Europium doped lanthanide silicon oxynitride and preparation method thereof

A silicon oxygen nitrogen compound technology, applied in the field of europium doped lanthanide silicon oxygen nitrogen compound and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

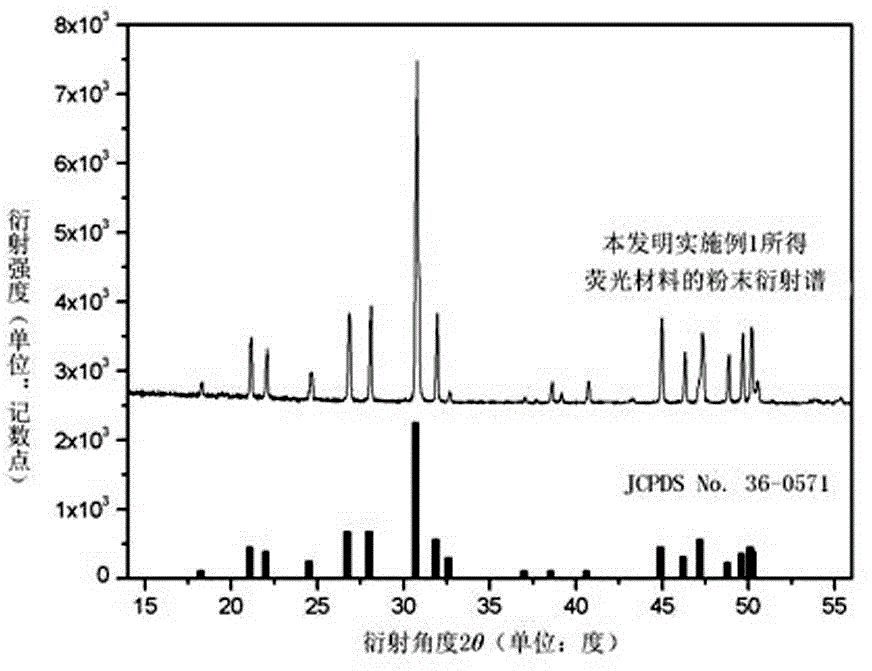

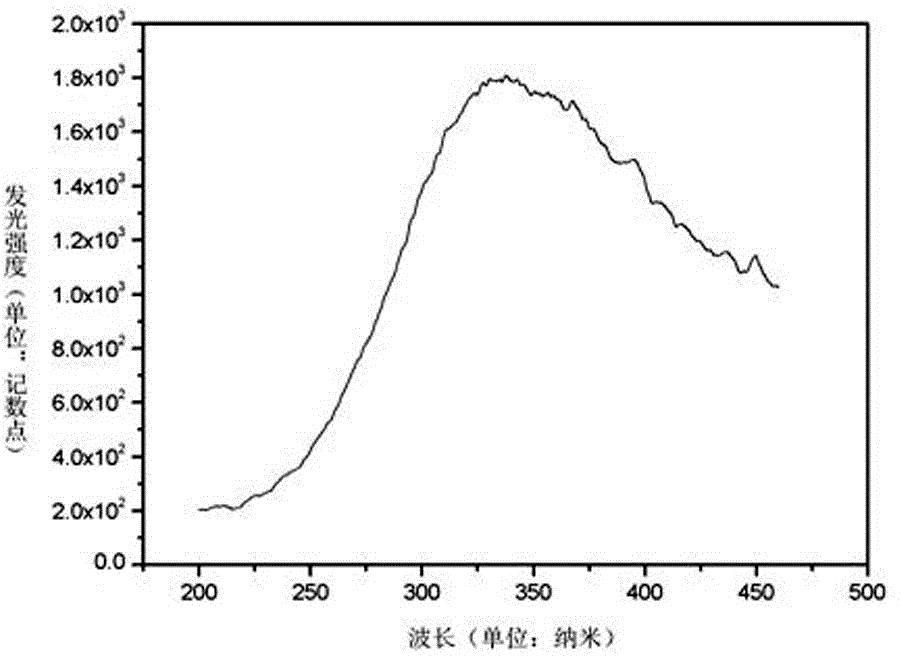

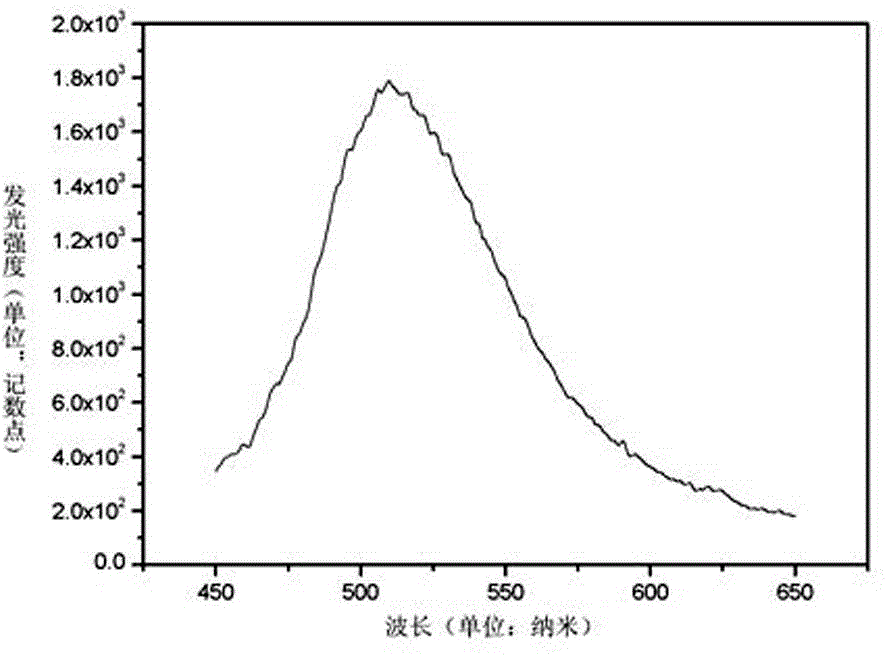

Embodiment 1

[0033] According to chemical formula (La 0.95 Eu 0.05 ) 5 Si 3 o 12 Weighing the molar ratio of each element in N Raw materials: La 2 o 3 Powder 5.004g, SiO 2 Powder 0.8740g, Si 3 N 4 Powder 0.2265g, Eu 2 o 3The powder is 0.2846 g; after mixing, put it in a ball mill, and mill it for 1 hour, take out the ball mill powder, and press it with a tablet machine, the pressure of the tablet machine is 15MPa, the thickness of the tablet is about 11mm, and the diameter is 13mm; the sample is placed in a high-temperature and high-pressure graphite furnace In the middle, fully vacuumize, feed the nitrogen-hydrogen mixed gas source according to the volume ratio of nitrogen and hydrogen at 95:5, raise the temperature to 1250°C, keep warm and sinter for 3 hours; cut off the hydrogen gas source, close the valves of other gas sources, and fill the high Pure nitrogen until the pressure in the furnace is 0.5MPa, heat up to 1550°C, heat-preserve and sinter for 3 hours; open the valve o...

Embodiment 2

[0035] According to chemical formula (La 0.99 Eu 0.01 ) 5 Si 3 o 12 Weighing the molar ratio of each element in N Raw materials: La 2 o 3 Powder 5.002g, SiO 2 Powder 0.8385g, Si 3 N 4 Powder 0.2177g, Eu 2 o 3 Powder 0.0544g; after mixing, put it in a ball mill, ball mill for 1 hour, take out the ball mill