Titanium dioxide photocatalysis composite film and preparation method thereof

A titanium dioxide and composite thin film technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as cumbersome steps, and achieve simple process conditions, tight integration, The effect of improving the degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

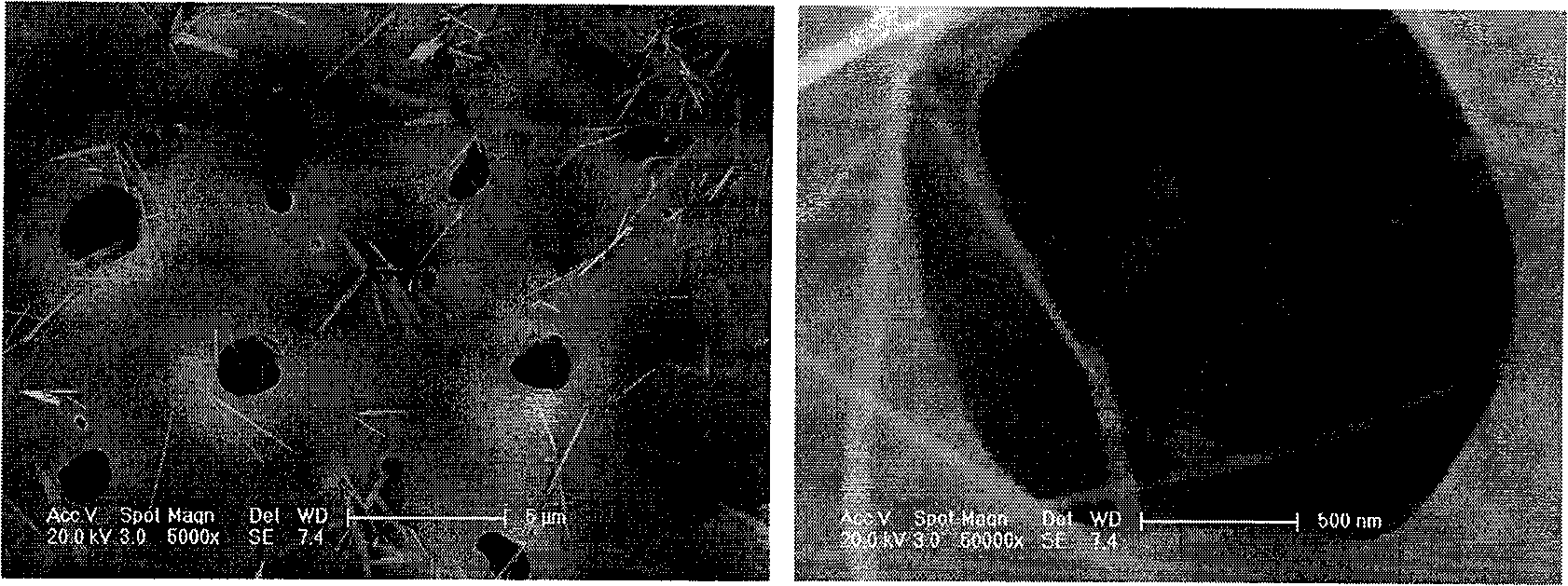

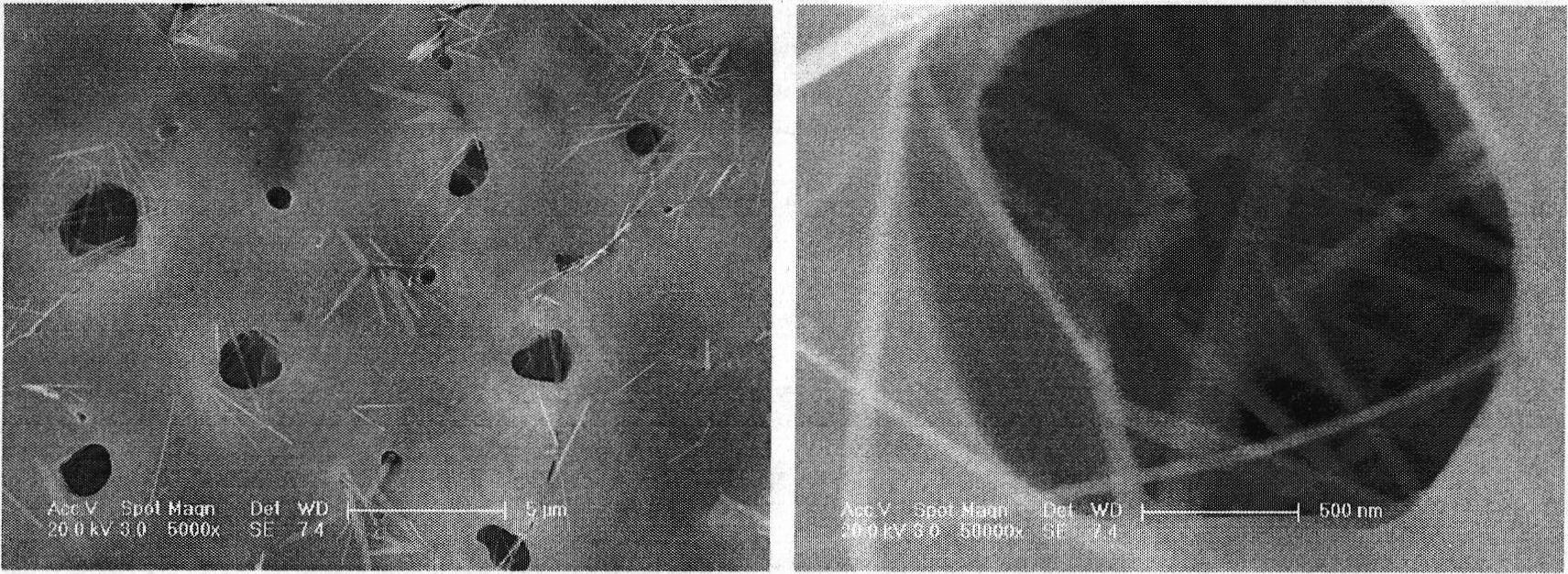

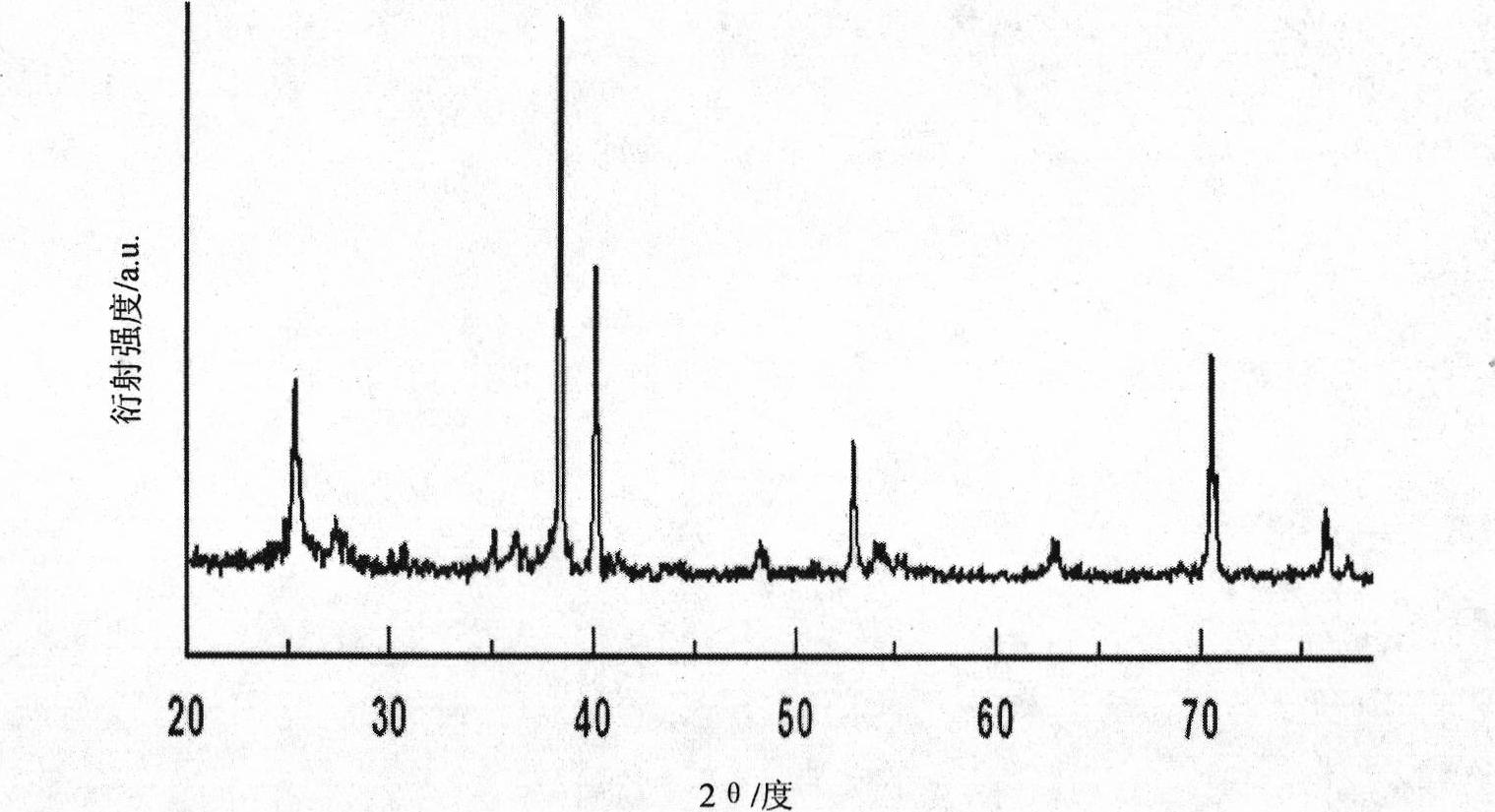

[0033] Embodiment 1: Weigh 18g anhydrous sodium carbonate, 2g sodium silicate nonahydrate, add 1000ml deionized water to dissolve and place in the reaction tank as electrolyte; weigh 2g Eu 2 o 3 , add a small amount of deionized water to ultrasonically disperse and add it to the electrolyte, and stir it with an electric mixer to disperse evenly in the electrolyte; through the action of circulating condensed water, the temperature of the entire system in the reaction tank is controlled within 40°C; choose polishing treatment The final titanium alloy was used