Patents

Literature

54 results about "Cadmium carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the cadmium carbonate exposed group, 3 out of 52 rats died, and in the cadmium fume exposed group, 25 out of 52 rats died. Cadmium blood levels indicated that cadmium from the cadmium carbonate and fume was absorbed to a greater degree than cadmium from the red and yellow pigments.

Carbon dioxide sensor

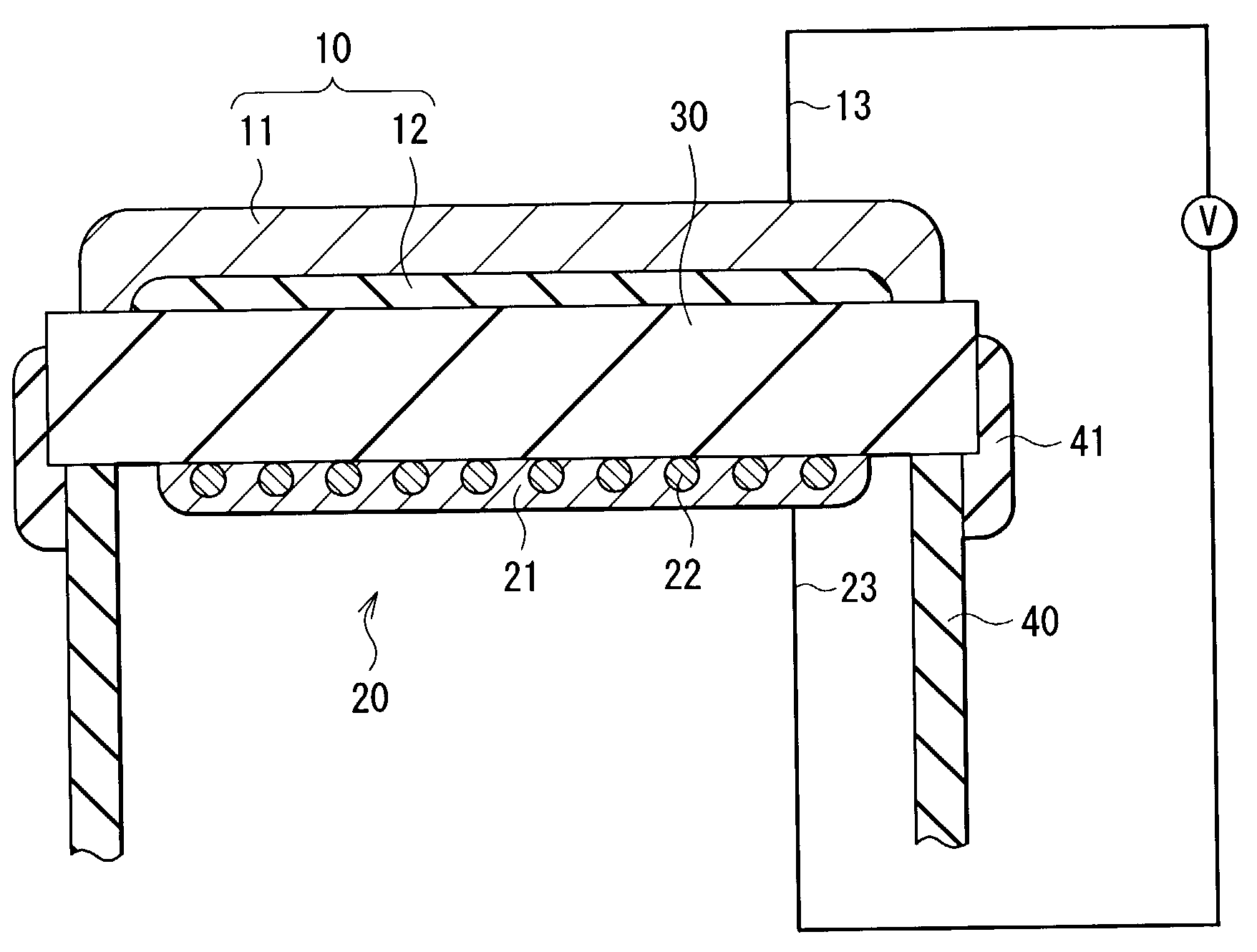

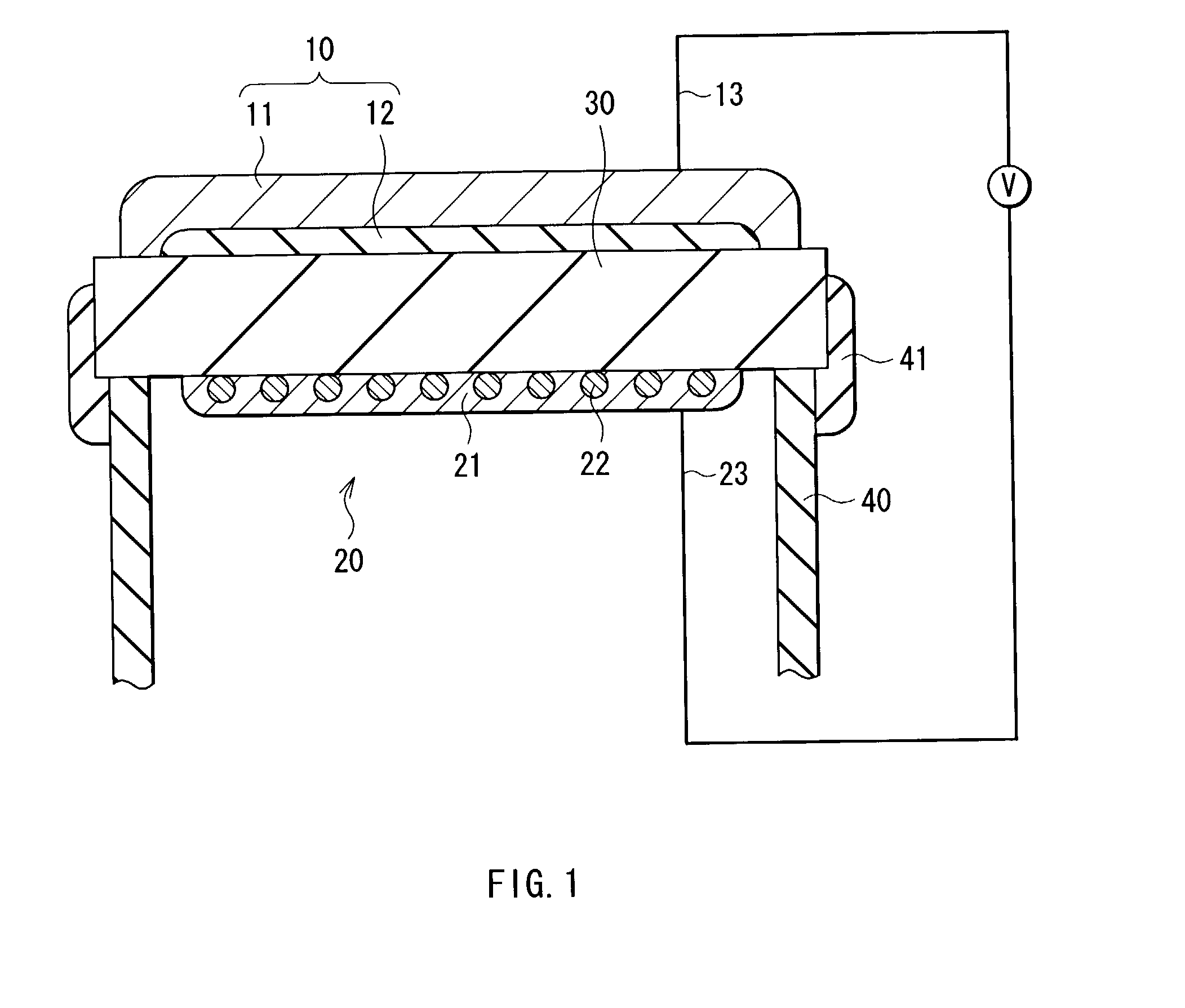

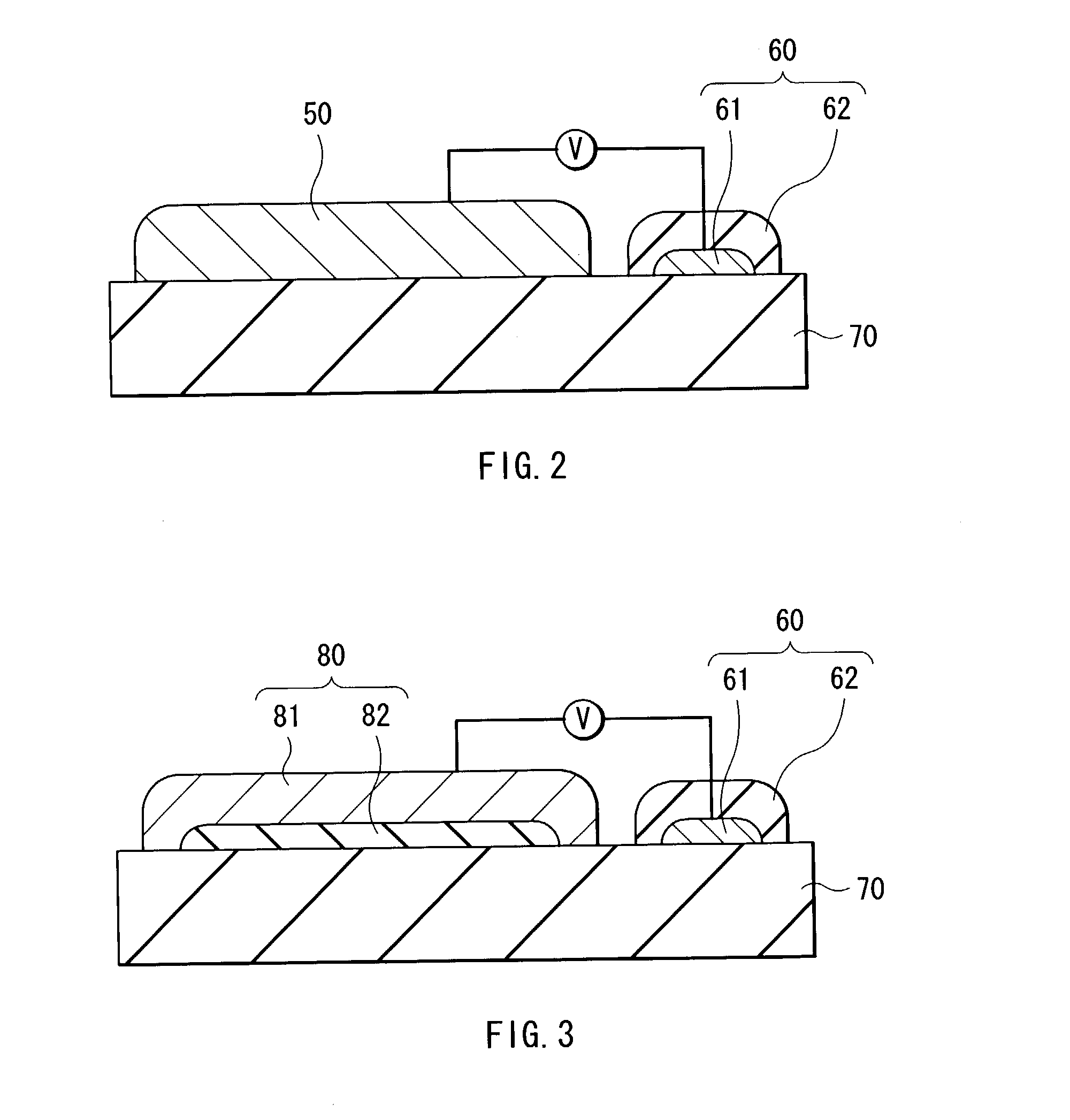

InactiveUS20040158410A1Gas analyser construction detailsSpecial data processing applicationsIndiumAlkaline earth metal