powder, and press it with a tablet machine. In the middle, fully vacuumize, feed the nitrogen-hydrogen mixed gas source according to the volume ratio of nitrogen and hydrogen at 95:5, raise the temperature to 1250°C, keep warm and sinter for 3 hours; cut off the hydrogen gas source, close the valves of other gas sources, and fill the high Pure nitrogen until the pressure in the furnace is 0.5MPa, heat up to 1450°C, heat-preserve and sinter for 3 hours; open the valve of the outlet pipe, reduce the pressure in the furnace to normal pressure, open the valve of the inlet pipe, and make the volume ratio of nitrogen and hydrogen 95:5 Introduce nitrogen and hydrogen mixe...

Embodiment 3

[0037] According to chemical formula (La 0.9 Eu 0.1 ) 5 Si 3 o 12 Weighing the molar ratio of each element in N Raw materials: La 2 o 3 Powder 5.0002 g, SiO 2 Powder 0.9022g, Si 3 N 4 Powder 0.2390g, Eu 2 o 3 0.6000 g of powder; after mixing, put it in a ball mill and mill it for 1 hour, take out the ball mill powder, and press it with a tablet machine. In the middle, fully vacuumize, feed the nitrogen-hydrogen mixed gas source according to the volume ratio of nitrogen and hydrogen at 95:5, raise the temperature to 1250°C, keep warm and sinter for 3 hours; cut off the hydrogen gas source, close the valves of other gas sources, and fill the high Pure nitrogen until the pressure in the furnace is 0.5MPa, heat up to 1500°C, heat-preserve and sinter for 3 hours; open the valve of the outlet pipe, reduce the pressure in the furnace to normal pressure, open the valve of the inlet pipe, and set the volume ratio of nitrogen and hydrogen to 95:5 Introduce nitrogen and hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com