Patents

Literature

34 results about "Europium(III) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Europium(III) oxide (Eu₂O₃), is a chemical compound of europium and oxygen. It is widely used as a red or blue phosphor in television sets and fluorescent lamps, and as an activator for yttrium-based phosphors. It is also an agent for the manufacture of fluorescent glass. Europium fluorescence is used in the anti-counterfeiting phosphors in Euro banknotes.

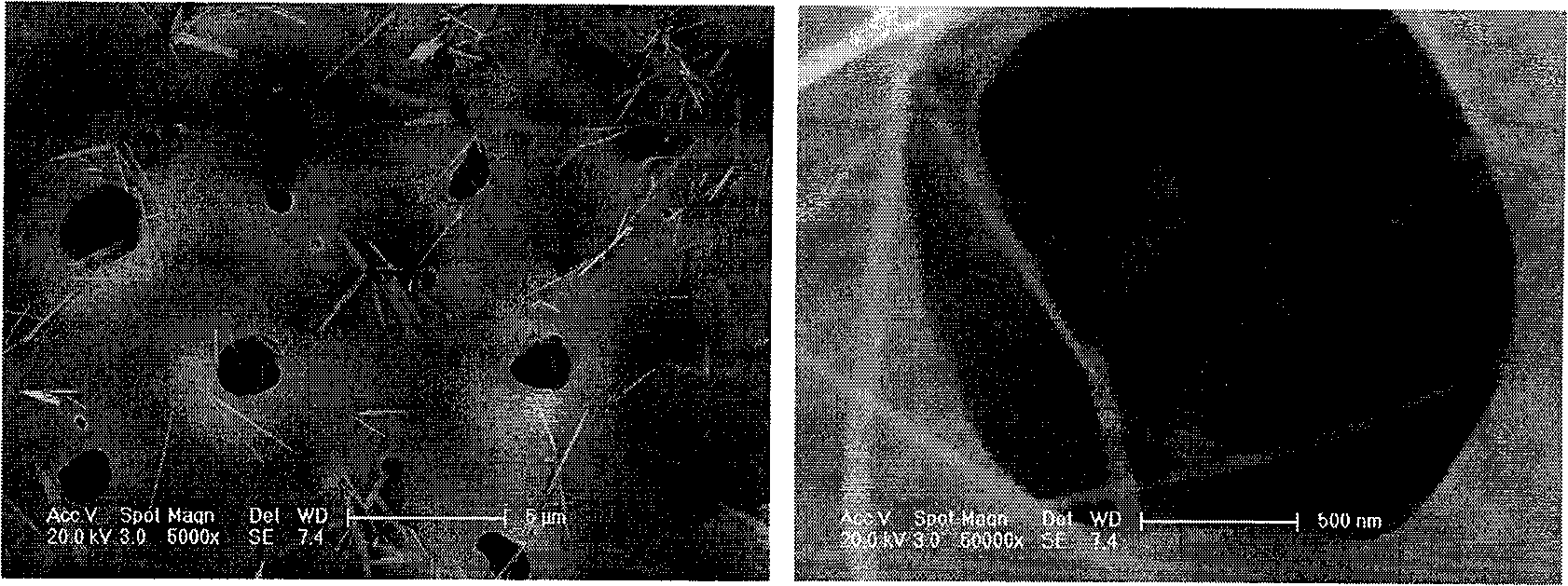

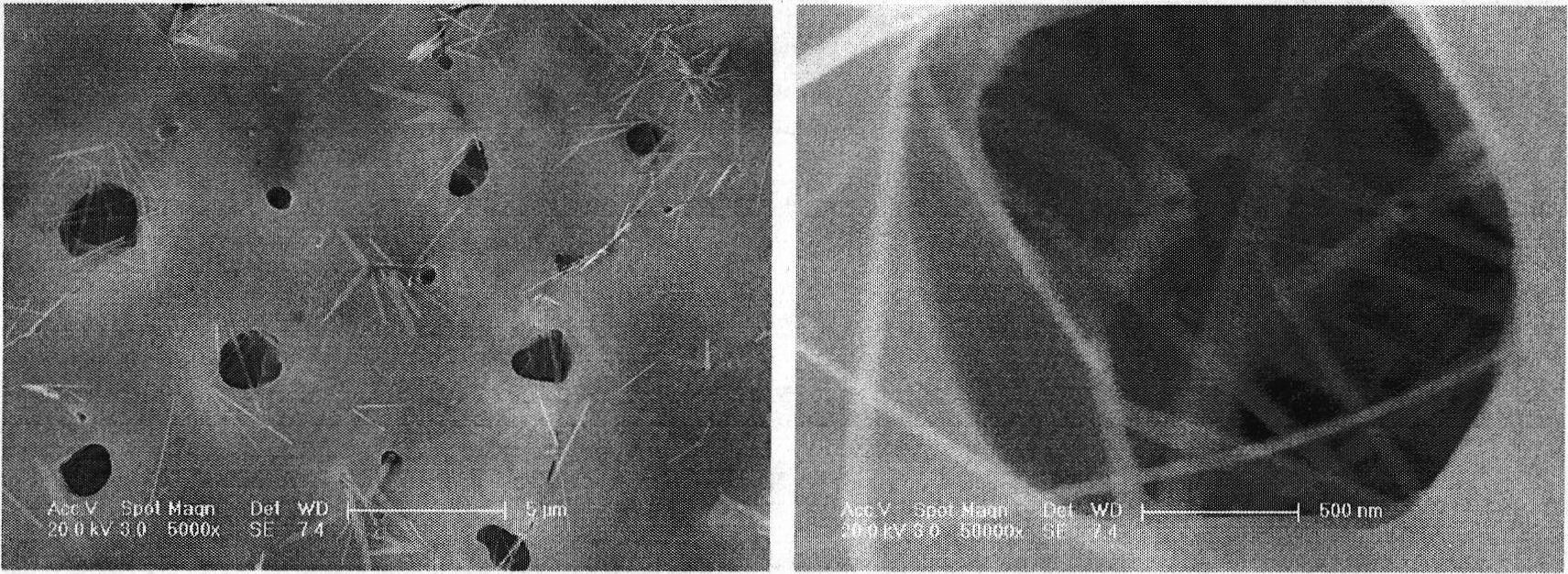

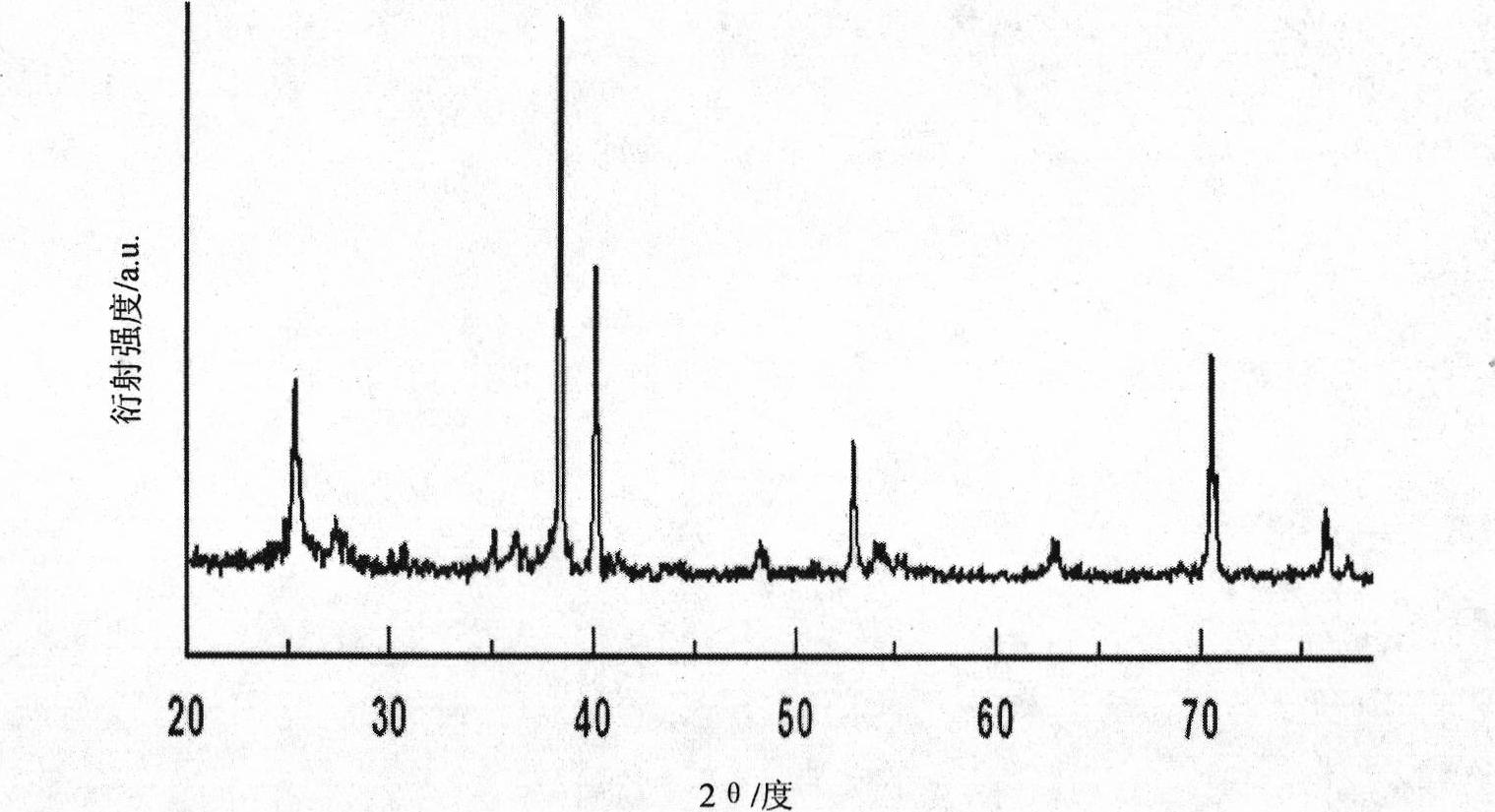

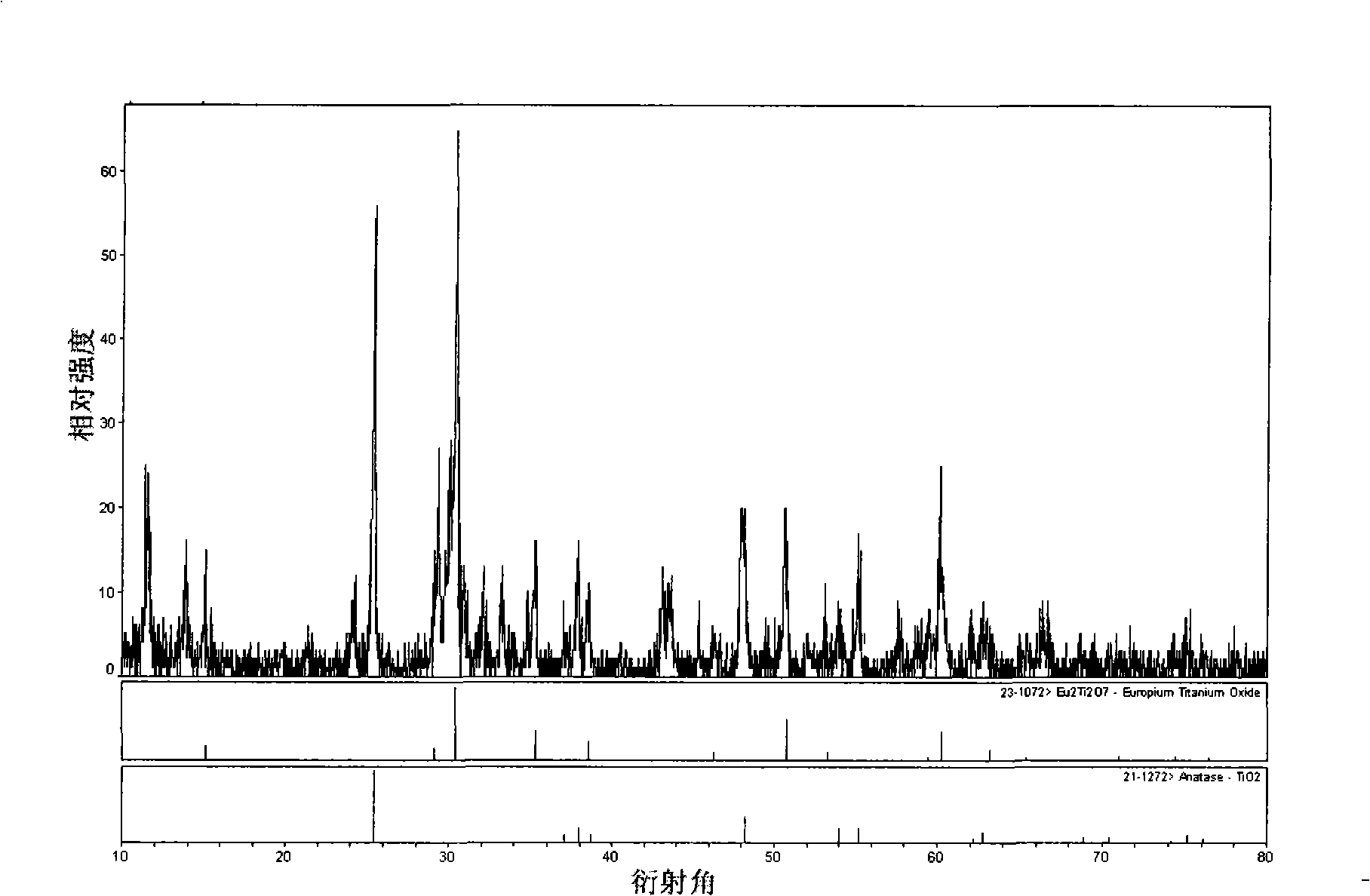

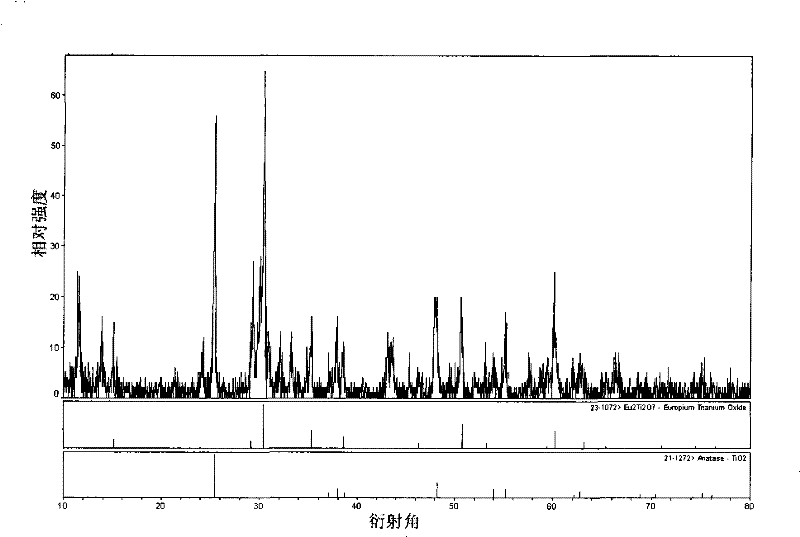

Titanium dioxide photocatalysis composite film and preparation method thereof

InactiveCN101812714AIncrease dosagePlay a practical roleSurface reaction electrolytic coatingCatalyst activation/preparationQuantum yieldMicro arc oxidation

The invention provides a titanium dioxide (TiO2) photocatalysis composite film and a preparation method thereof. The titanium dioxide (TiO2) photocatalysis composite film is generated in situ on a titanium alloy (Ti-6Al-4V) substrate by adopting a micro-arc oxidation (MAO) method, the film contains grains of rare earth oxides of europiumsesquioxide (Eu2O3) in a one-dimensional structure, and the film has the crystalling phase of anatase. Eu2O3 grains have the effect of catalysts or catalyst accelerators in the TiO2 photocatalysis composite films, and the compounding time of TiO2 photo-induced electrons and hole pairs can be prolonged in the photocatalysis process, so the optical photon yield can be improved. The invention is applied to the photocatalysis purification field. Compared with uncompounded TiO2 films, the TiO2 photocatalysis composite film of the invention has the advantages that the absorption efficiency on ultraviolet light and visible light is obviously improved, the degradation efficiency of the organic pollution can be improved by about one time.

Owner:WUHAN UNIV

Low-hydroxyl yellow light-filtering quartz tube and preparation method thereof

The invention discloses a low-hydroxyl yellow light-filtering quartz tube and a preparation method thereof. The low-hydroxyl yellow light-filtering quartz tube is prepared from the following raw materials by optimal weight percent: 94% to 99% of quartz sand with high purity, 0.1% to 0.5% of cobaltous oxide, 0.1% to 2% of ceric oxide, 0.1% to 0.5% of europium oxide, 0.1% to 0.5% of aluminum oxide, 0.1% to 0.5% of titanium oxide, 0.1% to 0.5% of potassium oxide and 0.1% to 0.5% of sodium oxide. The low-hydroxyl yellow light-filtering quartz tube also has the advantage of being more reasonable in formula matching besides having the advantages of the ordinary ultraviolet-filtering quartz glass tube. According to the testing of a conventional method, the compressive strength of the low-hydroxyl yellow light-filtering quartz tube is greatly improved while the damage of an automobile lamp to a baking varnish is greatly decreased due to the addition of multiple metal oxides and rare earth elements; the safety performance of the low-hydroxyl yellow light-filtering quartz tube is improved at the same time.