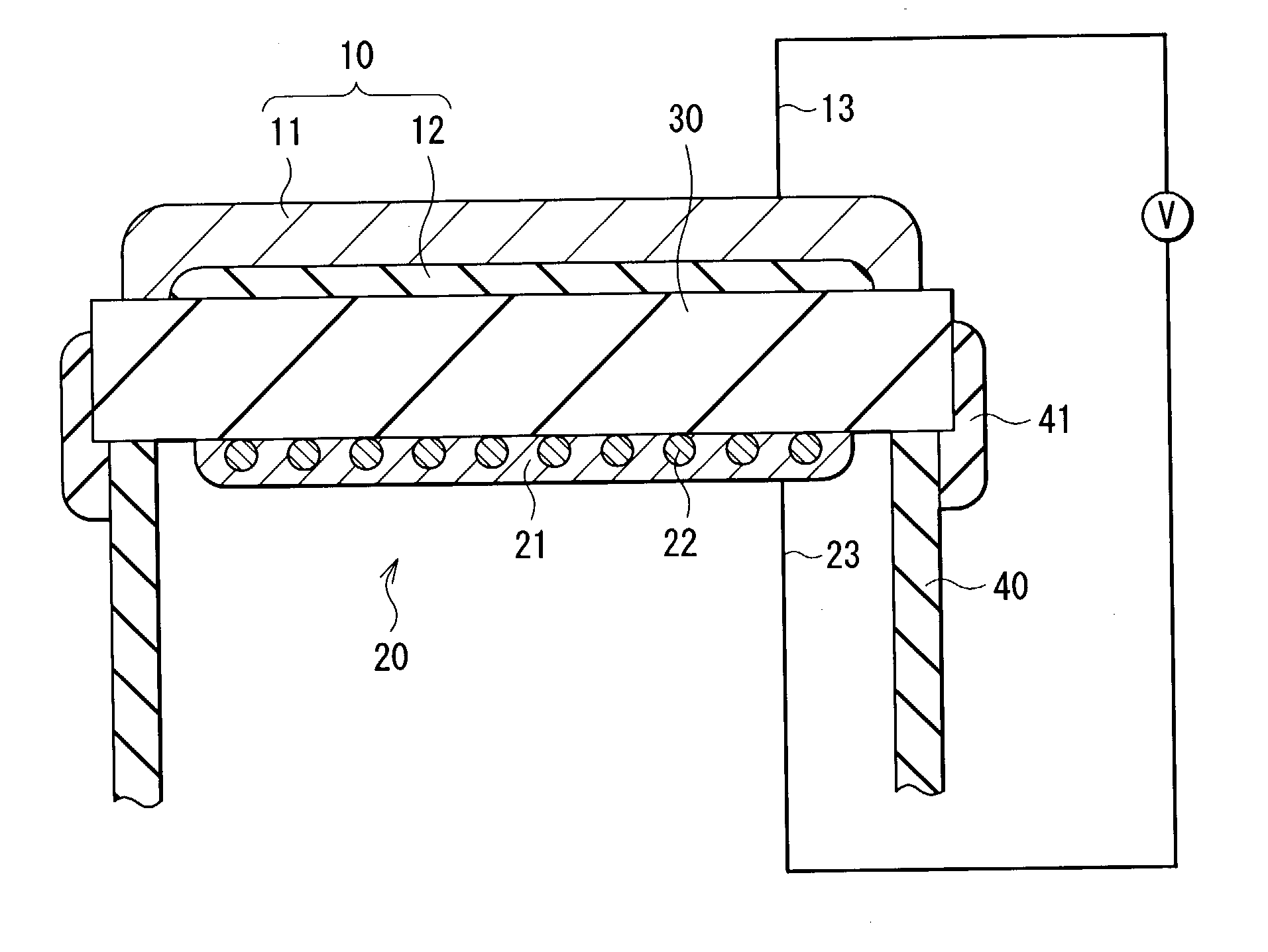

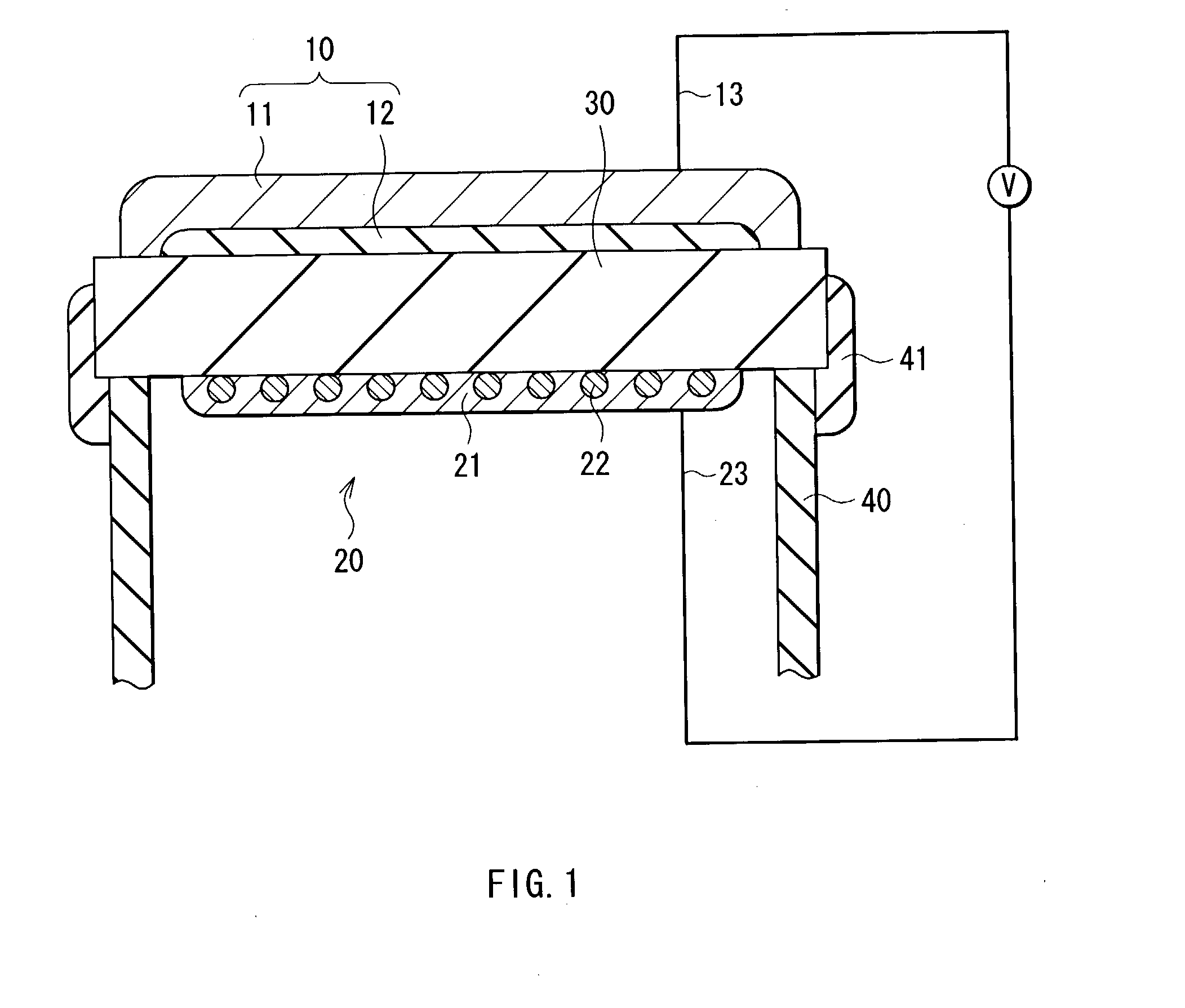

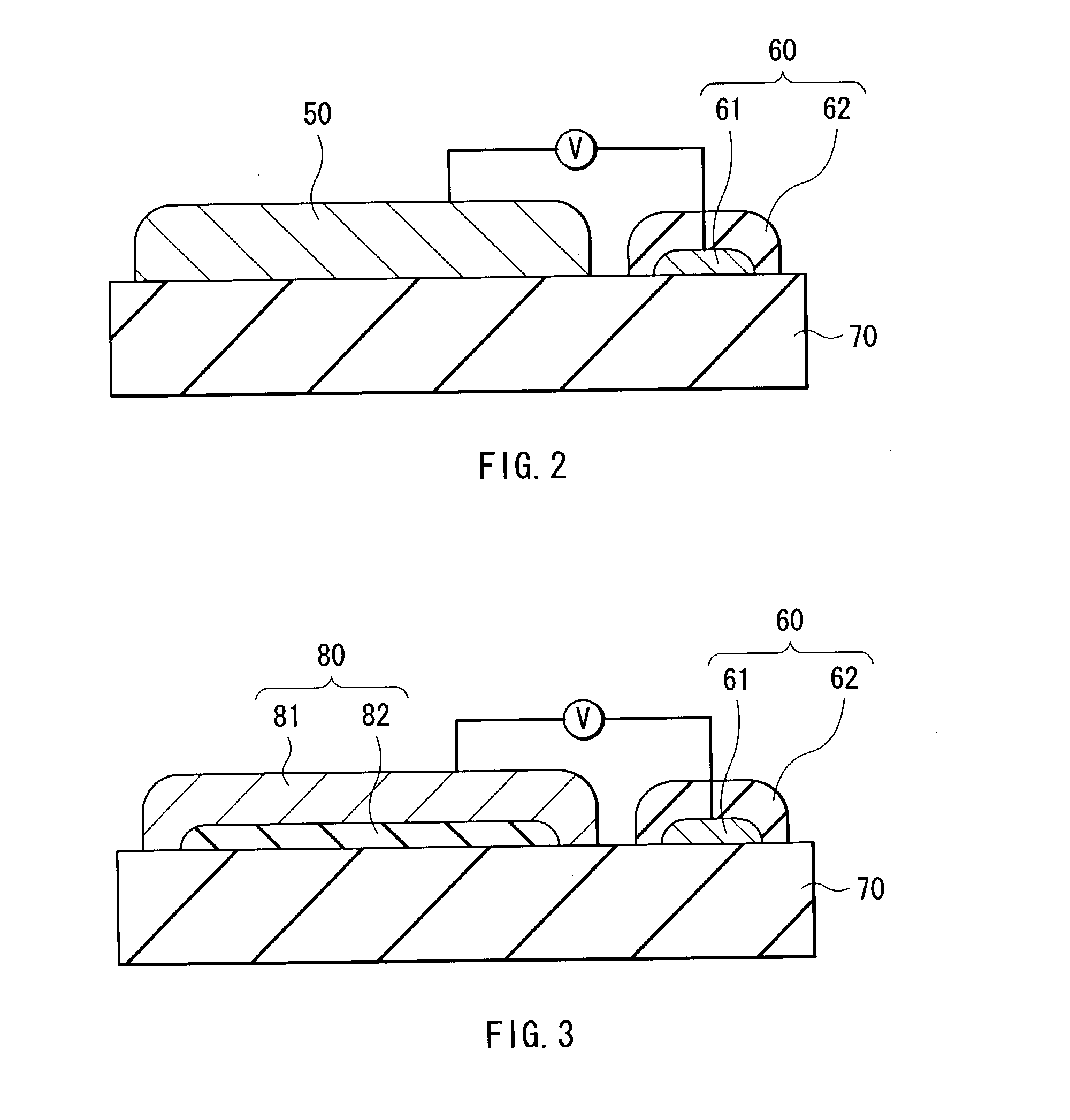

A carbon oxide sensor having high sensitivity capable of reduction of influence of humidity is provided. A detection electrode and a counter electrode are provided on one side of an electrolyte, respectively. The detection electrode contains a metal oxide and a metal carbonate including plural components. The metal carbonate preferably contains a first component of alkali metal carbonate and a second component of at least one element selected from the group consisting of alkali earth metal carbonate, transition metal carbonate, zinc carbonate, cadmium carbonate, indium carbonate, lead carbonate and bismuth carbonate. Specifically, it is preferable to contain the first component including Li2CO3 and the second component including at least one element selected from the group consisting of BaCO3, CaCO3 and SrCO3.

Owner:TDK CORPARATION

Method for preparing CdS/MoS2 composite hollow-block photocatalyst

InactiveCN106378160AFully crystallizedGood dispersionCatalyst activation/preparationSodium bicarbonateSodium molybdate

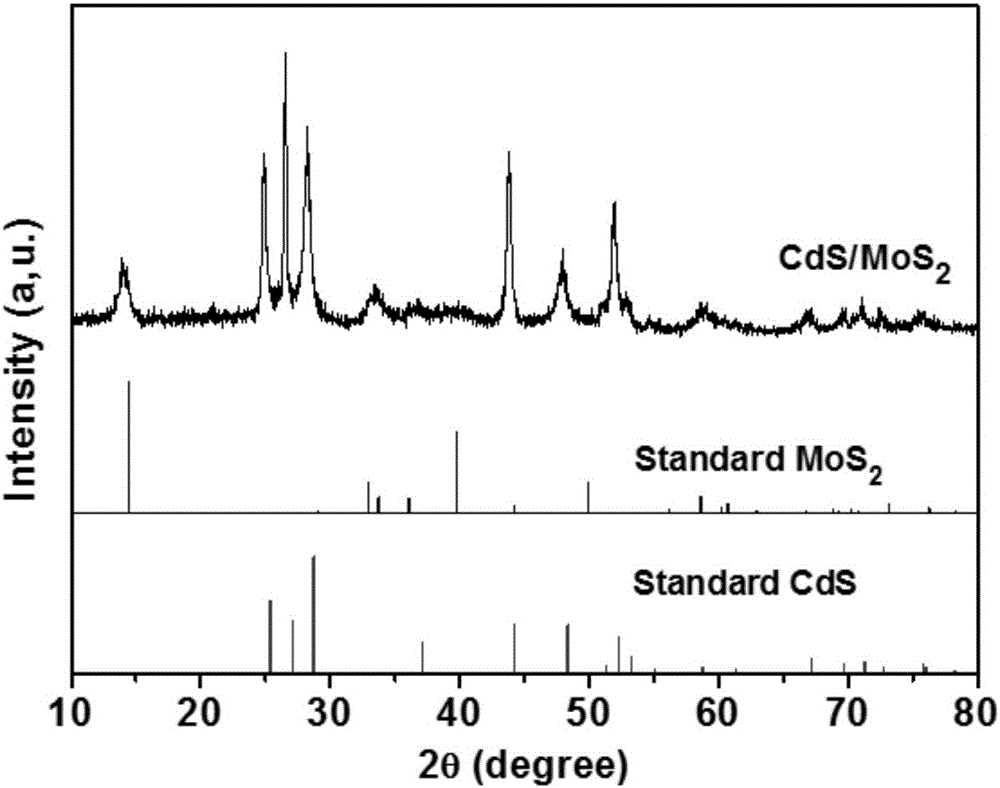

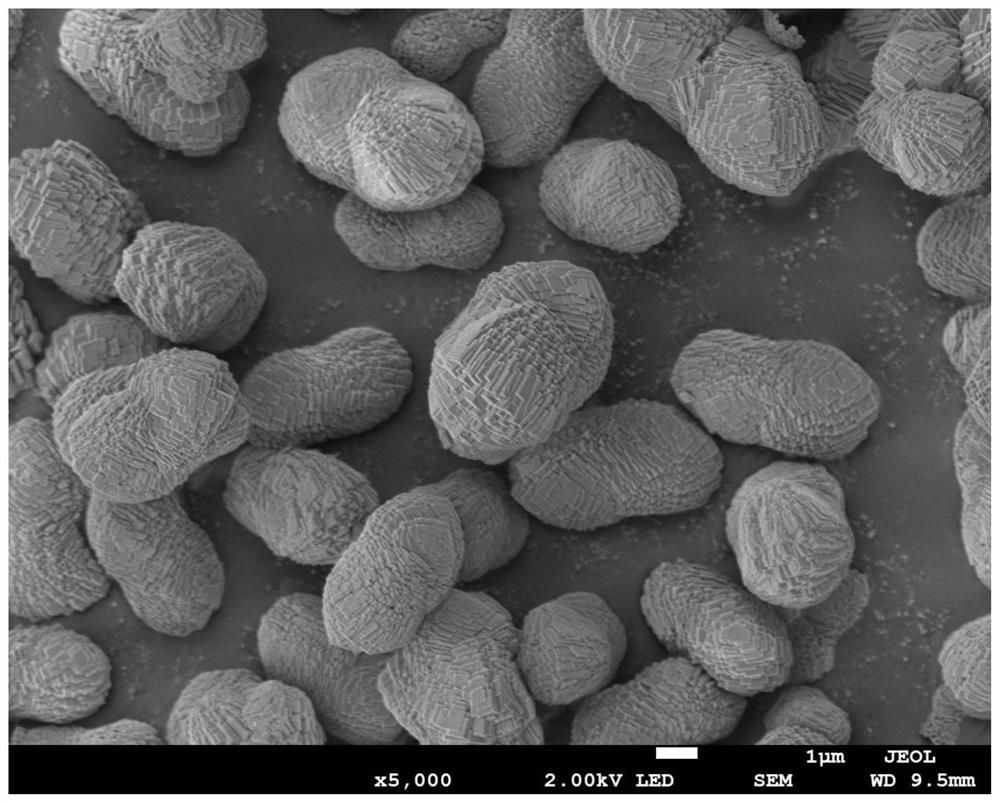

The invention relates to the technical field of composite nanomaterials and in particular discloses a method for preparing a CdS / MoS2 composite hollow-block photocatalyst by taking cadmium acetate, sodium bicarbonate, PVP, sodium molybdate and thiourea as raw materials, particularly a method for preparing a component photocatalyst with the advantages of simple preparation process and excellent visible-light catalytic activity of the product. The method comprises the following steps: weighing cadmium acetate and PVP, and dissolving in deionized water according to a mass ratio of 1:10; adding sodium bicarbonate into the mixture, so that the mass ratio of the cadmium acetate to sodium bicarbonate is 1:2; stirring and reacting at room temperature for 2 hours, washing and centrifuging the product after the reaction is completed, thereby obtaining cadmium carbonate; dissolving the cadmium carbonate, sodium molybdate and thiourea in the deionized water according to a mass ratio of (1):(0.15-1.4):(4), mixing and stirring, carrying out a hydrothermal reaction under the condition of 220 DEG C for 24 hours, washing and centrifuging the product after the reaction is completed, and drying, thereby obtaining the CdS / MoS2 composite photocatalyst.

Owner:JIANGSU UNIV

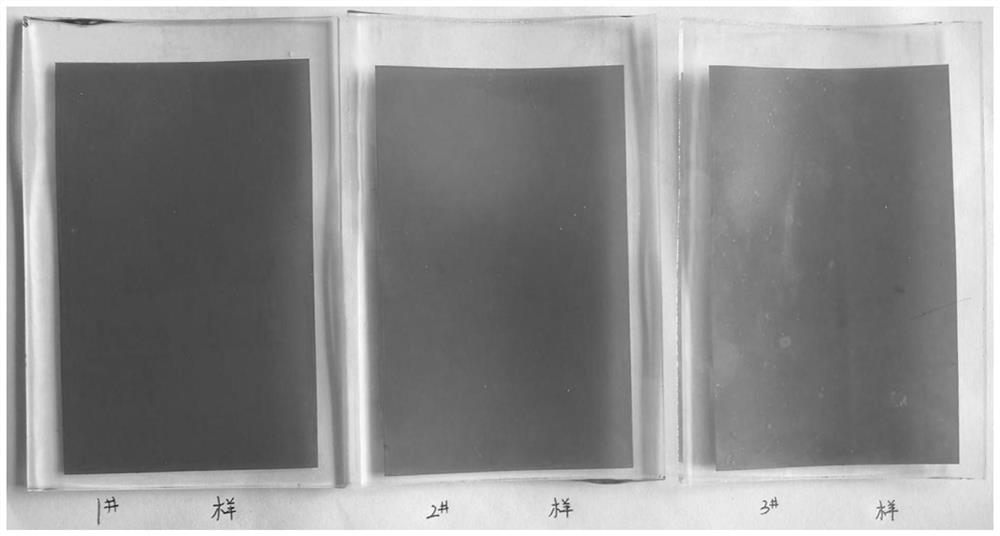

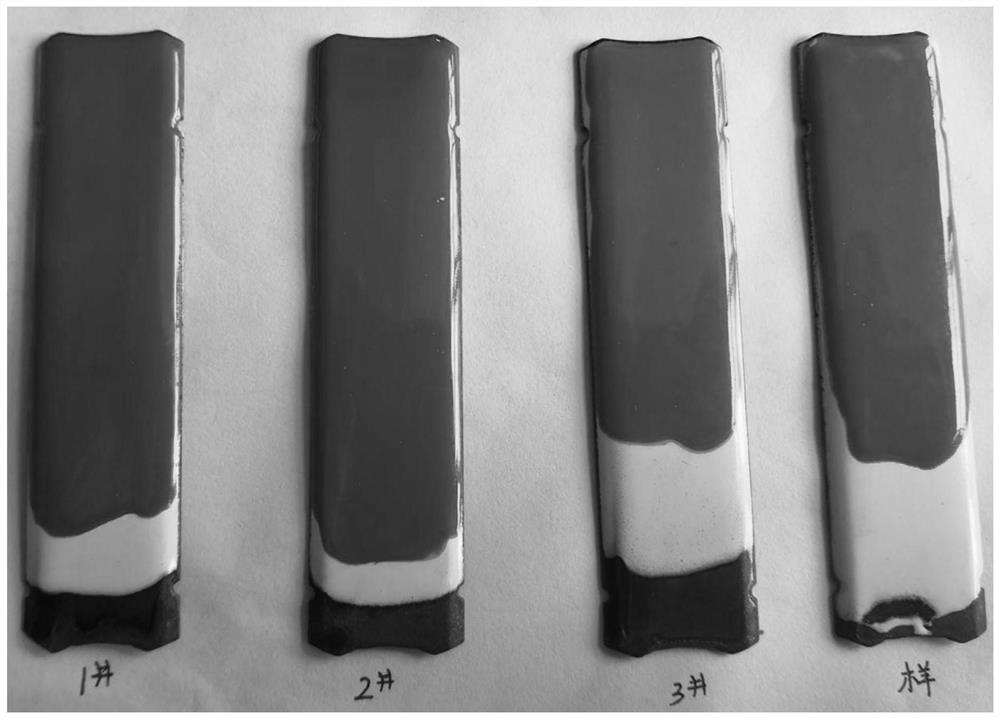

Scarlet glaze material for ceramics and preparation method thereof

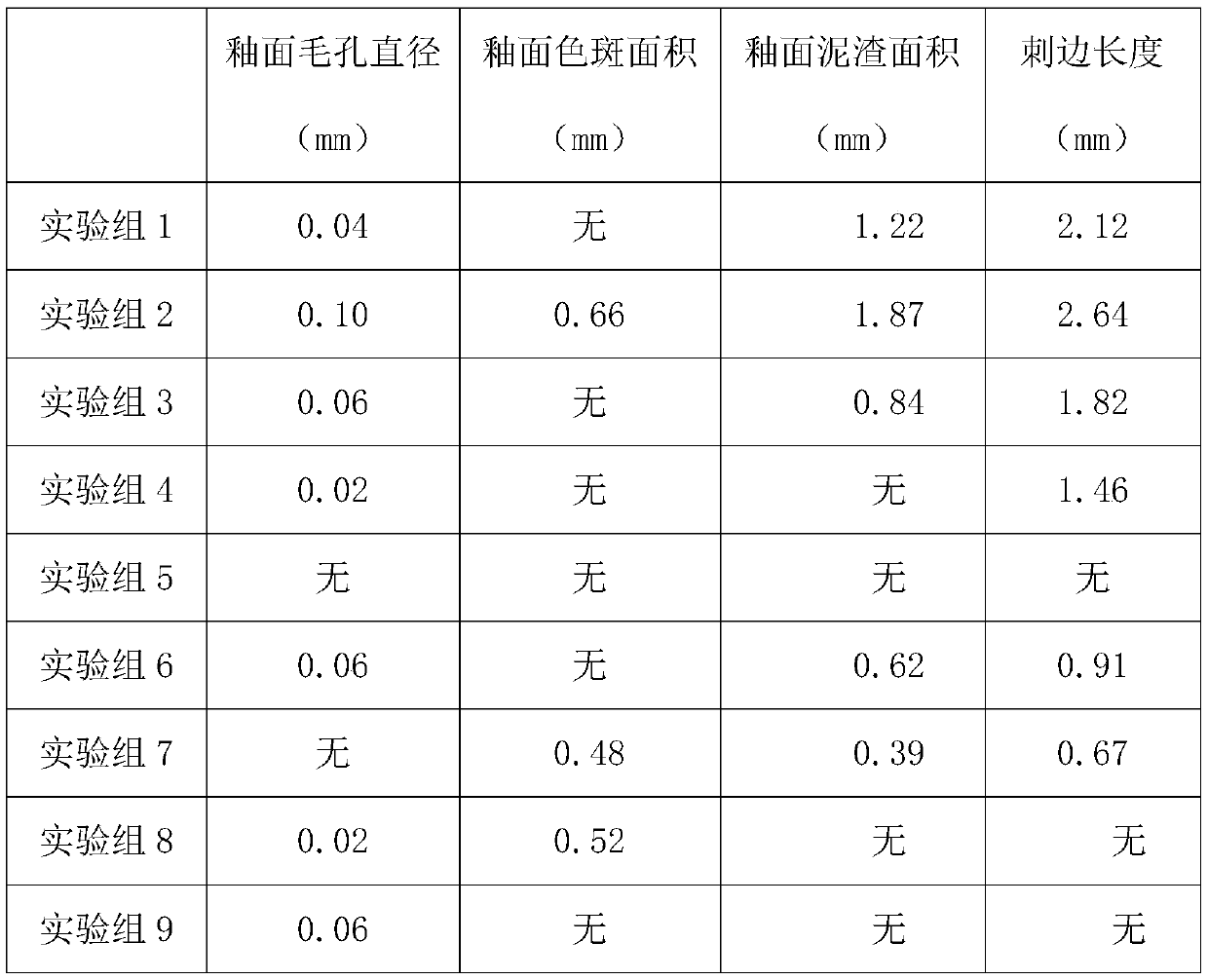

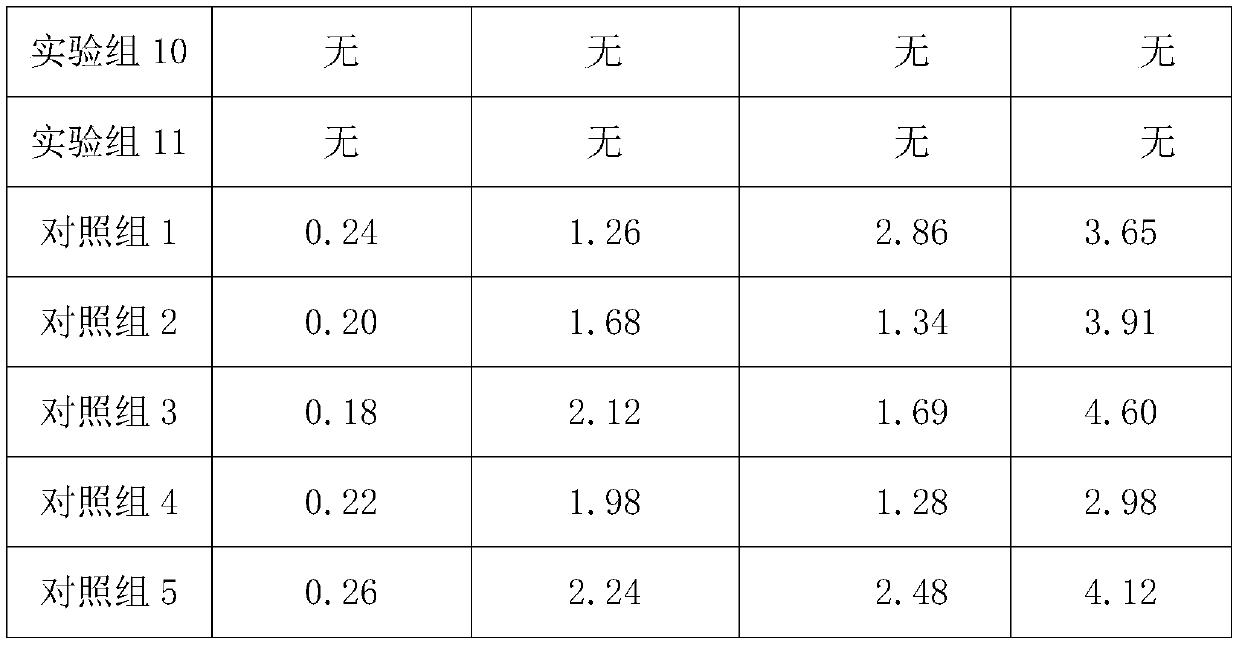

The invention relates to a scarlet glaze material for ceramics, which is prepared from 30-50 parts of potash feldspar, 20-40 parts of quartz, 5-15 parts of marble, 8-15 parts of kaolin, 6-10 parts of clear frit, 0.1-0.5 part of cadmium carbonate, 4-12 parts of scarlet pigment and 50-70 parts of water. The preparation method comprises the following steps: evenly mixing the 30-50 parts of potash feldspar, 20-40 parts of quartz, 5-15 parts of marble, 8-15 parts of kaolin, 6-10 parts of clear frit and 50-70 parts of water, and carrying out ball milling for 15-20 hours until the fineness reaches 325 meshes; evenly mixing the 0.1-0.5 part of cadmium carbonate and 4-12 parts of scarlet pigment, and carrying out ball milling until the fineness reaches 325 meshes; and finally, evenly mixing the two mixtures to obtain the scarlet glaze material for ceramics. The glaze material has the advantages of favorable combination performance with the green body, pure and bright color, high stability and high gloss.

