Low-temperature cadmium-selenium red glaze powder and preparation method and application thereof

The technology of cadmium selenium red and glaze powder is applied in the field of low-temperature cadmium selenium red glaze powder and its preparation, and can solve the problems of poor glaze effect of cadmium selenium red glaze powder and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

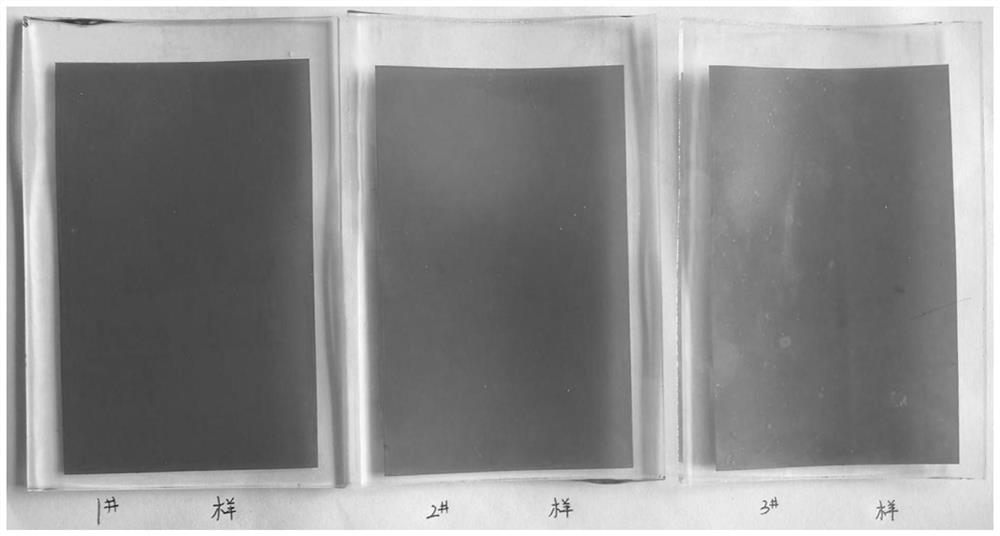

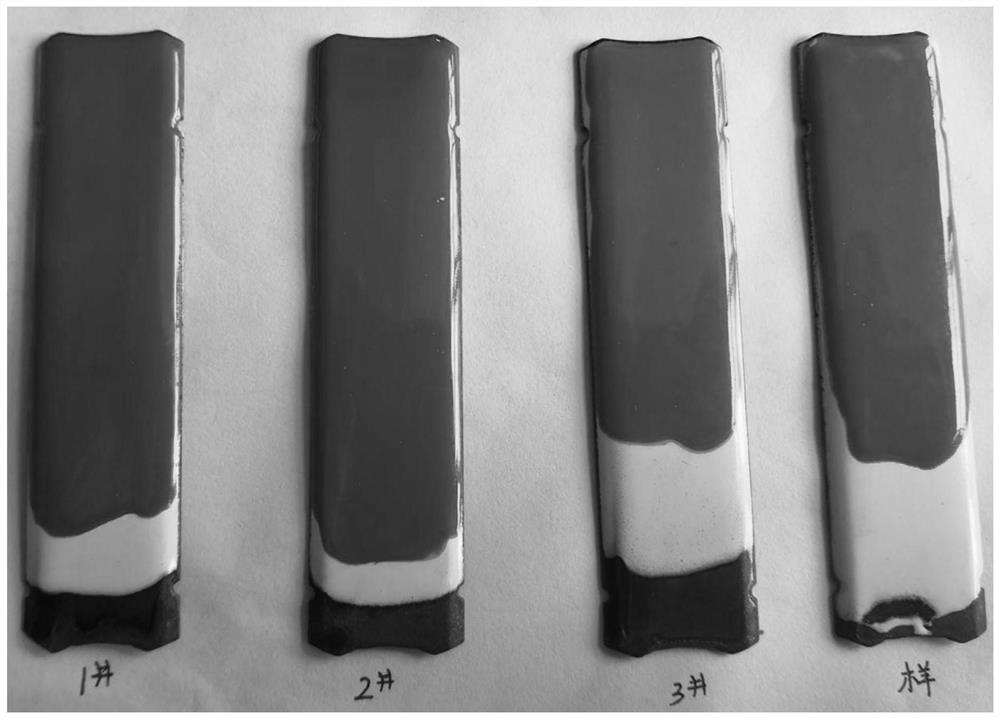

Embodiment 1

[0034] Low-temperature frit formula: red lead 59.5%, boric acid 17.2%, quartz 8.6%, cadmium carbonate 6.7%, borax 3.5%, kaolin 4.5%.

[0035] ①Dry mill the ingredients according to the proportion for 10 minutes, make powder, calcined at 950°C, after reaching the set temperature, water quench, then wet grind until the fineness of 250 mesh sieve is less than 0.03%, vacuum filter, dry, powder, that is Frit powder.

[0036] ②Frit powder 82%, kaolin 5%, zirconia 1%, cadmium selenium red material 12% dry mill for 10 minutes, powder, calcined at 750 ℃, after reaching the set temperature, water quenching, and then wet mill to fineness 250-mesh sieve with a residue of less than 0.03%, vacuum filtration, drying, and powdering to obtain low-temperature cadmium-selenium red glaze powder.

Embodiment 2

[0038] Low-temperature frit formula: red lead 60%, boric acid 17%, quartz 9%, cadmium carbonate 7%, borax 4%, kaolin 2%.

[0039] ①Dry mill the ingredients according to the proportion for 10 minutes, powder, calcined at 1000°C, after reaching the set temperature, quench in water, then wet grind until the fineness of 250 mesh sieve is less than 0.03%, vacuum filter, dry, powder, that is Frit powder.

[0040] ②Frit powder 82%, kaolin 5%, zirconia 1%, cadmium selenium red material 12% dry mill for 10 minutes, pulverized, calcined at 800 ℃, after reaching the set temperature, quenched in water, and then wet milled to fineness 250-mesh sieve with a residue of less than 0.03%, vacuum filtration, drying, and powdering to obtain low-temperature cadmium-selenium red glaze powder.

Embodiment 3

[0042] Low-temperature frit formula: red lead 62.3%, boric acid 17.9%, quartz 9.1%, cadmium carbonate 6.5%, borax 4.2%, kaolin 0%.

[0043] ①Dry mill the ingredients according to the proportion for 10 minutes, powder, calcined at 900°C, after reaching the set temperature, quench in water, then wet grind to a fineness of 250 mesh sieve and the residue is less than 0.03%, vacuum filter, dry, and powder, that is Frit powder.

[0044] ②Frit powder 82%, kaolin 5%, zirconia 1%, cadmium selenium red material 12% dry mill for 10 minutes, powder, calcined at 850 ℃, after reaching the set temperature, water quenching, and then wet mill to fineness 250-mesh sieve with a residue of less than 0.03%, vacuum filtration, drying, and powdering to obtain low-temperature cadmium-selenium red glaze powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com