Owner:NANTONG HUITONG TEXTILE EQUIP

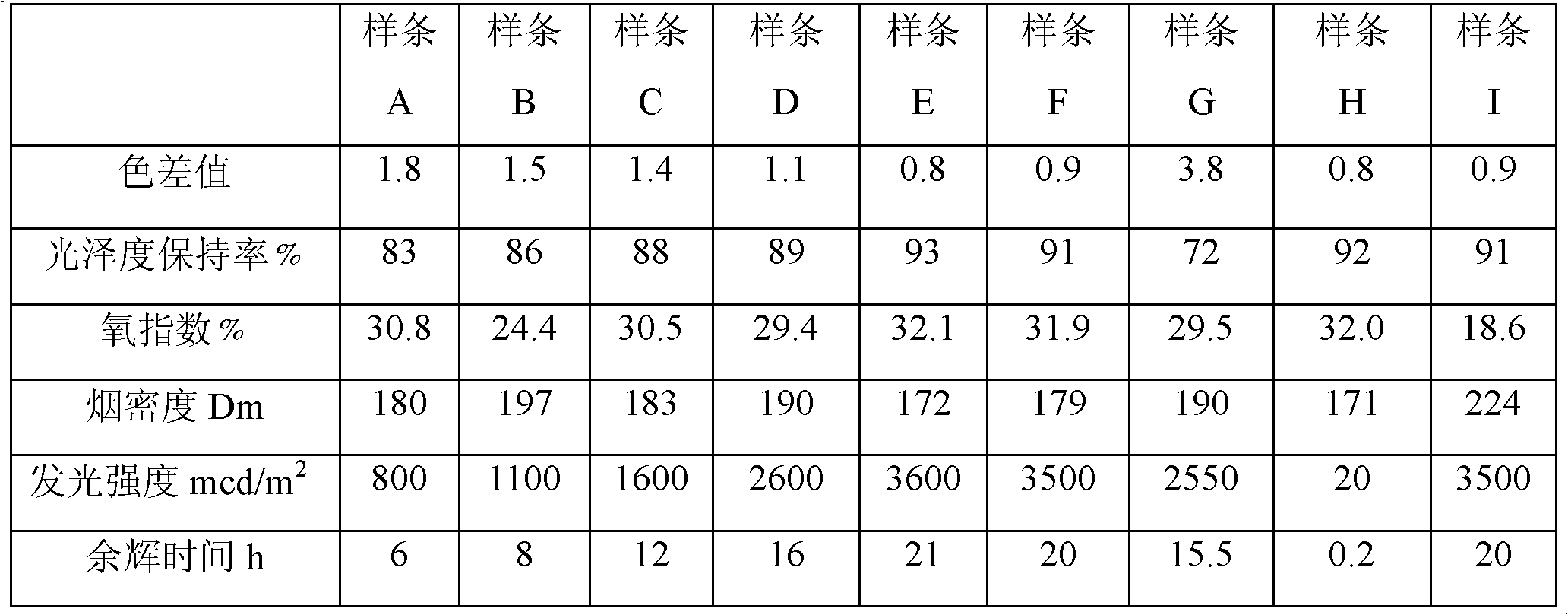

Luminescent material and preparation method and application thereof

ActiveCN102807866AGood weather resistanceStrong persistenceLuminescent compositionsMasterbatchWeather resistance

The invention belongs to the technical field of modifying and processing technology for macromolecule, and relates to a luminescent material and a preparation method and application thereof. The luminescent material includes the following components based on weight proportion: 90-100 portions of aluminium oxide, 80-95 portions of calcium carbonate, 8-20 portions of boric acid, 1.5-5 portions of europium oxide, 2-4 portions of terbium oxide. Compared with the prior art, master batches of weather-resistant energy-storage luminescent polyethylene plastic prepared from the luminescent material of the invention have excellent weather-resistant performance and durability, environment-friendly degradation products, longer luminescence time and zero radioactivity. The master batches of the luminescent material are widely used in architectural ornament, transportation, fire protection, electrocommunication, subway tunnels, advertising boards and other plastic products.

Owner:江苏融威实业有限公司

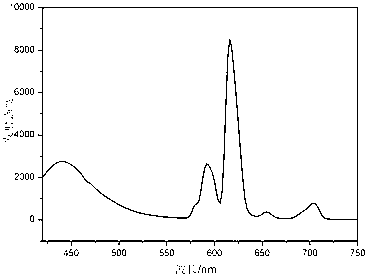

Infrared colorful false proof material and preparation method thereof

InactiveCN101058707AWide spectral rangeHigh fluorescence brightnessOther chemical processesInorganic pigment treatmentFluorescenceLanthanum fluoride

The invention discloses an infrared colorful false proof material and making method, which comprises the following steps: selecting certain proportional alumina, lead fluoride, beryllium fluoride, calcium fluoride, strontium fluoride, lanthanum fluoride, europium trioxide, samarium trioxide, thulium trioxide and gadolinium trioxide as raw materal; blending these raw materials; grinding; heating; insulating; heating again; quenching; cooling; grinding; packing. The spectral scale is broad to form 3-6 different colorful fluorescences stimulated by laser at 960nm, which is fit for falseproof marking material.

Owner:龙彪

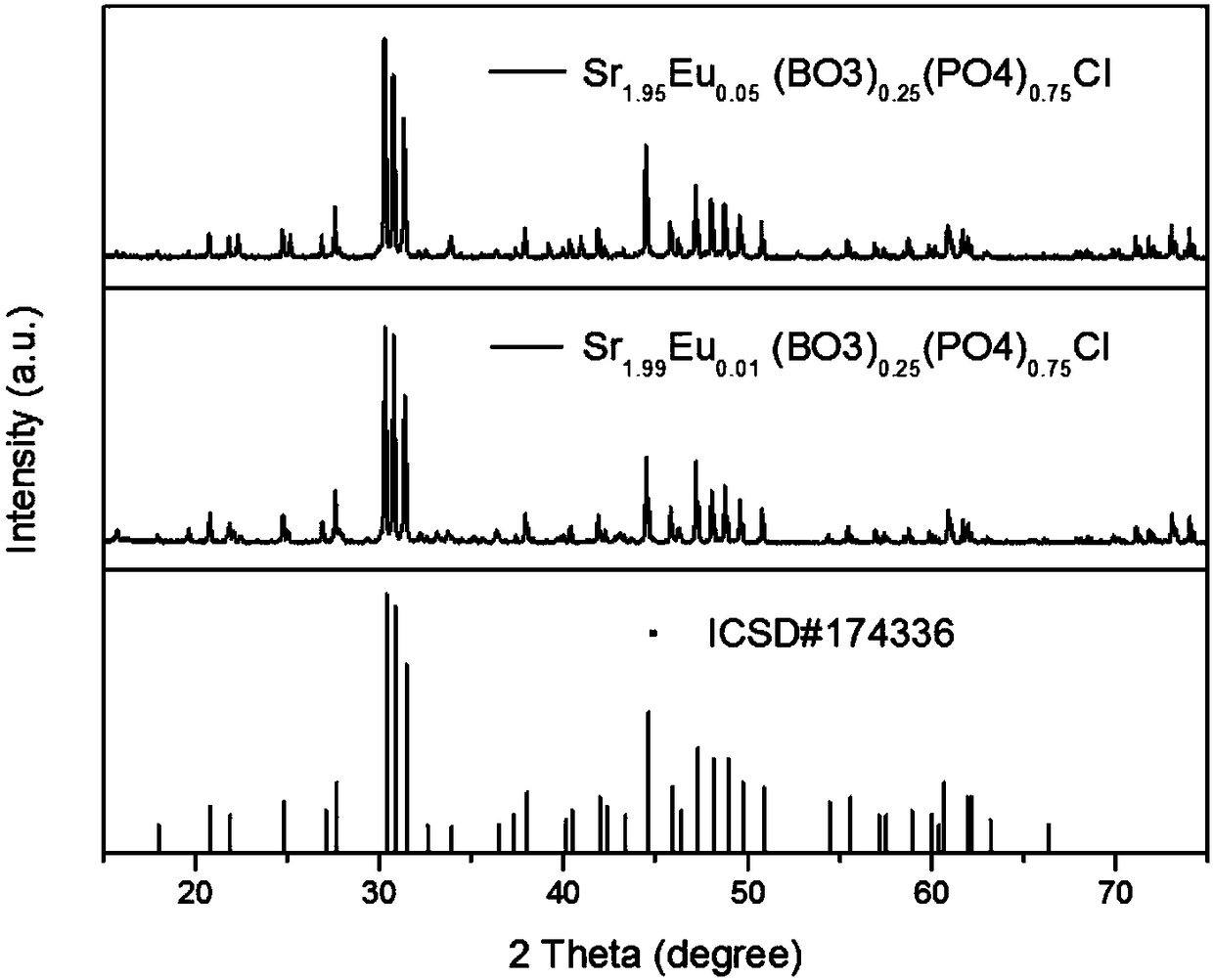

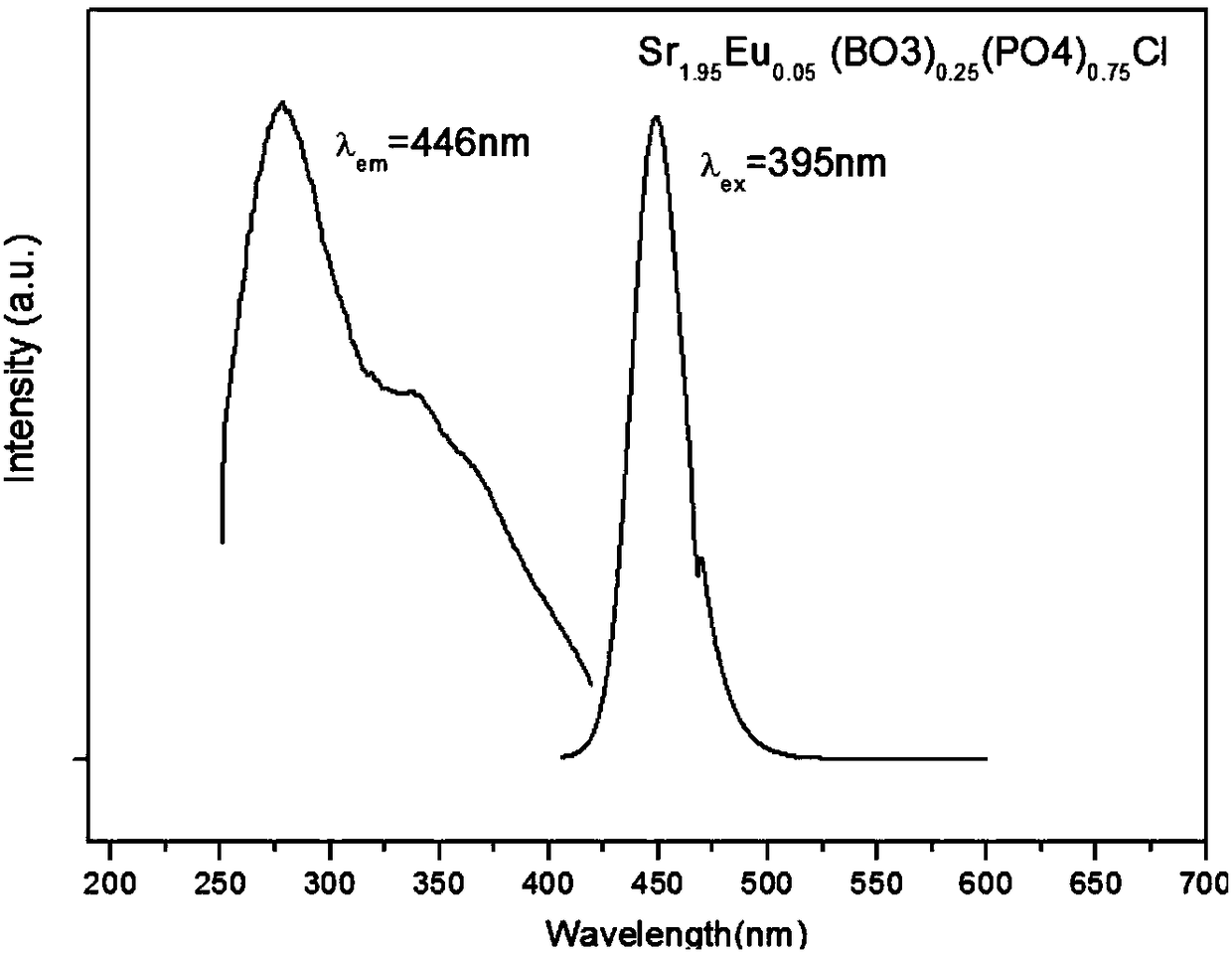

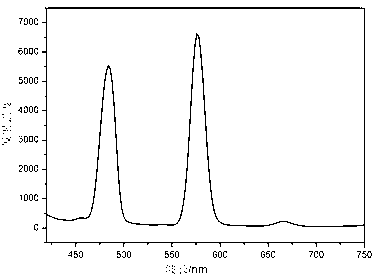

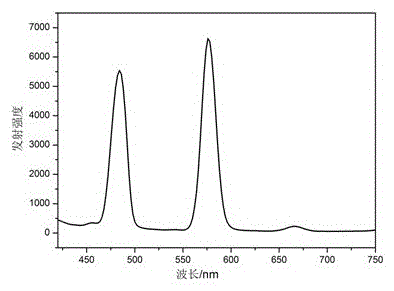

Blue fluorescent powder for three-primary-color warm white LEDs and preparation method of blue fluorescent powder

ActiveCN108085004AHigh light efficiencyEnergy efficient lightingLuminescent compositionsCarbonateEuropium(III) oxide

The invention discloses blue fluorescent powder for three-primary-color warm white LEDs and a preparation method of the blue fluorescent powder. The preparation method comprises the steps of: adoptingstrontium carbonate (SrCO3), anhydrous ammonium chloride (NH4Cl), boric acid (H3BO3), europium oxide (Eu2O3) and ammonium dihydrogen phosphate (NH4H2PO4) as raw materials, and adopting a solid-phasesintering method in a reducing atmosphere to obtain the blue fluorescent powder with a chemical formula of Sr(2-x)Eux(BO3)y(PO4)(1-y)Cl, wherein 0.001<=x<=0.1, and 0.001<=y<=0.5. By mixing the blue fluorescent powder with CaAlSiN3:Eu<2+> red fluorescent powder and (SrBa)2SiO4:Eu<2+> green fluorescent powder at a certain ratio, near-ultraviolet light-excited warm-white light emission with high color rendering indexes and high luminous efficiency can be achieved, and the blue fluorescent powder has a very broad application prospect.