Owner:CHAOZHOU QINGFA CERAMICS

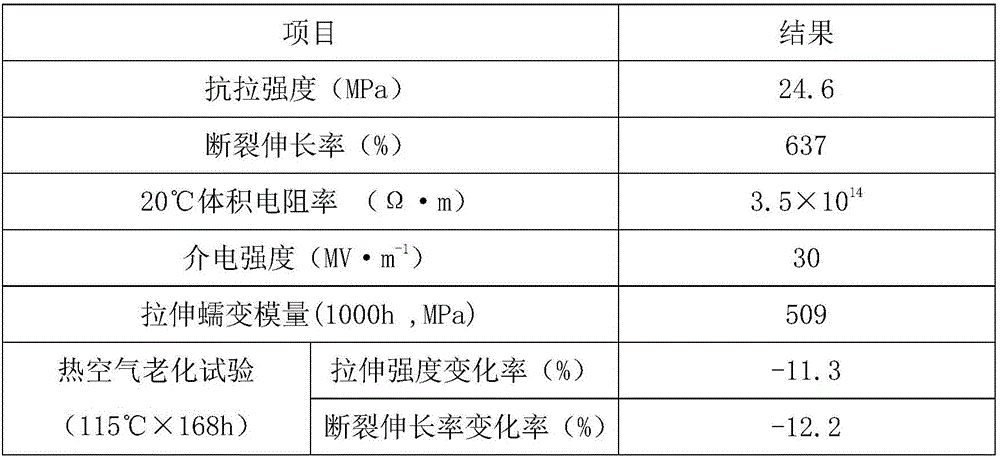

Anti-tear cable material used for high-speed railway motor train unit and preparation method of anti-tear cable material

The invention discloses an anti-tear cable material used for a high-speed railway motor train unit and a preparation method of the anti-tear cable material. The anti-tear cable material used for the high-speed railway motor train unit comprises the following raw materials in parts by weight: 67 to 89 parts of polyurethane rubber, 22 to 36 parts of styrene-butadiene rubber, 15 to 25 parts of thermoplastic polyester elastic bodies, 4 to 8 parts of vinyl silicone oil, 17 to 26 parts of fumed silica, 3 to 6 parts of cadmium carbonate, 2 to 3 parts of lauroyl peroxide, 1.5 to 2.5 parts of triallyl isocyanurate, 1 to 2 parts of ammonium benzoate, 3 to 5 parts of poly-alpha-olefin, 5 to 10 parts of tert-butyl phenolic tackifying resin, 2 to 4 parts of triethylhexanoin, 10 to 15 parts of methylpentachlorostearate, 14 to 18 parts of carbon nano tubes, 10 to 15 parts of a diopside powder, 1 to 2 parts of 4,4'-dithiodimorpholine, 0.5 to 1 part of P-tert-butylphenol, and 20 to 25 parts of a composite flame retardant. The cable material provided by the invention combines the advantages of the raw materials such as the polyurethane rubber, the styrene-butadiene rubber, and the thermoplastic polyester elastic bodies, the tearing strength of a conventional cable material is improved, and the cable material is enabled to have excellent tear resistance, has the effect of bearing relatively great mechanical external force, and has the advantages of excellent chemical stability, heat resistance and age resistance, and long service life.

