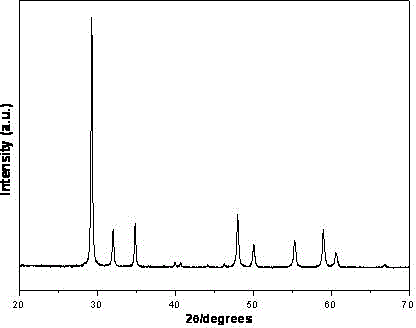

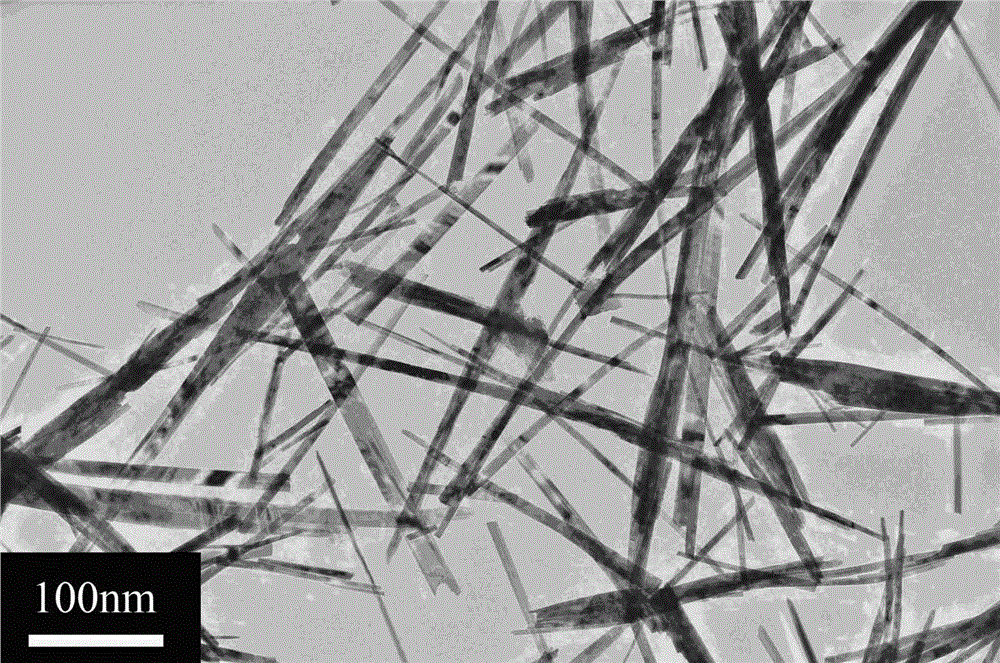

Method for preparing cadmium molybdate nanorod

A cadmium molybdate and nanorod technology, applied in the directions of nanotechnology, nanotechnology, chemical instruments and methods, can solve problems such as inconvenience in handling, and achieve the effects of simple operation, easy industrial production and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A preparation method of cadmium molybdate nanorods, comprising the steps of:

[0018] Step 1, dissolving cadmium chloride in deionized water to form an aqueous cadmium chloride solution, adjusting the concentration of cadmium chloride in the solution to be 0.1-3.0mol / L; dissolving potassium carbonate in deionized water to form an aqueous solution of potassium carbonate, Adjust the concentration of potassium carbonate in the solution to 0.1-3.0mol / L; dissolve sodium tungstate in deionized water to form an aqueous sodium tungstate solution, and adjust the concentration of sodium tungstate in the solution to 0.1-3.0mol / L;

[0019] Step 2, mixing and reacting the cadmium chloride solution and potassium carbonate solution prepared in step 1 to obtain cadmium carbonate precipitation;

[0020] Step 3. After mixing the sodium tungstate solution prepared in step 1 with the cadmium carbonate precipitate prepared in step 2, add the mixture into the inner tank of the reactor, and u...

Embodiment 1

[0029] Step 1, dissolving cadmium chloride in deionized water to form an aqueous cadmium chloride solution, adjusting the concentration of cadmium chloride in the solution to be 0.16mol / L;

[0030] Step 2, potassium carbonate is dissolved in deionized water to form an aqueous solution of potassium carbonate, and the concentration of the potassium carbonate in the adjustment solution is 0.16mol / L;

[0031] Step 3, dissolving sodium tungstate in deionized water to form an aqueous solution of sodium tungstate, adjusting the concentration of sodium tungstate in the solution to 0.16mol / L;

[0032] Step 4, the cadmium chloride solution that step 1 makes and the potassium carbonate solution that step 2 makes are mixed reaction according to molar ratio 1:1, obtain cadmium carbonate precipitation;

[0033] Step 5. After mixing the sodium tungstate solution prepared in step 3 with the cadmium carbonate precipitate prepared in step 4 according to the molar ratio of 1:1, add the mixture i...

Embodiment 2

[0039] Step 1, dissolving cadmium chloride in deionized water to form an aqueous cadmium chloride solution, adjusting the concentration of cadmium chloride in the solution to be 1.8mol / L;

[0040] Step 2, potassium carbonate is dissolved in deionized water to form an aqueous solution of potassium carbonate, and the concentration of the potassium carbonate in the regulating solution is 1.8mol / L;

[0041] Step 3, dissolving sodium tungstate in deionized water to form an aqueous solution of sodium tungstate, adjusting the concentration of sodium tungstate in the solution to 1.8mol / L;

[0042] Step 4, the cadmium chloride solution that step 1 makes and the potassium carbonate solution that step 2 makes are mixed reaction according to molar ratio 1:1, obtain cadmium carbonate precipitation;

[0043] Step 5. After mixing the sodium tungstate solution prepared in step 3 with the cadmium carbonate precipitate prepared in step 4 according to the molar ratio of 1:1, add the mixture into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com