Owner:杨鹏

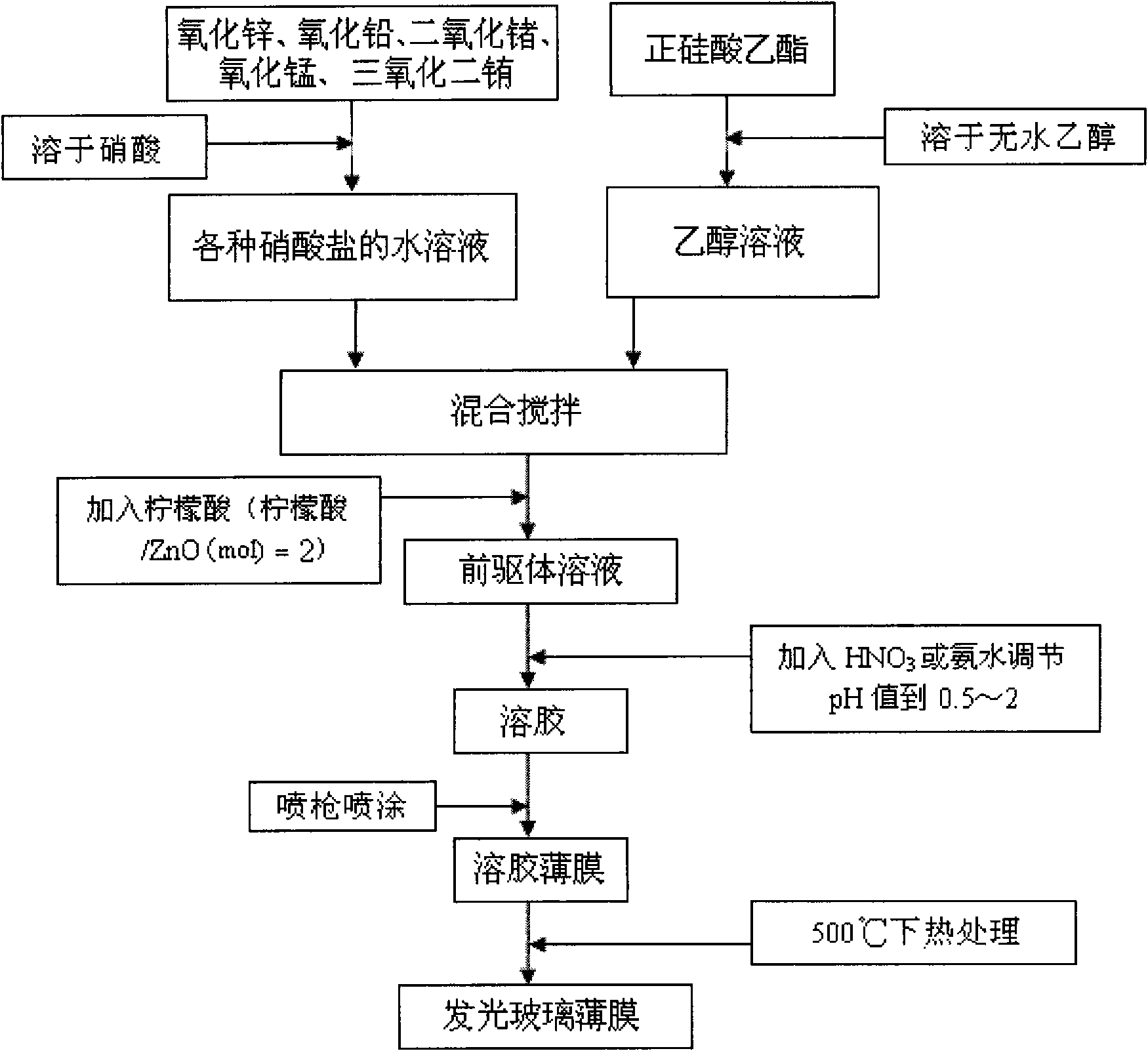

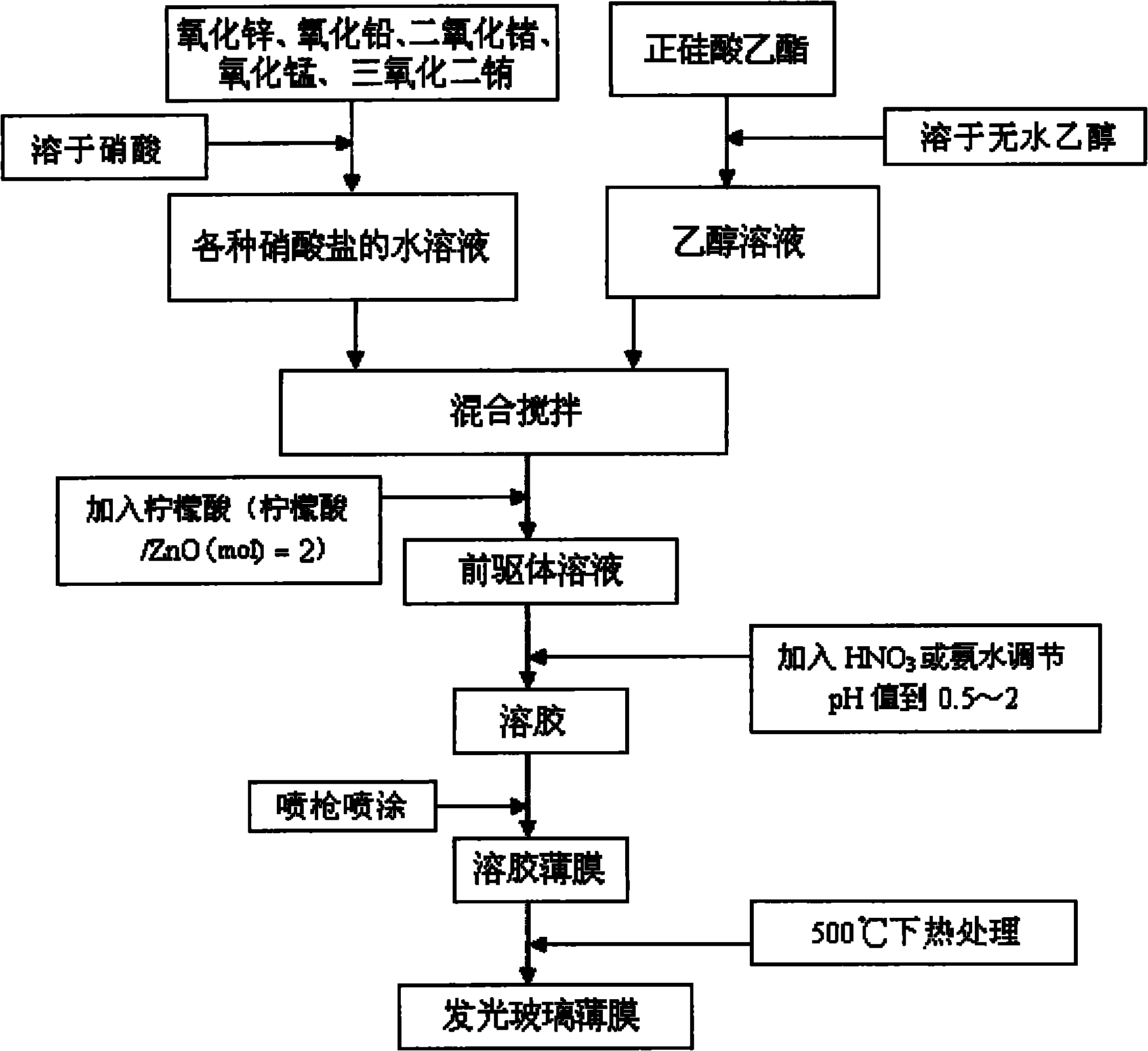

Germanate glass luminescent film and preparation method

The invention discloses a preparation method of a germanate glass luminescent film. The method comprises the following steps: selecting zinc oxide, lead oxide, germanium oxide and silicon dioxide as glass substrate and selecting manganese oxide and europium sesquioxide as luminescent agents; dissolving tetraethoxysilane in absolute ethyl alcohol and dissolving other oxides in a nitric acid solution to prepare a 0.5-1.5mol / L nitrate solution; mixing the solution, stirring and adding a certain amount of citric acid as a chelating agent; regulating pH to 0.5-1 to prepare sol; atomizing the prepared sol at a nozzle of a spray gun by high pressure gas to allow deposition on a high-temperature quartz glass substrate to form uniform film; keeping the formed film at constant temperature of 500 DEC C for 2-5h; meanwhile, charging a gas mixture of nitrogen and hydrogen into a heating furnace as reducing atmosphere to finally obtain colorless transparent glass film which can emit bright red fluorescence in the presence of 254nm ultraviolet irradiation.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