Owner:ANHUI KANGLIYA CO LTD

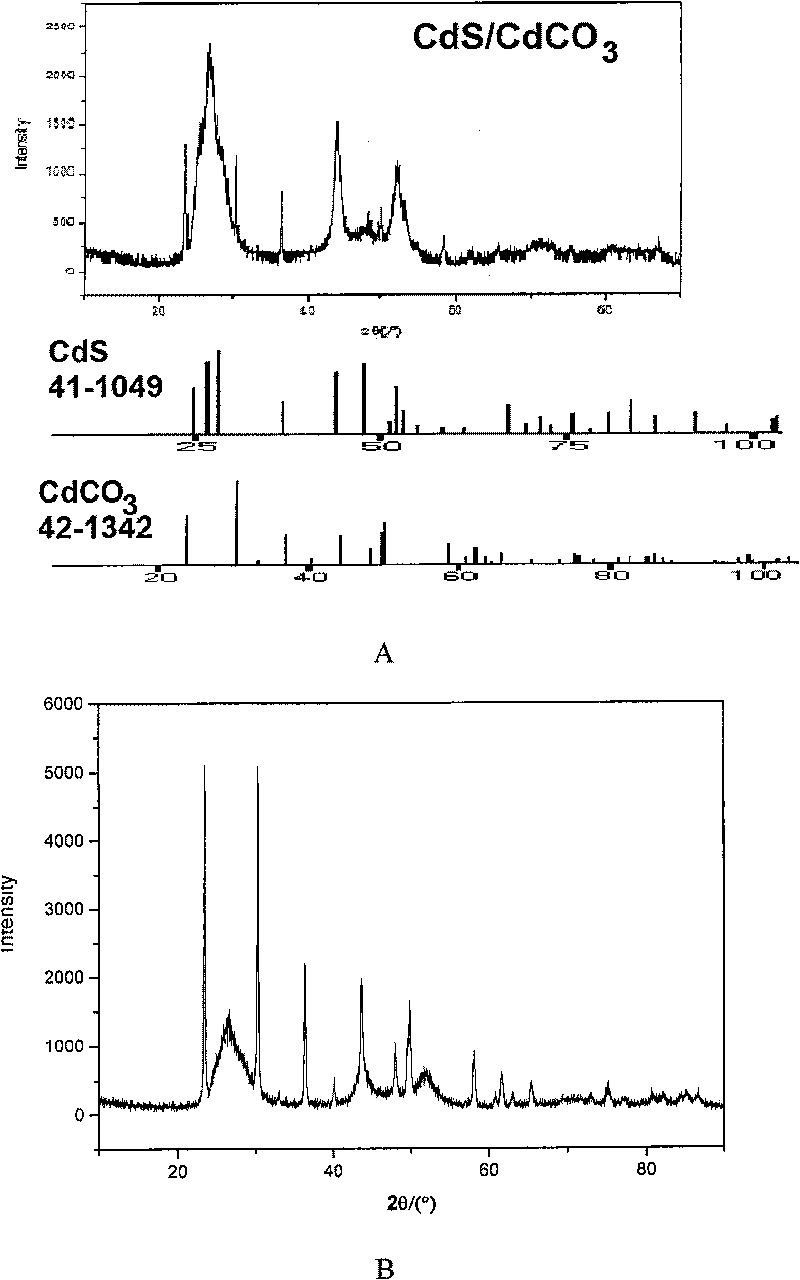

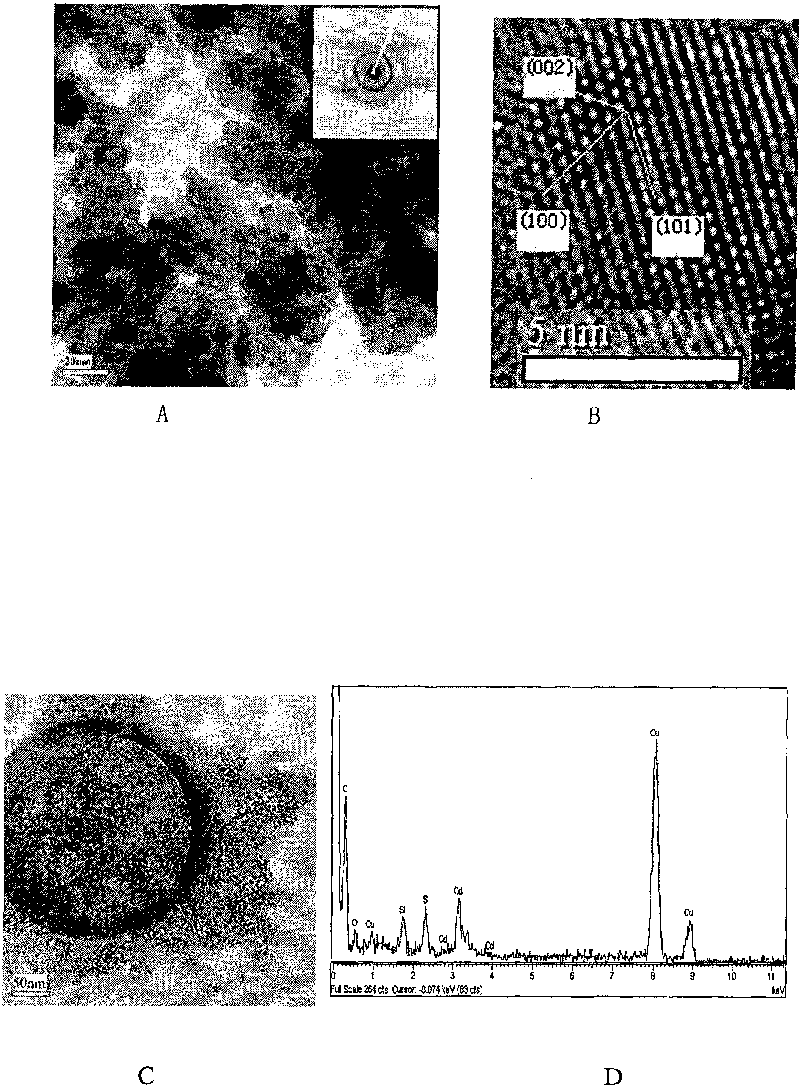

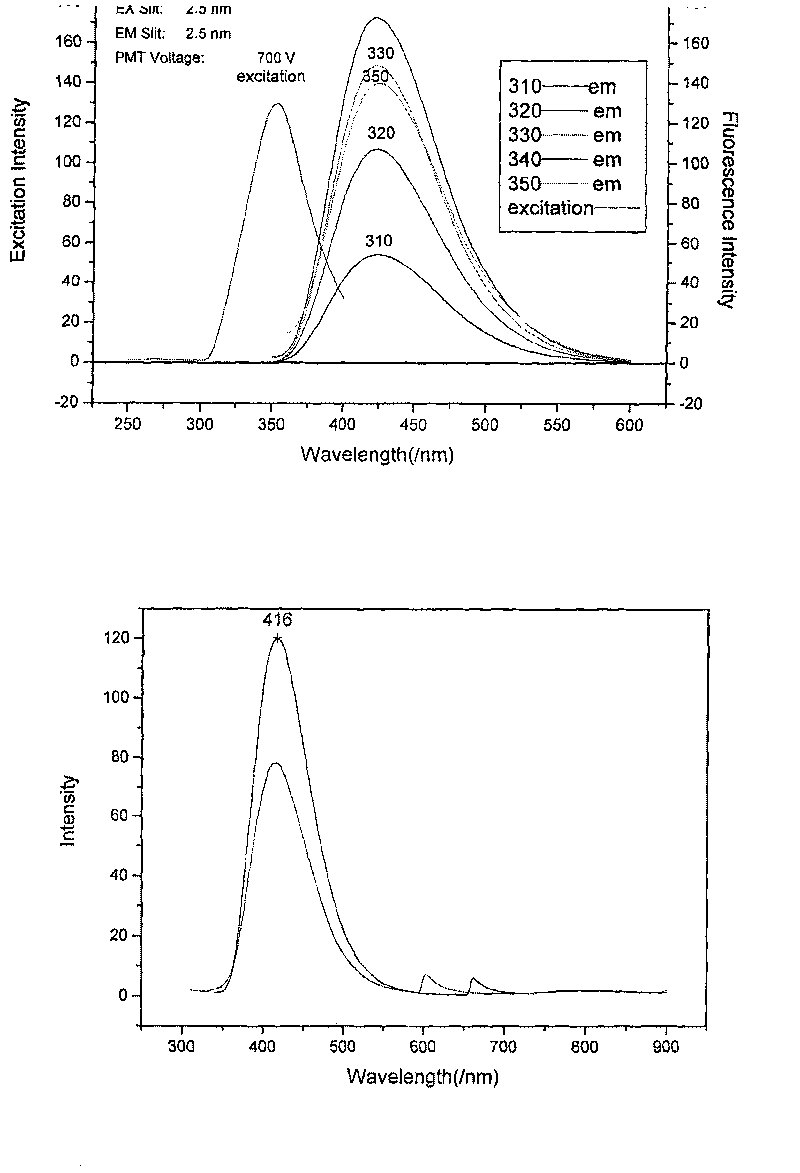

Nano-crystal with core-shell structure and preparation method thereof

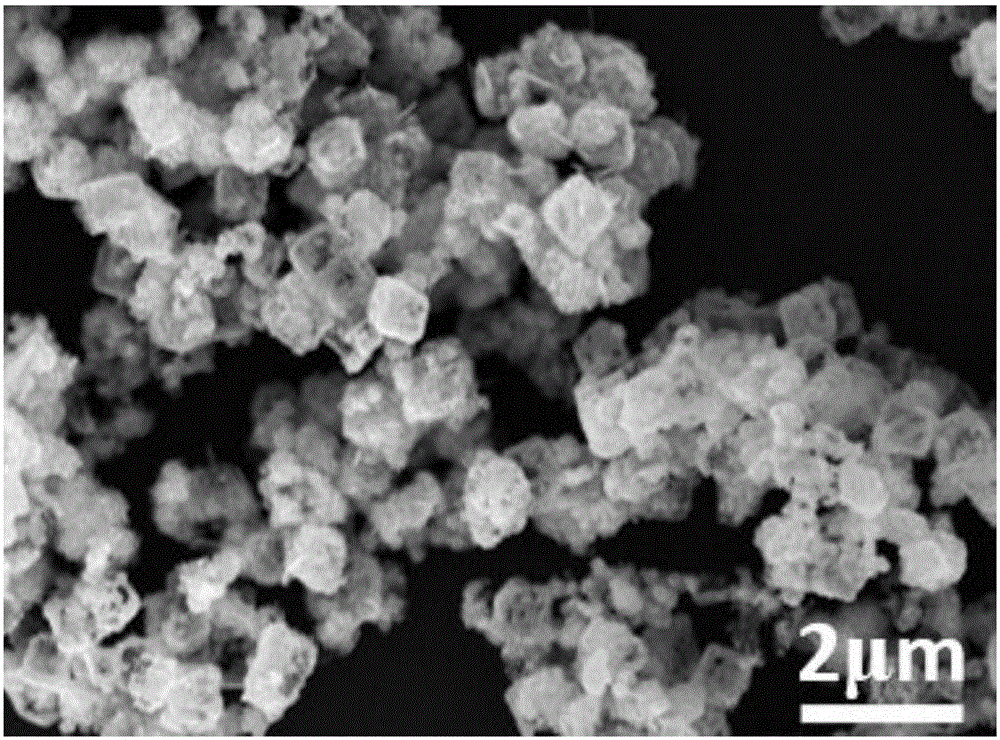

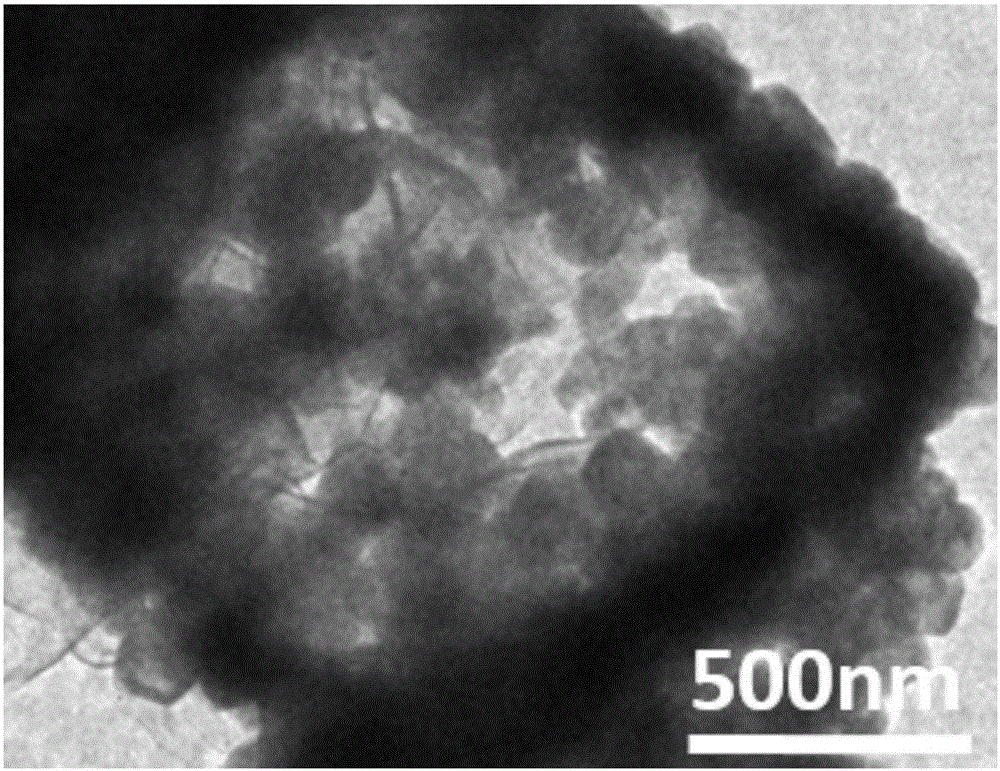

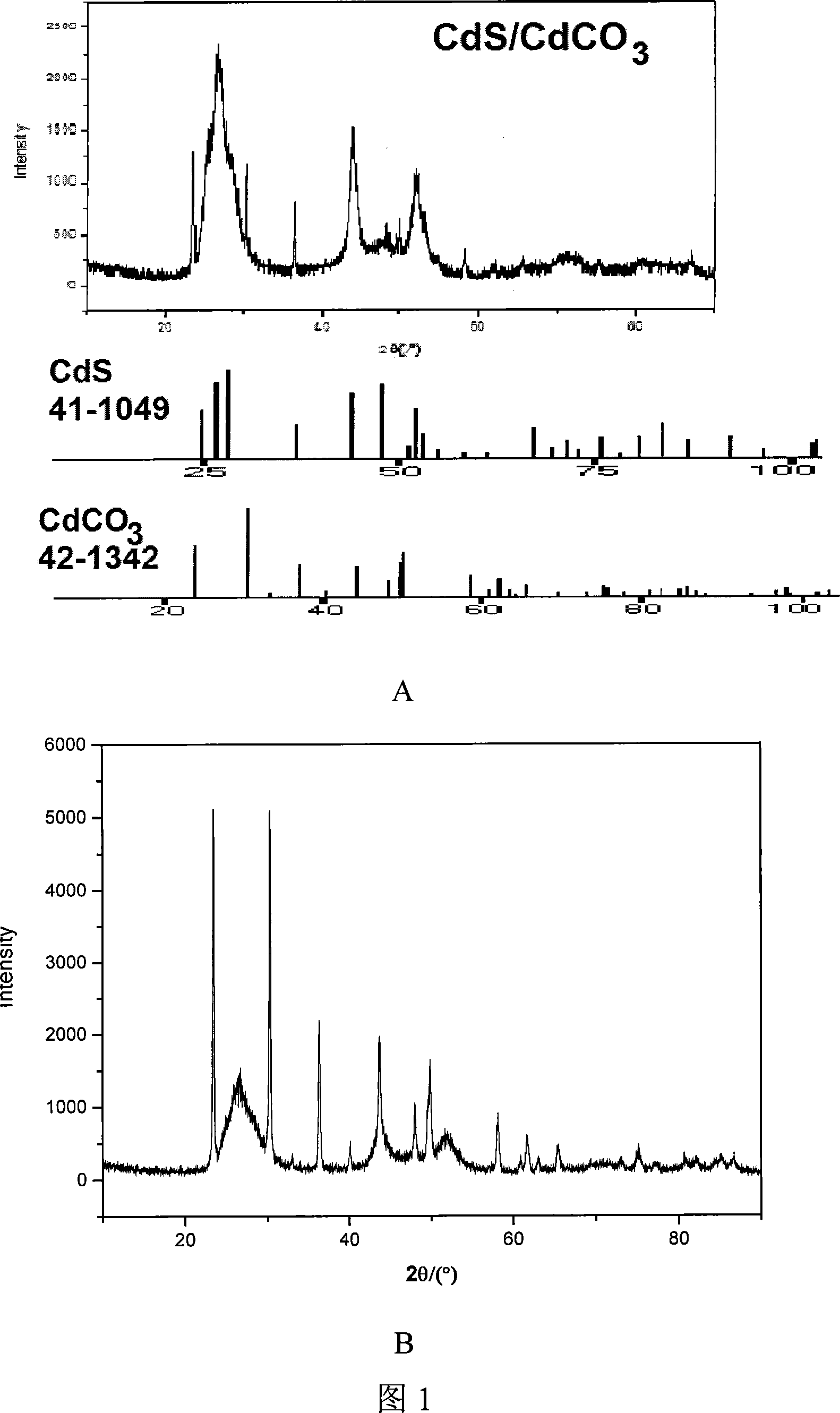

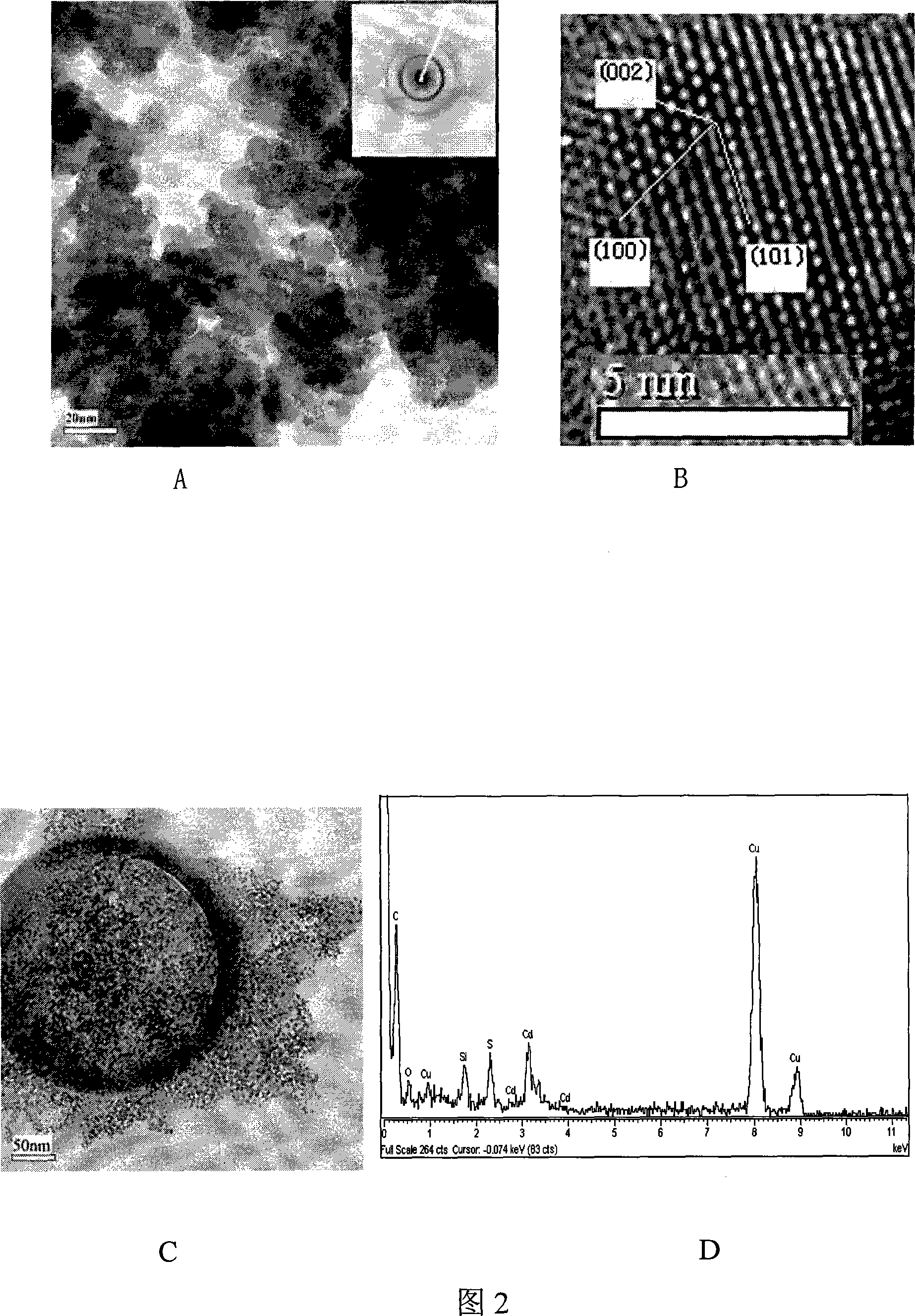

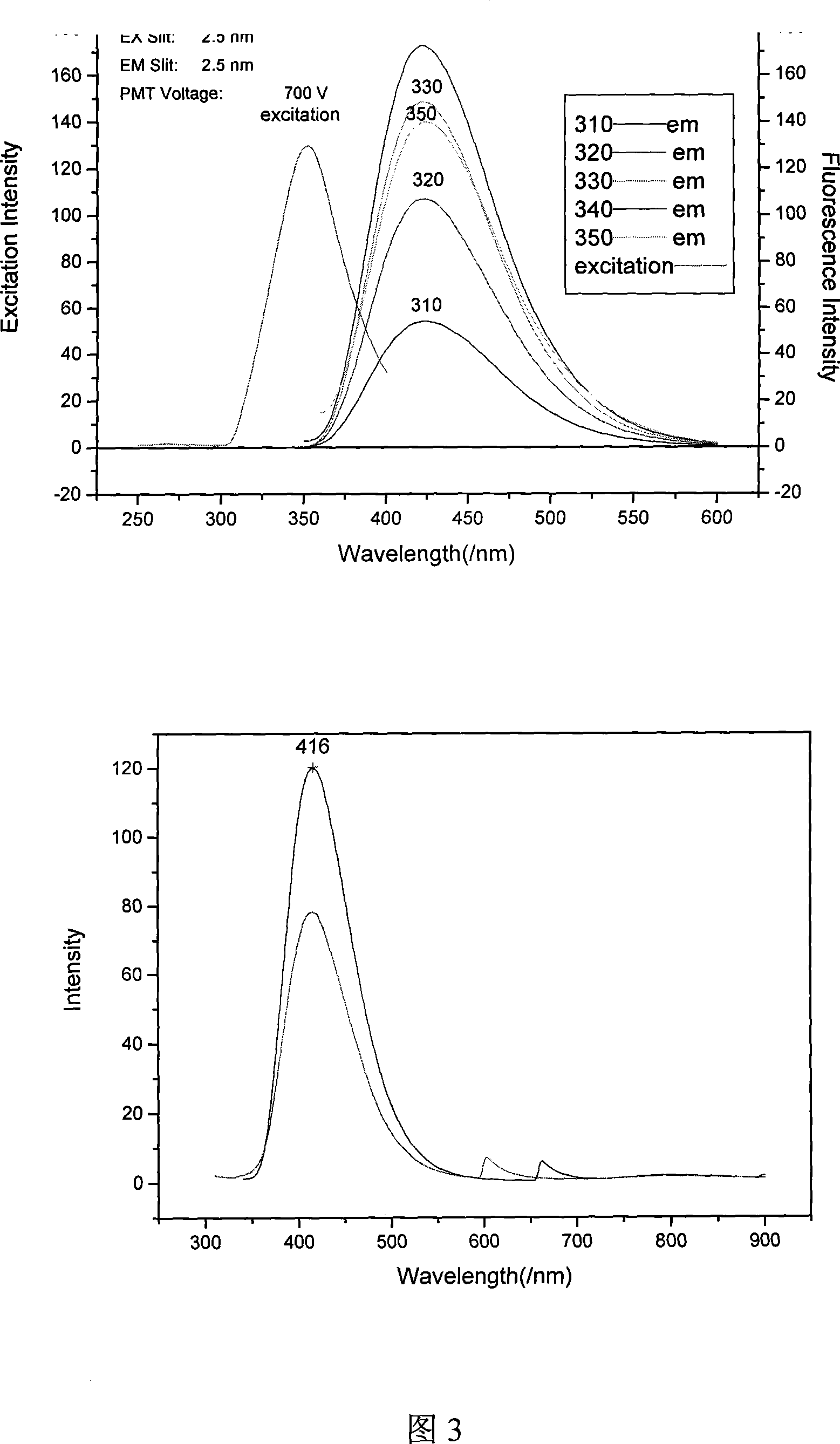

InactiveCN101186816AAvoid toxicityImprove stabilitySemi-permeable membranesNanostructure manufactureFluorescenceCadmium carbonate

