Method for recycling and refining nickel and cadmium in solid hazardous wastes

A hazardous waste and solid technology, applied in the direction of improving process efficiency, can solve the problems of long process flow, high equipment requirements and increased cost input of extraction method, and achieve the effect of broadening the scope of application, reducing the process flow and improving the metal grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

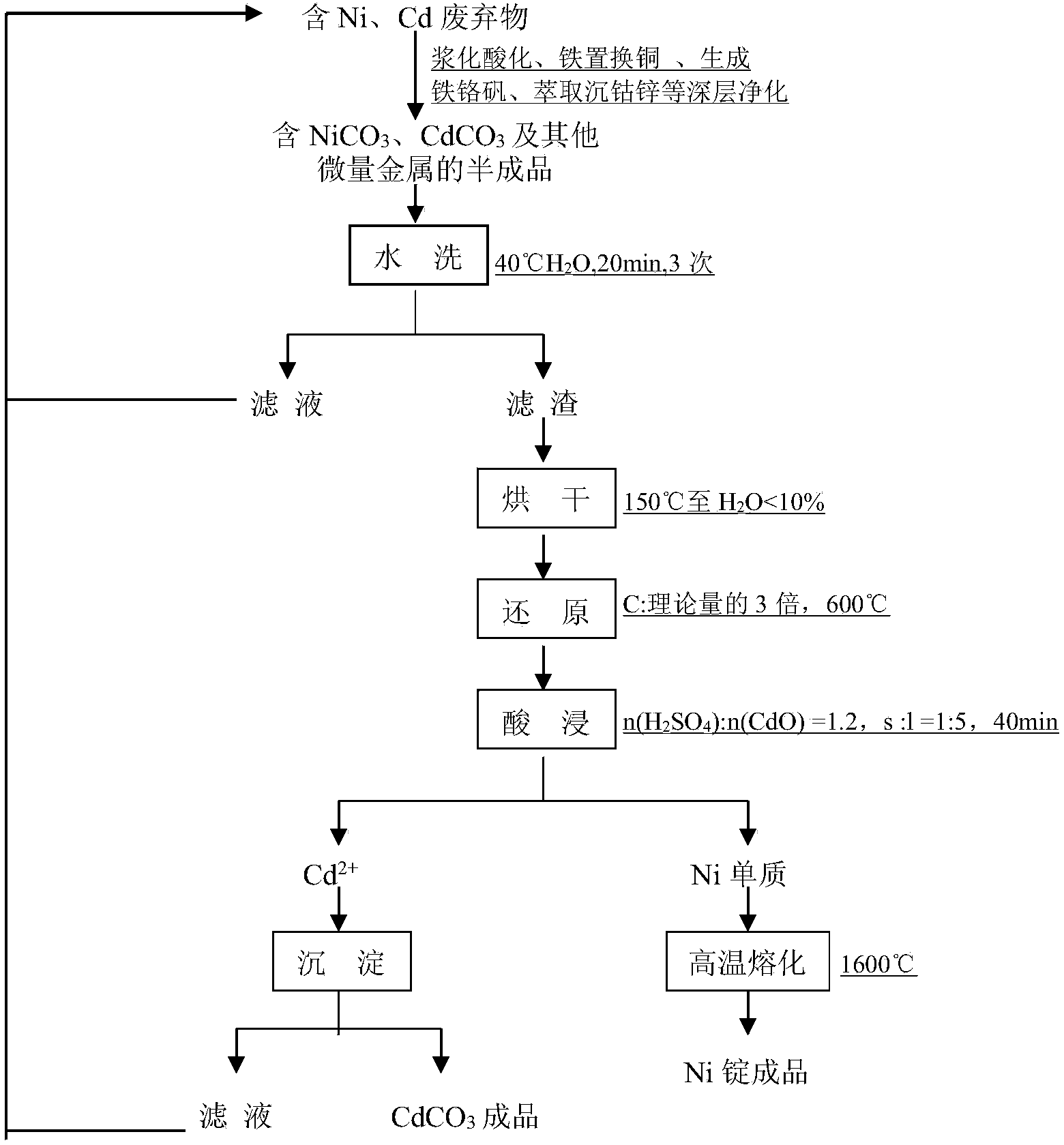

[0043] figure 1 It is a process flow diagram of the present invention.

[0044] (1) Nickel carbonate, cadmium carbonate intermediate product wet sample analysis: Obtain nickel carbonate, cadmium carbonate intermediate product wet sample containing nickel, cadmium, calcium, magnesium, zinc, iron from the production line, dry the wet sample to constant weight (mass. m 1 ), the measured wet sample moisture of nickel carbonate and cadmium carbonate intermediate product is 64.47%wt. Stir and wash the dried and finely ground raw materials with 40°C distilled water (solid-to-liquid mass ratio 1:5) for 20 minutes, change the water and wash repeatedly 3 times to wash off most of the soluble salt sodium sulfate (Na 2 SO 4 ), the filter cake was dried to constant weight after filtration (mass m 2 ), the weight loss rate after stirring and washing the fine raw material after drying is 34.70% (weight loss rate=(m 1 —m 2 ) / m 1 *100%). The dried filter cake was ground into fine piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com