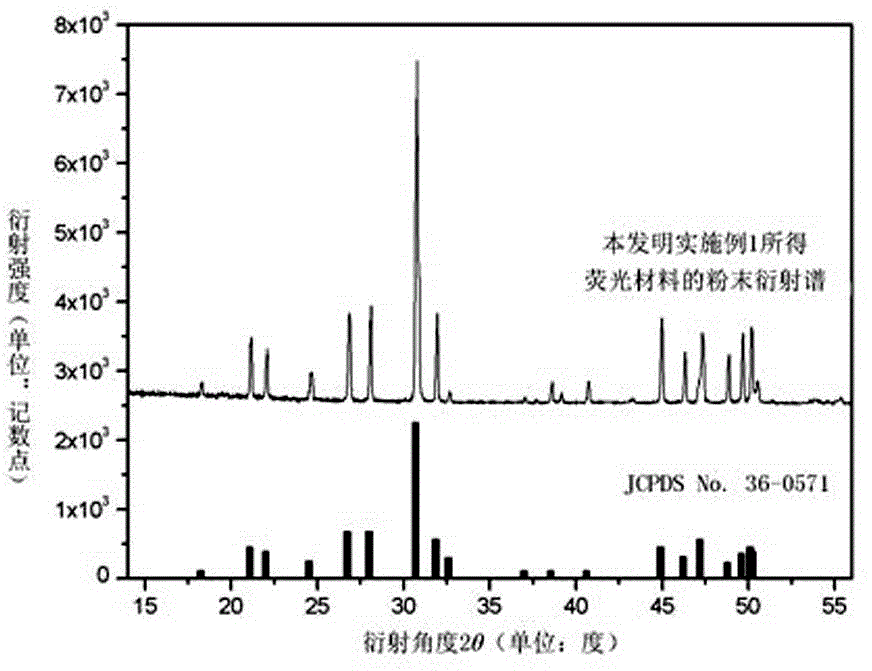

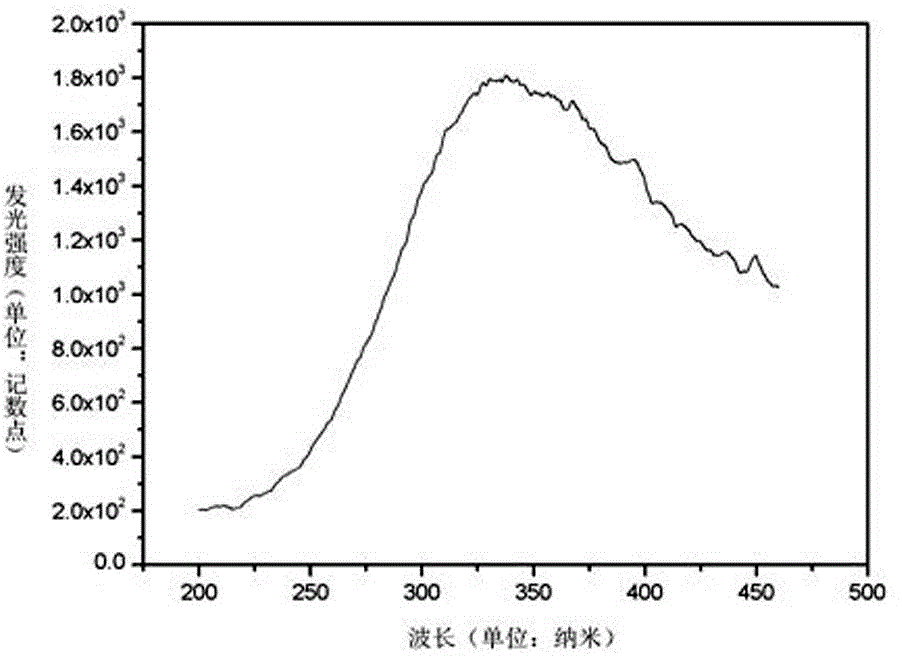

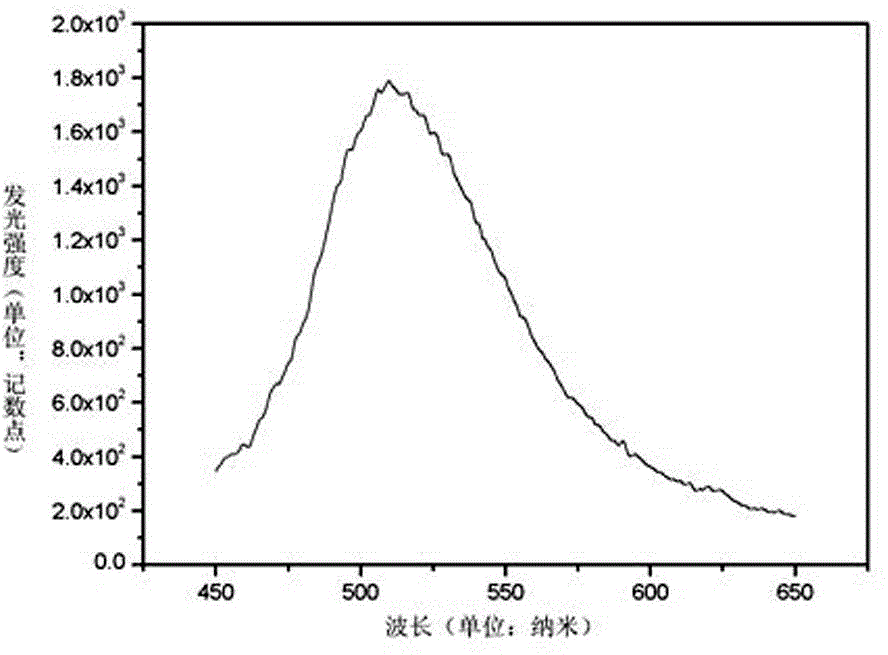

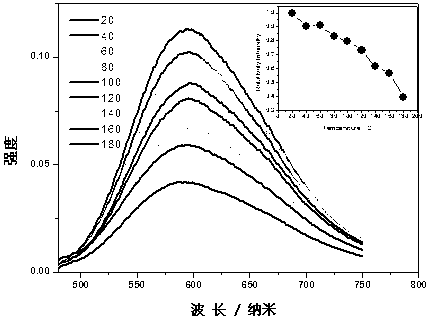

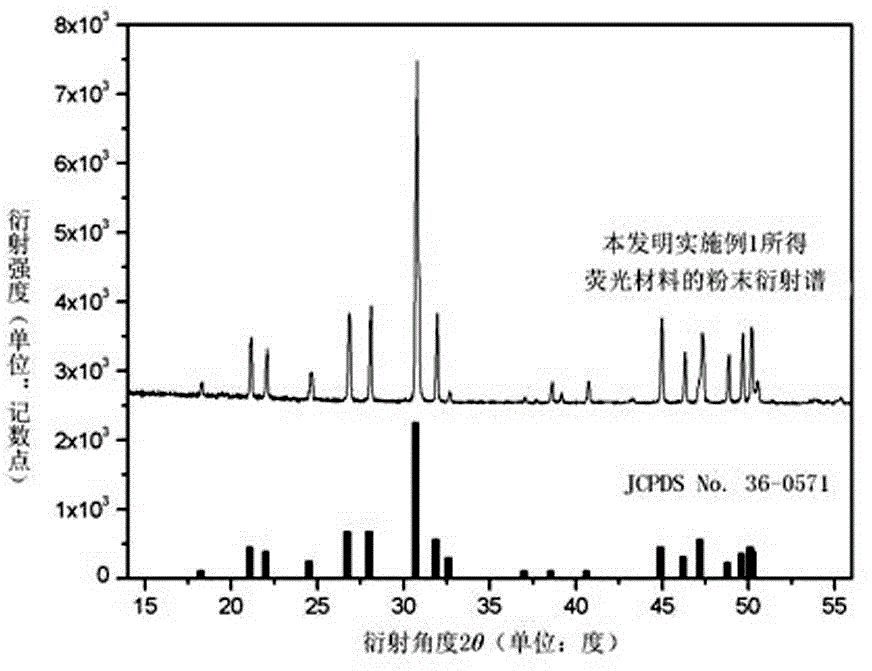

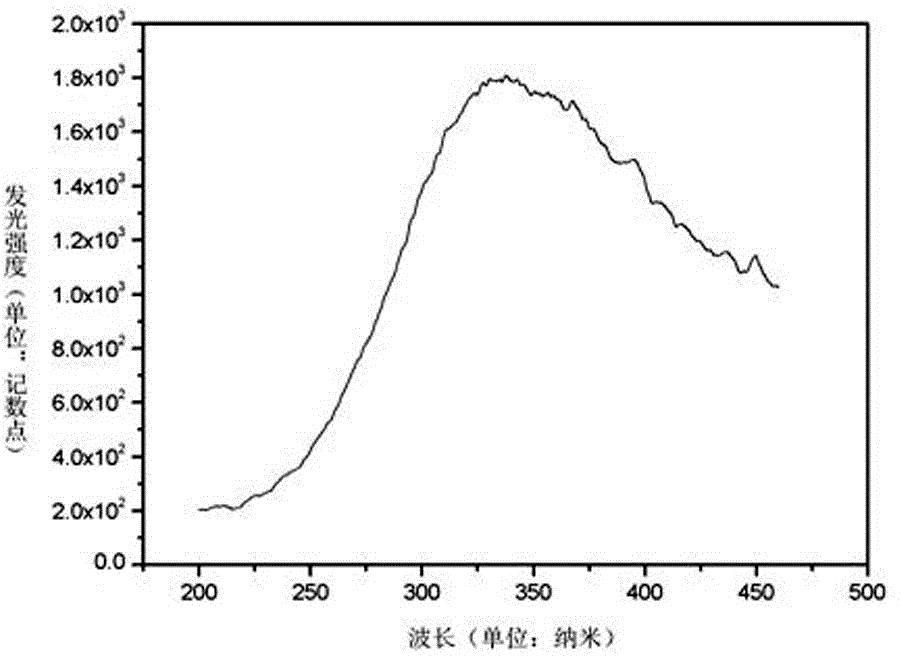

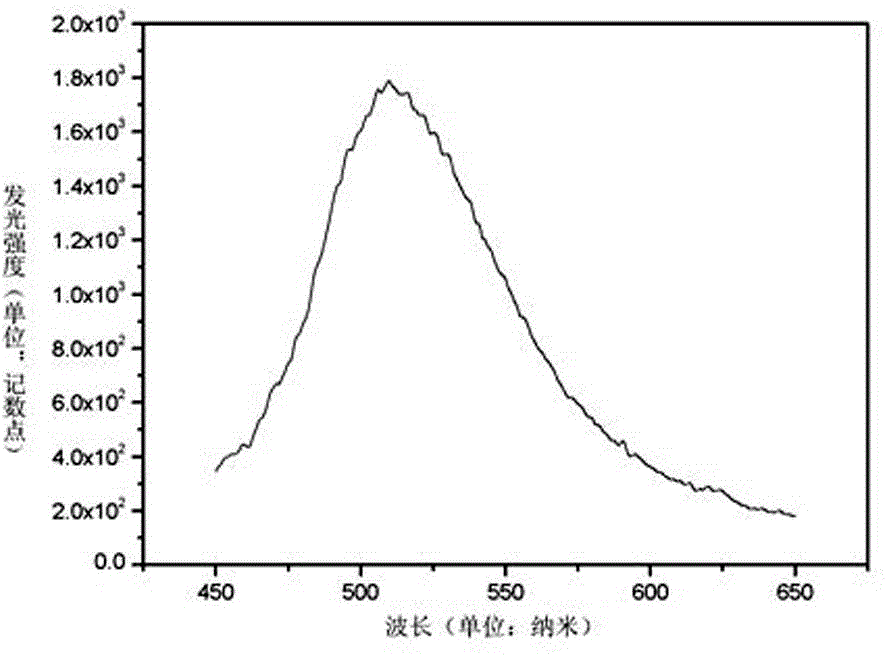

Europium doped lanthanide silicon oxynitride and preparation method thereof

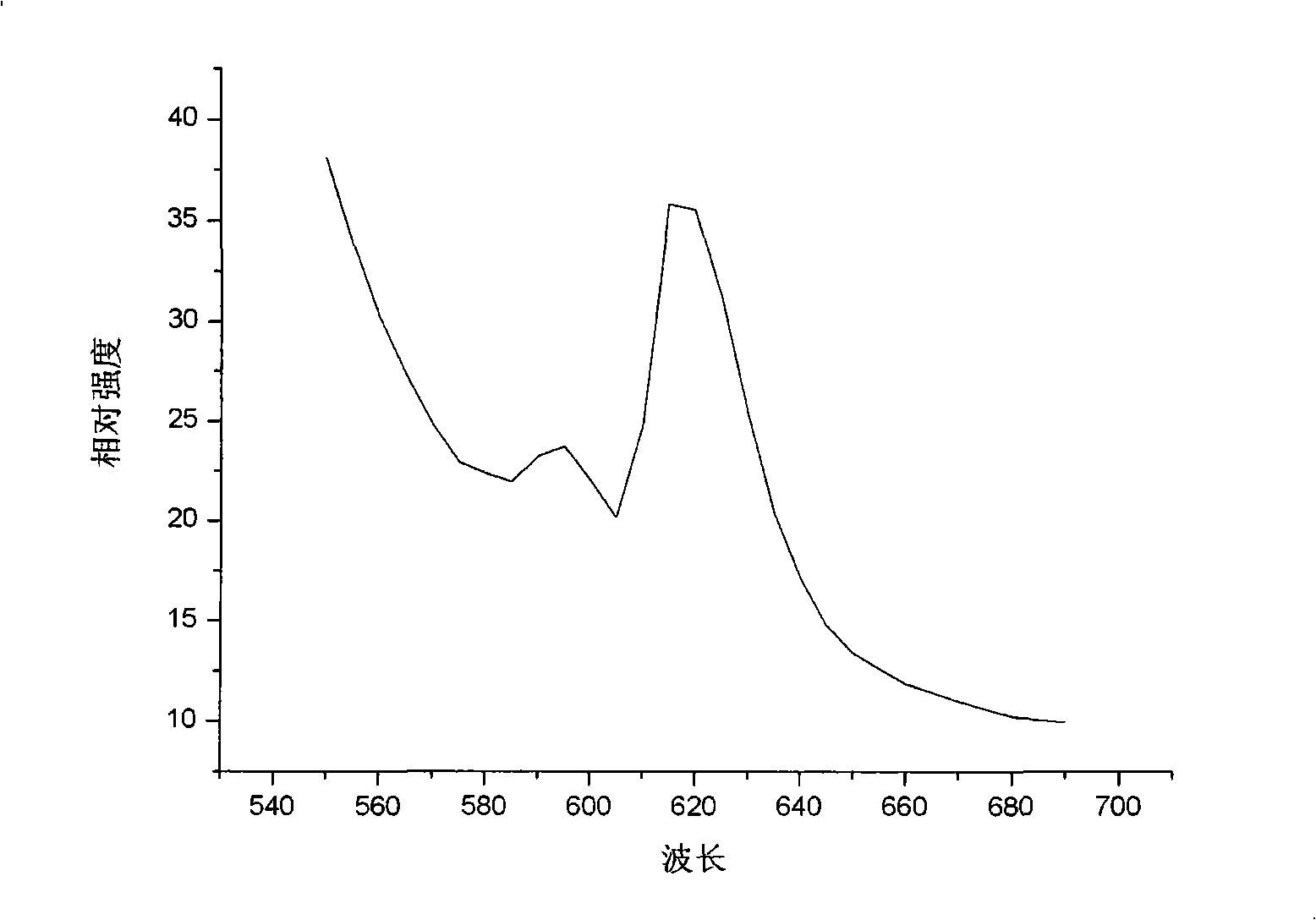

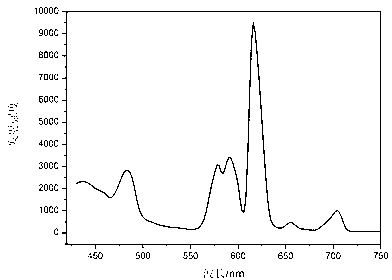

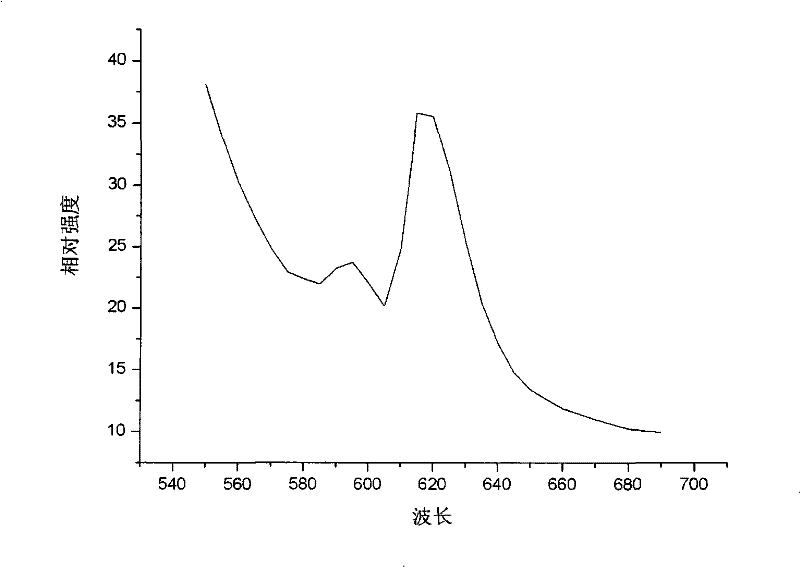

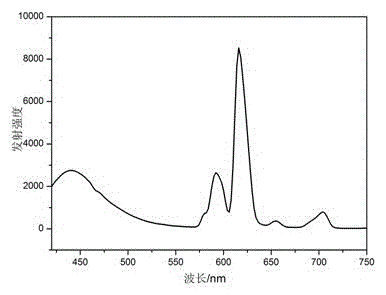

InactiveCN103146386AStrong emission peakStrong excitation peakLuminescent compositionsFurnace temperatureHydrogen atmosphere

The invention discloses a europium doped lanthanide silicon oxynitride, of which the chemical general formula is La5-5xEu5xSi3O12N, wherein x is more than 0 and less than 0.25. The preparation method comprises the steps of: (a) weighing raw materials: lanthanum trioxide, silicon dioxide, silicon nitride and europium oxide, according to the molar ratio of the chemical formula La5-5xEu5xSi3O12N (x is more than 0 and less than 0.25); (b) ball-milling the raw materials and tabletting; (c) putting tablets into a high temperature furnace, under the nitrogen hydrogen atmosphere, raising the furnace temperature to 1000-1250 DEG C, and sintering for 3-10 hours; (d) turning off a hydrogen source, under the environment of charging nitrogen gas, keeping the high temperature furnace at a pressure of 0.5-1MPa, raising the furnace temperature to 1450-1550 DEG C, and continuously sintering the tablets for 3-10 hours; and (e) ventilating to release the pressure in the furnace to be an ordinary pressure, cooling down the high temperature furnace to room temperature by circulating under the nitrogen-hydrogen mixed atmosphere, taking out the sample tablets, and grinding, thus obtaining a fluorescent material. The fluorescent material prepared by the preparation method is stable in physicochemical property, convenient to control luminescence property, simple in preparation method, and free from environmental pollution, and is applicable to industrialized mass production.

Owner:HEBEI UNIVERSITY

Preparation method of titanium dioxide europium-doped nano-film sol

InactiveCN101538065AReduce manufacturing costEasy to operateTitanium dioxideEthylenediamineSesquioxide

The invention discloses a preparation method of titanium dioxide europium-doped nano-film sol. In the method, metatitanic acid (H2TiO3) is washed by distilled water repeatedly, and put into an oven to be baked for 12 hours at 60 DEG C; europium sesquioxide (Eu2O3) is dissolved in nitric acid to obtain europium ion; H2Ti3 and K2CO3 are evenly mixed according to mol ratio of 5.2:1, europium ion is added into the mixture according to 0.2-3% of mass fraction of titanium, and little absolute ethyl alcohol is added into the mixture simultaneously, the mixture being fully ground is put in a muffle to be calcined for 6-15 hours at 600-1000 DEG C, the material being calcined is taken out and added into hydrochloric acid of 1mol / L according to the proportion of 4g / L to be stirred, filtration washing is carried out for 24-72 hours, the filter cake is added into 4-n-butyl ammonium hydroxide or ethylene dimine according to the proportion of 0.4g / L to be stirred for 24-72 hours, is then centrifugated at the high speed centrifugation of 10000r / min to obtain titanium dioxide europium-doped nano-film sol. The invention is convenient in operation, low in cost and suitable for industrialized prosuction.

Owner:EAST CHINA NORMAL UNIV

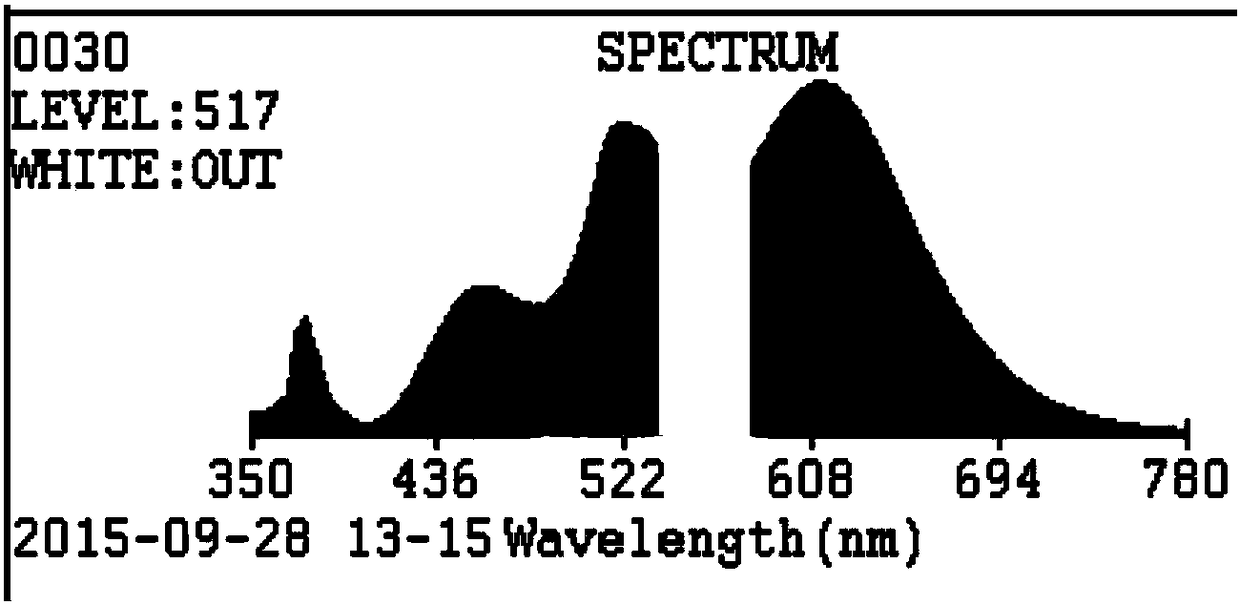

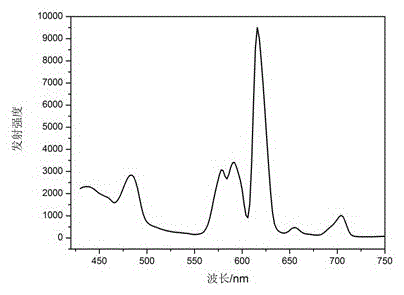

Preparation method of Eu2O3-Dy2O3-codoped zinc-silicon-system microcrystalline glass

The invention discloses a preparation method of Eu2O3-Dy2O3-codoped zinc-silicon-system microcrystalline glass. According to the preparation method, zinc oxide, boric acid, silicon dioxide, aluminum trioxide, sodium carbonate, titanium oxide, dysprosium trioxide, and europium trioxide are adopted as raw materials; the raw materials are grinded and mixed; the mixture is fused under a temperature of 1400-1500 DEG C, and glass is molded and prepared; the molded glass is annealed for 2-3h under a temperature of 500-600 DEG C, such that internal stress is eliminated, and the glass is cooled to room temperature; the annealed glass is subjected to a crystallization treatment, wherein the glass is nucleated for 2-5h under a temperature of 550-650 DEG C and crystallized for 6-12h under a temperature of 750-800 DEG C, such that the zinc-silicon-system luminescent microcrystalline glass is obtained. The method provided by the invention has the advantages of short production period and low cost. The prepared luminescent microcrystalline glass has the advantages of high luminous efficiency, high uniformity, long service life, energy saving, and environment-friendliness. When the glass is used in LED lamps, cost is reduced, and luminescent performance is improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

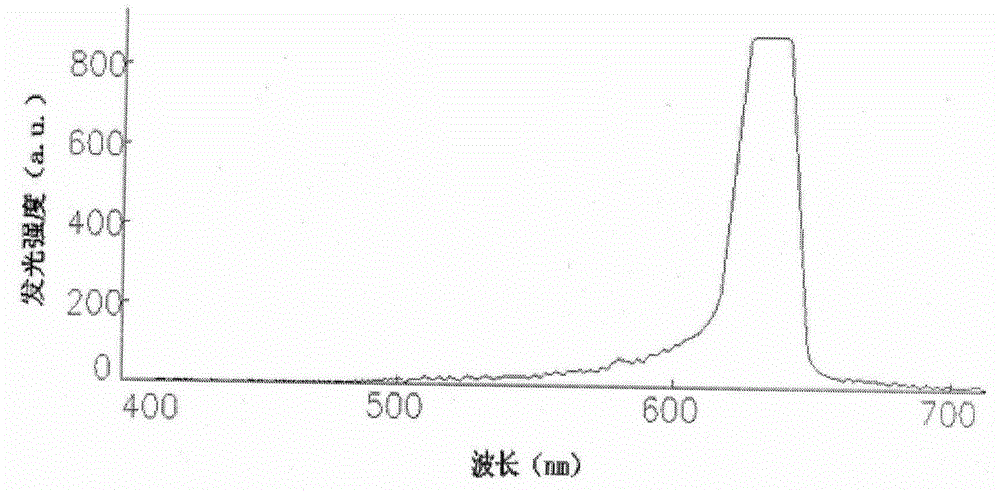

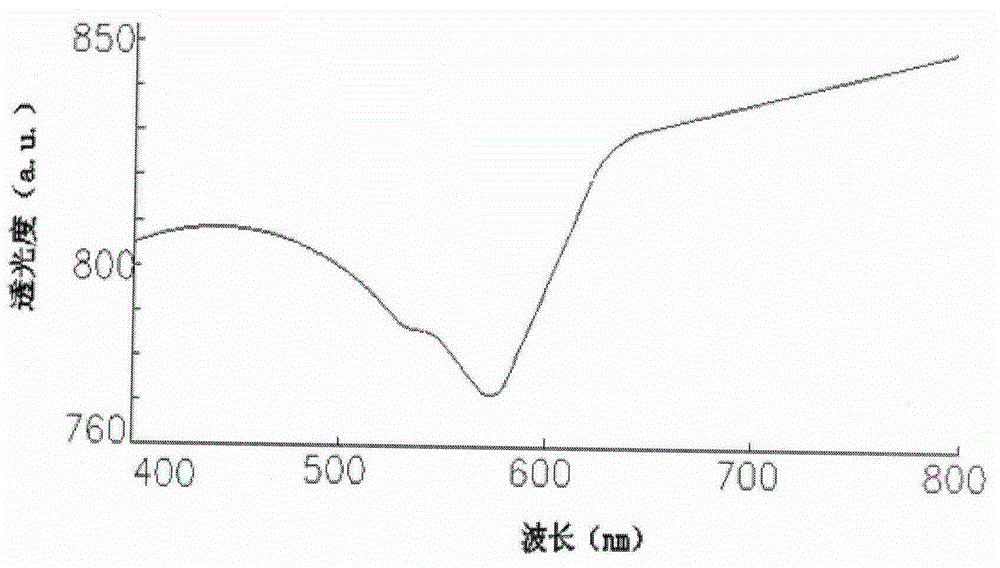

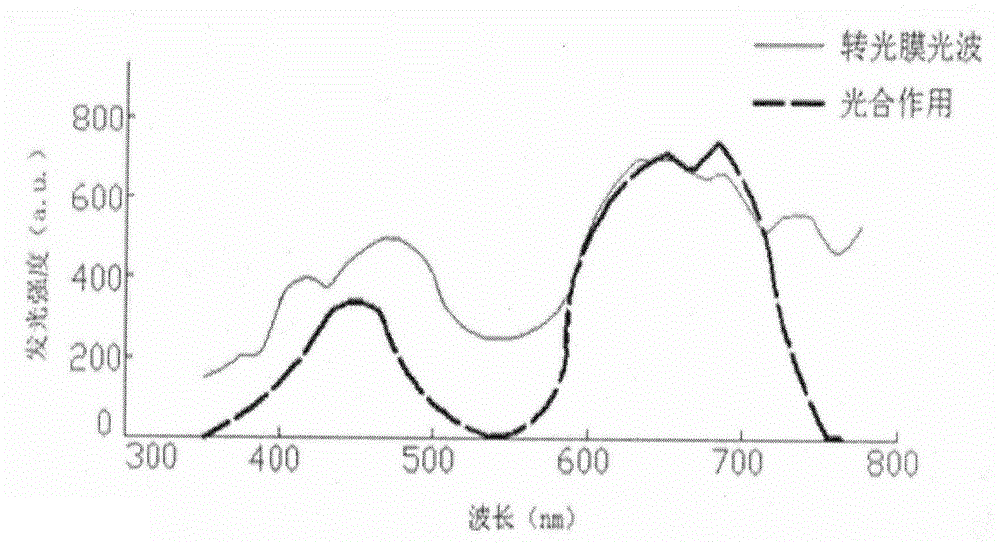

Agricultural daylight greenhouse orange light conversion membrane

InactiveCN104893066APromote growthRealize light wave conversionClimate change adaptationSynthetic resin layered productsPolyolefinFiltration

The invention discloses an agricultural daylight greenhouse orange light conversion membrane. A monobasic complex crystal is prepared from a nitric acid solution and europium oxide, industrial ethanol is added into the monobasic complex crystal so that an europium monobasic complex is obtained, phenanthroline is added into the europium monobasic complex so that an europium dibasic complex is obtained, the europium dibasic complex slurry is put into a vacuum suction filter and then is subjected to pumping filtration so that europium complex powder is obtained, the europium complex powder, a plastic fluorescent dye and linear low density high pressure polythene are subjected to wet processing, the product is subjected to water grinding, phase inversion, water washing and drying to form color master batches, and the color master batches are added into a middle layer of a polythene or polyolefin film according to a ratio of 2.5% so that a light conversion greenhouse film is produced. The agricultural daylight greenhouse orange light conversion membrane realizes light wave transition and promotes plant growth.