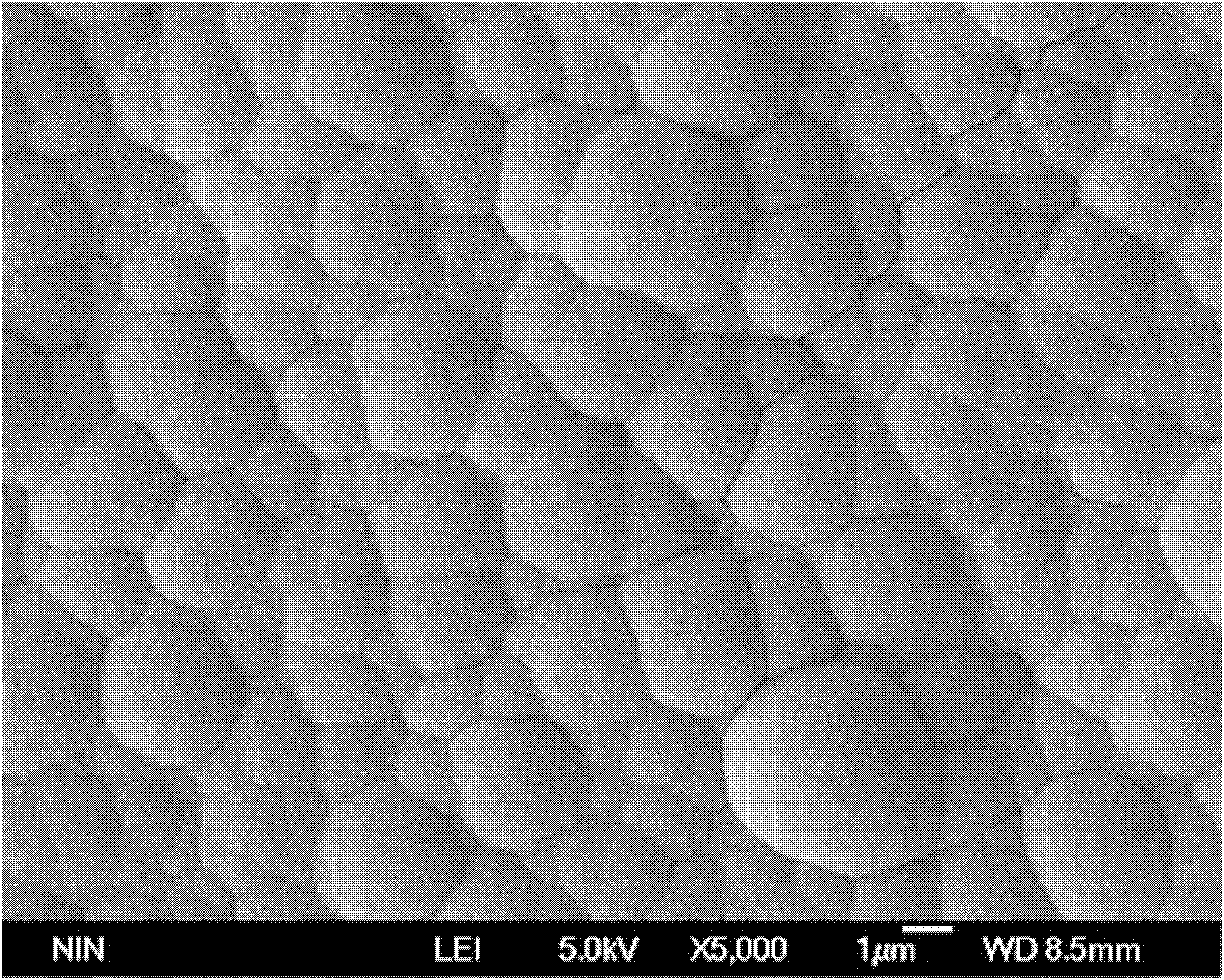

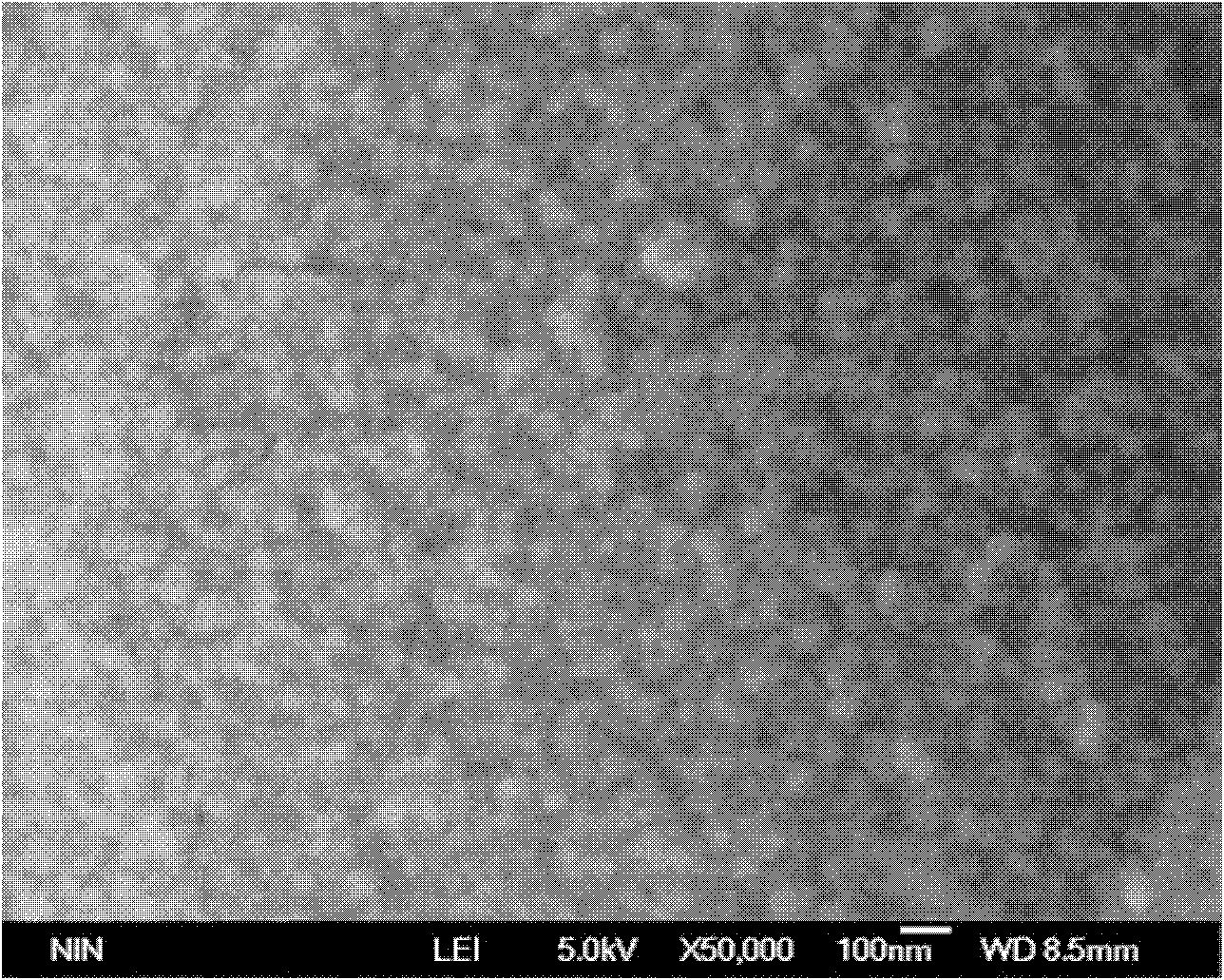

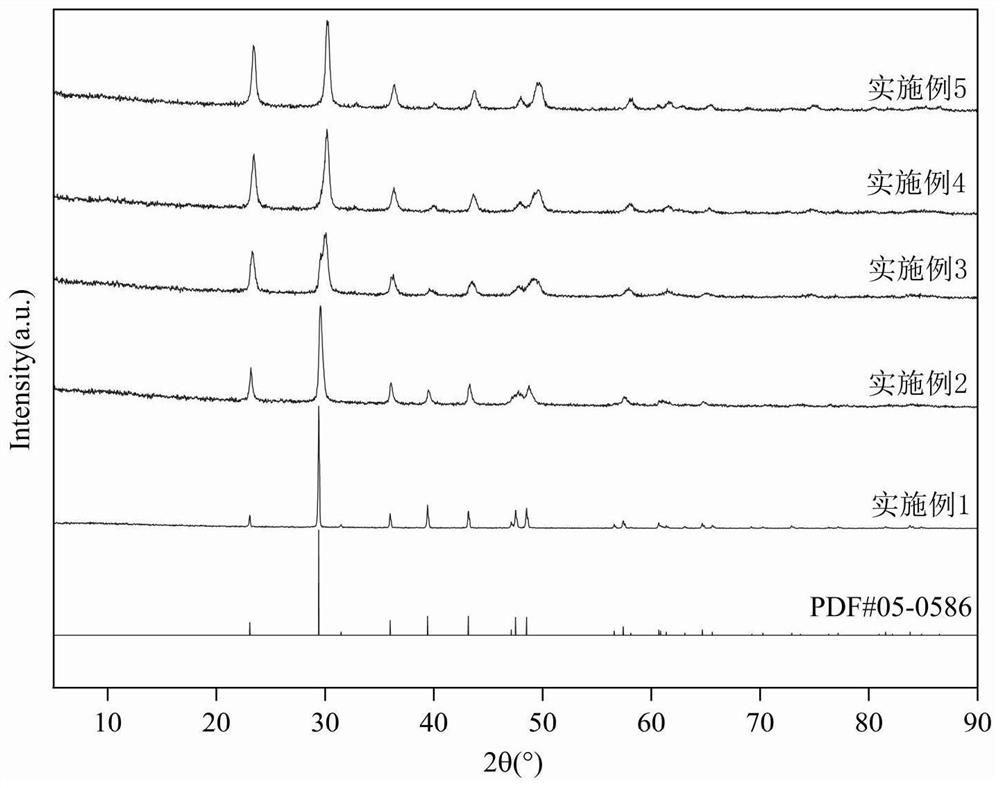

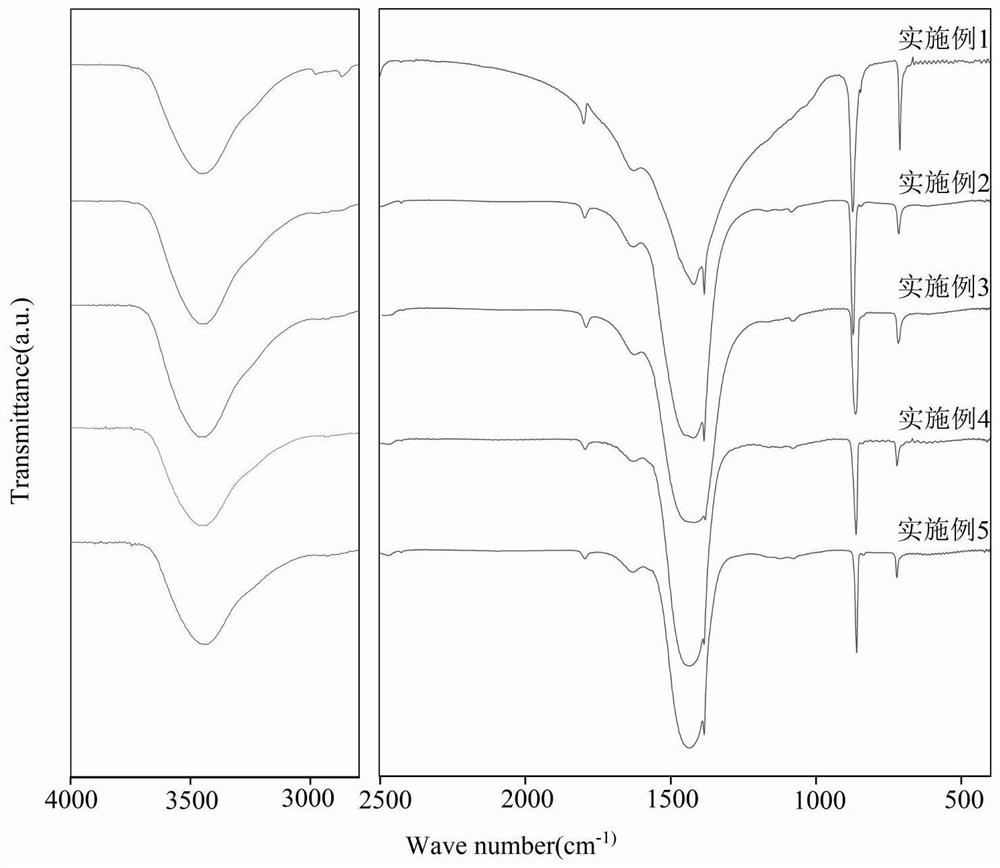

The invention discloses a nanocrystalline with core-shell structure. The nanocrystalline is of a core-shell structure and takes cadmium sulphide as a core and cadmium carbonate as a peripheral shell. A process for preparing the nanocrystalline is that the mol ratio of water-soluble cadmium acetate and sulfur source Cd / S is x, whichin 1.1<=x<=1.4, and raw materials are placed in a high-pressure autoclave to react under the condition that reaction system is of pH 9 to 13, wherein the concentration of the water-soluble cadmium acetate in the reaction system is 5 to 54.5 mmol / L, and the concentration of the sulfur source is 4.5 to 50 mmol / L. The invention is simple in process, easy in operation and low in price, further, the prepared nanocrytalline which is of cadmium sulphide or cadmium carbonate core-shell structure is prepared and the particle diameter of the nanocrytalline is -5nm. The invention has the advantages of high chemical stability, good fluorescence-emission monochromaticity, relatively narrow peak width at half height and the like in comparison with an existing nude nanocrystalline product, which saves precious placing time for surface finish of the nanocrystalline and improves fluorescent property, thereby enabling the nanocrystalline to be used as biological tissue marks after subsequent treatment such as the surface finish and the like.