as the anode material, and the stainless steel plate was used as the cathode material. The pulse voltage was slowly increased to 350V between the two electrodes, and the reaction was stable for 15 minutes. After the reaction, the titanium alloy anode was cleaned with ultrasonic waves.

Embodiment 2

[0034] Embodiment 2: Weigh 25g anhydrous sodium carbonate, 2g sodium silicate nonahydrate, add 1000ml deionized water to dissolve and place in reaction tank as electrolyte; Weigh 5g Eu 2 o 3 , add a small amount of deionized water to ultrasonically disperse and add it to the electrolyte, and stir it with an electric mixer to disperse evenly in the electrolyte; through the action of circulating condensed water, the temperature of the entire system in the reaction tank is controlled within 40°C; choose polishing treatment The final titanium alloy was used as the anode material, and the stainless steel plate was used as the cathode material. The pulse voltage was slowly increased to 400V between the two electrodes, and the reaction was stable for 5 minutes. After the reaction, the titanium alloy anode was cleaned with ultrasonic waves.

Embodiment 3

[0035] Embodiment 3: Weigh 15g anhydrous sodium carbonate, 10g sodium silicate nonahydrate, add 1000ml deionized water to dissolve and place in the reaction tank as electrolyte; weigh 1g Eu 2 o 3 , add a small amount of deionized water to ultrasonically disperse and add it to the electrolyte, and stir it with an electric mixer to disperse evenly in the electrolyte; through the action of circulating condensed water, the temperature of the entire system in the reaction tank is controlled within 40°C; choose polishing treatment The final titanium alloy was used as the anode material, and the stainless steel plate was used as the cathode material. The pulse voltage was slowly increased to 250V between the two electrodes, and the reaction was stable for 30 minutes. After the reaction, the titanium alloy anode was cleaned with ultrasonic waves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com