Owner:侯培毅

Method for preparing luminescent plastic rattan

The invention discloses a method for preparing luminescent plastic rattan. The method includes operation steps of (1), uniformly mixing strontium carbonate, aluminum oxide, europium sesquioxide, basicbismuth carbonate, dysprosium oxide and boric acid with one another and carrying out high-temperature calcining to obtain long-afterglow luminescent materials; (2), mixing the long-afterglow luminescent materials and tetrabutylammonium iodide with one another, heating mixtures until the tetrabutylammonium iodide is completely dissolved, uniformly stirring the mixtures, and then cooling the mixtures until the temperatures of the mixtures reach the room temperature so as to obtain long-afterglow luminescent materials with coated films; (3), uniformly mixing polyethylene resin, the long-afterglow luminescent materials with the coated films, antioxidants and dispersing agents with one another to obtain mixtures, adding the mixtures into a screw extruder, melting and extruding the mixtures toobtain functional master batch and preparing the luminescent plastic rattan from the functional master batch. The method has the advantages that the luminescent plastic rattan prepared by the aid of the method is excellent in water resistance, and the luminescent materials can be prevented from being dissolved out in use procedures; the luminescent materials are free of influence on the original excellent performance of the polyethylene resin.

Owner:ANHUI JINYUAN HOUSEHOLD ARTS

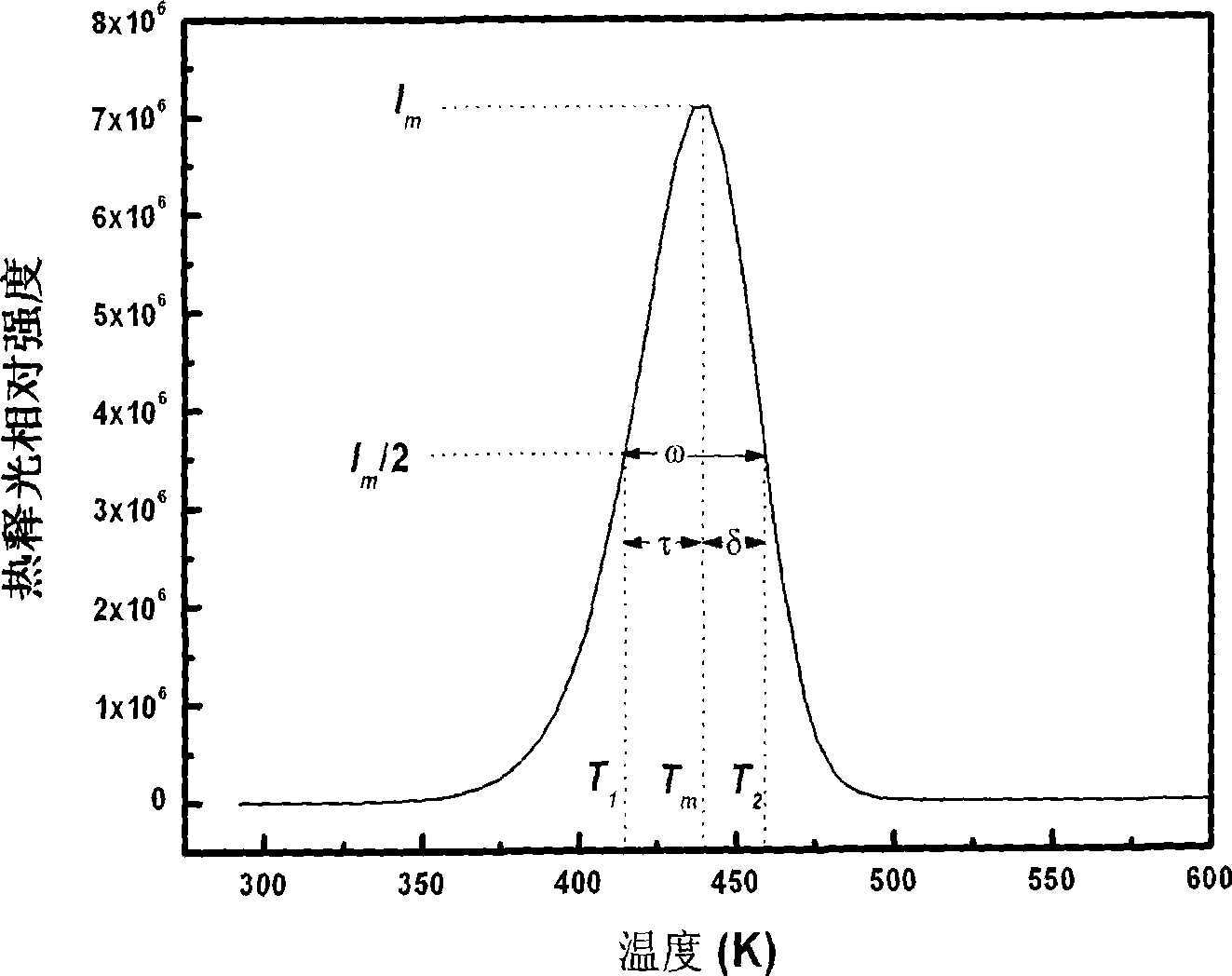

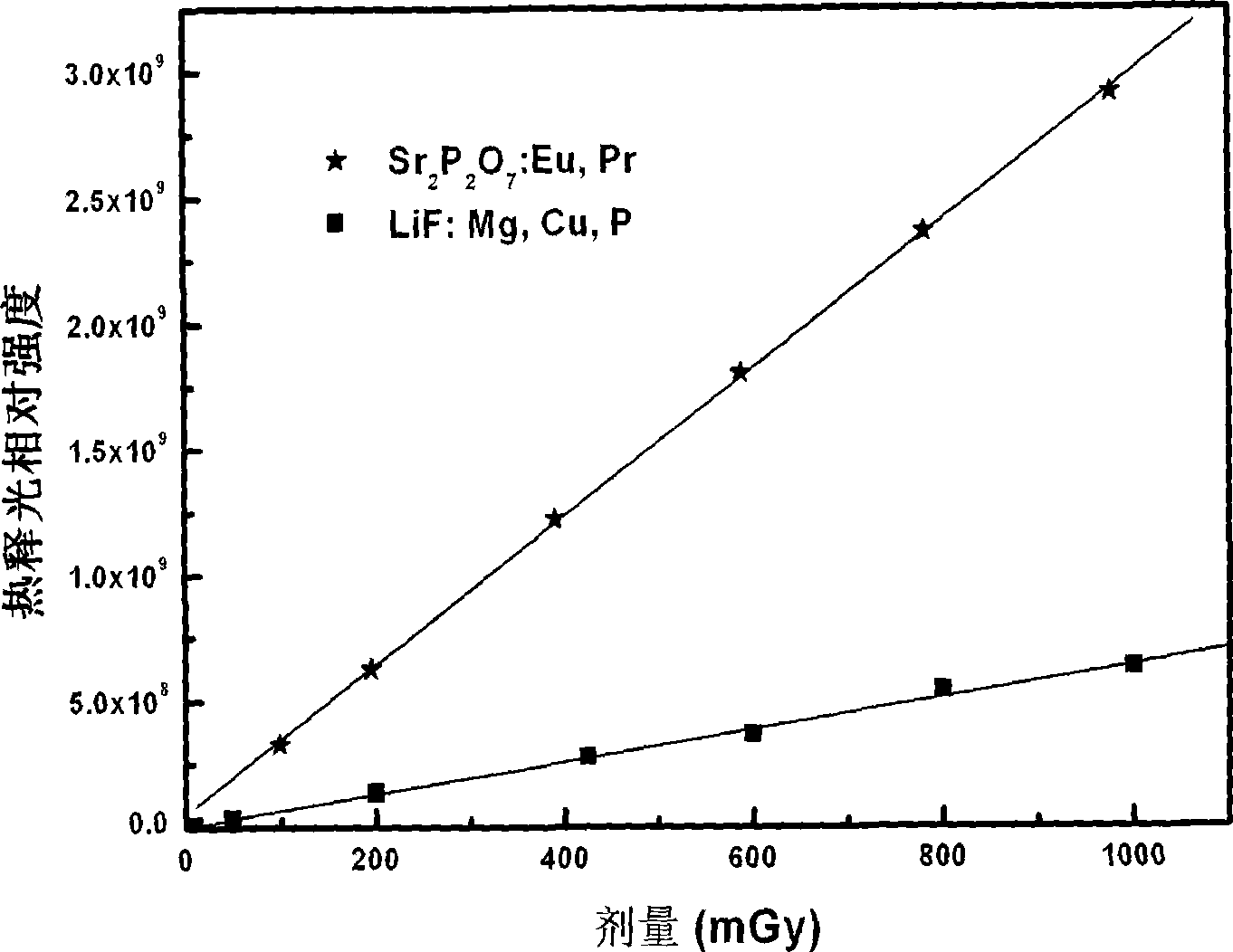

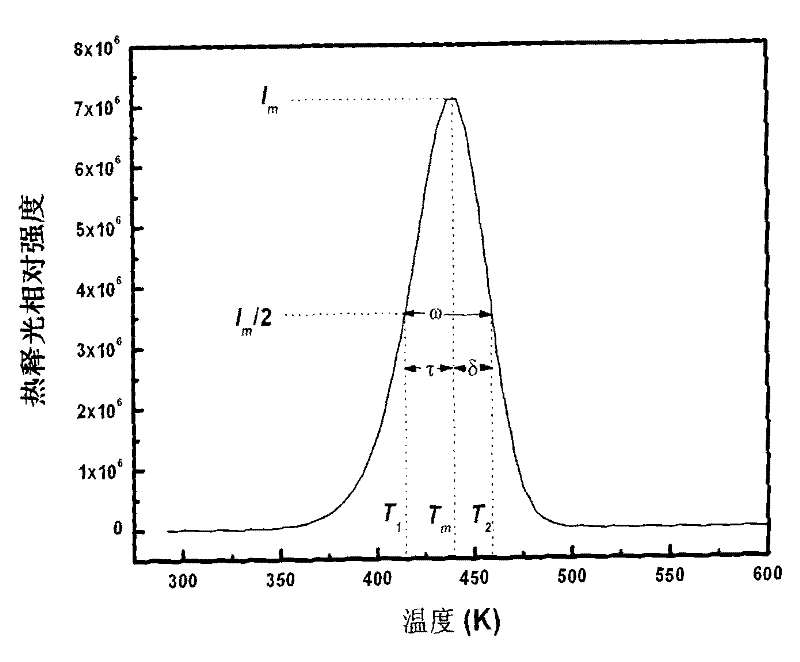

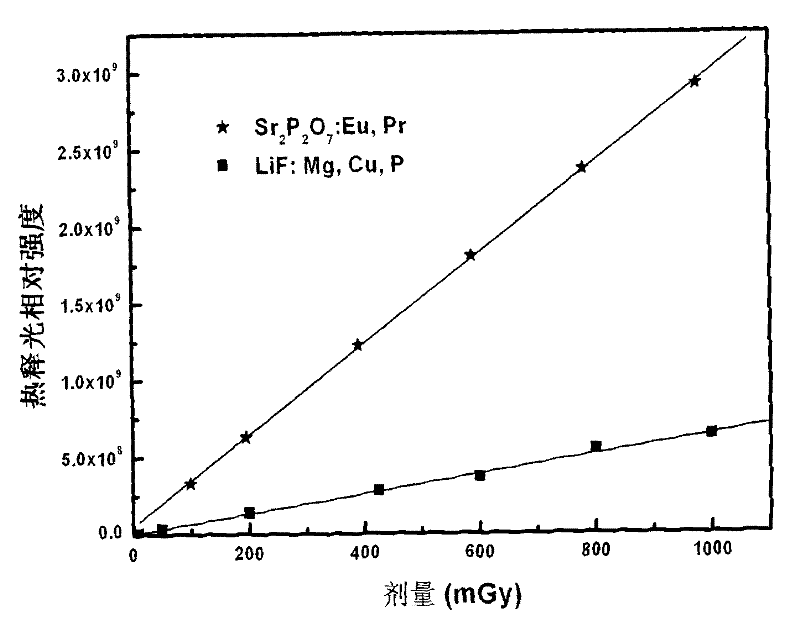

Preparation of solid thermoluminescent dosemeter material

InactiveCN101434840AHigh sensitivityEasy to prepareLuminescent dosimetersLuminescent compositionsEuropium(III) oxideThermoluminescence dosimetry

The invention provides a solid thermoluminescence dosimeter, relating to the following chemical formula: Sr2P2O7:xEu<2+>, yPr<3+>. The raw materials strontium hydrogen phosphate, ammonium dihydrogen phosphate, europium oxide and praseodymium oxide are weighed according to dosage ratio, grinded, mixed uniformed and filled in a roasting vessel; the roasting vessel is then placed in a high-temperature furnace under the sintering atmosphere of CO gas, H2 gas or the mixed gas of N2 and H2 and sintered at the temperature of 900-1400 DEG C for 3-6 hours, thus obtaining target material. After being radiated by Gama-ray, the thermoluminescence curve is single peak with the peak temperature of 439.5K; the thermoluminescence sensitivity is 4.6 times of dosimeter (LiF:Mg, Cu, P) which is widely used at present and has the highest sensitivity; furthermore, the solid thermoluminescence dosimeter material has good linearity at the dosage response of the thermoluminescence at 100-1000mGy and is a good thermoluminescence dosimeter material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

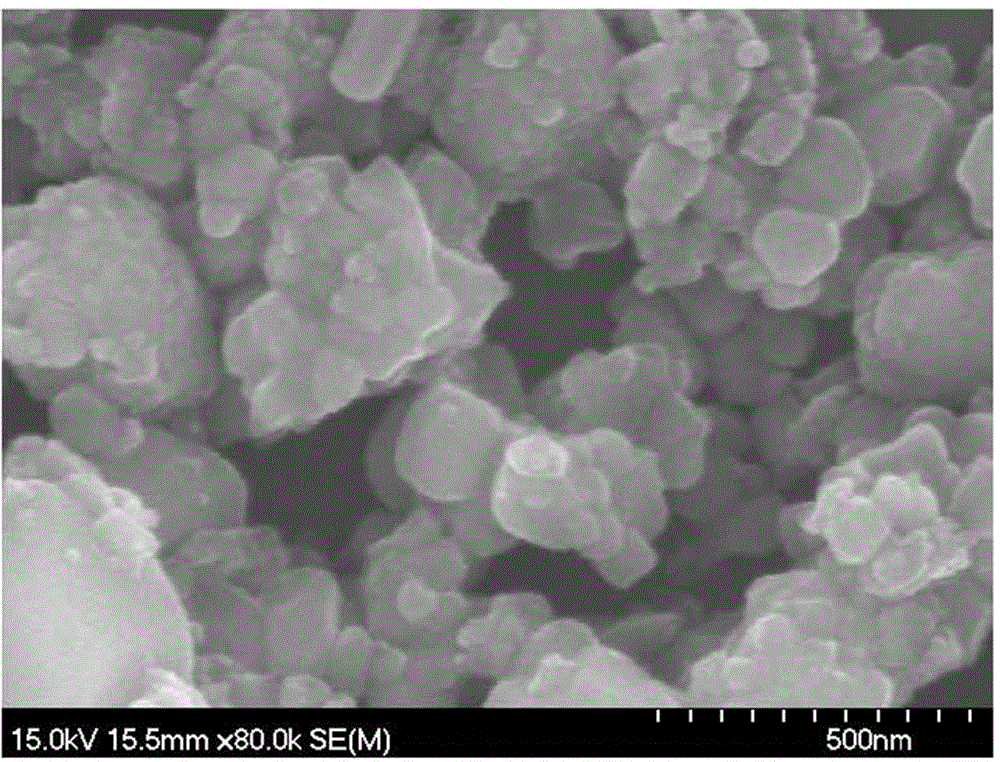

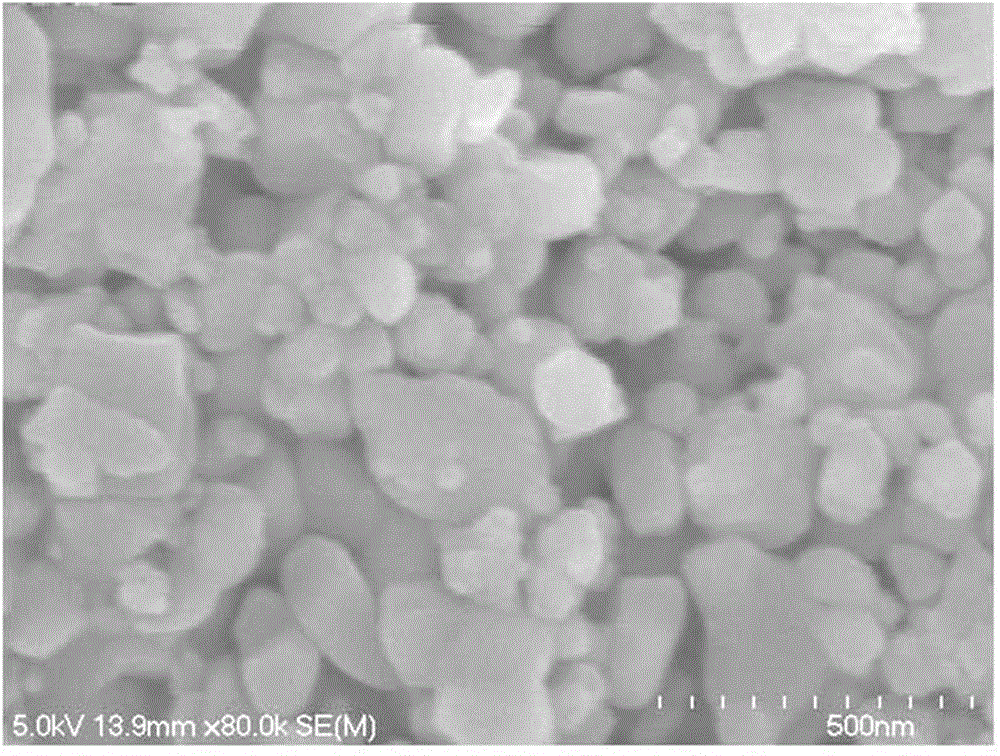

Preparation method of solar cell down-conversion material europium doped yttrium vanadate nanopowder