Owner:HENAN UNIV OF SCI & TECH

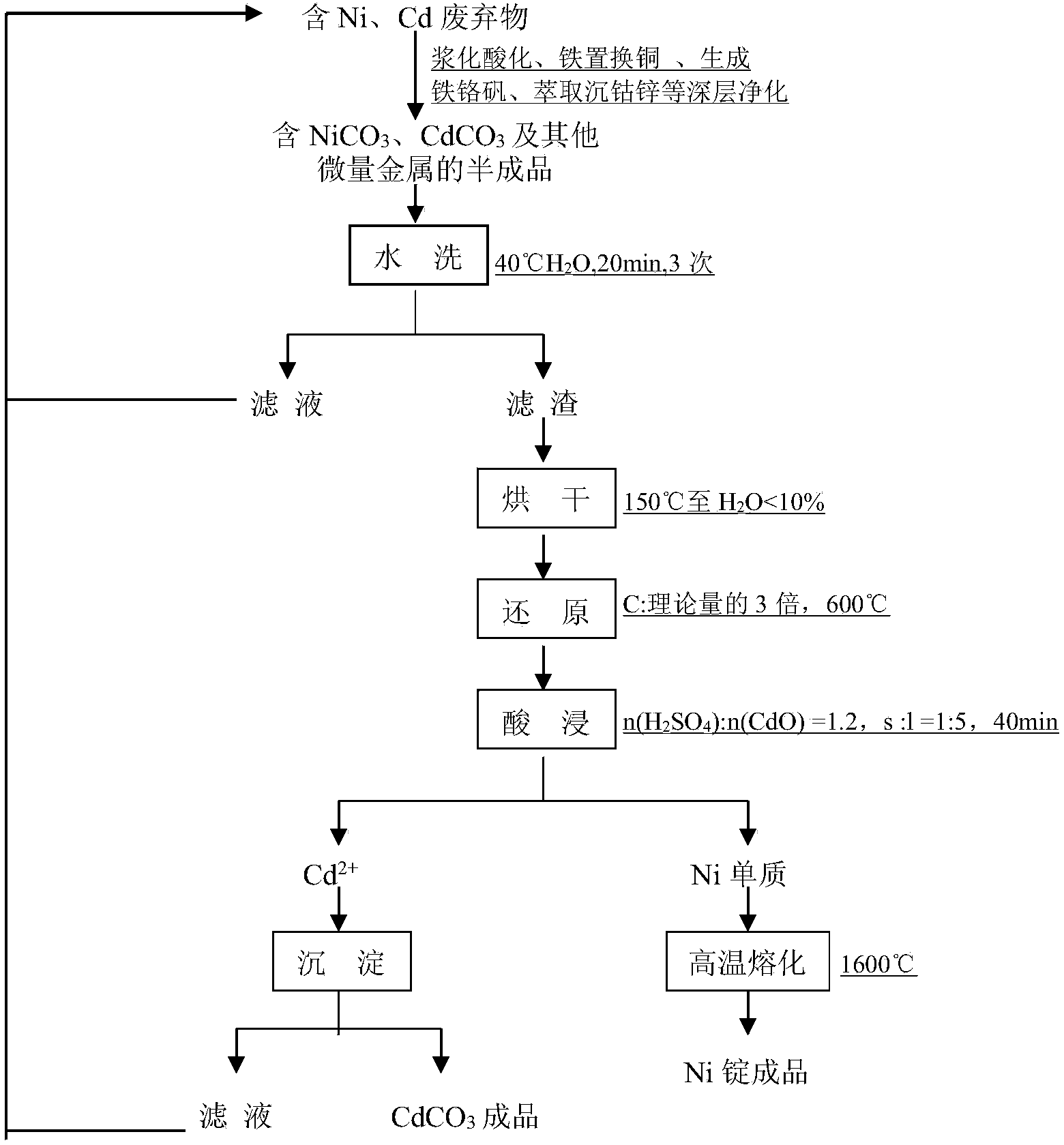

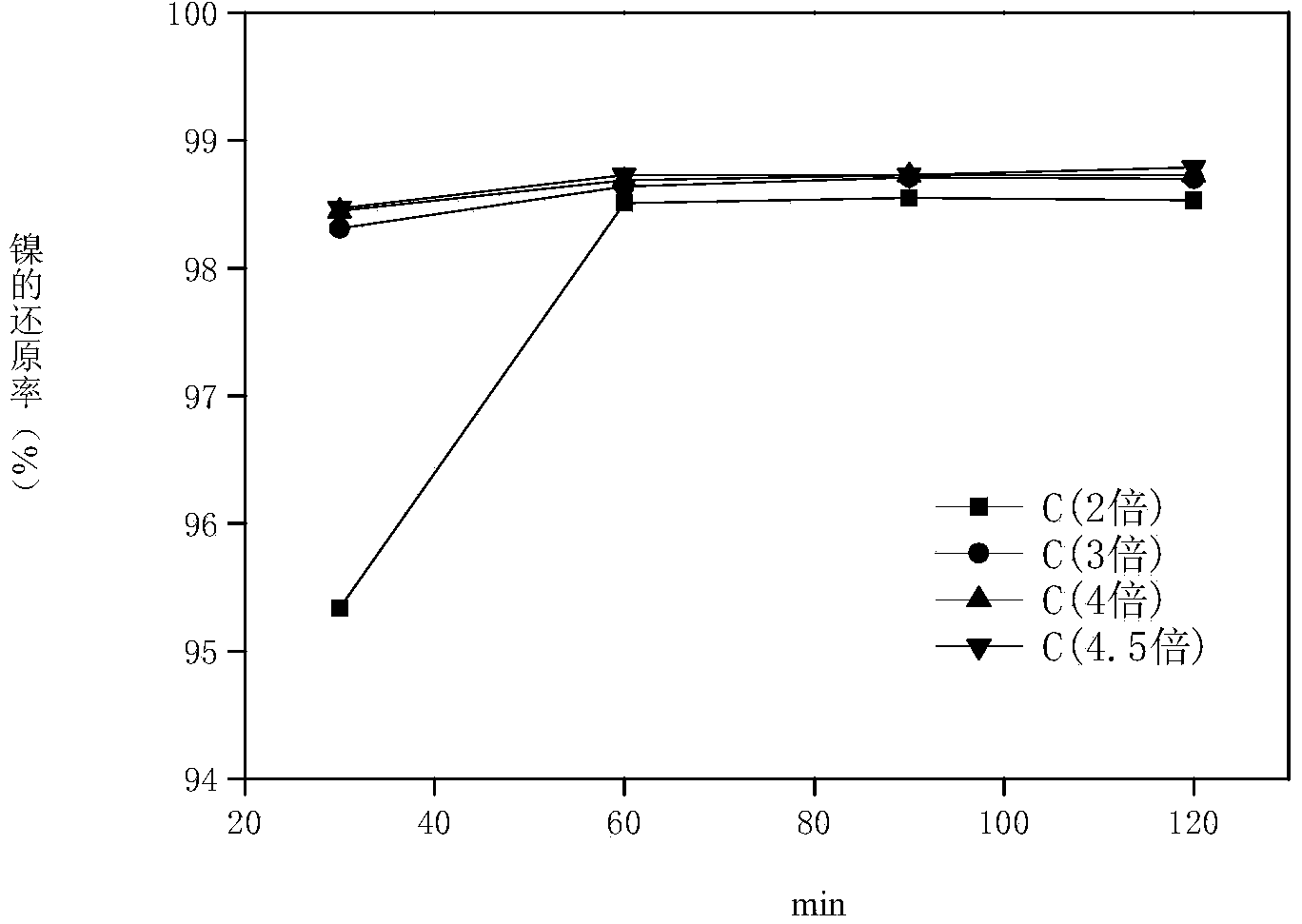

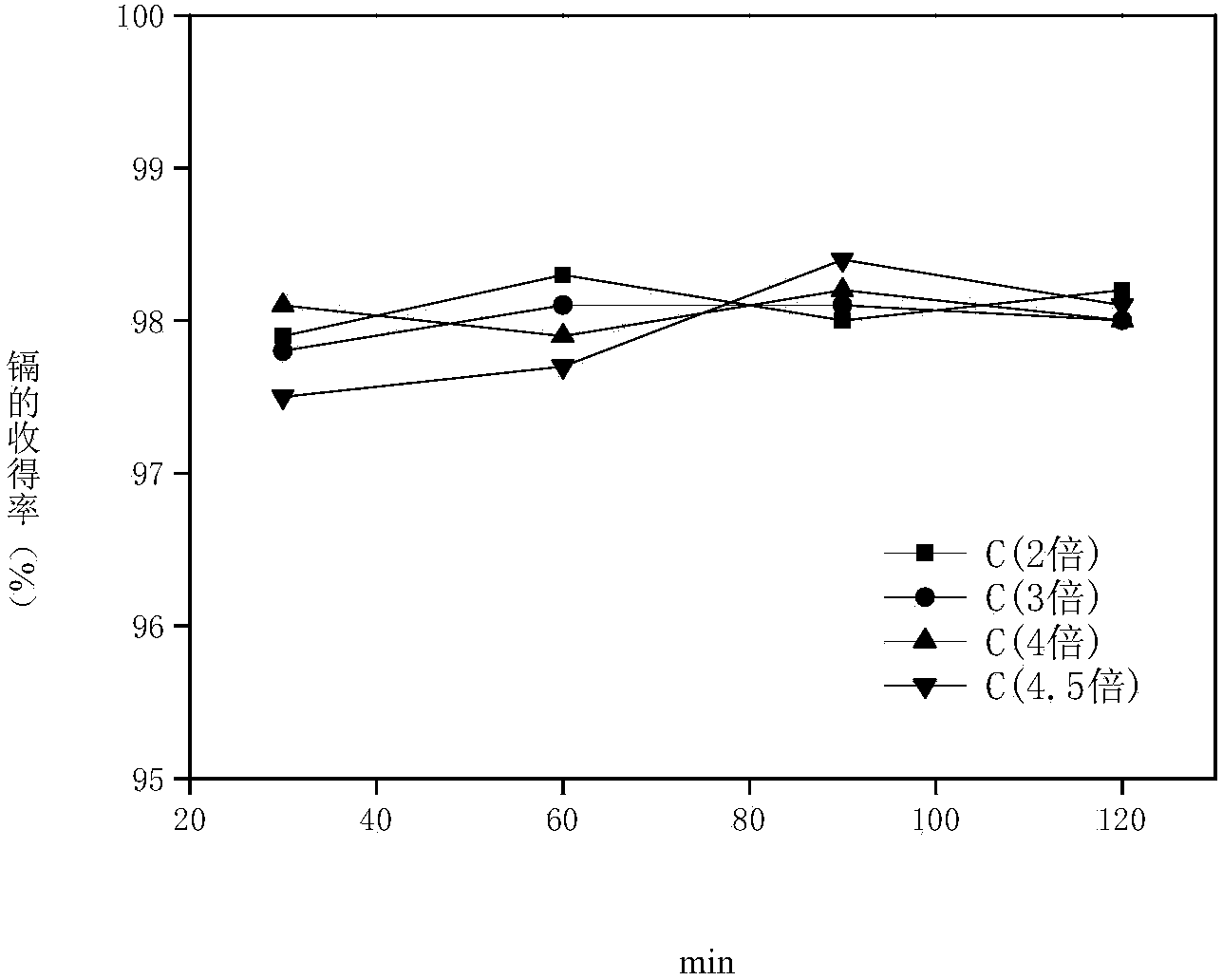

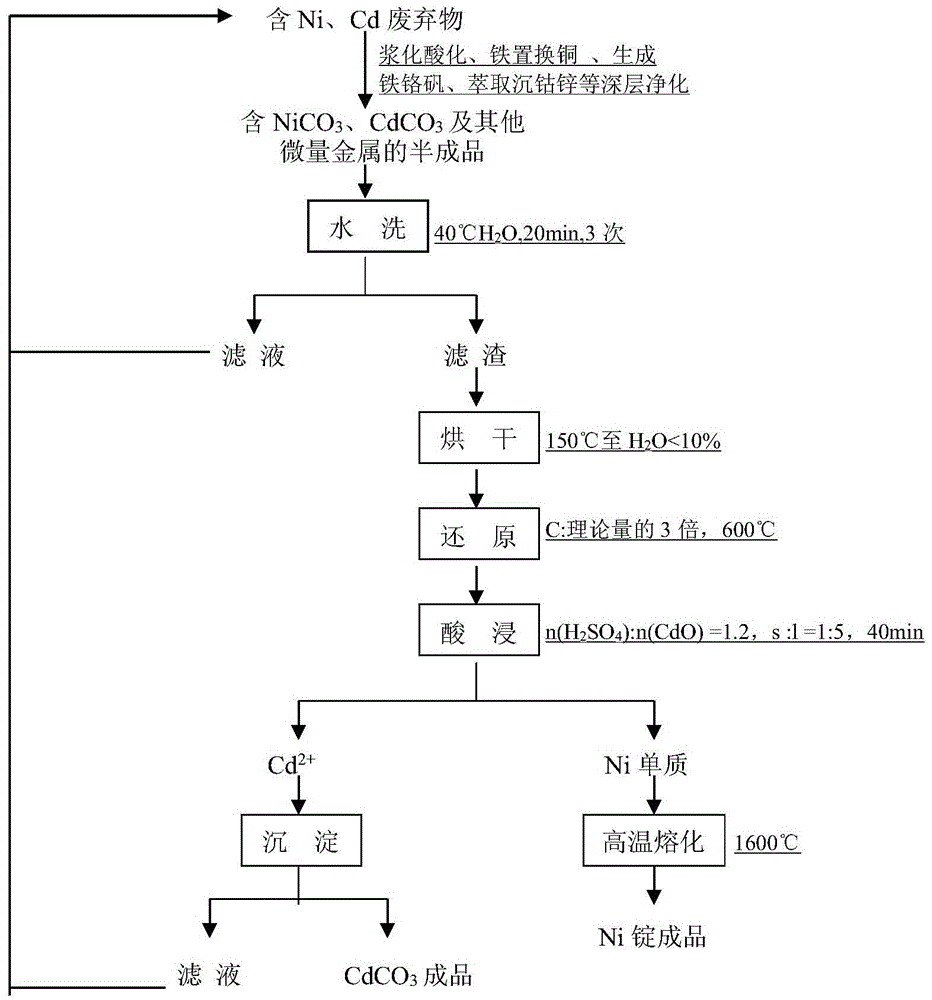

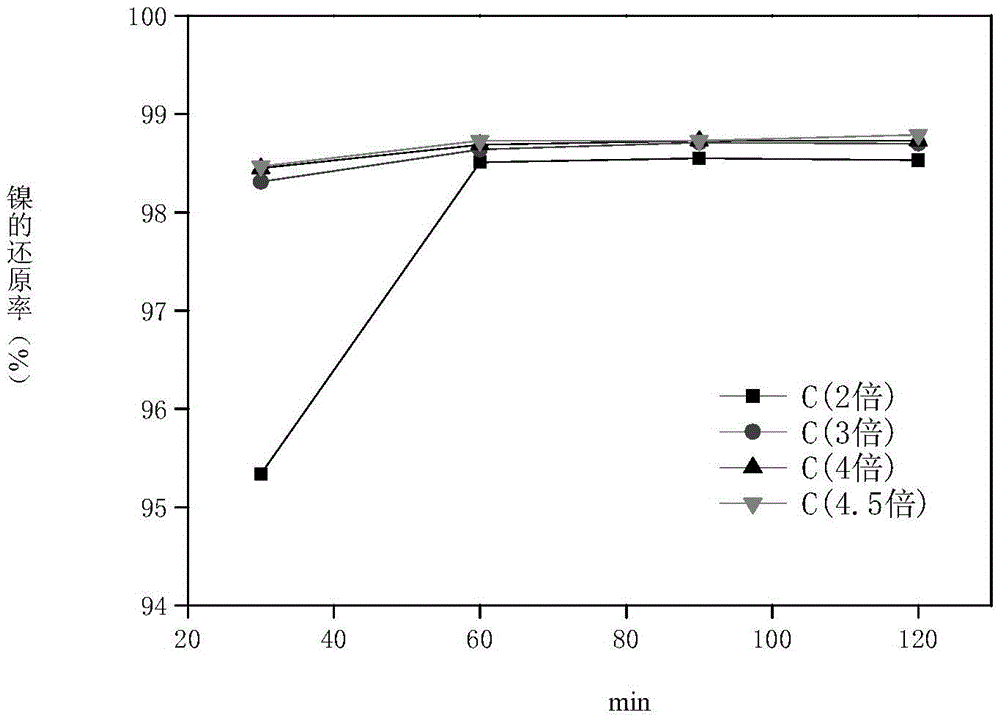

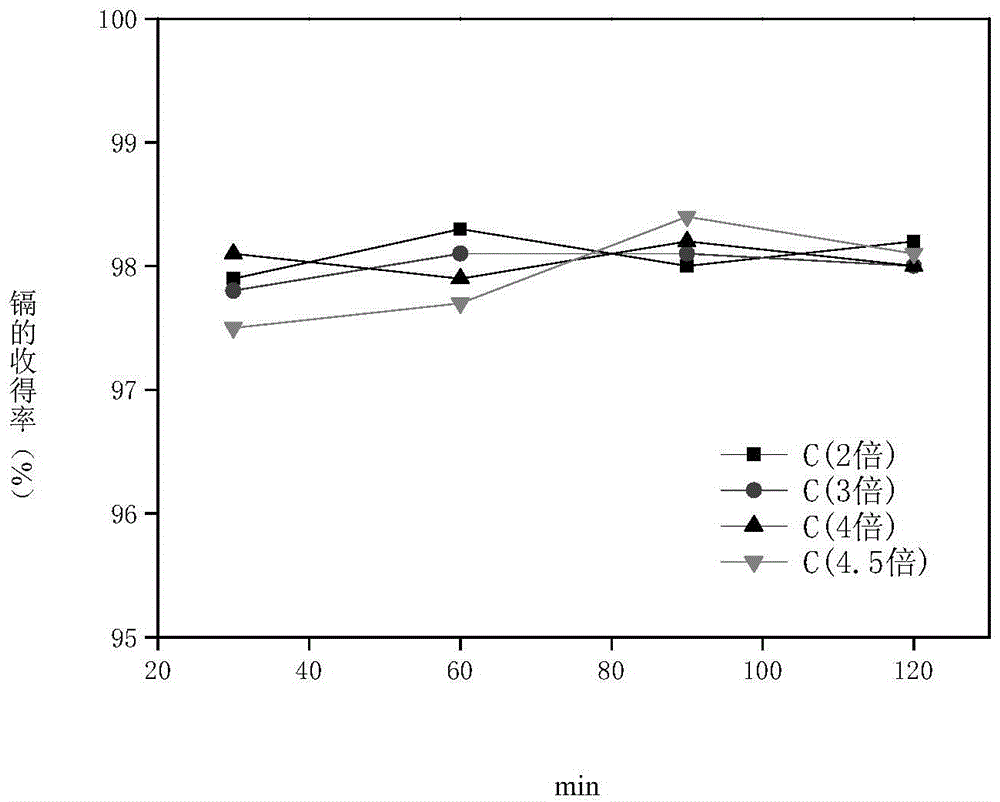

Method for recycling and refining nickel and cadmium in solid hazardous wastes

ActiveCN104141044AReduce pollutionReduce loss rateProcess efficiency improvementDissolutionCadmium carbonate

The invention discloses a method for recycling and refining nickel and cadmium in solid hazardous wastes. The method disclosed by the invention comprises the following steps: reducing semi-finished products by using a carbon-containing reducing agent, wherein the semi-finished products are nickel carbonate and cadmium carbonate which are generated during a treatment process of hazardous wastes containing heavy metals including nickel and cadmium and contain lots of nickel and cadmium and less magnesium, caecum and iron; then carrying out acid leaching; controlling the condition to ensure that cadmium oxide in the system is dissolved but the metallic nickel is not dissolved so as to realize separation of nickel and cadmium; melting the separated metallic nickel at the temperature of 1600 DEG C to form a nickel ingot product of which the grade is above 99%; putting a Cd<2+> solution obtained through dissolution into a workshop process and precipitating the solution by using sodium carbonate so as to obtain a CdCO3 product of which the purity is higher than 98%. The method disclosed by the invention can be used for greatly reducing energy consumption and environmental pollution and has the advantages of short process and easy control over conditions; substances contained in raw materials need not to be purified specially, a high-purity product can be obtained under the condition that the procedures are reduced; the reducing agent is selected conveniently according to local production conditions and is low in cost.

Owner:CHINA WEST NORMAL UNIVERSITY +1

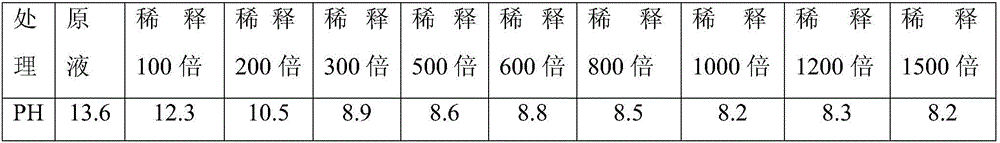

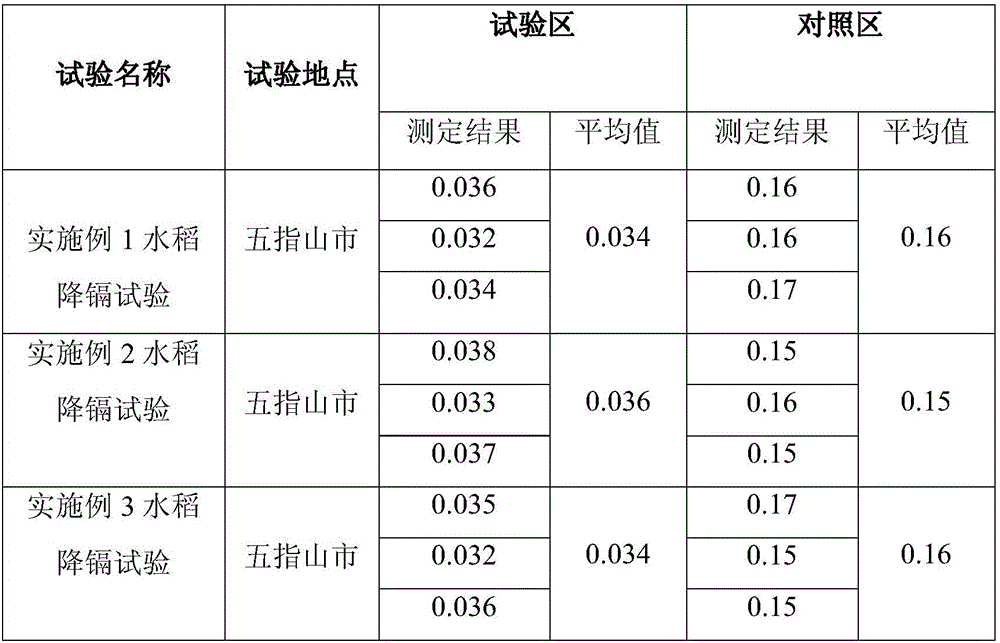

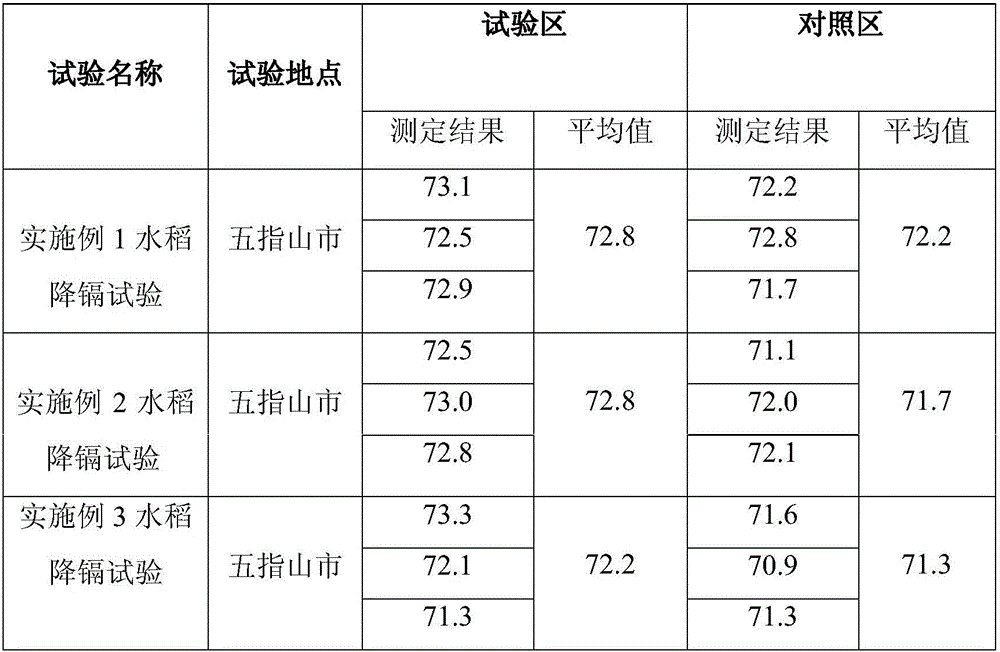

Acidic-soil-improvement cadmium-lowering fertilizer capable of lowering cadmium content in paddy rice

ActiveCN106478300AImprove fertilityReduce cadmium contentAnimal corpse fertilisersAlkali orthophosphate fertiliserSucrosePhosphate

The invention discloses an acidic-soil-improvement cadmium-lowering fertilizer capable of lowering cadmium content in paddy rice. The fertilizer is prepared by sufficiently and uniformly stirring the following raw materials in percentage by weight: 8-10% of fish protein solution, 10-12% of sodium humate, 2-5% of sodium sulfide, 5-8% of potassium hydroxide, 10-15% of potassium dihydrogen phosphate, 10-15% of ammonium carbonate, 20-25% of urea and 10-35% of sucrose fermentation liquid. The acidic-soil-improvement cadmium-lowering fertilizer has the buffer function, can keep the soil pH within the range of 6.5-8.0 all the time, can not salinize the soil after long-term application, and is safe to use. The cadmium-lowering fertilizer contains abundant hydroxyl ions, and is capable of releasing sulfur ions through the fish protein solution, sodium sulfide and the like and releasing carbonate ions through the ammonium carbonate. The hydroxyl ions and cadmium ions form the cadmium hydroxide precipitate (Cd(OH)2), the sulfur ions and cadmium ions form the cadmium sulfide precipitate (CdS), and the carbonate ions and cadmium ions form the cadmium carbonate precipitate (CdCO3); the cadmium lowering effect is greatly enhanced under the combined actions of the cadmium hydroxide precipitate, cadmium sulfide precipitate and cadmium carbonate precipitate.

Owner:ANALYSIS & TESTING CENT CHINESE ACADEMY OF TROPICAL AGRI SCI

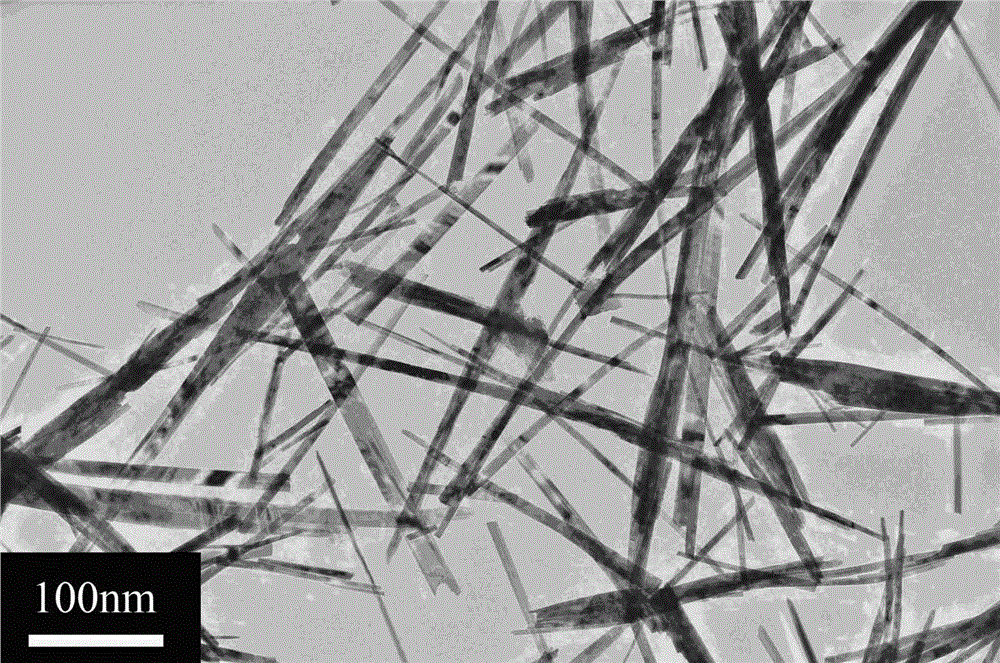

Method for preparing cadmium molybdate nanorod

InactiveCN104671285AEasy to operateEasy to realize industrial productionMaterial nanotechnologyMolybdeum compoundsPhotoluminescenceCadmium carbonate

The invention discloses a method for preparing a cadmium molybdate nanorod. The method comprises the following steps: mixing a cadmium chloride solution and a potassium carbonate solution, and reacting to obtain a cadmium carbonate precipitate; mixing the precipitate with a sodium tungstate solution, adding the mixture into a reaction kettle, preserving the temperature to 110-150 DEG C for 2-6 hours, and performing hydrothermal treatment; naturally cooling to room temperature, adding sodium molybdate powder, preserving the temperature to 180-220 DEG C for 8-12 hours, and performing hydrothermal treatment; and naturally cooling the reaction kettle to room temperature, discharging the kettle, repeatedly washing the reaction product by using distilled water, filtering, and drying, thereby obtaining the cadmium molybdate nanorod. The preparation of the cadmium molybdate nanorod having a one-dimensional structure is realized at the first time, the preparation method has the advantages that the process flow is simple, any organic surfactant is not used and the pollution is avoided, industrial production is easily realized, and the cadmium molybdate nanorod has wide application values in the fields of photoluminescence, optical fibers and sensors.

Owner:LUOYANG INST OF SCI & TECH

Method for preparing mixed product of carbonate and lithium sulfate from manganese-containing waste liquid

InactiveCN102115125AEliminate pollutionEasy to operateCalcium/strontium/barium carbonatesAluminium compoundsManganeseCadmium carbonate

The invention provides a method for preparing a mixed product of carbonates and lithium sulfate from a manganese-containing waste liquid. The manganese-containing waste liquid generated during the production of hydroquinone is filtered to produce a clear filtrate containing manganese sulfate, ammonium sulfate and sulfuric acid and a filter cake containing simple substance residues; the filter cake containing the simple substance residues reacts with an excessive amount of sulfuric acid to produce a liquid containing calcium sulfate, magnesium sulfate, zinc sulfate, sodium sulfate, aluminum sulfate, cadmium sulfate and nickel sulfate; then the liquid mixes and reacts with a lithium carbonate liquid to produce a mixed liquid of lithium sulfate and carbonates including calcium carbonate, magnesium carbonate, zinc carbonate, sodium carbonate, aluminum carbonate, cadmium carbonate and nickel carbonate; the mixed liquid is filtered to produce a filter cake of calcium carbonate and a filtrate containing carbonates and lithium sulfate; and the filtrate containing carbonates and lithium sulfate is distilled under a reduced pressure and cooled to crystallize mixed carbonate crystals and lithium sulfate crystals, and the crystallization product is filtered and separated to obtain a mixed product of carbonates and lithium sulfate.

