investment costs, Reduce dosage, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

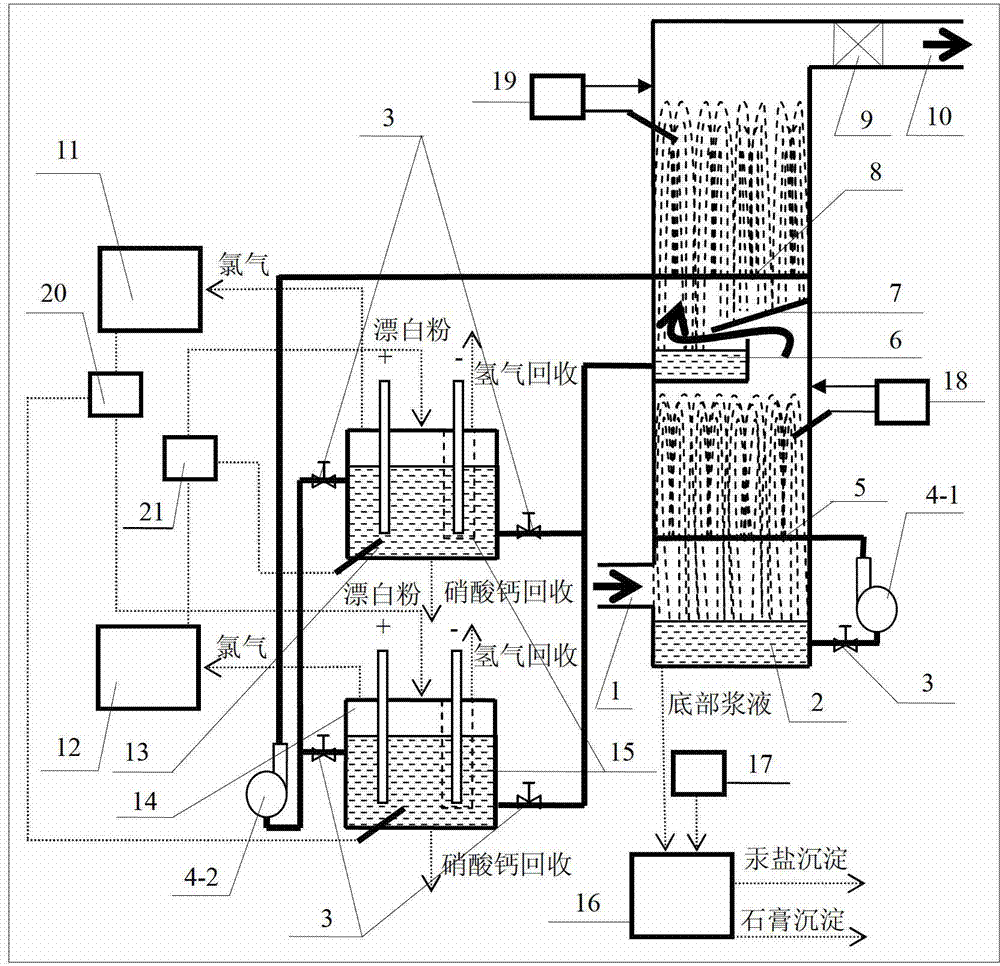

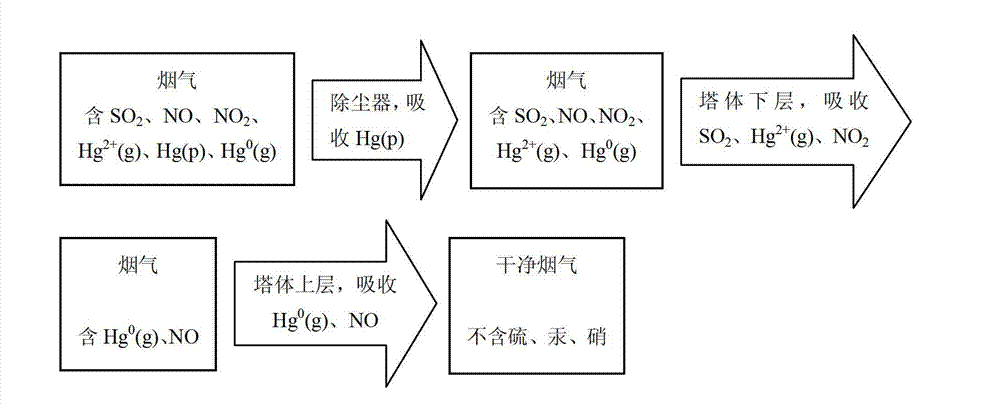

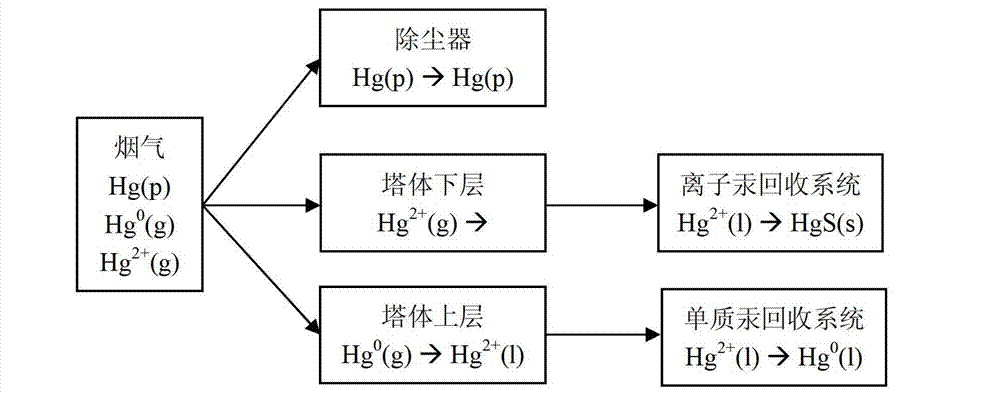

[0038] Tower part: This part is divided into two layers to remove pollutants in the flue gas. The dust from the dust collector contains SO 2 , NO, NO 2 , Hg 2+ (g) and Hg 0 (g) The flue gas at 90-120°C enters the lower layer of the tower body from the flue gas inlet 1, and the desulfurizing agent slurry in the desulfurizing agent slurry pool 2 is controlled at 5.8-6.2 by the first pH online monitoring feedback adjustment device 18 In between, the desulfurizer slurry is regulated by the flow control valve 3, and is transported to the desulfurizer slurry spray pipe 5 by the desulfurizer slurry circulation pump 4-1, and the desulfurizer slurry spray pipe 5 is sprayed upward to form a liquid curtain, and the flue gas Contact with the liquid curtain to generate mass transfer and reaction, and remove SO in the flue gas 2 , NO 2 and Hg 2+ (g). Contains NO and Hg at this time 0 The flue gas of (g) continues upwards, and the space between the oxidant slurry tank 6 and the oxida...

Embodiment 2

[0070] In the first electrolytic cell 13 or the second electrolytic cell 14 in embodiment 1, the oxidant slurry in the upper layer of the tower body oxidizes NO and Hg 0 At the same time as (g), it is in the state of continuous energization and electrolysis. The working process of this embodiment is similar to that of embodiment 1, and the difference with embodiment 1 is: in the flue gas Hg 0 (g) When the concentration is low, the first electrolytic cell 13 or the second electrolytic cell 14 does not conduct electrified electrolysis until the Hg in the oxidizing agent slurry 2+ (l) After accumulating to a certain concentration, then energize and electrolyze out Hg 0 (l), which can save power consumption compared with continuous energization electrolysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com