InactiveCN104371724AControl contentUniform particle sizeLuminescent compositionsAmmonium metavanadateSolar cell

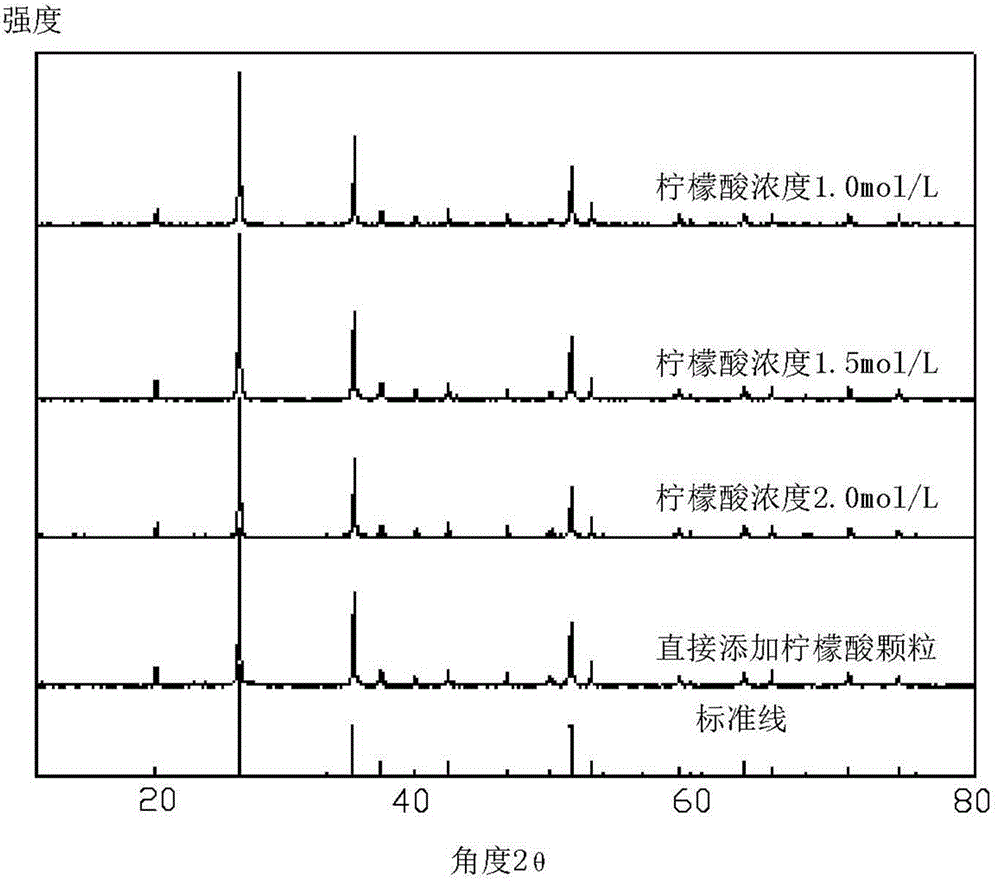

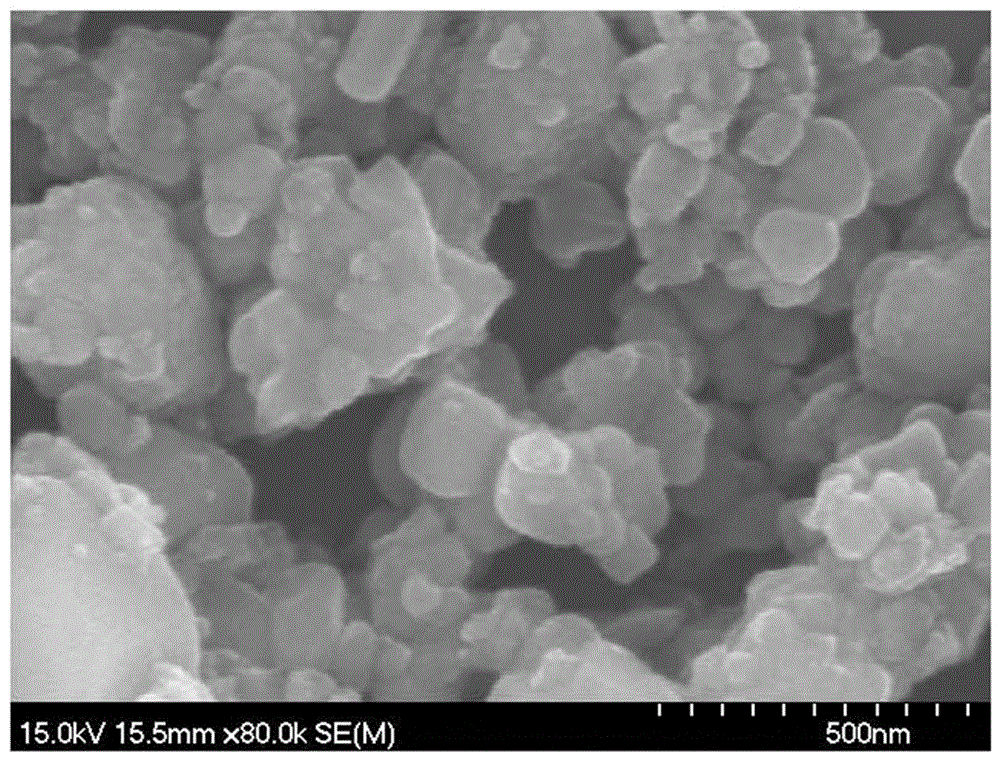

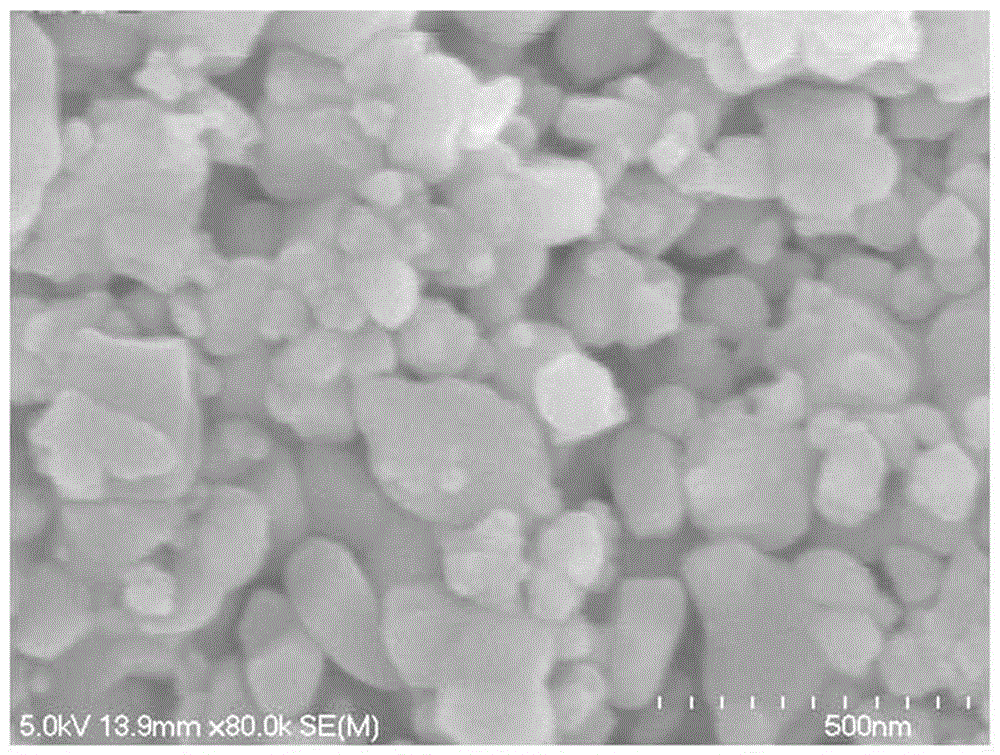

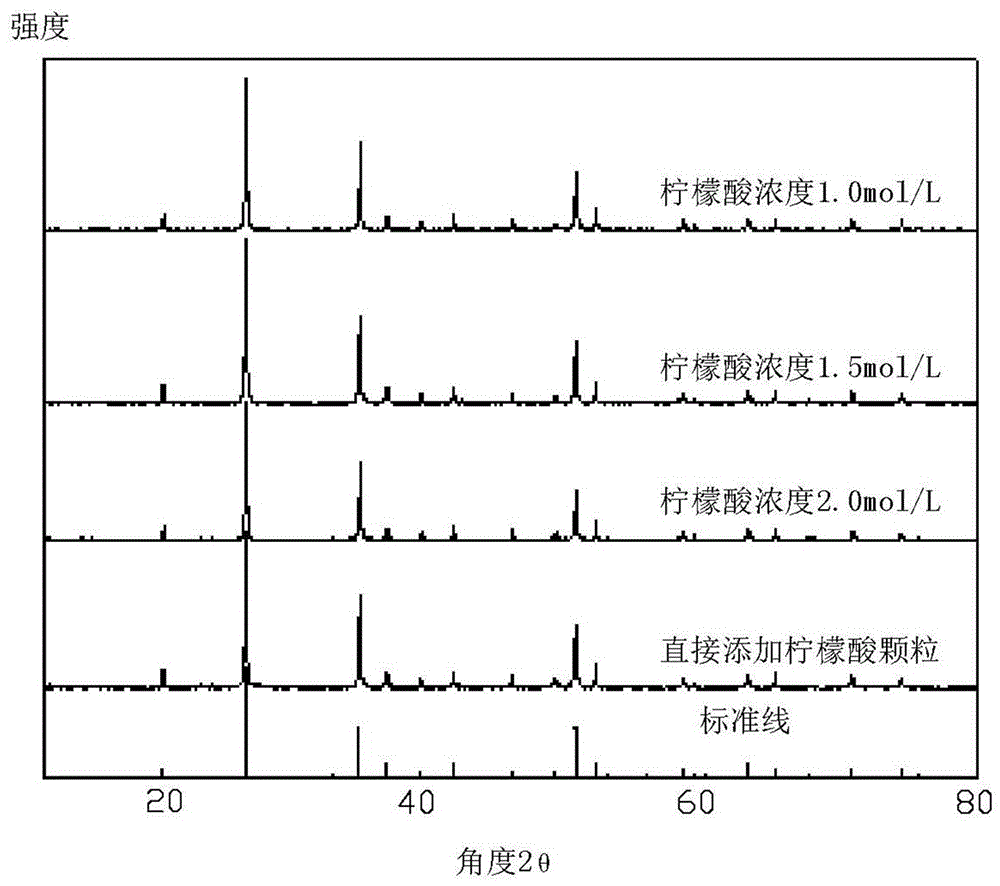

A preparation method of a solar cell down-conversion material YVO4:Eu3<+> nanopowder comprises the following steps: weighing yttria (Y2O3) and europium(III) oxide (Eu2O3) according to a molar ratio of 1:1, mixing, adding the obtained mixture to nitric acid, and dissolving Y2O3 and Eu2O3 to obtain a clarified solution containing yttrium ions and europium ions; adding ammonium metavanadate (NH4VO3) to the clarified solution according to a molar ratio of ammonium metavanadate to the above metal ions of 1:1; adding a citric acid solution with the concentration of 1.4-1.6mol / L to make a molar ratio of citric acid to the metal ions reach 2:1; taking a quantitative amount of ammonia water, and slowly adding the quantitative amount of ammonia water to the above obtained citric acid-containing solution; adding a certain amount of a dispersing agent, and aging for a period of time to obtain a sol; and heating the sol to obtain xerogel, and grinding the xerogel to obtain the YVO4:Eu3<+> nanopowder.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Formula for producing low-cost ultrahigh-speed heat-conducting LED die-cast aluminum radiator

InactiveCN105401003ALow proportion of added ingredientsLow costLighting heating/cooling arrangementsSemiconductor devices for light sourcesHeat conductingDie casting

The invention discloses a formula for producing a low-cost ultrahigh-speed heat-conducting LED die-cast aluminum radiator. The low-cost ultrahigh-speed heat-conducting LED die-cast aluminum radiator comprises, by weight, 1%-10% of tin, 1%-10% of magnesium, 1%-10% of zinc, 0.5%-3% of nano-europium oxide, 0.5%-3% of nano-terbium oxide, 0.1%-1% of raney nickel catalysts and the balance aluminum. Compared with an existing cast-aluminum radiator which is high in price and contains precious metal or alloy materials on the market, the LED die-cast aluminum radiator produced through the formula has the same or higher heat conduction coefficient and is lower in cost; the LED die-cast aluminum radiator has extremely high market advantages and market competitiveness under the combined action of the two advantages.

Owner:简淦欢

Color-changing coating for copper

InactiveCN103665967ALow discoloration temperatureHigh precisionThermosensitive paintsCupric nitrateEuropium(III) oxide

A color-changing coating for copper comprises the components in parts by mass as follows: 100 parts of potassium iodide, 15-30 parts of nitric acid, 15-20 parts of cupper nitrate, 15-25 parts of strontium nitrate, 25-45 parts of aluminum nitrate, 10-25 parts of mercury nitrate, 10-20 parts of silver nitrate, 5-10 parts of europium oxide, 10-20 parts of dysprosium oxide, 10-15 parts of ammonium carbonate, 5-10 parts of ammonium bicarbonate, 15-25 parts of sulfur dioxide and 10-20 parts of water. The color-changing coating turns red from orange at the temperature of 35 DEG C, turns orange yellow from red at the temperature of 40 DEG C, turns orange red from orange yellow at the temperature of 45 DEG C and turns brown from orange red at the temperature of 50 DEG C.

Owner:JIANGSU PAQINI COPPER IND

Preparation method of europium-doped yttrium vanadate nanopowder for solar cell down conversion material

InactiveCN104371724BControl contentUniform particle sizeLuminescent compositionsAmmonium metavanadateSolar cell

A preparation method of a solar cell down-conversion material YVO4:Eu3<+> nanopowder comprises the following steps: weighing yttria (Y2O3) and europium(III) oxide (Eu2O3) according to a molar ratio of 1:1, mixing, adding the obtained mixture to nitric acid, and dissolving Y2O3 and Eu2O3 to obtain a clarified solution containing yttrium ions and europium ions; adding ammonium metavanadate (NH4VO3) to the clarified solution according to a molar ratio of ammonium metavanadate to the above metal ions of 1:1; adding a citric acid solution with the concentration of 1.4-1.6mol / L to make a molar ratio of citric acid to the metal ions reach 2:1; taking a quantitative amount of ammonia water, and slowly adding the quantitative amount of ammonia water to the above obtained citric acid-containing solution; adding a certain amount of a dispersing agent, and aging for a period of time to obtain a sol; and heating the sol to obtain xerogel, and grinding the xerogel to obtain the YVO4:Eu3<+> nanopowder.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