Owner:何云

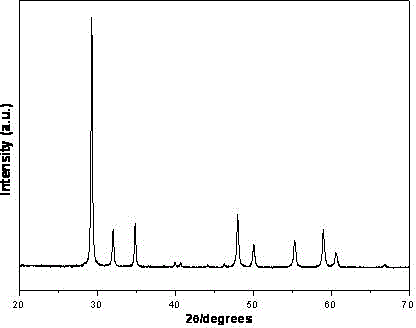

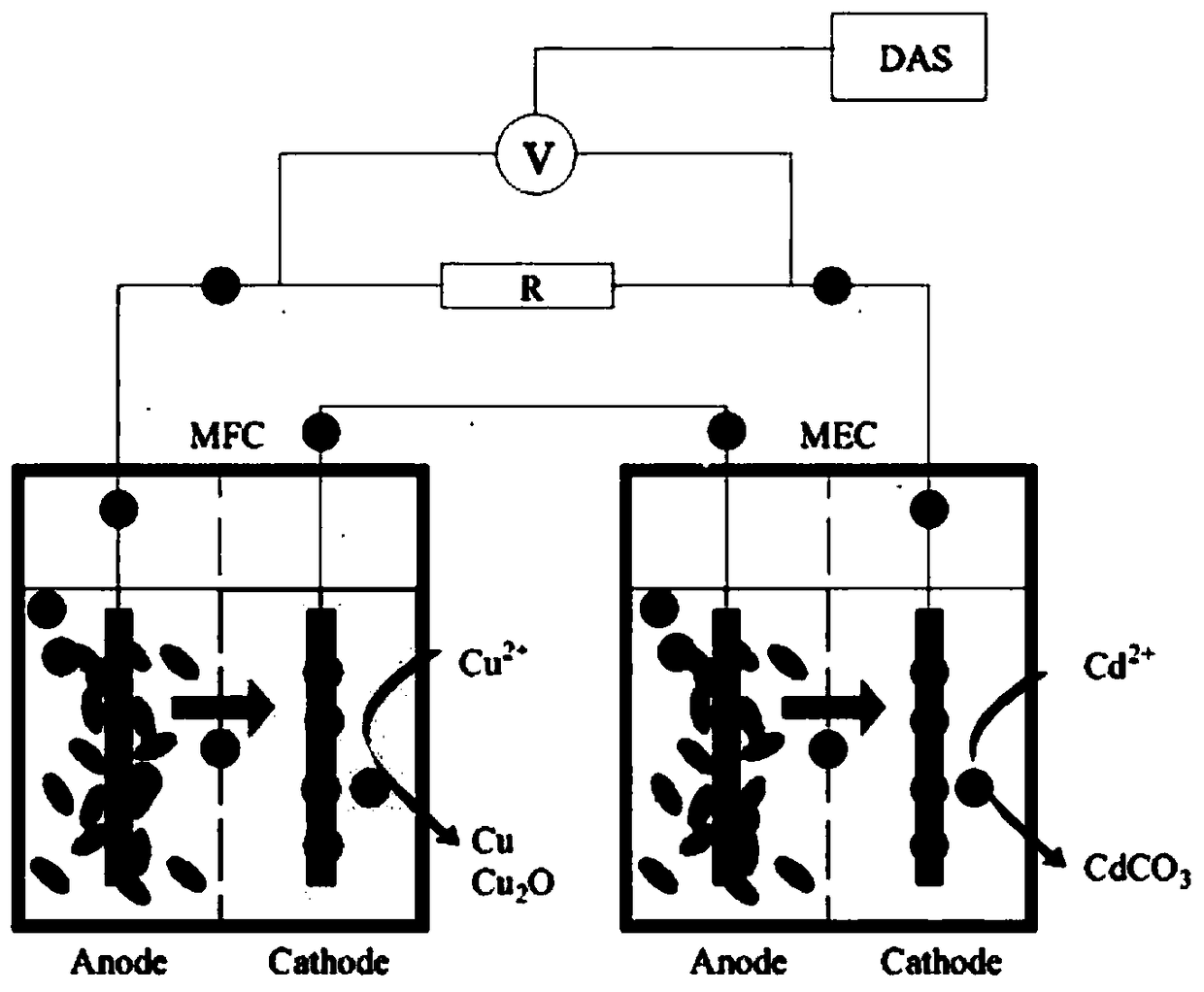

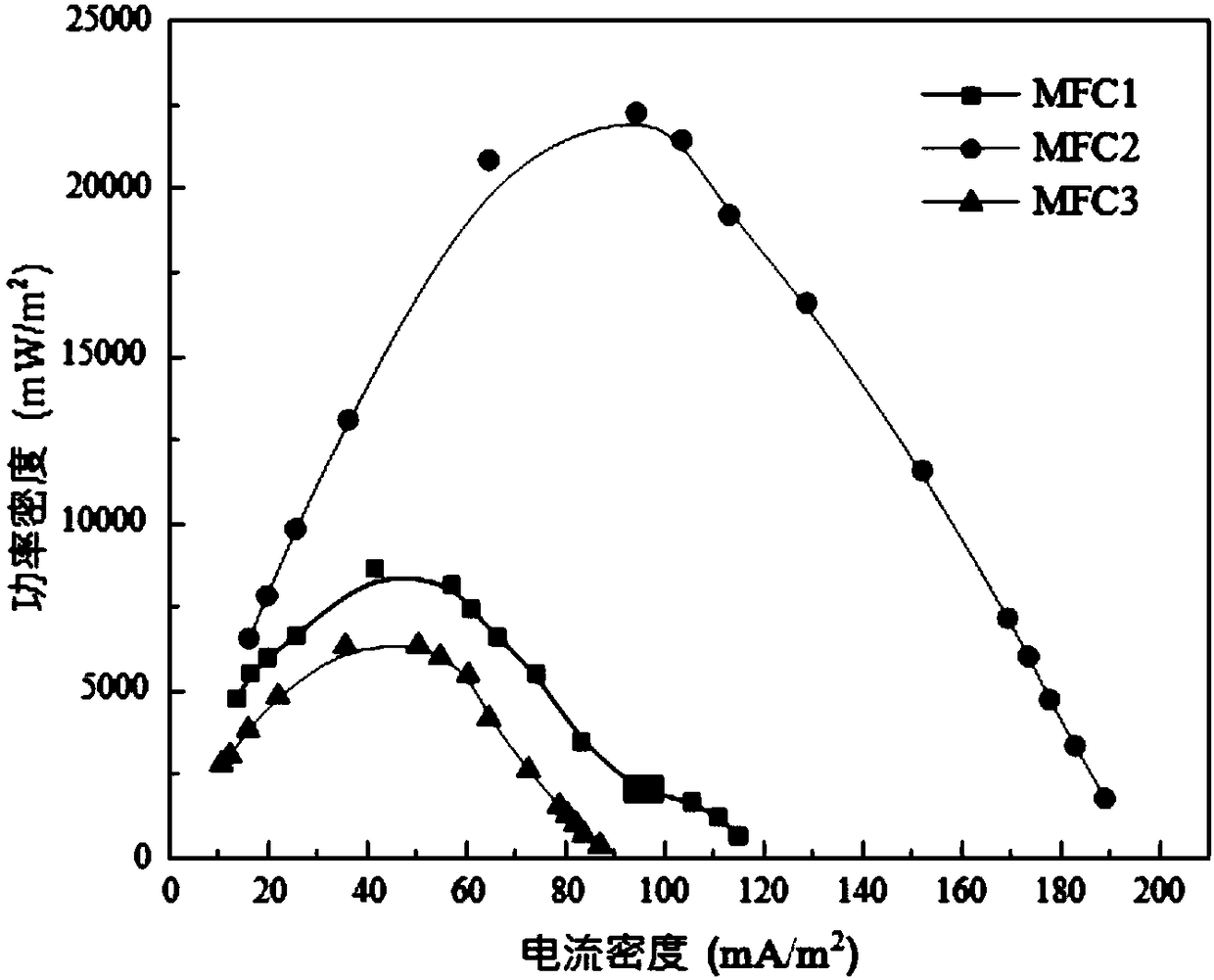

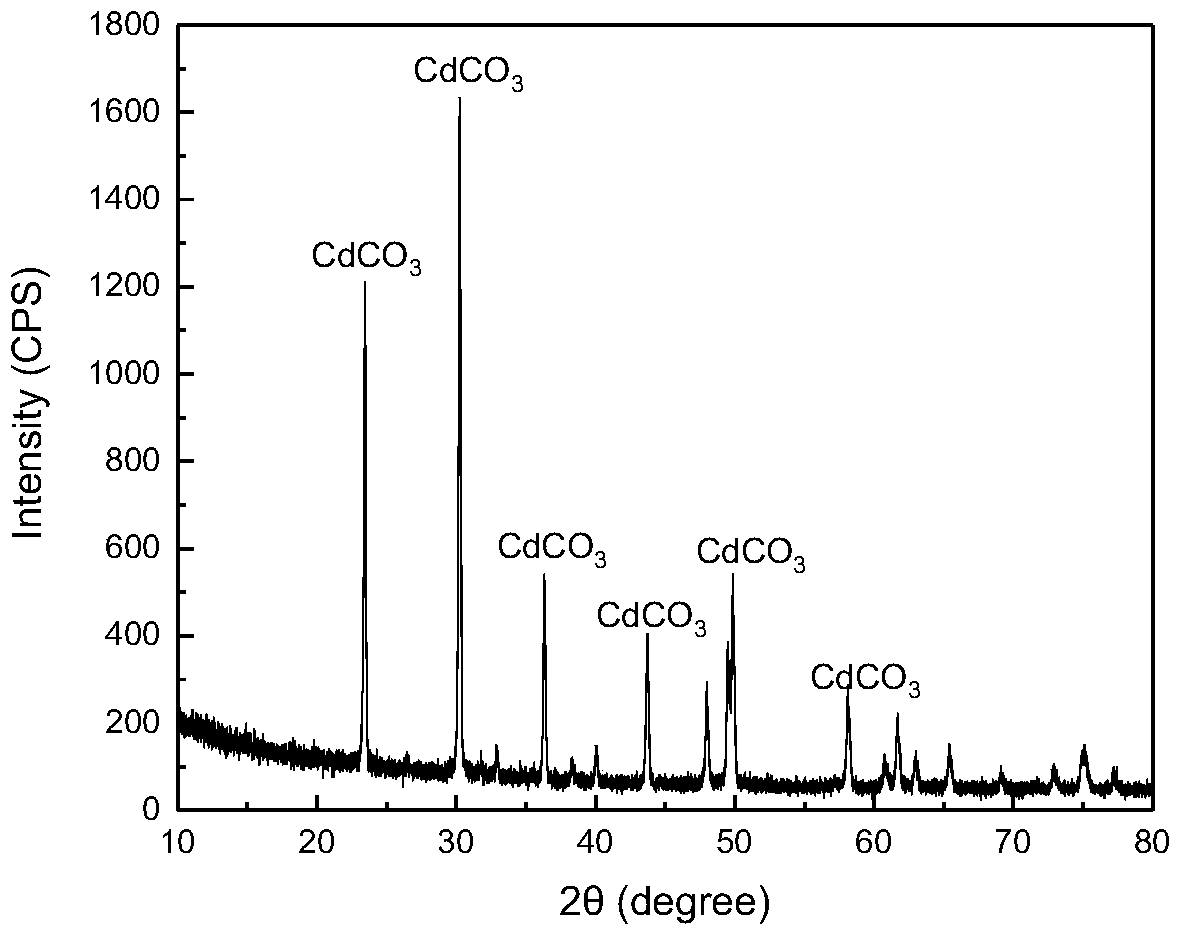

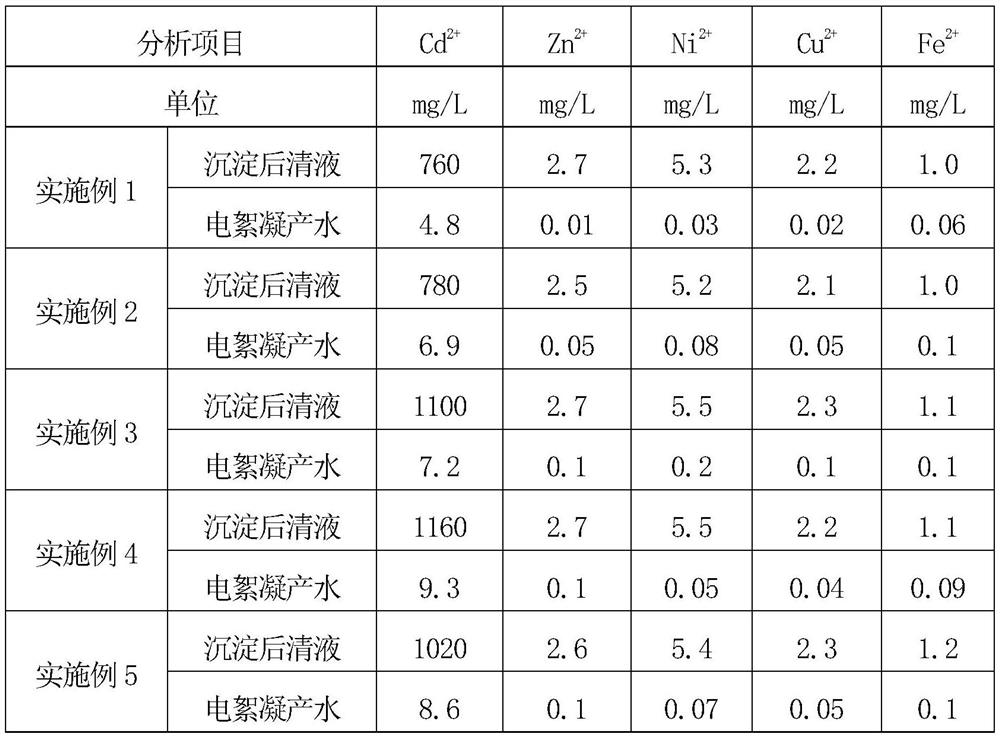

Method for removing cadmium ions in heavy metal wastewater

InactiveCN109052620AAchieve removalRealize self-driving operationTreatment by combined electrochemical biological processesWater contaminantsCathodic reactionCadmium carbonate

The invention discloses a method for removing cadmium ions in heavy metal wastewater, which uses electric energy generated by microbial fuel cell degraded organic matter to drive a microbial electrolysis cell to treat cadmium-containing heavy metal wastewater, does not consume external electric energy or generate secondary pollution during the whole process, and is an environment-friendly new method for treatment of cadmium-containing heavy metal wastewater. The method comprises the following three steps: 1, determination of MFC operating parameters; 2, construction of an MFC-MEC self-driven coupling system; and 3, treatment of the cadmium-containing heavy metal wastewater, wherein through the steps 1 and 2, the cadmium-containing heavy metal wastewater is treated through MEC cathodic reaction, catholyte is the cadmium-containing heavy metal wastewater, the pH value is 1-5, carbon paper is used as anode, and stainless steel, a titanium plate and carbon paper are used as cathode material. After the end of MEC reaction, the cathode is taken out and an MEC cathode reduction product is collected. XRD detection proves that the MEC cathode reduction product is cadmium carbonate and the cadmium ion removal rate is 89.5%.

Owner:JIANGSU UNIV OF TECH

Method for preparing mixed product of carbonate and magnesium sulfate from manganese-containing waste solution

InactiveCN102139905AEliminate pollutionEasy to operateCalcium/strontium/barium carbonatesAluminium compoundsManganeseCadmium carbonate

The invention provides a method for preparing a mixed product of carbonate and magnesium sulfate from a manganese-containing waste solution. The method comprises the following steps of: firstly, extracting and filtering the manganese-containing waste solution obtained in production of hydroquinone to obtain a clear filter liquor including manganese sulfate, magnesium sulfate and sulfuric acid as well as filter cakes including elemental residues, reacting the filter cakes including elemental residues with excessive sulfuric acid to obtain a solution including calcium sulfate, magnesium sulfate, zinc sulfate, sodium sulfate, aluminum sulfate, cadmium sulfate and nickel sulfate; secondly, mixing and reacting the solution with magnesium carbonate to obtain a mixed solution of carbonate and magnesium sulfate as well as the carbonate including calcium carbonate, zinc carbonate, sodium carbonate, aluminum carbonate, cadmium carbonate and nickel carbonate; thirdly, filtering the mixed solution of carbonate and magnesium sulfate to obtain calcium carbonate filter cakes and a filter liquor including carbonate and magnesium sulfate, washing, drying and crashing the carbonate filter cakes to obtain a calcium carbonate product; finally, decompressing and distilling, cooling and crystallizing the filter liquor including carbonate and magnesium sulfate to obtain the mixed product of carbonate and magnesium sulfate.

Owner:何云

Carbon dioxide sensor

InactiveUS7006926B2Reduce impactUsing mechanical meansGas analyser construction detailsIndiumAlkaline earth metal

A carbon oxide sensor having high sensitivity capable of reduction of influence of humidity is provided. A detection electrode and a counter electrode are provided on one side of an electrolyte, respectively. The detection electrode contains a metal oxide and a metal carbonate including plural components. The metal carbonate preferably contains a first component of alkali metal carbonate and a second component of at least one element selected from the group consisting of alkali earth metal carbonate, transition metal carbonate, zinc carbonate, cadmium carbonate, indium carbonate, lead carbonate and bismuth carbonate. Specifically, it is preferable to contain the first component including Li2CO3 and the second component including at least one element selected from the group consisting of BaCO3, CaCO3 and SrCO3.

Owner:TDK CORPARATION

Medical low-temperature reversible temperature-indicating coating and preparation method thereof

The invention discloses a medical low-temperature reversible temperature-indicating coating and a preparation method thereof; raw materials comprise epoxy modified organic silicon resin, lead dioxide, ethyl cellulose, cadmium carbonate, calcium fluoride, a talcum powder, barium sulfate, Sudan orange, titanium dioxide and red cyanine; the product is in reversible single color change at the temperature of 70-90 DEG C, a color is turned from red to purple, and the color is turned from purple to orange at the temperature of 140-180 DEG C; the product has the viscosity of 60-80 s, is resistant to water for 3-7 d without blistering, is non-toxic and has good heat resistance, and the temperature measurement range is from room temperature to 200 DEG C; and temperature measurement is fast, simple and reliable, and the product can be widely produced and constantly replaces conventional materials.

Owner:SUZHOU BEC BIOLOGICAL TECH

Brazing flux used for braze welding of metal parts

InactiveCN101537551AImprove wettabilitySatisfied with the qualityWelding/cutting media/materialsSoldering mediaHydrofluoric acidAluminium hydroxide

The invention discloses a brazing flux used for braze welding of metal parts. The material of the brazing flux consists of main material and accessories, wherein the main material comprises hydrofluoric acid, aluminium hydroxide and potassium carbonate and the accessories comprise cadmium oxide, cadmium carbonate and zinc oxide. After being melted, the brazing flux permeates into capillaries of parent metal to be melted with surface metal of the parent metal into alloy so as to remove an oxide film on the surface of brazing metal and brazing filler metal. The brazing flux can effectively prevent the oxidization of the brazing filler metal at high temperature, reduce the surface tension of the brazing filler metal in melting state and enhance the wettability to base metal by the brazing filler metal so as to promote the flushing and distribution of the brazing filler metal, lead the brazing filler metal to form good brazing seams whiling filling gap clearances so as to obtain the satisfactory quality of brazed joints.

Owner:JIANGMEN WEISITE WELDING MATERIAL TECH

Scarlet glaze material for ceramics and preparation method thereof

The invention relates to a scarlet glaze material for ceramics, which is prepared from 30-50 parts of potash feldspar, 20-40 parts of quartz, 5-15 parts of marble, 8-15 parts of kaolin, 6-10 parts of clear frit, 0.1-0.5 part of cadmium carbonate, 4-12 parts of scarlet pigment and 50-70 parts of water. The preparation method comprises the following steps: evenly mixing the 30-50 parts of potash feldspar, 20-40 parts of quartz, 5-15 parts of marble, 8-15 parts of kaolin, 6-10 parts of clear frit and 50-70 parts of water, and carrying out ball milling for 15-20 hours until the fineness reaches 325 meshes; evenly mixing the 0.1-0.5 part of cadmium carbonate and 4-12 parts of scarlet pigment, and carrying out ball milling until the fineness reaches 325 meshes; and finally, evenly mixing the two mixtures to obtain the scarlet glaze material for ceramics. The glaze material has the advantages of favorable combination performance with the green body, pure and bright color, high stability and high gloss.

Owner:CHAOZHOU QINGFA CERAMICS

Steel antirust paint

InactiveCN104327735APrevent rustNo pollution in the processAnti-corrosive paintsCelluloseO-Phosphoric Acid

A steel antirust paint is prepared from the following raw materials in parts by weight: 8-14 parts of water-based resin, 2-7 parts of a defoaming agent, 1-5 parts of a propellant, 5-9 parts of phosphoric acid, 3-7 parts of laury alcohol ether, 2-6 parts of methyl cellulose, 5-9 parts of cadmium carbonate, 1-3 parts of a film-forming auxiliary agent, 5-7 parts of an acrylic emulsion, 4-8 parts of dichloromethane, 4-6 parts of organic glass crumbs, and 3-7 parts of liquid paraffin. The steel antirust paint has the beneficial effects that the steel antirust paint can form a dense antirust oil film on steel, prevents the steel from rusting, and besides, has no pollution and low cost.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Method for synthesizing cadmium selenide and quantum point with cadmium selenide cadmium sulfide nucleocapsid structure

InactiveCN1317737CMild reaction conditionsSimple methodLaser detailsNanostructure manufactureMicroparticleCarboxylic acid

The method includes following steps: the cadmium oxide, cadmium carbonate, alkyl carboxylic acid, oleic acid, selenourea, thiourea are taken as raw material. Under the cover of oleic acid, or TOPO, or lauryl amine, or hexadecyl amine, or octadecyl amine, the alkyl carboxylic acid cadmium or the toluol solution of oleic acid cadmium reacts with aqueous solution of selenourea or thiourea at interface to form semiconductor nano-microparticles. Theses semiconductor nano-microparticles can implement wavelength tunable visible light under ultraviolet lamp.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Nano-crystal with core-shell structure and preparation method thereof

InactiveCN101186816BAvoid toxicityImprove stabilitySemi-permeable membranesNanostructure manufactureFluorescenceCadmium carbonate

The invention discloses a nanocrystalline with core-shell structure. The nanocrystalline is of a core-shell structure and takes cadmium sulphide as a core and cadmium carbonate as a peripheral shell.A process for preparing the nanocrystalline is that the mol ratio of water-soluble cadmium acetate and sulfur source Cd / S is x, whichin 1.1<=x<=1.4, and raw materials are placed in a high-pressure autoclave to react under the condition that reaction system is of pH 9 to 13, wherein the concentration of the water-soluble cadmium acetate in the reaction system is 5 to 54.5 mmol / L, and the concentration of the sulfur source is 4.5 to 50 mmol / L. The invention is simple in process, easy in operation and low in price, further, the prepared nanocrytalline which is of cadmium sulphide or cadmium carbonate core-shell structure is prepared and the particle diameter of the nanocrytalline is -5nm. The invention has the advantages of high chemical stability, good fluorescence-emission monochromaticity,relatively narrow peak width at half height and the like in comparison with an existing nude nanocrystalline product, which saves precious placing time for surface finish of the nanocrystalline and improves fluorescent property, thereby enabling the nanocrystalline to be used as biological tissue marks after subsequent treatment such as the surface finish and the like.

