Fluorescent powder capable of exciting white light emission and suitable for ultraviolet LED and preparation method thereof

A phosphor and LED chip technology, applied in luminescent materials, chemical instruments and methods, electrical components, etc., can solve problems such as nano-fluorescence pink drift, and achieve the effects of improving luminous efficiency, good thermal stability, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

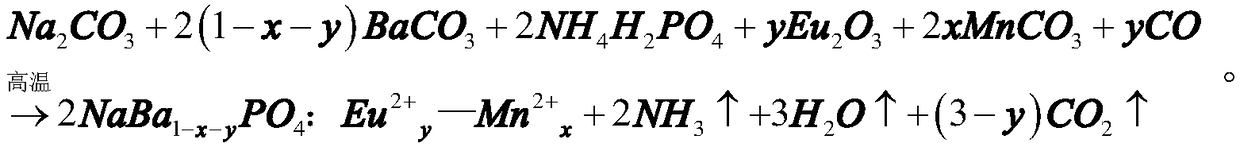

[0021] Weigh sodium carbonate, barium carbonate, ammonium dihydrogen phosphate or diammonium hydrogen phosphate, europium trioxide, and carbonate Manganese, the above raw materials are ground and mixed in an agate mortar, then put into a corundum crucible and then put into a 2 with N 2 In a box-type furnace with a gas atmosphere of mixed gas and a temperature of 1100°C-1300°C, react at a high temperature for 3-8 hours, then naturally cool to room temperature, take it out, and grind it into powder again to obtain a finished phosphor powder. In containing CO, or H 2 with N 2 Carrying out under the gas atmosphere of the mixed gas ensures that the trivalent europium in dieuropium trioxide can be reduced to divalent europium.

Embodiment 2

[0023] Weigh 0.3180g of sodium carbonate, 1.0815g of barium carbonate, 0.6902g of ammonium dihydrogen phosphate, 0.0053g of europium trioxide, and 0.0552g of manganese carbonate, grind and mix the above raw materials in an agate mortar and put them into a corundum crucible Then put it into a box-type furnace and set it at 1200°C, react in a CO atmosphere for 6 hours, cool it down to room temperature naturally, take it out, and grind it into powder again to get the finished phosphor powder.