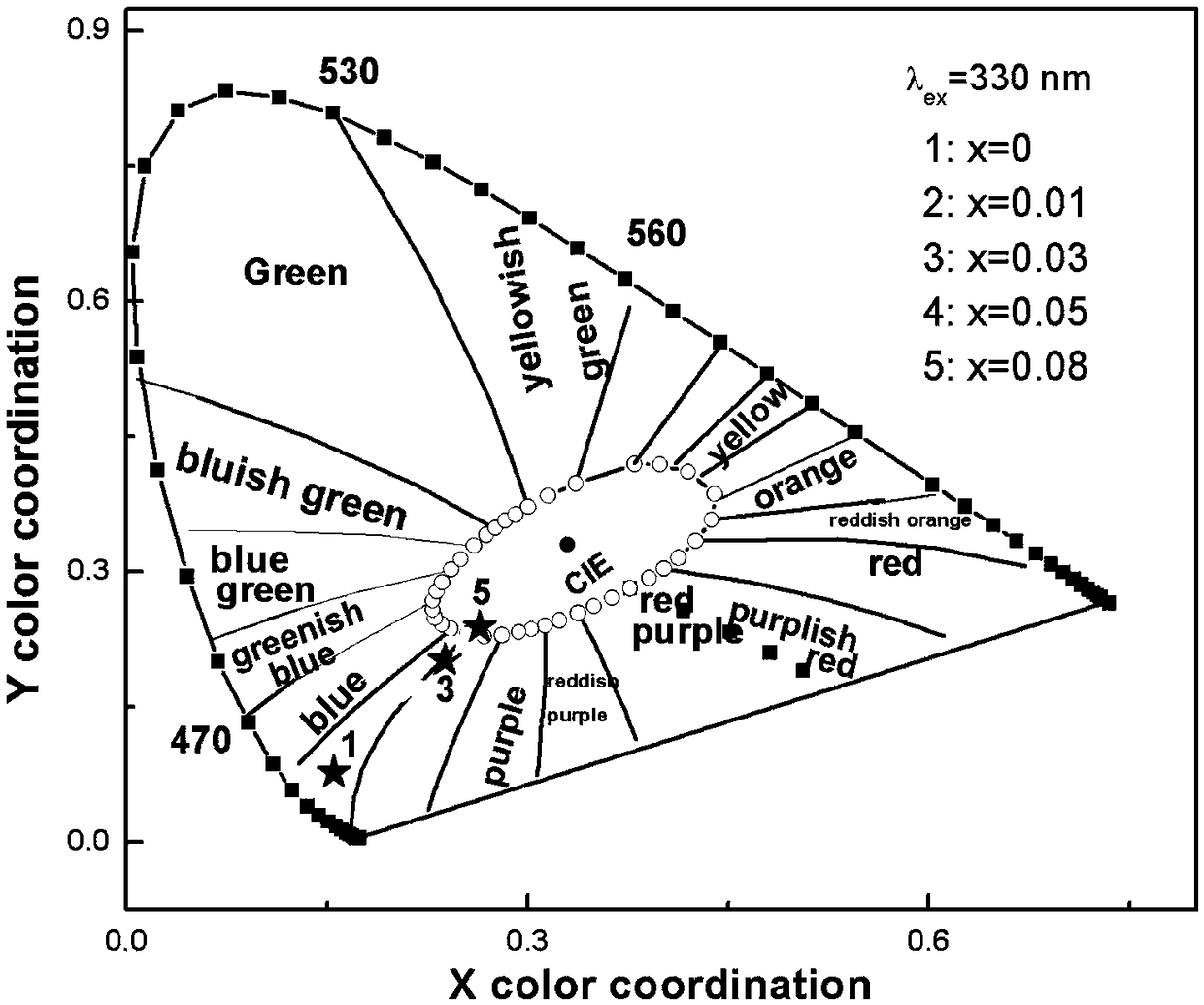

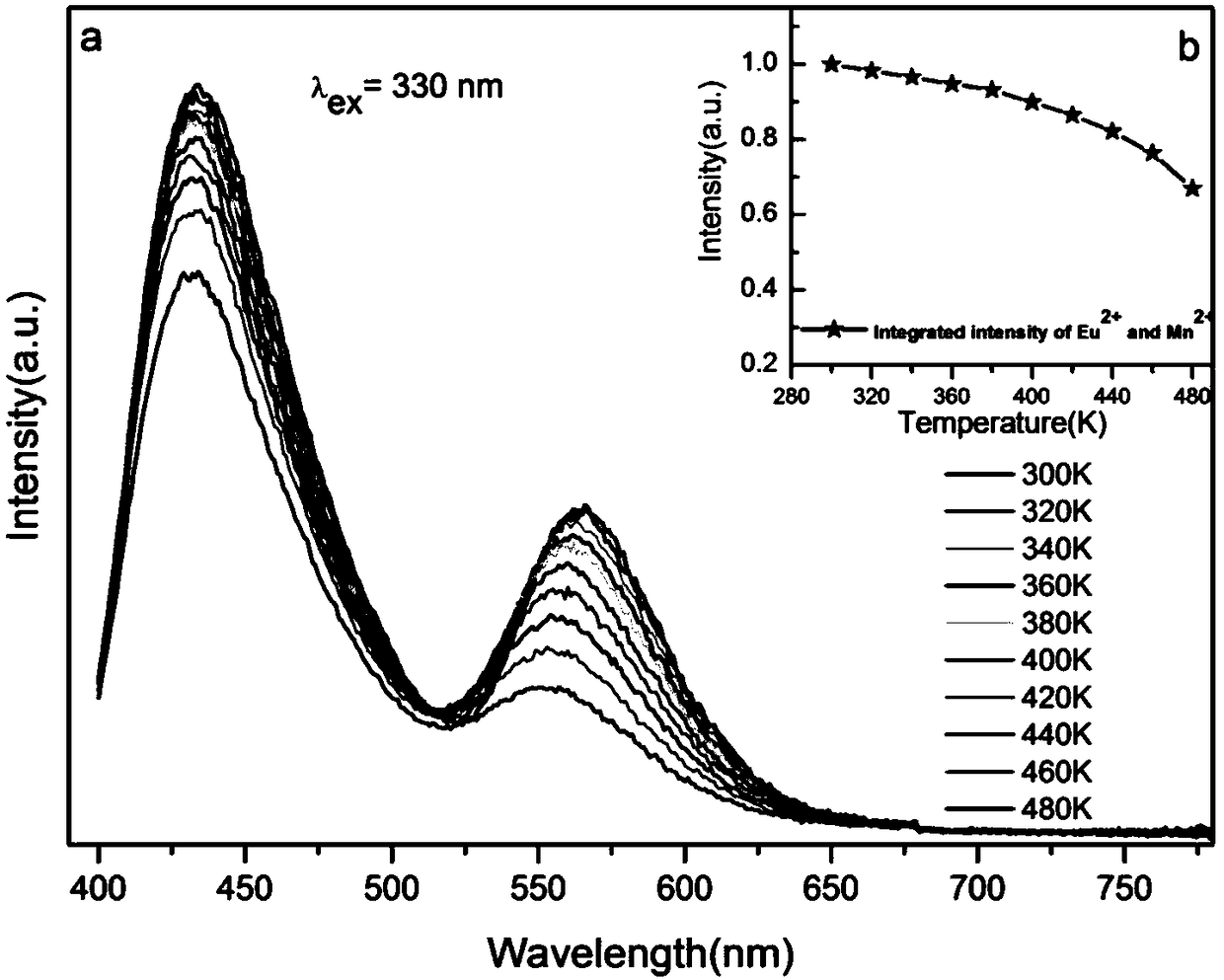

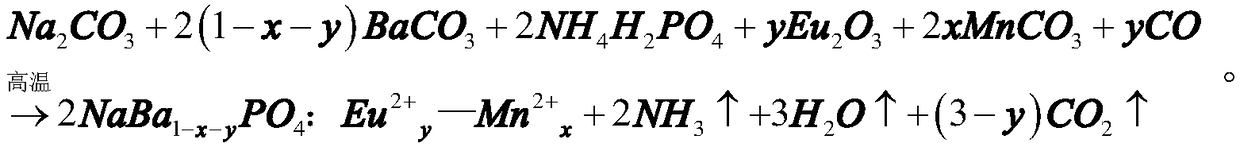

Fluorescent powder capable of exciting white light emission and suitable for ultraviolet LED and preparation method thereof

InactiveCN109181692ALower sintering temperatureImprove thermal stabilityEnergy efficient lightingLuminescent compositionsPhosphateHeat stability

The invention relates to the technical field of fluorescent powder preparation and relates to a fluorescent powder capable of exciting white light emission and suitable for ultraviolet LED and a preparation method thereof. The method comprises the following steps: S1) respectively weighting sodium carbonate, barium carbonate, ammonium dihydrogen phosphate or diammonium hydrogen phosphate, europiumoxide and manganese carbonate at mole ratio of 0.5:(0.995-x):1:0.0025:x, milling and uniformly mixing, thereby acquiring a mixture; S2) putting the mixture into a high temperature furnace under a reducing atmosphere, standing by and reacting, thereby acquiring an initial product of fluorescent powder; S3) cooling the initial product of fluorescent powder and then milling, thereby acquiring an endproduct of fluorescent powder with a chemical formula of NaBa1-x-yPO4:Eu2+y-Mn2+x and used for coating an ultraviolet LED chip. The fluorescent powder prepared according to the invention is a singlesubstrate white light fluorescent powder, so that the re-absorption problem of multi-powder combining schemes can be avoided. Phosphate is served as the substrate of the fluorescent powder, so that the heat stability is high, the defect of color drifting phenomenon during use process caused by different heat stabilities of different powders can be further avoided, and the purposes of enhancing thestability of fluorescent powder and increasing the luminous efficiency can be achieved.

Owner:WUYI UNIV

Radiating type lighting LED lamp glass and preparation method thereof

The invention discloses radiating type lighting LED lamp glass which is prepared from the following raw materials in parts by weight: 10 to 30 parts of silicon dioxide, 25 to 45 parts of europium oxide, 10 to 30 parts of potassium carbonate, 15 to 35 parts of lauric acid, 10 to 40 parts of glass powder, 5 to 25 parts of glass fiber, 2 to 10 parts of binder, 5 to 15 parts of photo-diffusion powder, 3 to 13 parts of antifog additive and 4 to 16 parts of heat conduction powder. The radiating type lighting LED lamp glass has the advantages of convenient processing technology and long service life.

Owner:ANHUI ZHAOLI OPTO ELECTRONICS TECH

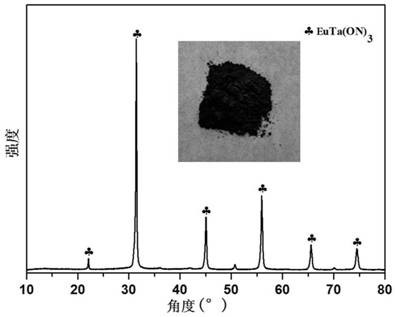

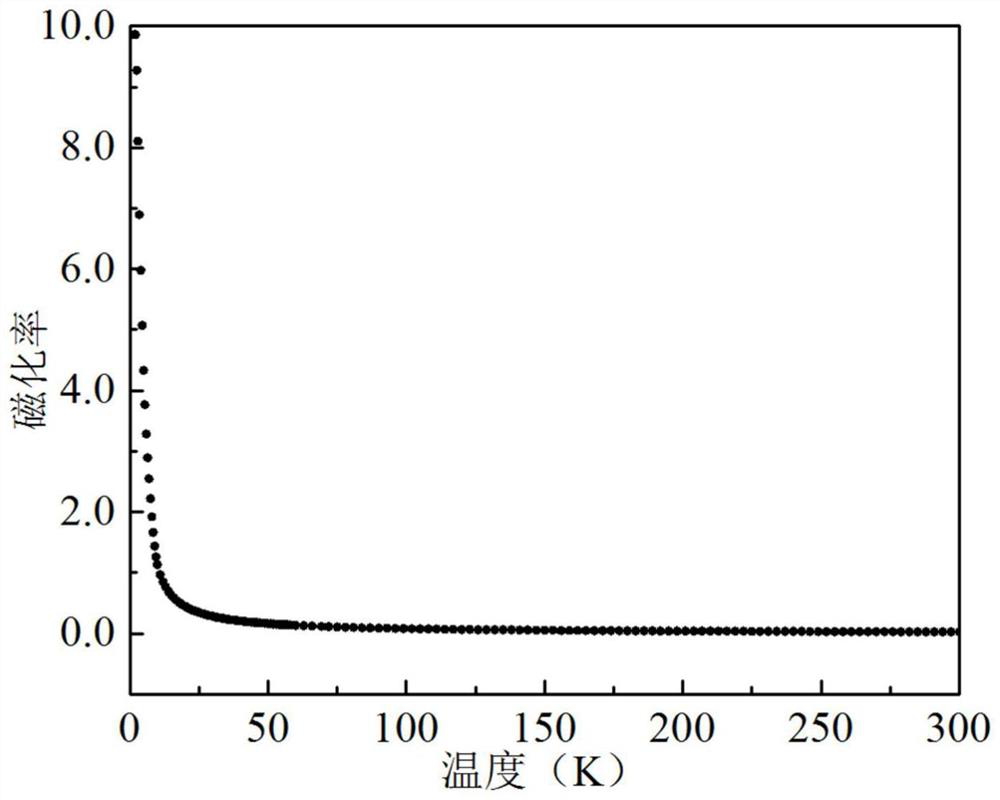

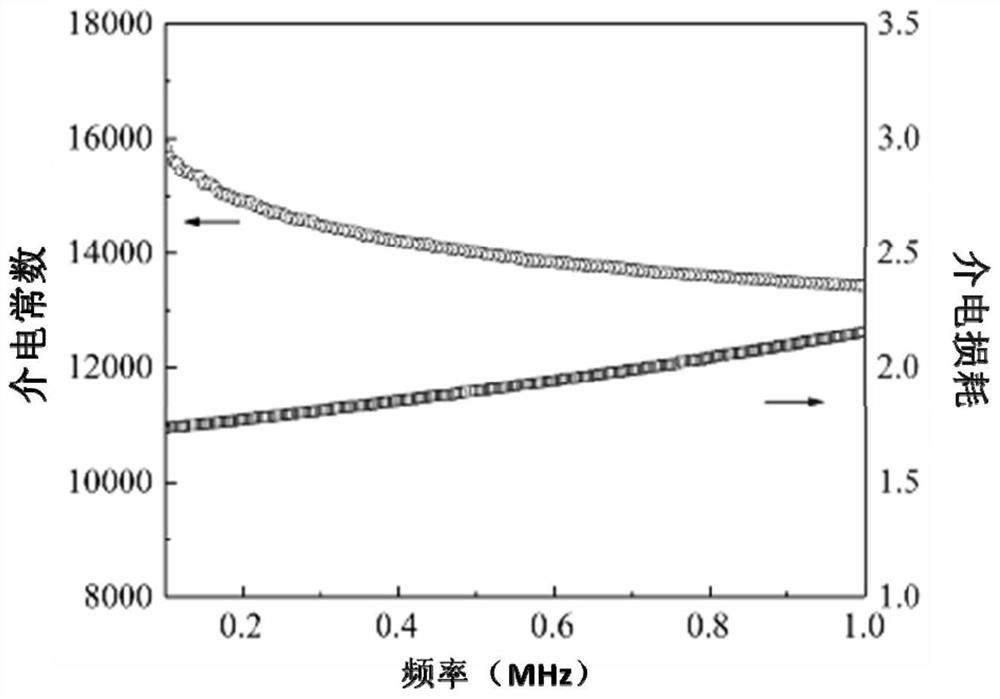

Non-stoichiometric oxynitride nano powder and preparation method thereof

The invention discloses non-stoichiometric oxynitride nano powder and a preparation method thereof. The preparation method comprises the following steps: firstly, dissolving europium oxide powder, tantalum pentoxide powder and urea in absolute ethyl alcohol, carrying out ball milling to obtain mixed slurry, drying the mixed slurry to obtain mixed precursor powder, calcining the mixed precursor powder in a protective atmosphere to obtain EuTa(O, N)3 oxynitride nano powder, and carrying out ammonification annealing treatment on the EuTa(O, N)3 oxynitride nano powder in an ammonia atmosphere to obtain the oxynitride nano powder EuTaOaNb with the non-stoichiometric ratio, wherein a is more than or equal to 1.5 and less than or equal to 2.5, b is more than or equal to 0.5 and less than or equal to 1.5, and a:bis not equal to 2:1. According to the invention, the method has the advantages of low cost, simple process, high product purity and the like, and the prepared product is good in dielectric property and magnetism.

Owner:NAT UNIV OF DEFENSE TECH

Preparation of solid thermoluminescent dosemeter material

InactiveCN101434840BHigh sensitivityEasy to prepareLuminescent dosimetersLuminescent compositionsThermoluminescenceDosimeter

The invention provides a solid thermoluminescence dosimeter, relating to the following chemical formula: Sr2P2O7:xEu2+, yPr3+. The raw materials strontium hydrogen phosphate, ammonium dihydrogen phosphate, europium oxide and praseodymium oxide are weighed according to dosage ratio, grinded, mixed uniformed and filled in a roasting vessel; the roasting vessel is then placed in a high-temperature furnace under the sintering atmosphere of CO gas, H2 gas or the mixed gas of N2 and H2 and sintered at the temperature of 900-1400 DEG C for 3-6 hours, thus obtaining target material. After being radiated by Gama-ray, the thermoluminescence curve is single peak with the peak temperature of 439.5K; the thermoluminescence sensitivity is 4.6 times of dosimeter (LiF:Mg, Cu, P) which is widely used at present and has the highest sensitivity; furthermore, the solid thermoluminescence dosimeter material has good linearity at the dosage response of the thermoluminescence at 100-1000mGy and is a good thermoluminescence dosimeter material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

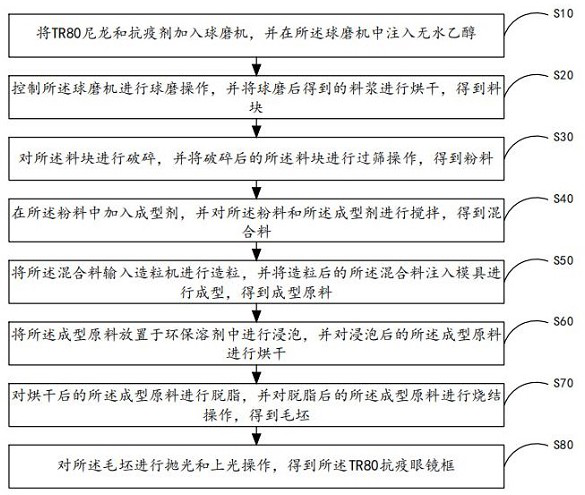

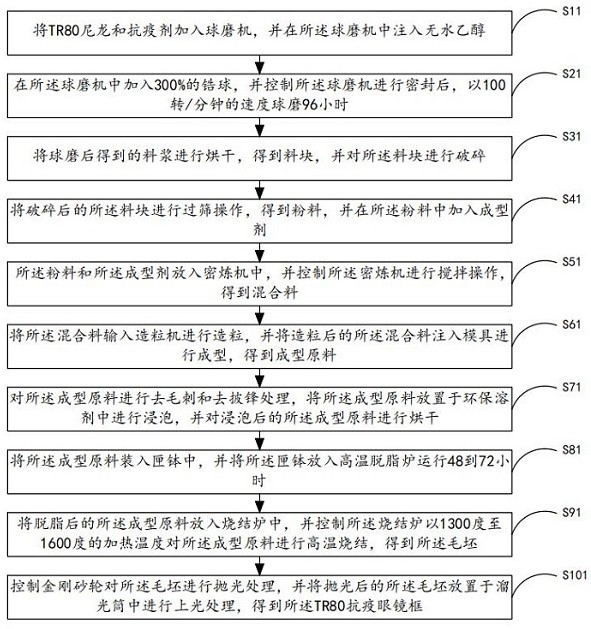

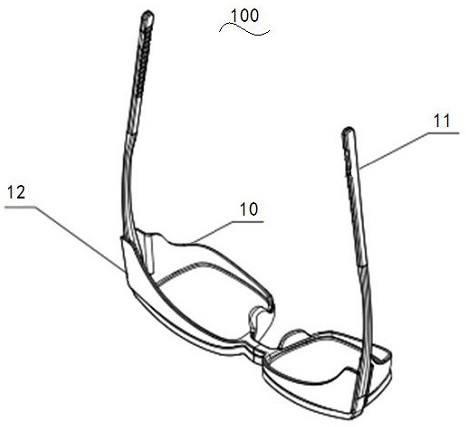

A kind of anti-epidemic spectacle frame manufacturing method and anti-epidemic spectacle frame

The invention provides a method for making an anti-epidemic spectacle frame and the anti-epidemic spectacle frame. The method comprises: adding nylon TR80 and an anti-epidemic agent into a ball mill, wherein the composition of the anti-epidemic agent includes zirconia (ZrO 2 ), barium titanate (BaTiO 3 ), molecular sieve catalyst and europium trioxide (Eu 2 o 3 ), the raw materials are subjected to steps such as ball milling and stirring to obtain a mixture; the mixture is input into a granulator for granulation, and the granulated mixture is injected into a mold for molding to obtain a molding raw material; the molding raw material is placed in an environmentally friendly solvent for soaking Finally, drying; degreasing the dried molding raw materials, and sintering the degreased molding raw materials to obtain blanks; polishing and glazing the blanks to obtain anti-epidemic spectacle frames. In the present invention, the anti-epidemic agent is added into the raw material of the spectacle frame, so that the spectacle frame obtained has an anti-epidemic effect, and the damage to human skin caused by spraying the bactericide or the bactericidal liquid is prevented.