Owner:HENAN UNIV OF SCI & TECH

Method for manufacturing silver cadmium oxide material and product

InactiveCN103555987BEvenly distributedImprove electrical contact performanceContactsCadmium carbonateRotary furnace

The invention discloses a method for manufacturing a silver cadmium oxide material. The method comprises the following steps: (a) preparing 10-30 percent of cadmium carbonate, 0.1-0.5 percent of nickel carbonate, 0.05-0.2 percent of manganese carbonate and the balance of silver nitrate; (b) dissolving by using excessive dilute nitric acid, dissolving the silver nitrate by using pure water, mixing and stirring; (c) preparing a saturated sodium carbonate solution; (d) adding the sodium carbonate solution into a mixed solution while stirring, so as to generate a precipitate; and stopping adding after the PH value of the solution reaches 11; (e) repeatedly washing the generated precipitate and drying; (f) heating to the temperature of 300-450 DEG C, and keeping the temperature; (g) introducing hydrogen after the temperature of the powder is lower than 60 DEG C, heating to the temperature of 250-320 DEG C, keeping the temperature, and then cooling to room temperature; (h) performing ball milling on the powder, sieving the powder by using a 200-meshes sieve; (i) oxidizing in a rotary furnace, introducing compressed air, heating to the temperature of 300 DEG C, keeping the temperature, and cooling to room temperature; (j) performing ball milling on the powder, sieving the powder by using the 200-meshes sieve, loading the powder in a mold for isostatic pressing; and (k) sintering the material for 2-3 hours, and performing extrusion forming for later use.

Owner:SICHUAN FEILONG ELECTRIC MATERIALS

Method for resourceful treatment of cadmium-containing heavy metal wastewater

InactiveCN112429888ASolve processing problemsTo achieve the purpose of resource utilizationWater treatment parameter controlWater contaminantsSludgeElectro flocculation

The invention discloses a method for resourceful treatment of cadmium-containing heavy metal wastewater, which comprises the following steps: adding a precipitant into cadmium-containing wastewater togenerate cadmium carbonate precipitate aiming at cadmium plating layer stripping solution wastewater, washing the cadmium salt precipitate, filtering, and carrying out heat treatment to thermally decompose cadmium carbonate to generate cadmium oxide which is used for preparing cyaniding cadmium plating solution for continuous resourceful utilization; after precipitation, removing heavy metal ionsin a supernatant through electric flocculation, and recycling electric flocculation produced water or partially discharging as cadmium-containing plating piece stripping mother liquor; performing electric flocculation treatment on acidic wastewater generated by nitric acid washing and filtering to remove heavy metal ions and then discharging after reaching the standard. According to the method, the cadmium element and the wastewater in the cadmium-containing wastewater are recycled, the purpose of recycling is achieved, the amount of hazardous waste sludge is reduced, the operation cost is low, the problem of heavy metal treatment is solved, and the method has obvious economic benefits and environmental protection benefits.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Anti-corrosion anti-abrasion creep-resistant electric wire cable material for household electrical appliances and preparation method of anti-corrosion anti-abrasion creep-resistant electric wire cable material

InactiveCN106496751AImprove creep resistanceImprove heat aging resistancePlastic/resin/waxes insulatorsSlagEngineering

The invention discloses an anti-corrosion anti-abrasion creep-resistant electric wire cable material for household electrical appliances and a preparation method of the anti-corrosion wear-proof creep-resistant electric wire cable material. The anti-corrosion wear-proof creep-resistant electric wire cable material is prepared from the following raw materials by weight: 65 to 80 parts of polyethylene, 26 to 39 parts of polyvinylidene fluoride, 18 to 34 parts of allyl diglycol carbonate resin, 10 to 15 parts of datolite, 5 to 10 parts of boron-rich slag, 10 to 15 parts of pentaerythrityl tetraisostearate, 15 to 25 parts of para-polyphenyl, 8 to 12 parts of candelilla wax, 6 to 9 parts of cadmium carbonate, 5 to 10 parts of carbonyl iron powder, 2 to 4 parts of lanthanum laurate and 12 to 17 parts of porous konilite. The cable material prepared from the raw materials of polyethylene, polyvinylidene fluoride, allyl diglycol carbonate resin, para-polyphenyl, nano-diamond, carbonyl iron powder, porous konilite and the like is high in creep resistance, high in heat aging resistance, and high in abrasion resistance and corrosion resistance, is not likely to wear or cause corrosion damage and is long in service life.

Owner:周先强

Method for preparing cadmium sulfide nanometer membrane by self assembly

InactiveCN101853901AComplete shapeUniform sizeFinal product manufactureSemiconductor devicesCadmium carbonateCadmium sulfide

The invention provides a method for preparing a cadmium sulfide nanometer membrane by self assembly. The method comprises the following steps of: mixing cadmium carbonate and trimethylamine to obtain A, and adding deionized water into A to obtain B; adding PVP into the B, performing magnetic stirring to obtain C, adding thioacetamide into the C, and uniformly stirring the mixture to obtain D; adjusting a pH value of the solution D to 4.0 to 10.0 to obtain precursor solution; soaking a clean ITO base plate in benzene solution of CTAB at room temperature, taking the base plate out, and drying the base plate in an argon protective atmosphere; placing the dried ITO base plate in the precursor solution for deposition at room temperature for 5 to 40 hours to prepare a cadmium sulfide membrane; and drying the prepared cadmium sulfide membrane in a vacuum dry box to obtain the cadmium sulfide nanometer membrane. Because the method of the invention adopts the self assembly, the cadmium sulfide nanometer membrane prepared by the method has a complete shape and uniform size; and the thickness of the membrane and the size of crystal grains can be controlled by controlling the concentration and pH value of the reaction precursor solution and the deposition time. The cadmium sulfide nanometer membrane prepared by the method has the advantages of high repeatability and easy formation of large-area membranes; and the method has the advantages of easy operation, readily available raw materials and low preparation cost.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing carbonate and strontium sulfate mixed product from manganese-containing waste liquid

InactiveCN102120601AEliminate pollutionEasy to operateCalcium/strontium/barium carbonatesAluminium compoundsDistillationManganese

The invention provides a method for preparing a carbonate and strontium sulfate mixed product from manganese-containing waste liquid, comprising the steps of: leaching manganese-containing waste liquid obtained from hydroquinone production to obtain clear filter liquor containing manganese sulfate, ammonium sulfate and sulfuric acid and a filter cake containing elementary-substance residues; making the filter cake containing elementary-substance residues react with an excessive amount of sulfuric acid to obtain a solution containing calcium sulfate, manganese sulfate, zinc sulfate, sodium sulfate, aluminum sulfate, cadmium sulfate and nickel sulfate; then making the obtained solution react with a strontium carbonate solution to obtain a strontium sulfate and carbonate mixed solution containing calcium carbonate, manganese carbonate, zinc carbonate, sodium carbonate, aluminum carbonate, cadmium carbonate and nickel carbonate; filtering to obtain a calcium carbonate filter cake and a filer liquor containing the carbonate and the strontium sulfate; washing, drying and crushing the calcium carbonate filter cake to obtain a calcium carbonate product; and carrying out reduced-pressure distillation and cooling crystallization on the filter liquor containing the carbonate and the strontium sulfate to obtain the carbonate and strontium sulfate mixed product.

Owner:何云

A method for preparing cadmium oxide from zinc smelting cadmium-containing fumes

The invention discloses a method for preparing cadmium oxide from zinc smelting cadmium dust. The main steps are: adding zinc smelting cadmium dust to 30-120g / L sulfuric acid solution, and reacting at a reaction temperature of 20-80°C to obtain sulfuric acid Cadmium solution; add iron salt to the obtained cadmium sulfate solution, then add hydrogen peroxide or air for oxidation, adjust the pH value to 4~9 with sodium hydroxide, filter after precipitation, and extract the filtrate through organic phosphorus extractant to obtain zinc removal. CdSO4 solution after mixing; add urea in the solution according to the ratio of cadmium to urea in the amount of 1:1~1:7, use sodium hydroxide solution to adjust the pH to 6~11, then add it to the high-pressure reactor for hydrothermal reaction The cadmium carbonate obtained by the reaction is filtered and washed, and then roasted to prepare cadmium oxide powder. The method has the advantages of simple process, high recovery rate of cadmium and high purity of cadmium oxide.

Owner:CENT SOUTH UNIV

Preparation method and application of calcite-otavite solid solution

PendingCN113695353ALow costEasy to operateSolid waste disposalElectronic waste recyclingCalciteCadmium carbonate

The invention discloses a method for synthesizing a calcite-otavite mixed crystal solid solution through a precipitation method. An anhydrous potassium carbonate preparation solution is used as a base solution, then calcium nitrate and cadmium nitrate solutions with different molar ratios and a metal salpeter solution obtained by dissolving calcium carbonate and cadmium carbonate with concentrated nitric acid with a corresponding molar ratio are added into a potassium carbonate solution, and the calcite-otavite mixed crystal solid solution with high crystallinity and good stability is obtained. Finally, a proper amount of the calcite-otavite solid solution is taken, dissolving is carried out in three different solutions under the condition of 25 DEG C, and the migration, conversion and enrichment rules of cadmium in the calcite-otavite solid solution formed on the surface after the calcite adsorbs Cd < 2 + > are mastered. The calcite-otavite series solid solution synthesized by the method has the advantages that the cost is low, the control is easy, the calcite-otavite solid solution is easy to prepare instead of a mixture rich in cadmium and vaterite, and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Bright red glaze for ceramics, and preparation method thereof

ActiveCN110683762AReduce storage environment requirementsSave red propertyCeramic materials productionFritKaolin clay

The invention discloses a bright red glaze for ceramics, and a preparation method thereof, and relates to the technical field of ceramic glazes, wherein the bright red glaze is prepared from the following components by weight: 30-50 parts of potassium feldspar, 18-38 parts of quartz, 6-13 parts of marble, 8-15 parts of kaolin, 6-10 parts of transparent frit, 50-70 parts of water, 2-8 parts of bright red pigment and 1-3 parts of red corallite powder. According to the invention, cadmium carbonate is replaced with the red corallite powder as the fluxing agent, wherein the main component of the red corallite powder is CaCO3, so that the requirement on the storage environment of the red corallite powder is low, and the storage cost of the raw materials is saved; the red corallite powder has redattribute, so that the use of the bright red pigment is reduced so as to further reduce the cost; by using the red corallite powder to replace cadmium carbonate, the toxic substances such as cadmiumcompounds, cadmium dust and the like cannot be generated in the processing process so as to further improve the processing environment quality and ensure the body health of operators.

Owner:临沂晶石陶瓷有限公司

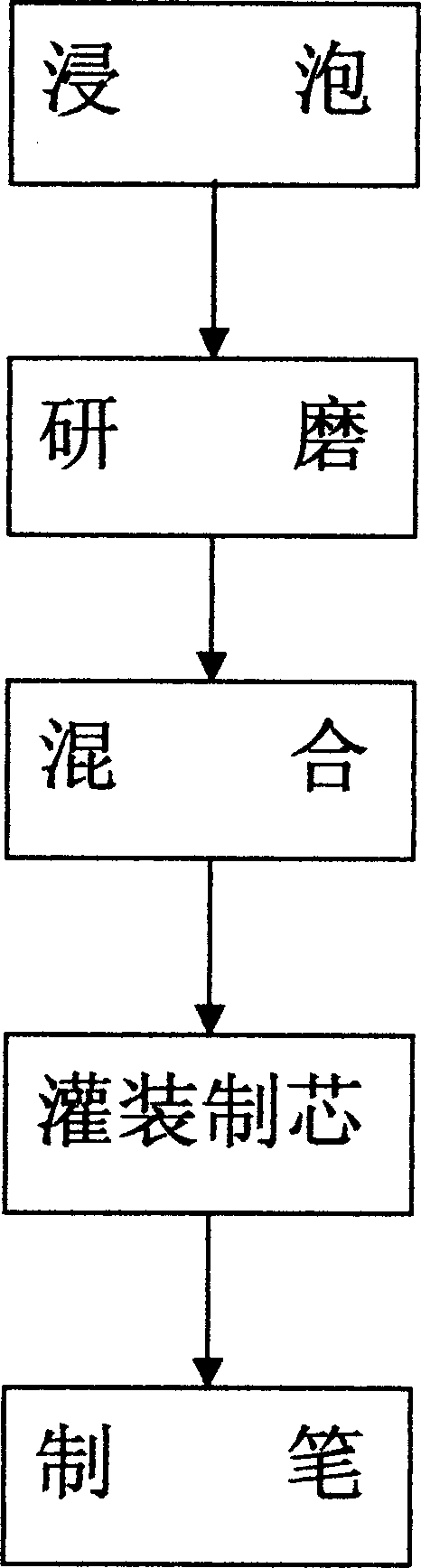

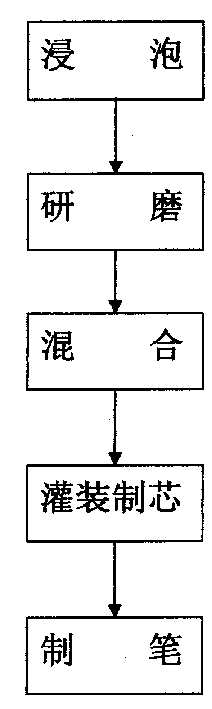

Short period recording pen

InactiveCN1473890ASave paperImprove confidentialityPencil leadsCadmium carbonateOleic Acid Triglyceride

Black cadmium oxide powder after being exposed to air for some time will reacts with CO2 in air to produce white cadmium carbonate. The present invention uses cadmium oxide as developing agent, and produces pen with cadmium oxide, dibutyl phthalate, xylene and oleic acid and through soaking, grinding, mixing, filling and other steps. The writing of the pen will change its color from black into white after some time. The present invention makes it possible to reuse the paper for several times and to protect some document against disclosing.

Owner:王力

Method for recycling and refining nickel and cadmium in solid hazardous waste

ActiveCN104141044BReduce pollutionReduce loss rateProcess efficiency improvementEnvironmental engineeringCadmium carbonate

The invention discloses a method for recycling and refining nickel and cadmium in solid hazardous wastes. The method disclosed by the invention comprises the following steps: reducing semi-finished products by using a carbon-containing reducing agent, wherein the semi-finished products are nickel carbonate and cadmium carbonate which are generated during a treatment process of hazardous wastes containing heavy metals including nickel and cadmium and contain lots of nickel and cadmium and less magnesium, caecum and iron; then carrying out acid leaching; controlling the condition to ensure that cadmium oxide in the system is dissolved but the metallic nickel is not dissolved so as to realize separation of nickel and cadmium; melting the separated metallic nickel at the temperature of 1600 DEG C to form a nickel ingot product of which the grade is above 99%; putting a Cd<2+> solution obtained through dissolution into a workshop process and precipitating the solution by using sodium carbonate so as to obtain a CdCO3 product of which the purity is higher than 98%. The method disclosed by the invention can be used for greatly reducing energy consumption and environmental pollution and has the advantages of short process and easy control over conditions; substances contained in raw materials need not to be purified specially, a high-purity product can be obtained under the condition that the procedures are reduced; the reducing agent is selected conveniently according to local production conditions and is low in cost.

Owner:CHINA WEST NORMAL UNIVERSITY +1

Low-temperature cadmium-selenium red glaze powder and preparation method and application thereof

The invention discloses low-temperature cadmium-selenium red glaze powder and a preparation method and application thereof. The preparation method of the low-temperature cadmium-selenium red glaze powder comprises the steps: performing dry grinding on red lead, boric acid, quartz, cadmium carbonate, borax and kaolin, and preparing a mixture; grinding the mixture into powder, calcining for the first time, cooling with water, carrying out wet grinding, sieving, drying, and grinding into powder again to obtain low-temperature frit powder; carrying out dry grinding and mixing on the low-temperature frit powder, kaolin, zirconium oxide and a cadmium-selenium red pigment, then carrying out powdering, secondary calcination, water cooling, wet grinding, sieving, drying, and then carrying out powdering again so as to obtain low-temperature cadmium-selenium red glaze powder; with the steps of optimizing a formula of a low-temperature frit, carrying out wet grinding on the low-temperature frit toprepare frit powder, carrying out uniform dry grinding on the frit powder and a cadmium-selenium red pigment, calcining, carrying out water quenching, carrying out wet grinding to obtain low-temperature cadmium-selenium red glaze powder, and carrying out the secondary sintering process to fully volatilize volatile matters in the low-temperature cadmium-selenium red glaze powder, pores are not generated when the low-temperature cadmium-selenium red glaze powder is applied to glass and enamel, the color of the glaze surface is brighter, and the glossiness is higher.

Owner:FOSHAN HUAYI CERAMIC COLORS CO LTD

Electromagnetic-interference-resistant fireproof insulating paint and preparation method thereof

InactiveCN104403531AHigh strengthImprove toughnessFireproof paintsPolyester coatingsPyrrolidinonesPolystyrene

The invention discloses an electromagnetic-interference-resistant fireproof insulating paint. The electromagnetic-interference-resistant fireproof insulating paint is characterized by being prepared from the following materials in parts by weight: 28 to 34 parts of alkyd resin, 2 to 3 parts of cadmium carbonate, 22 to 26 parts of fluorocarbon resin, 5 to 7 parts of mineral oil, 1 to 3 parts of beeswax, 6 to 8 parts of polystyrene, 2 to 4 parts of titanium phosphide powder, 10 to 12 parts of 200# solvent oil, 6 to 9 parts of dimethyl benzene, 4 to 6 parts of lithopone, 2 to 3 parts of benzotriazole, 2 to 4 parts of a salt spray resistance assistant ZT-719, 1 to 2 parts of dicumyl peroxide, 1 to 3 parts of an antioxidant1010, 2 to 3 parts of dibutyl phthalate, 3 to 4 parts of flaky graphite powder, 4 to 6 parts of fused magnesite, 3 to 5 parts of N-methyl pyrrolidone, and 4 to 7 parts of an assistant. The paint provided by the invention has high strength and tenacity, good impact resistance, and also has abrasive resistance and oxidation resistance; the paint still keeps good fireproof and insulating performance in wet environment, and the added assistant has good electromagnetic interference resistance, and the paint can be applied to the protection of electrical equipment, reduces the danger coefficient, and improves the safety.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com