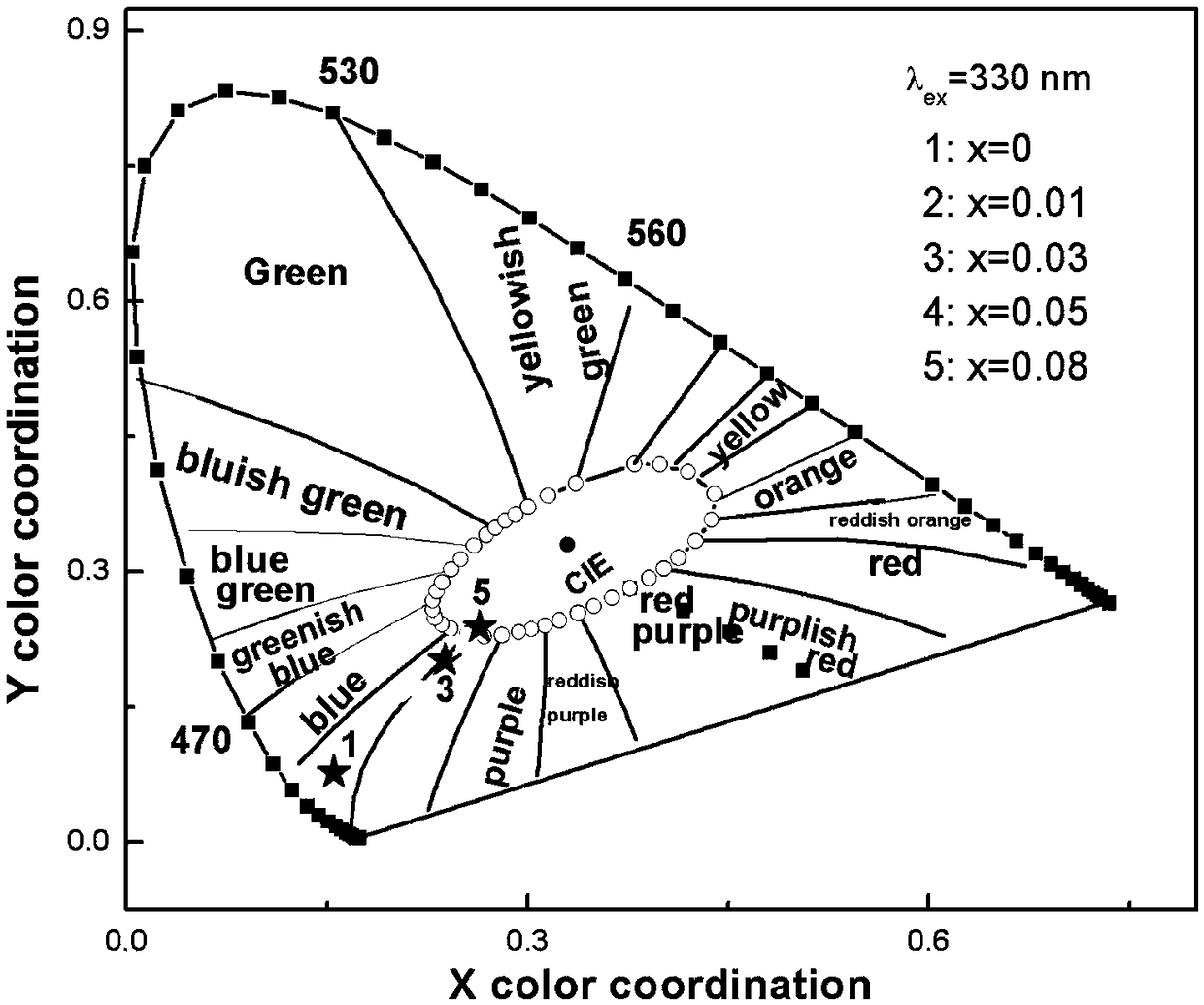

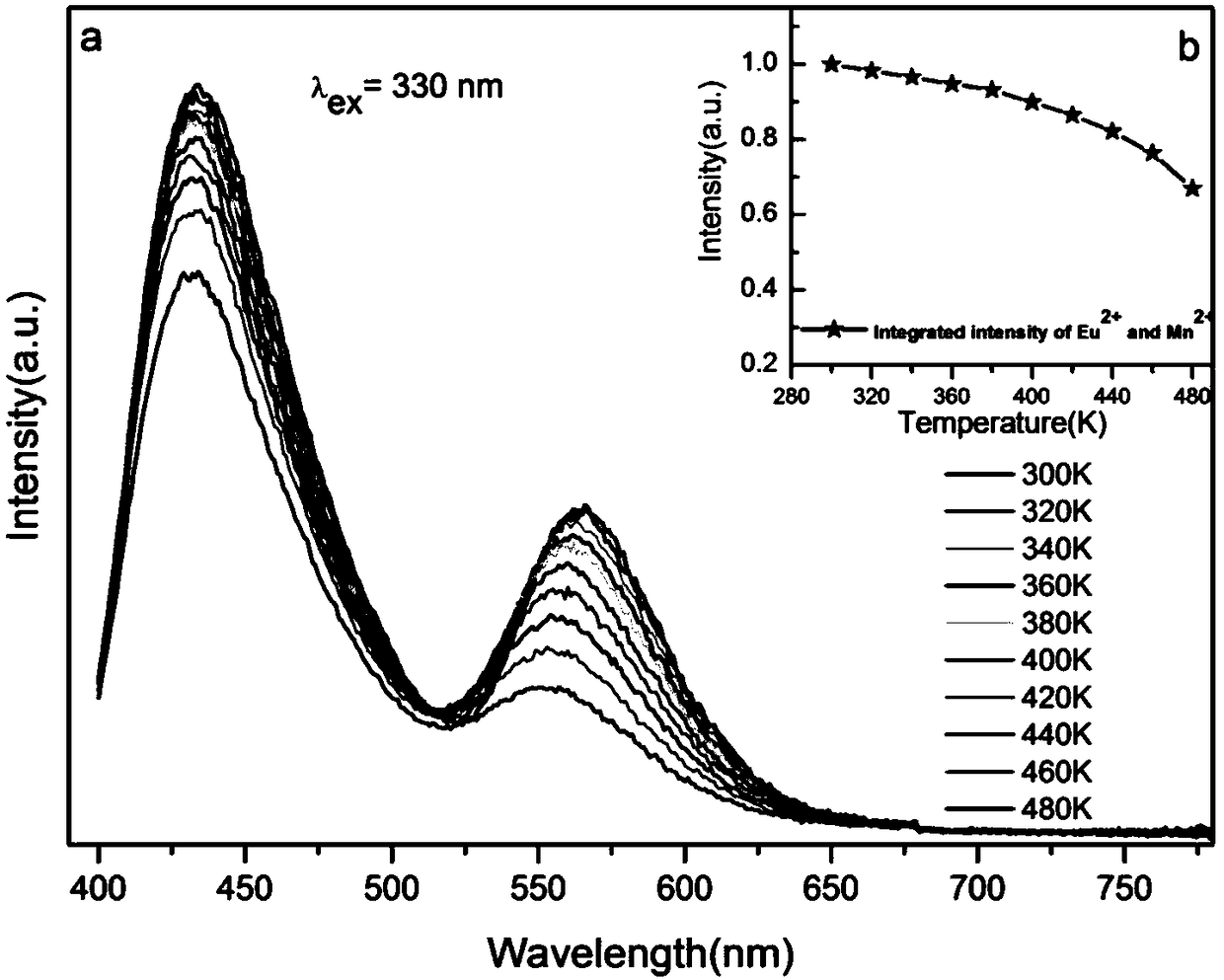

[0024] Thermal stability is an important indicator for evaluating the performance of phosphors. figure 1 It is the temperature-varying spectrogram of the phosphor powder obtained in Experiment 2, and the inner illustration is the curve of the emission intensity of the phosphor powder changing with the test temperature. It can be seen from the figure that as the test temperature increases, the emission intensity of the phosphor decreases slowly. When the measurement temperature rises to 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com