Owner:江鸿特材科技(深圳)有限公司

Preparation method of titanium dioxide europium-doped nano-film sol

InactiveCN101538065BReduce manufacturing costEasy to operateTitanium dioxideEthylenediamineSesquioxide

The invention discloses a preparation method of titanium dioxide europium-doped nano-film sol. In the method, metatitanic acid (H2TiO3) is washed by distilled water repeatedly, and put into an oven to be baked for 12 hours at 60 DEG C; europium sesquioxide (Eu2O3) is dissolved in nitric acid to obtain europium ion; H2Ti3 and K2CO3 are evenly mixed according to mol ratio of 5.2:1, europium ion is added into the mixture according to 0.2-3% of mass fraction of titanium, and little absolute ethyl alcohol is added into the mixture simultaneously, the mixture being fully ground is put in a muffle to be calcined for 6-15 hours at 600-1000 DEG C, the material being calcined is taken out and added into hydrochloric acid of 1mol / L according to the proportion of 4g / L to be stirred, filtration washing is carried out for 24-72 hours, the filter cake is added into 4-n-butyl ammonium hydroxide or ethylene dimine according to the proportion of 0.4g / L to be stirred for 24-72 hours, is then centrifugated at the high speed centrifugation of 10000r / min to obtain titanium dioxide europium-doped nano-film sol. The invention is convenient in operation, low in cost and suitable for industrialized prosuction.

Owner:EAST CHINA NORMAL UNIV

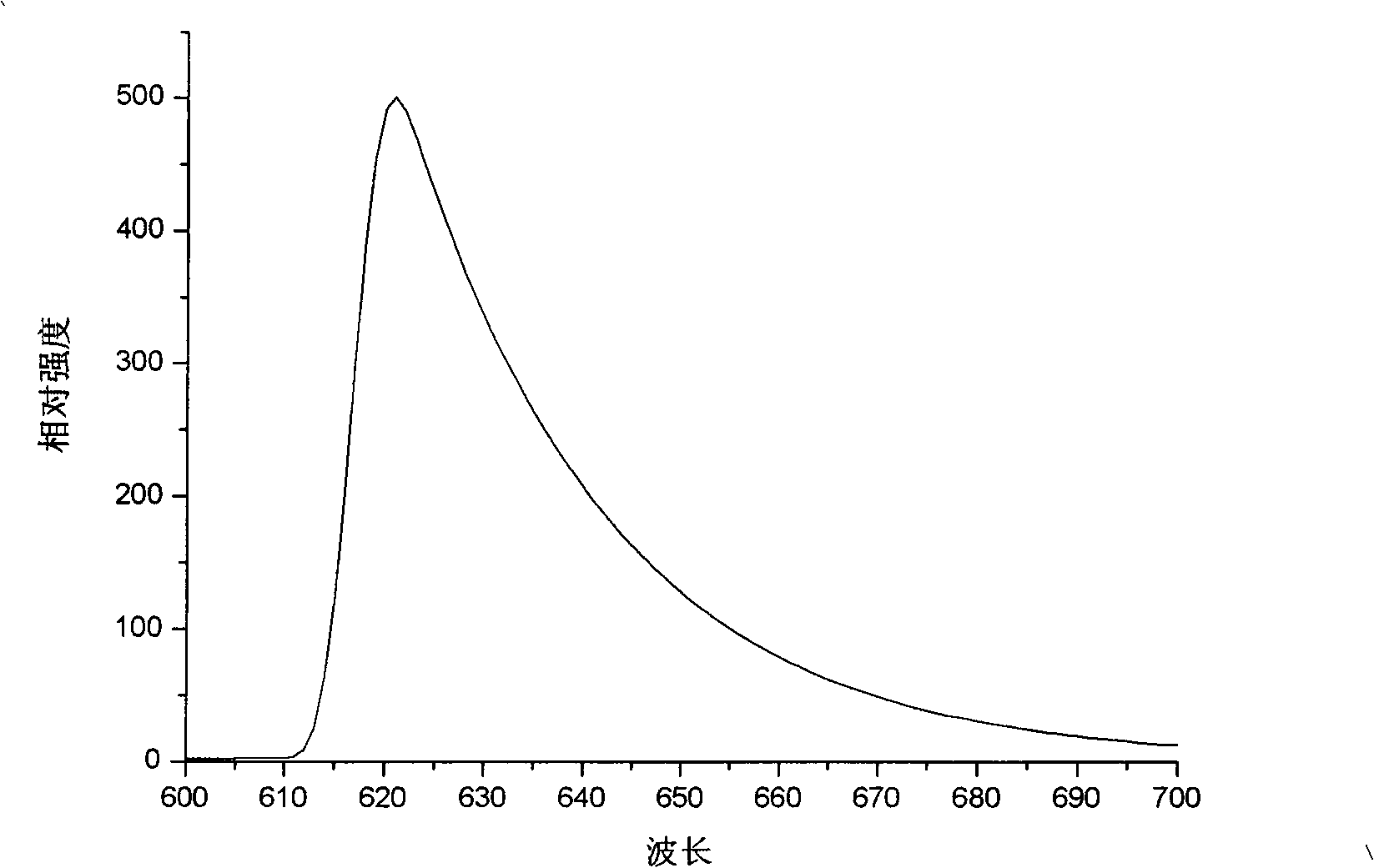

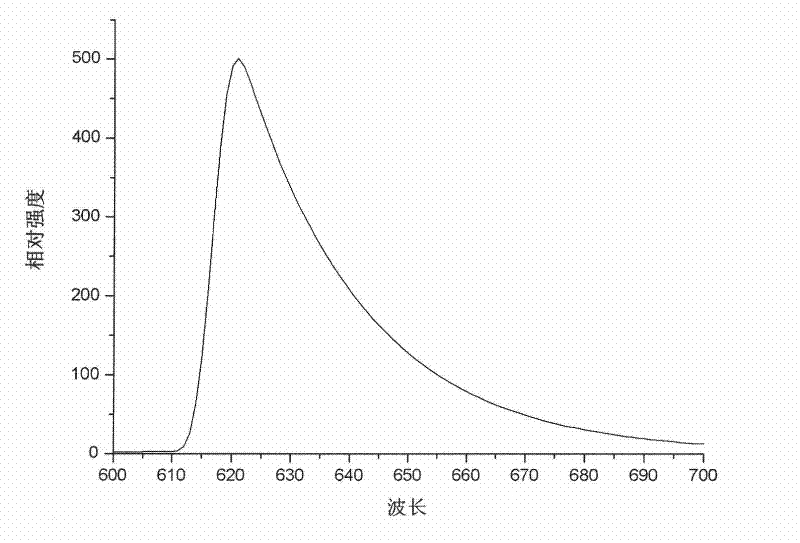

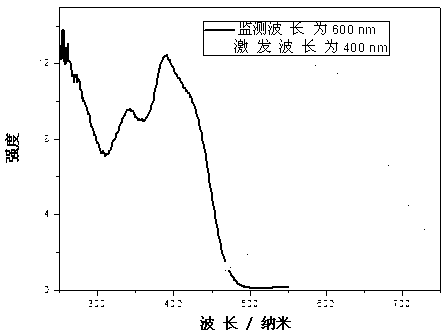

Orange-red rear-earth phosphors and preparation method thereof

InactiveCN103059843AStrong excitationStrong orange-red emissionLuminescent compositionsStrontium chloride hexahydrateStrontium bromide

The invention relates to orange-red rear-earth phosphors and a preparation method thereof. The orange-red rear-earth phosphors are prepared from strontium carbonate, calcium chloride, strontium chloride hexahydrate, strontium fluoride, strontium bromide, aluminum hydroxide, boric acid and europium oxide serving as raw materials by adopting a high-temperature solid state method. The preparation method comprises the following steps of: uniformly mixing the raw materials according to proportions, pre-sintering for 3-6 hours at 400-500 DEG C, cooling to a room temperature, taking out the raw materials and uniformly grinding again, reducing and sintering at a CO atmosphere for 4-10 hours at 1000-1200 DEG C, and grinding fine obtained sinters to obtain final products. The orange-red rear-earth phosphors have high luminous efficiency, good stability and very high quenching temperature and are suitable for InGaN chips giving out ultraviolet lights with about 400nm wavelength.

Owner:YUNNAN MINZU UNIV

Preparation method of eu2o3-dy2o3 double-doped zinc borosilicate glass-ceramics

The invention discloses a method for preparing Eu2O3-Dy2O3 double-doped zinc-boron-silicate glass-ceramics. The preparation method uses zinc oxide, boric acid, silicon dioxide, aluminum oxide, sodium carbonate, titanium dioxide, Dysprosium and europium trioxide are used as raw materials. After grinding and mixing the above raw materials, they are melted and shaped at 1400-1500°C to form glass, and the formed glass is annealed at 500-600°C for 2-3 hours to eliminate internal Stress, cooled to room temperature; crystallize the annealed glass, nucleate at 550-650°C for 2-5 hours, crystallize at 750-800°C for 6-12 hours, and finally obtain zinc borosilicate Luminous glass-ceramic. The invention has a short production cycle and low cost, and the prepared luminescent glass-ceramic has the advantages of high luminous efficiency, high uniformity, long life, energy saving and environmental protection, etc., and is applied to LED lamps to reduce costs and improve luminous performance.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Ceramic for heat-resistant wear-resistant nozzles and preparation method of ceramic

The invention discloses a ceramic for heat-resistant we-resistant nozzles. The ceramic is prepared from the following raw materials in parts by weight: 3-5 parts of europium oxide, 2-3 parts of dysprosium oxide, 4-7 parts of kyanite, 1-1.5 part of cadmium carbonate, 1-2 parts of sodium peroxide, 20-25 parts of quartzite, 22-27 parts of albite, 10-14 parts of nano titanium boride, 5-8 parts of nano tungsten carbide, 1-2 parts of sodium hydroxide, appropriate amount of deionized water, 3-4 parts of ethyl orthosilicate, appropriate amount of ethyl alcohol and 4-6 parts of an assistant. By adding europium oxide, dysprosium oxide, nano titanium boride and nano tungsten carbide, the hardness, the wear resistance and the heat resistance are improved, and the service lives of the nozzles produced by the ceramic is 2-3 times longer than the aluminum alloy nozzles; and by using the assistant, the surface smoothness, the wear resistance and the heat resistance of the ceramic can be improved.

Owner:ANHUI WANJIE HYDRAULIC TECH

Europium doped lanthanide silicon oxynitride and preparation method thereof

InactiveCN103146386BStrong emission peakStrong excitation peakLuminescent compositionsFurnace temperatureHydrogen atmosphere

The invention discloses a europium doped lanthanide silicon oxynitride, of which the chemical general formula is La5-5xEu5xSi3O12N, wherein x is more than 0 and less than 0.25. The preparation method comprises the steps of: (a) weighing raw materials: lanthanum trioxide, silicon dioxide, silicon nitride and europium oxide, according to the molar ratio of the chemical formula La5-5xEu5xSi3O12N (x is more than 0 and less than 0.25); (b) ball-milling the raw materials and tabletting; (c) putting tablets into a high temperature furnace, under the nitrogen hydrogen atmosphere, raising the furnace temperature to 1000-1250 DEG C, and sintering for 3-10 hours; (d) turning off a hydrogen source, under the environment of charging nitrogen gas, keeping the high temperature furnace at a pressure of 0.5-1MPa, raising the furnace temperature to 1450-1550 DEG C, and continuously sintering the tablets for 3-10 hours; and (e) ventilating to release the pressure in the furnace to be an ordinary pressure, cooling down the high temperature furnace to room temperature by circulating under the nitrogen-hydrogen mixed atmosphere, taking out the sample tablets, and grinding, thus obtaining a fluorescent material. The fluorescent material prepared by the preparation method is stable in physicochemical property, convenient to control luminescence property, simple in preparation method, and free from environmental pollution, and is applicable to industrialized mass production.

Owner:HEBEI UNIVERSITY

A kind of low hydroxyl yellow filter quartz tube and preparation method thereof

The invention discloses a low-hydroxyl yellow light-filtering quartz tube and a preparation method thereof. The low-hydroxyl yellow light-filtering quartz tube is prepared from the following raw materials by optimal weight percent: 94% to 99% of quartz sand with high purity, 0.1% to 0.5% of cobaltous oxide, 0.1% to 2% of ceric oxide, 0.1% to 0.5% of europium oxide, 0.1% to 0.5% of aluminum oxide, 0.1% to 0.5% of titanium oxide, 0.1% to 0.5% of potassium oxide and 0.1% to 0.5% of sodium oxide. The low-hydroxyl yellow light-filtering quartz tube also has the advantage of being more reasonable in formula matching besides having the advantages of the ordinary ultraviolet-filtering quartz glass tube. According to the testing of a conventional method, the compressive strength of the low-hydroxyl yellow light-filtering quartz tube is greatly improved while the damage of an automobile lamp to a baking varnish is greatly decreased due to the addition of multiple metal oxides and rare earth elements; the safety performance of the low-hydroxyl yellow light-filtering quartz tube is improved at the same time.

Owner:NANTONG HUITONG TEXTILE EQUIP

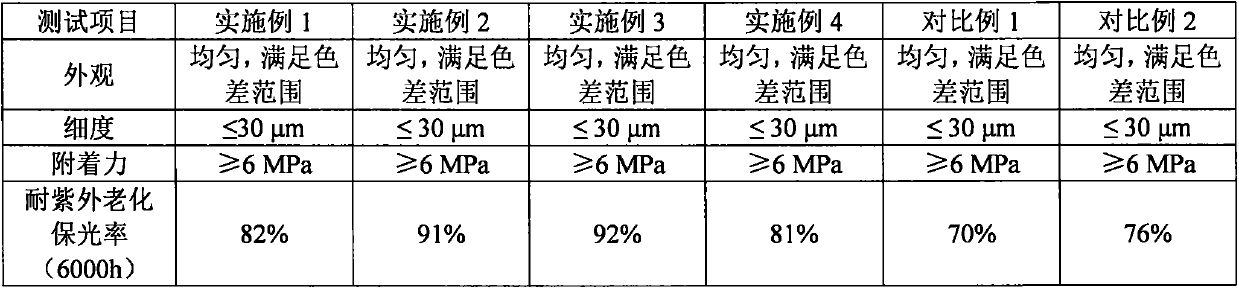

A kind of nano particle modified normal temperature curing fluorocarbon coating and preparation method thereof

ActiveCN105419601BGood weather resistanceGood masking effectAnti-corrosive paintsPolyurea/polyurethane coatingsUltraviolet lightsSolvent

The invention provides a room temperature cured fluorocarbon coating modified with nano particles and a preparation method of the room temperature cured fluorocarbon coating. The fluorocarbon coating specifically comprises a component A and a component B, wherein the component A comprises, by weight, 30%-45% of FEVE fluorocarbon resin, 20%-30% of nano-titanium dioxide filler, 2%-10% of discoid nano-europium oxide filler, 15%-20% of a solvent as well as a flatting agent, a defoaming agent, a wetting dispersant, a thixotropic agent and pigment which account for 4%-10% of the total mass of the component A; the component B comprises, in percentage by mass, 10%-50% of isocyanate type curing agents and a solvent. The weather resistance of the fluorocarbon coating is further improved through the higher shielding effect of nano-europium oxide for ultraviolet light and the composite effect of nano-titanium dioxide and nano-europium oxide.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Germanate glass luminescent film and preparation method

The invention discloses a preparation method of a germanate glass luminescent film. The method comprises the following steps: selecting zinc oxide, lead oxide, germanium oxide and silicon dioxide as glass substrate and selecting manganese oxide and europium sesquioxide as luminescent agents; dissolving tetraethoxysilane in absolute ethyl alcohol and dissolving other oxides in a nitric acid solution to prepare a 0.5-1.5mol / L nitrate solution; mixing the solution, stirring and adding a certain amount of citric acid as a chelating agent; regulating pH to 0.5-1 to prepare sol; atomizing the prepared sol at a nozzle of a spray gun by high pressure gas to allow deposition on a high-temperature quartz glass substrate to form uniform film; keeping the formed film at constant temperature of 500 DECC for 2-5h; meanwhile, charging a gas mixture of nitrogen and hydrogen into a heating furnace as reducing atmosphere to finally obtain colorless transparent glass film which can emit bright red fluorescence in the presence of 254nm ultraviolet irradiation.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Non-radioactive environment protection energy storage luminous ceramic glaze material

The non-radioactive environment protecting energy storage luminous ceramic glaze material is prepared with strontium carbonate, Al2O3, boric acid, Eu2O3, Dy2O3, borax, quartz, niter, limestone, talcum and sodium fluorosilicate, and through mixing and other steps. It has the advantages of no radioactivity and long luminous time.

Owner:张贵洲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com